Automatic unloading one-way valve of air compressor

An automatic unloading, one-way valve technology, used in machines/engines, mechanical equipment, liquid variable capacity machinery, etc., can solve problems such as high manufacturing and maintenance costs, inability to discharge compressed gas, damage to motors and compressors, etc. Achieve easy restart and continuous use, protection against wear, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

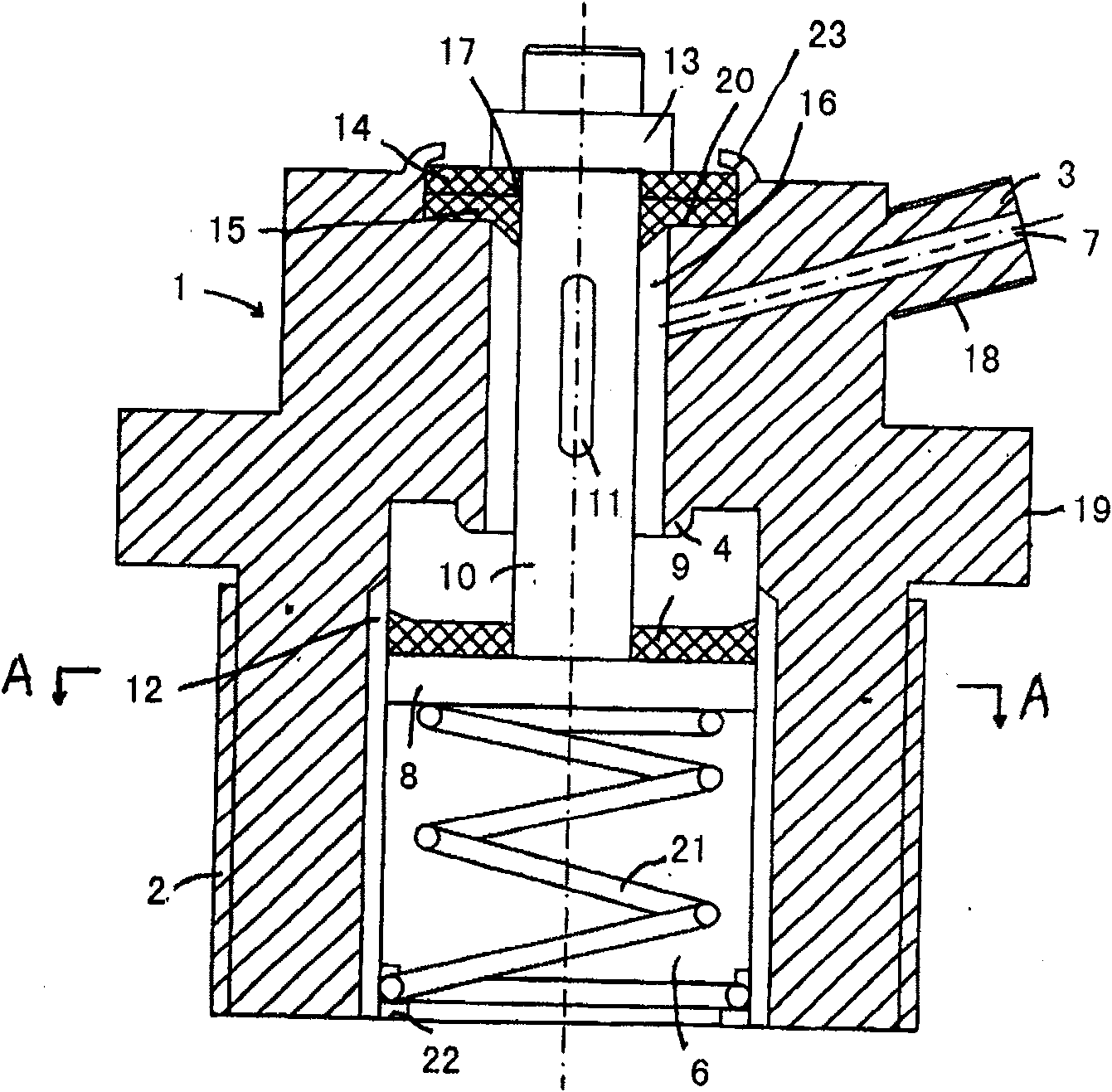

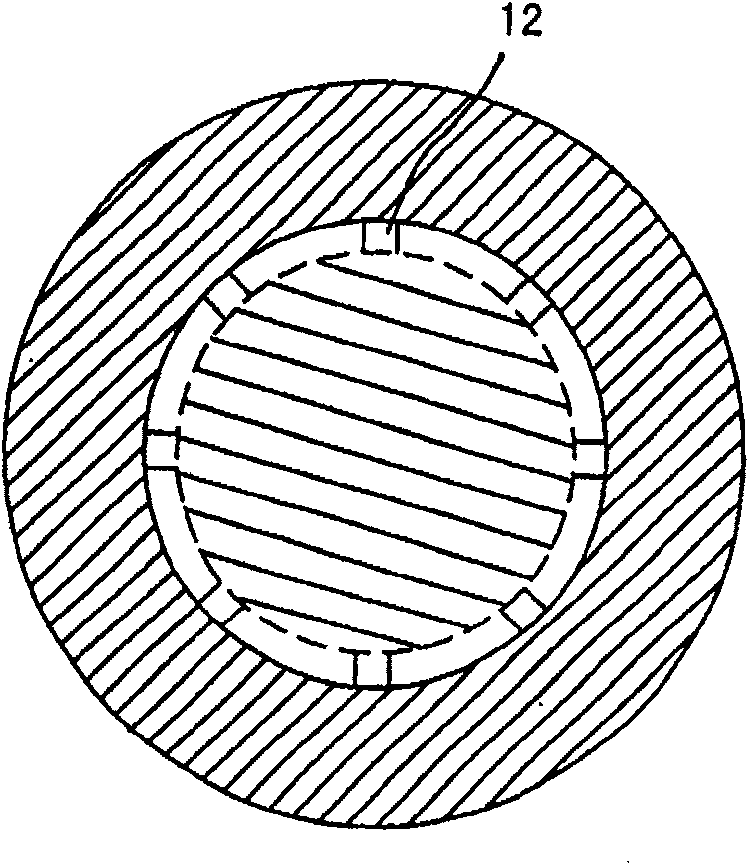

[0038] see figure 1 and figure 2 , an automatic unloading check valve for an air compressor, including a valve body 1, the lower part of the valve body 1 is provided with an external thread 2 connected with the air compressor air storage tank or a portable air pump connector, and the valve body 1 The upper part is provided with an intake pipe joint 3 connected with the valve body 1, and the intake pipe joint 3 is connected with the compressor through the external thread 18 on it; Hex face 19 on gas tank or portable air pump connector.

[0039] The air intake chamber 16 and the working chamber 6 are arranged on the same axis from top to bottom in the valve body 1 and sequentially penetrated; The air inlet chamber 16 and the working chamber 6 are on the same vertical axis. The air inlet hole 7 in the air inlet pipe joint 3 communicates with the air inlet cavity 16 in an obliquely intersecting manner.

[0040] Both the air inlet chamber 16 and the working chamber 6 are in th...

Embodiment 2

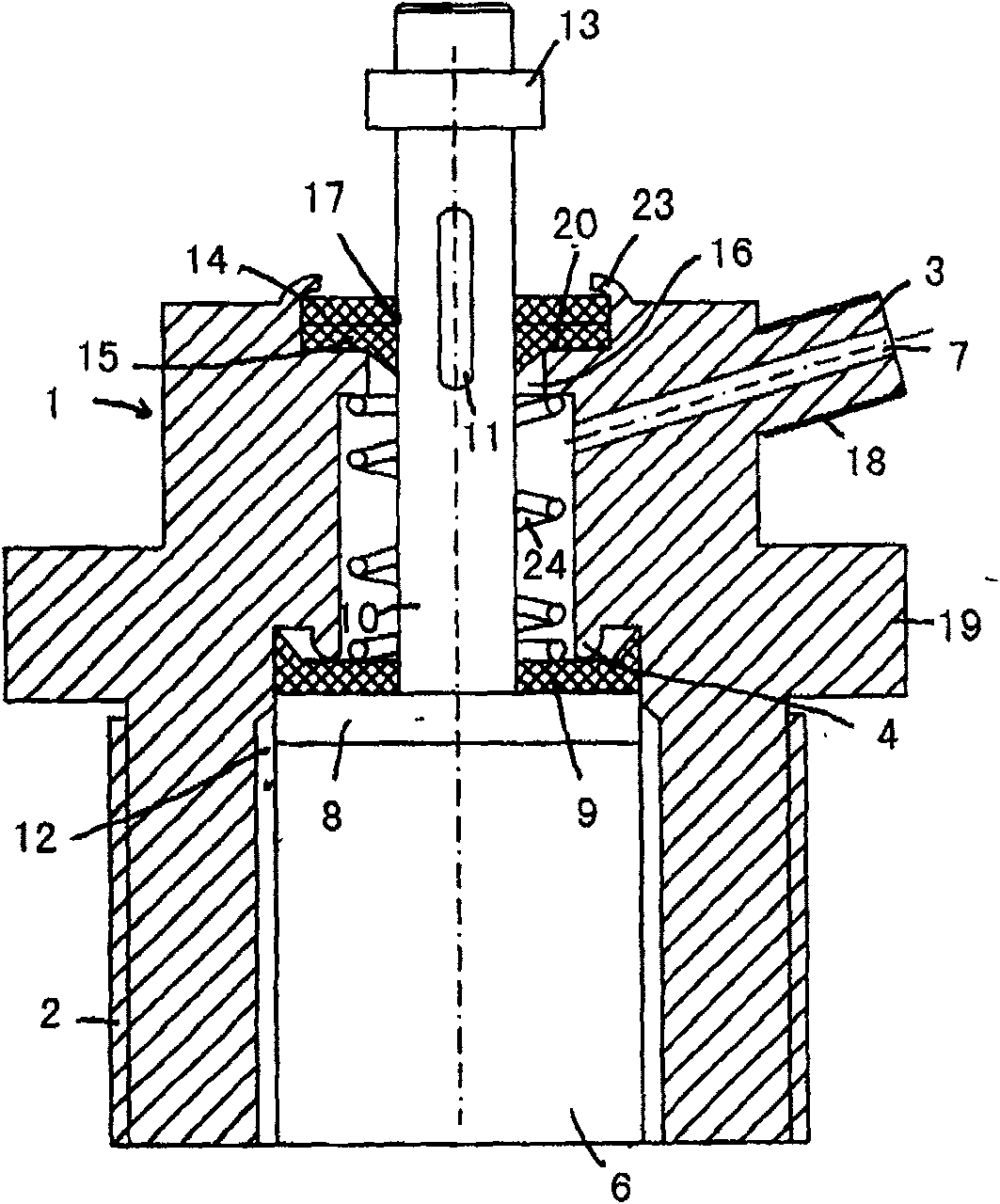

[0051] see image 3 , an automatic unloading check valve for an air compressor, including a valve body 1, the lower part of the valve body 1 is provided with an external thread 2 connected with the air compressor air storage tank or a portable air pump connector, and the valve body 1 The upper part is provided with an intake pipe joint 3 connected with the valve body 1, and the intake pipe joint 3 is connected with the compressor through the external thread 18 on it; Hex face 19 on gas tank or portable air pump connector.

[0052] The air intake chamber 16 and the working chamber 6 are arranged on the same axis from top to bottom in the valve body 1 and sequentially penetrated; The air inlet chamber 16 and the working chamber 6 are on the same vertical axis. The air inlet hole 7 in the air inlet pipe joint 3 communicates with the air inlet cavity 16 in an obliquely intersecting manner.

[0053] Both the air inlet chamber 16 and the working chamber 6 are in the shape of cyli...

Embodiment 3

[0062] see Figure 4 , The difference between this embodiment and Embodiment 2 is that the upper end surface of the working chamber 6 is a plane, and an upwardly protruding flange 5 is provided on the top of the central hole wall of the gasket 14 . All the other are with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com