Planar inner die forming label imbedding mechanism

An in-mold forming, flat technology, applied in labels, labeling machines, packaging, etc., can solve the problems of product defects and finished product yield, poor, etc., to reduce equipment costs, maintain compactness, and increase equipment utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In this way, in order to fully understand the industrial use value and structural innovation of the present invention, the explanation is as follows according to the accompanying drawings:

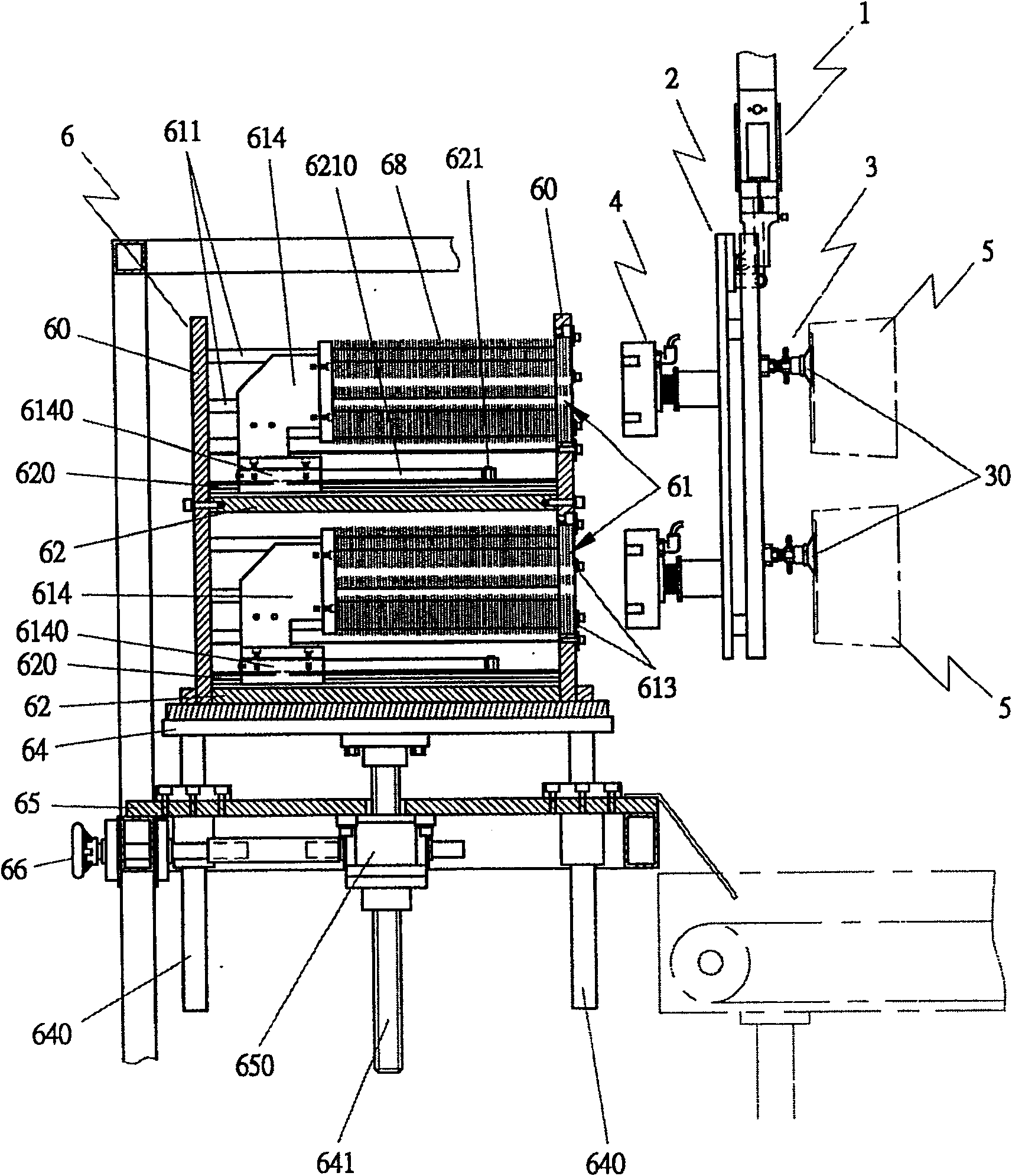

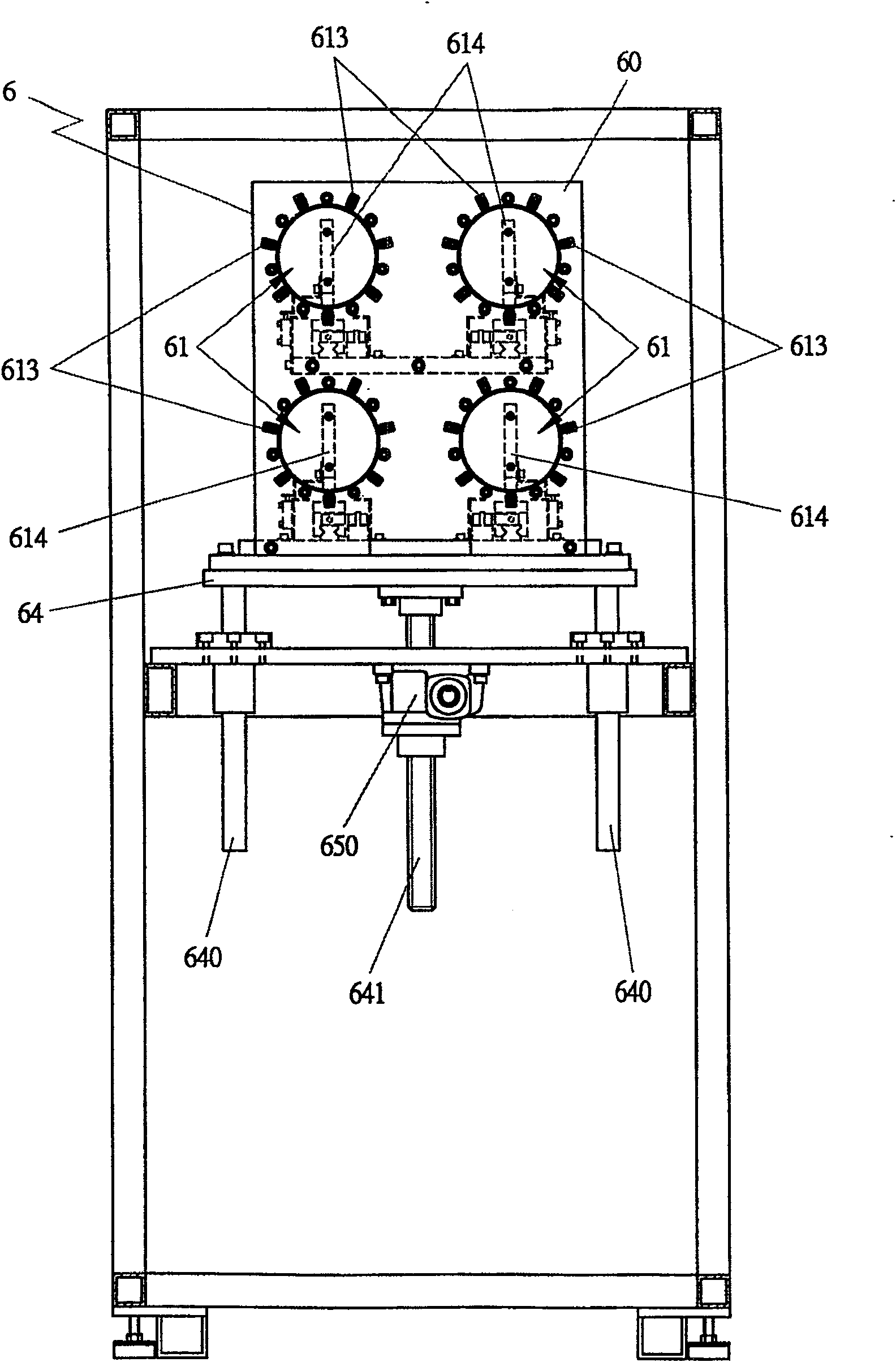

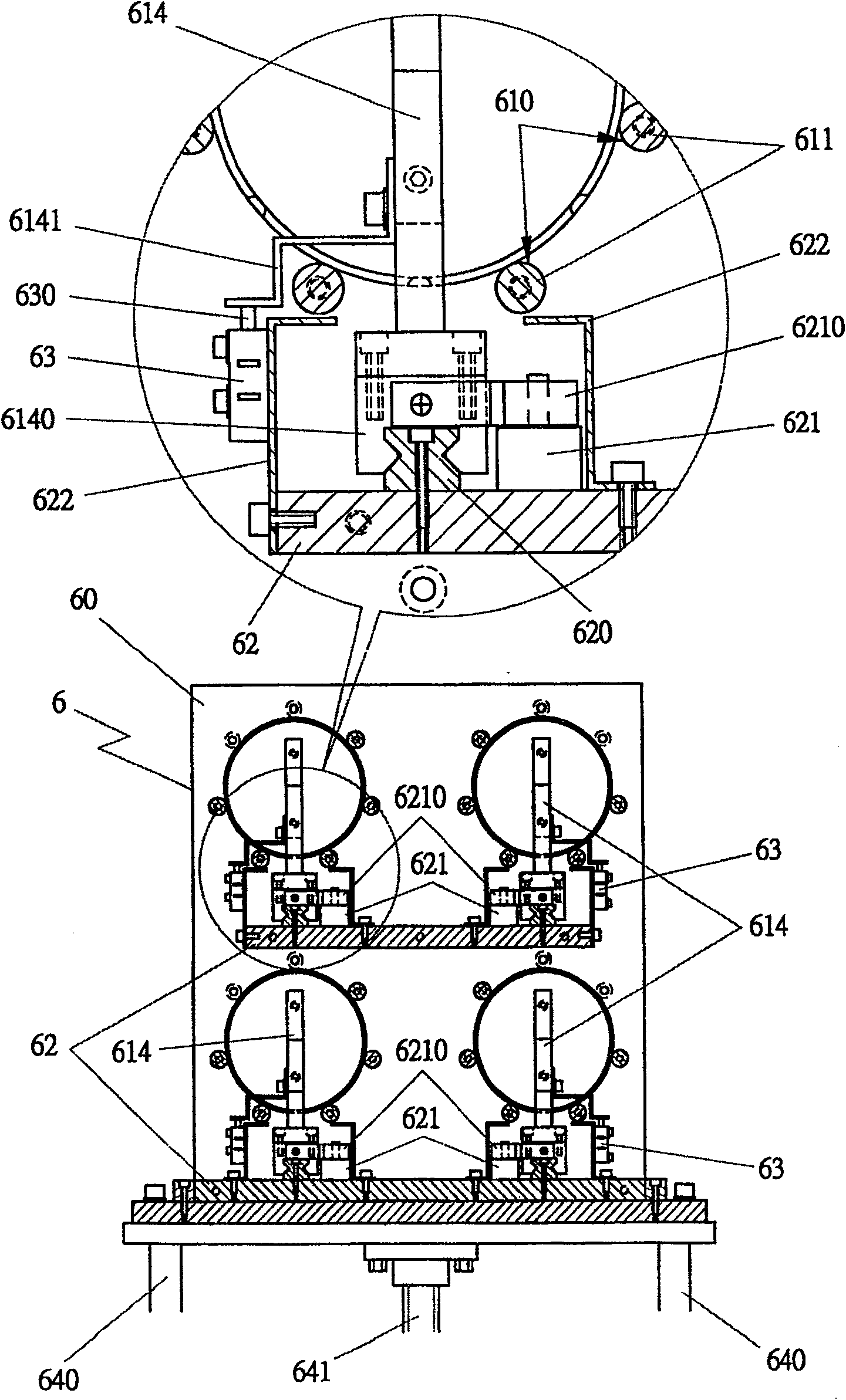

[0034] Such as Figure 1 to Figure 7 Shown is the planar in-mold label insertion mechanism of the present invention, including:

[0035] The mechanical arm 1, the mechanical arm 1 uses computer numerical control to operate its basic operations such as up, down, left, right, front and back. Since it is a generally known technology, the method and process of its computer numerical control will not be repeated here. .

[0036] Fixing seat 2 (such as figure 1 ), the fixed seat 2 is fixed under the aforementioned mechanical arm 1, so as to be driven by the mechanical arm 1 according to its movement, the fixed seat 2 is provided with a finished product take-out device 3, and the other side of the fixed seat 2 is provided with a pick / place label seat 4, so that although the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com