Micro-pressure stress test seat

A technology of compressive stress and test socket, which is applied in the direction of the measuring device casing, etc., can solve the problems of package damage, inability to quickly adjust the contact stress, and large elastic force of the second elastic element, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

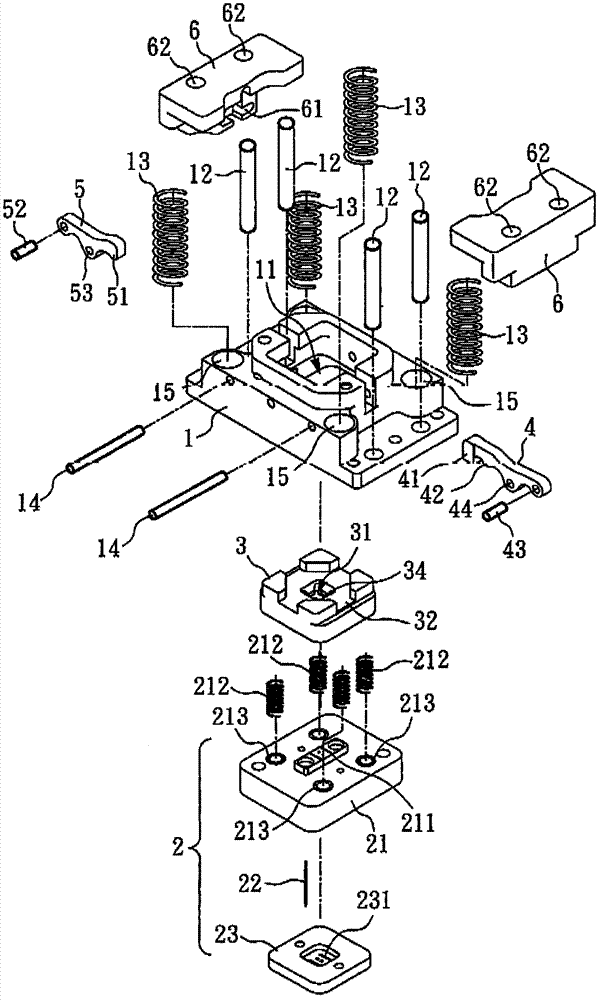

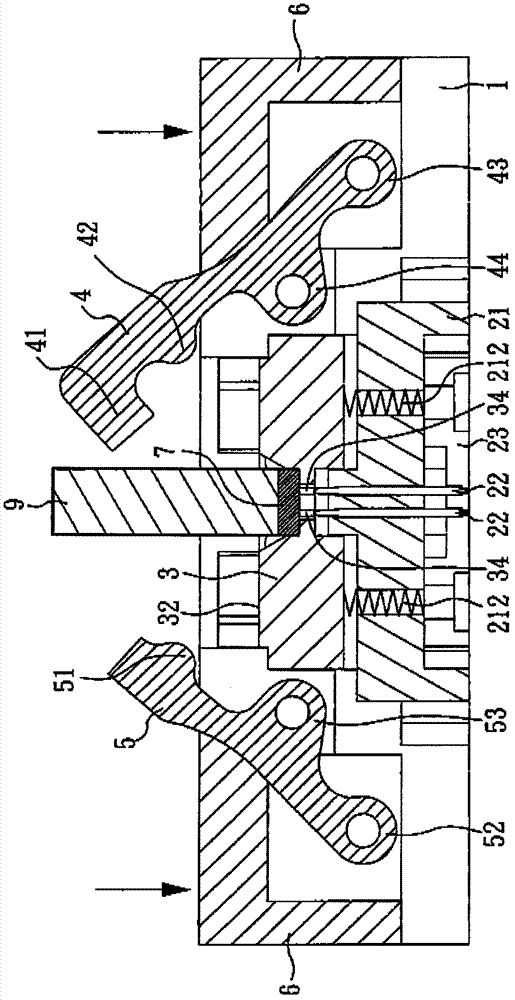

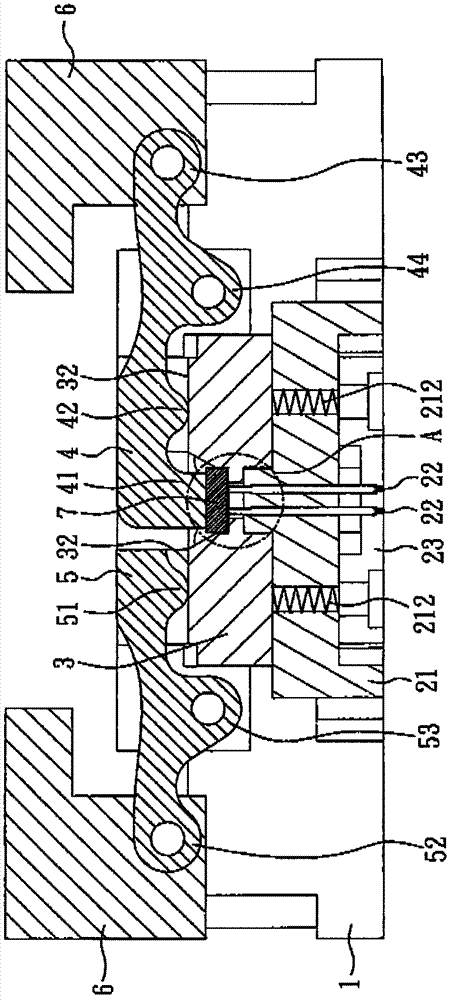

[0021] see figure 1 , figure 1 It is an exploded view of a preferred embodiment of the present invention. The micro-compressive stress test seat of this embodiment includes: a base 1 , a test port 2 , a guide seat 3 , a long press 4 , a short press 5 , and two press pieces 6 . The base 1 is provided with an accommodating groove 11, the test port 2 is arranged in the accommodating groove 11 of the base 1, the guide seat 3 is placed in the accommodating groove 11 of the base 1, and is located above the test port 2, A plurality of first elastic elements 212 are interposed between the guide seat 3 and the test port 2 , and in this embodiment, the plurality of first elastic elements 212 are springs.

[0022] The test port 2 includes a bottom plate 23 , a terminal fixing seat 21 , and a plurality of contact terminals 22 . Wherein, the terminal fixing seat 21 may include a plurality of grooves 213 to accommodate a plurality of first elastic elements 212 interposed between the guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com