Structure of golf iron head

A golf club head and structure technology, applied to golf balls, golf clubs, rackets, etc., can solve the problems of reducing elastic deformation capacity, vibration, affecting the structural strength of the club head 1, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the above and other objectives, features and advantages of the present invention more obvious and understandable, the following is a detailed description of the preferred embodiments of the present invention in conjunction with the accompanying drawings:

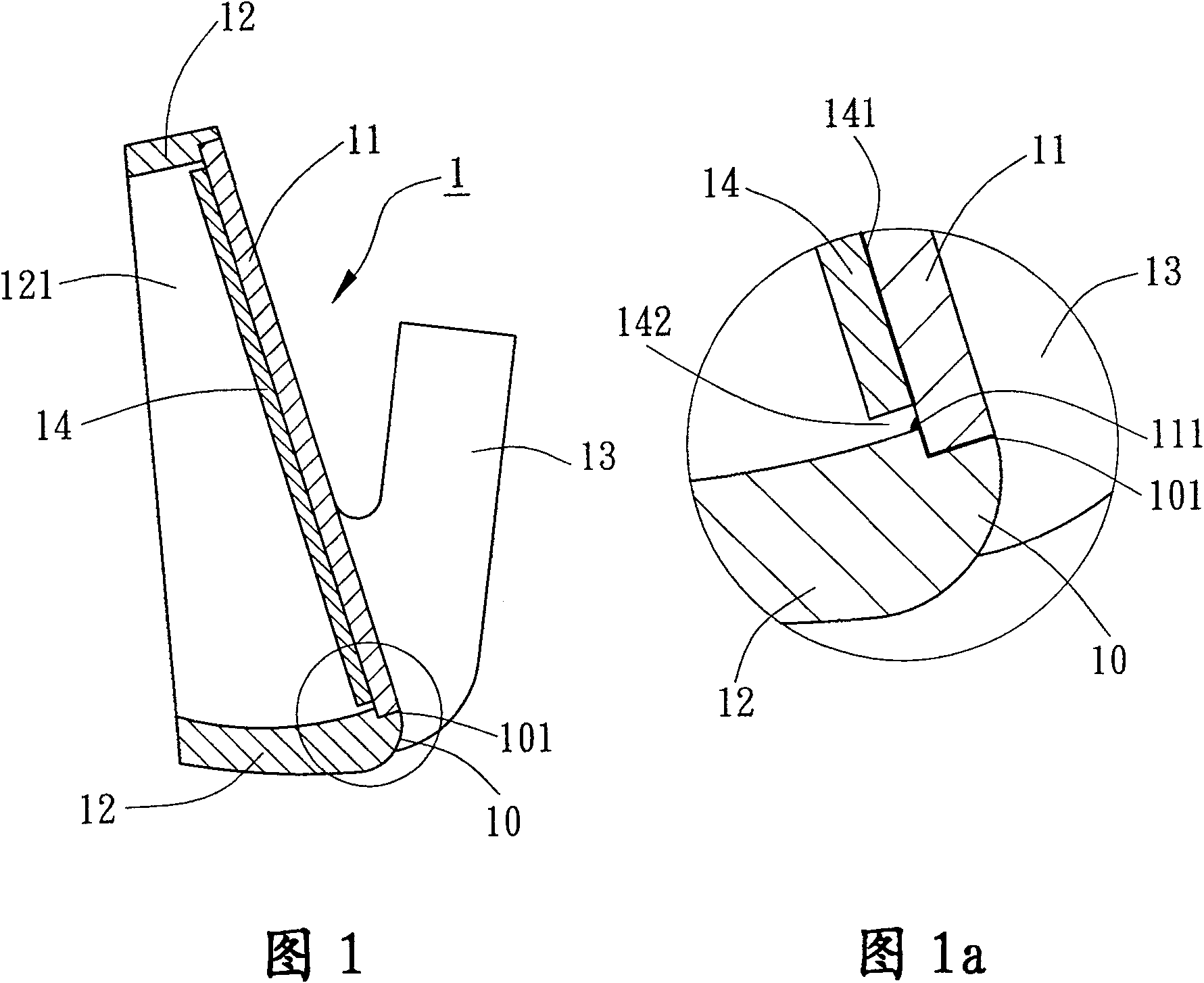

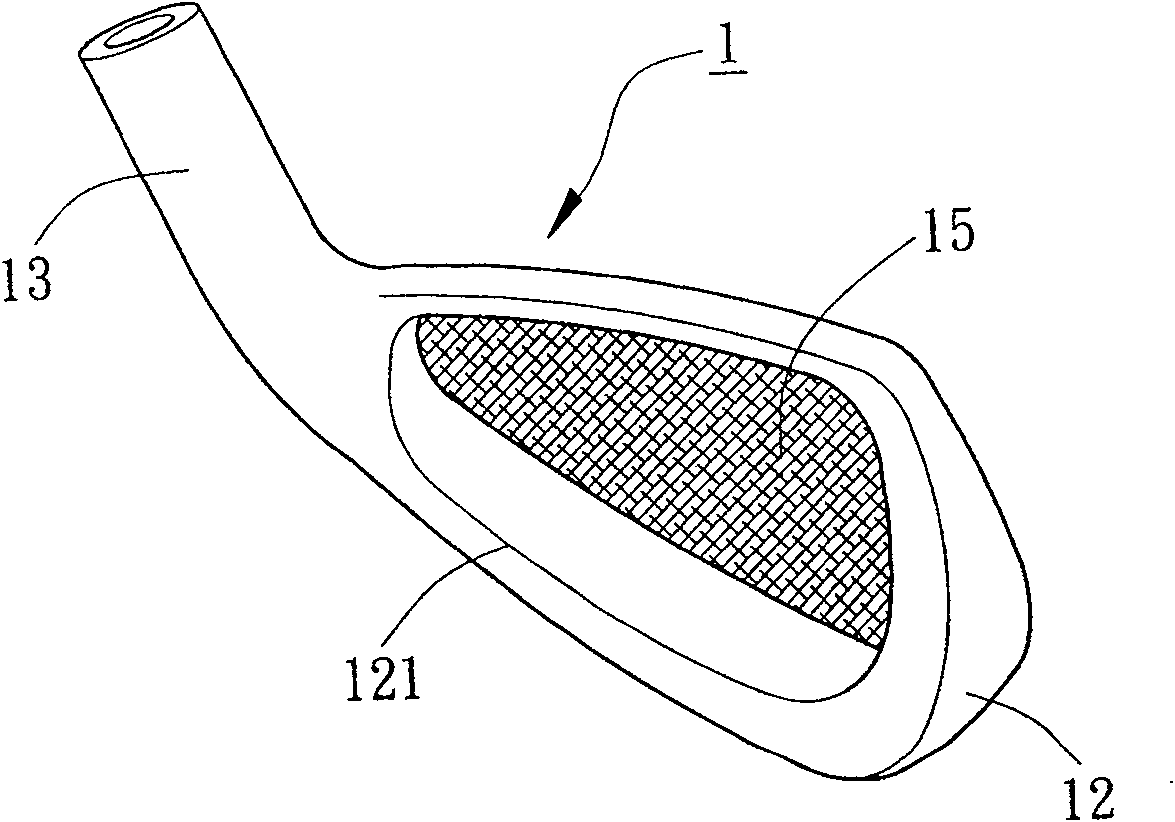

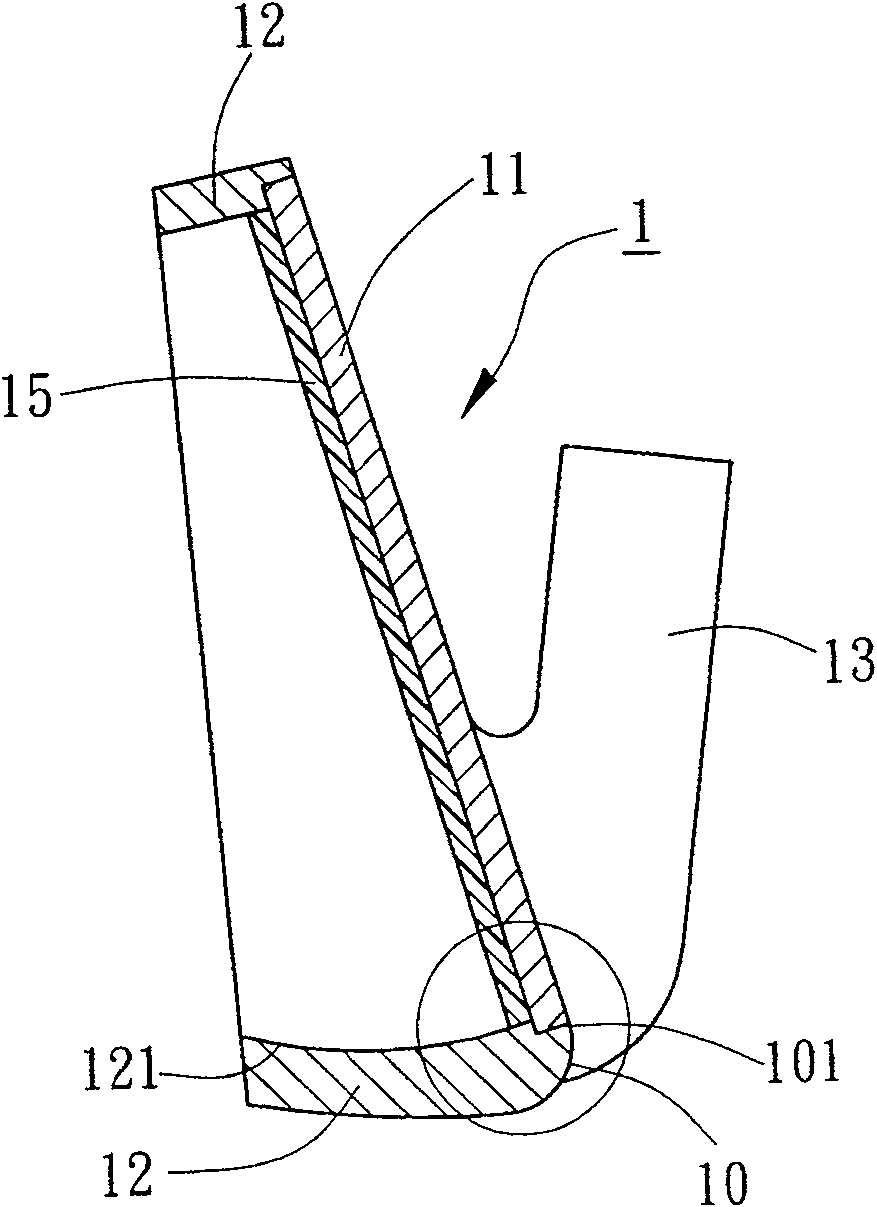

[0036] Please refer to figure 2 , 3 As shown in and 3a, the golf club head structure of the first embodiment of the present invention is a club head 1 made of metal and alloy materials. The club head 1 includes a body 10, a striking panel 11, a ring wall 12, and a set of Neck 13 and a strengthening plate 15. The front surface of the main body 10 can be formed with a panel joint 101 to combine with the striking panel 11. The striking panel 11 can optionally be joined to the panel of the main body 10 by embedding, pressing, brazing, welding, screwing, etc. The part 101 can also be directly formed on the main body 10 by means of integral molding. The striking panel 11 can be used to strike a golf ball. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com