Method for preparing multicolor luminescence rare earth-polyvinylpyrrolidone macromolecule composite material

A polyvinylpyrrolidone and composite material technology, which is applied in the directions of luminescent materials, chemical instruments and methods, can solve the problems of easy agglomeration, uneven distribution of rare earth complexes, and phase separation between two phases, and achieves uniform particle size distribution and easy production. Large-size display panel, thin and light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

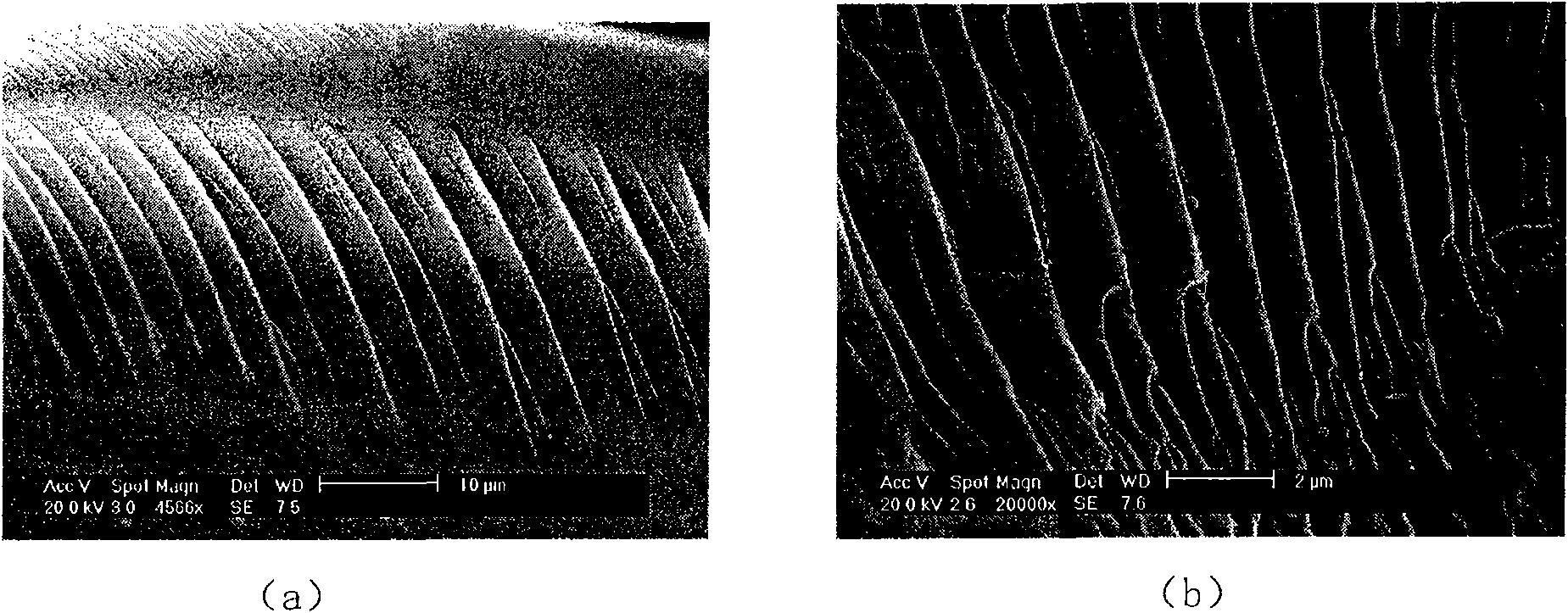

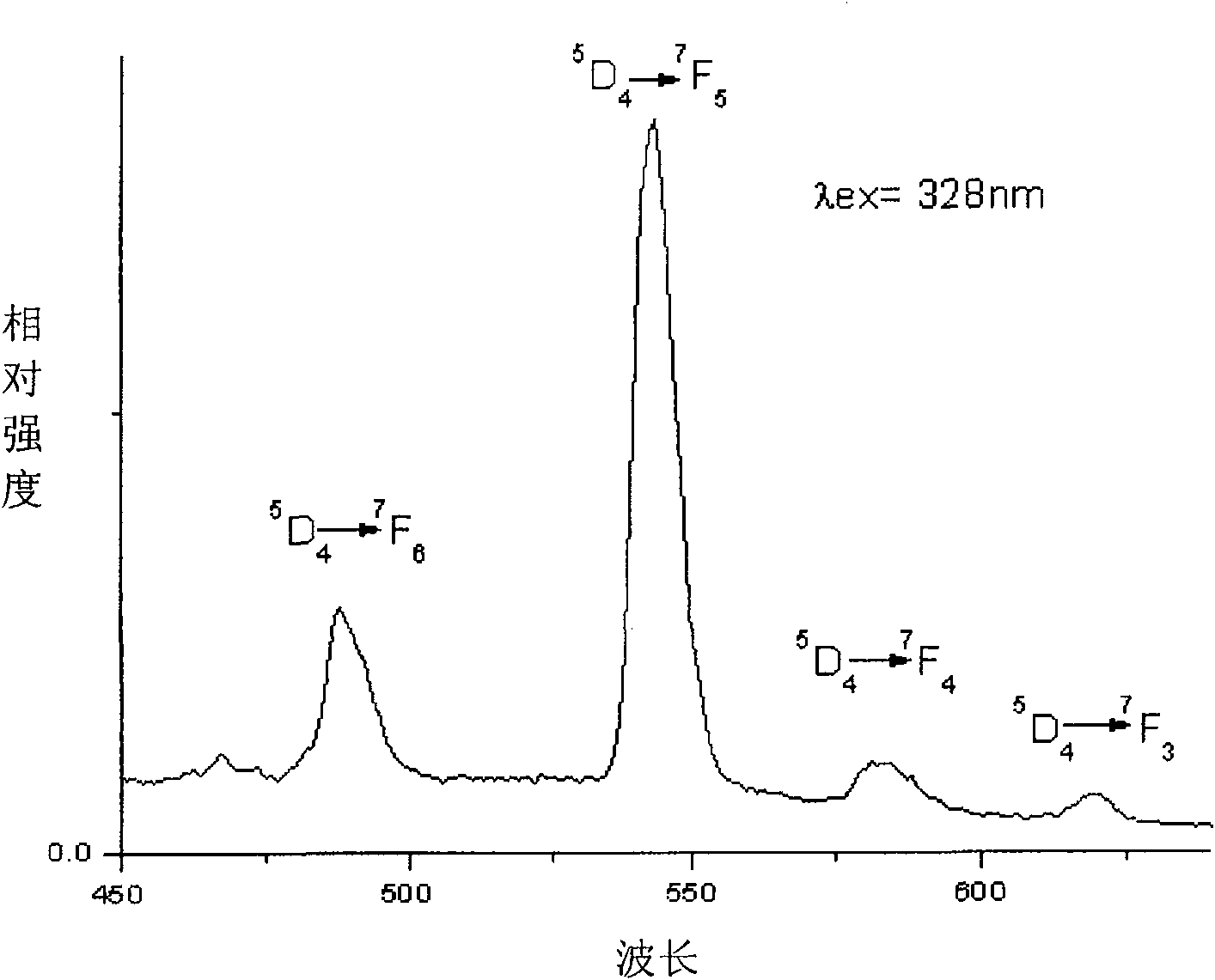

Embodiment 1

[0032] 2.79g of 2-hydroxynicotinic acid was dissolved in 20ml of anhydrous acetone, added to a three-necked flask and heated to reflux. A solution of 4.95 g of propyl triethoxysilyl isocyanate dissolved in 20 ml of anhydrous acetone was then added dropwise. After the dropwise addition, the temperature of the whole solution was controlled at 60° C., refluxed for 12 h under the protection of nitrogen, then cooled, and the solvent was distilled off under reduced pressure. The resultant was washed three times with 20 ml of cyclohexane to obtain a pale yellow oily liquid. The obtained oily organic bridge molecule system was dissolved in absolute ethanol and set aside. Dissolve 3.45g of polyvinylpyrrolidone in 10ml of N,N-dimethylformamide solution, then add dropwise the ethanol solution dissolving the organic bridge molecule, and add the ethanol solution of terbium nitrate or europium nitrate. The mixture was stirred for 3 hours at a temperature of 20° C., and then tetraethyl ort...

Embodiment 2

[0035] 2.44g of m-hydroxybenzoic acid was dissolved in 20ml of anhydrous ether, added to a three-necked flask and heated to reflux. Then, a solution of 4.95 g of triethoxysilylisocyanate dissolved in 20 ml of anhydrous diethyl ether was added dropwise. After the dropwise addition, the temperature of the whole solution was controlled at 65° C., refluxed for 13 h under the protection of nitrogen, then cooled, and the solvent was distilled off under reduced pressure. The resultant was washed three times with 20 ml of cyclohexane to obtain a pale yellow oily liquid. The obtained oily organic bridge molecules were dissolved in absolute ethanol and set aside. Dissolve 3.45g of polyvinylpyrrolidone in 10ml of N,N-dimethylformamide solution, then add dropwise the ethanol solution dissolving the organic bridge molecule, and add the ethanol solution of terbium nitrate or europium nitrate. The mixture was stirred for 4 hours at a temperature of 25° C., and then tetraethyl orthosilicate...

Embodiment 3

[0037] 2.68g of 2-acetylphenol was dissolved in 20ml of tetrahydrofuran, added to a three-necked flask and heated to flow. A solution of 4.95 g of propyl triethoxysilyl isocyanate dissolved in 20 ml of tetrahydrofuran was then added dropwise. After the dropwise addition, the temperature of the whole solution was controlled at 70° C., refluxed for 14 h under the protection of nitrogen, then cooled, and the solvent was distilled off under reduced pressure. The resultant was washed three times with 20 ml of cyclohexane to obtain a pale yellow oily liquid. The obtained oily organic bridge molecule system was dissolved in absolute ethanol and set aside. Dissolve 3.45g of polyvinylpyrrolidone in 10ml of N,N-dimethylformamide solution, then add dropwise the ethanol solution dissolving the organic bridge molecule, and add the ethanol solution of terbium nitrate or europium nitrate. The mixture was stirred for 5 hours at a temperature of 30° C., and then tetraethyl orthosilicate and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com