Unloading one-way valve of air compressor

A one-way valve and air compressor technology, used in control valves, valve devices, mechanical equipment, etc., can solve problems such as high manufacturing and maintenance costs, damage to motors and compressors, and single function, to protect against wear and tear, and be easy to rebuild. Start-up and continuous use, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below through specific embodiments, but it should be understood that the following specific embodiments are only exemplary, and the present invention is not limited thereto.

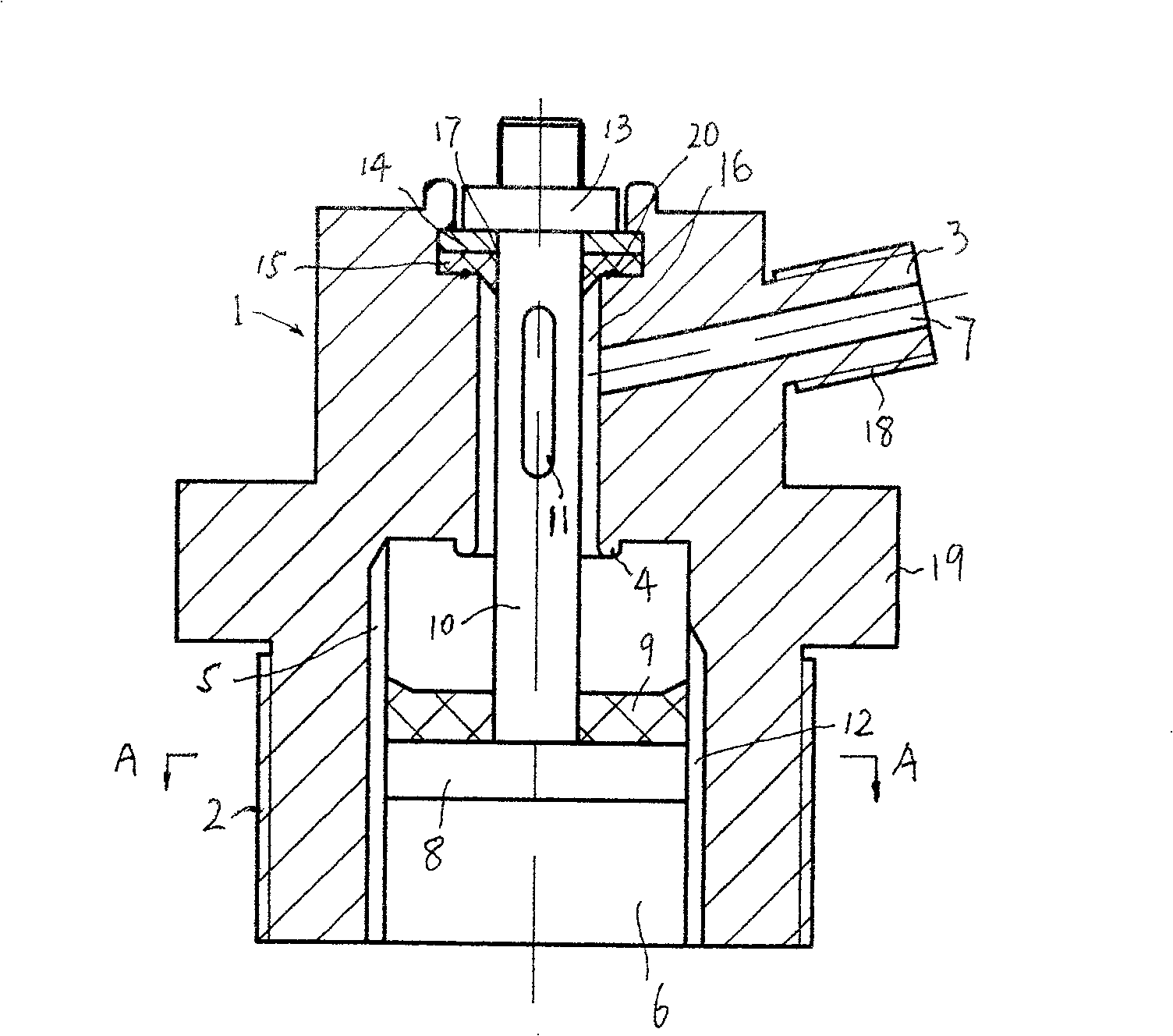

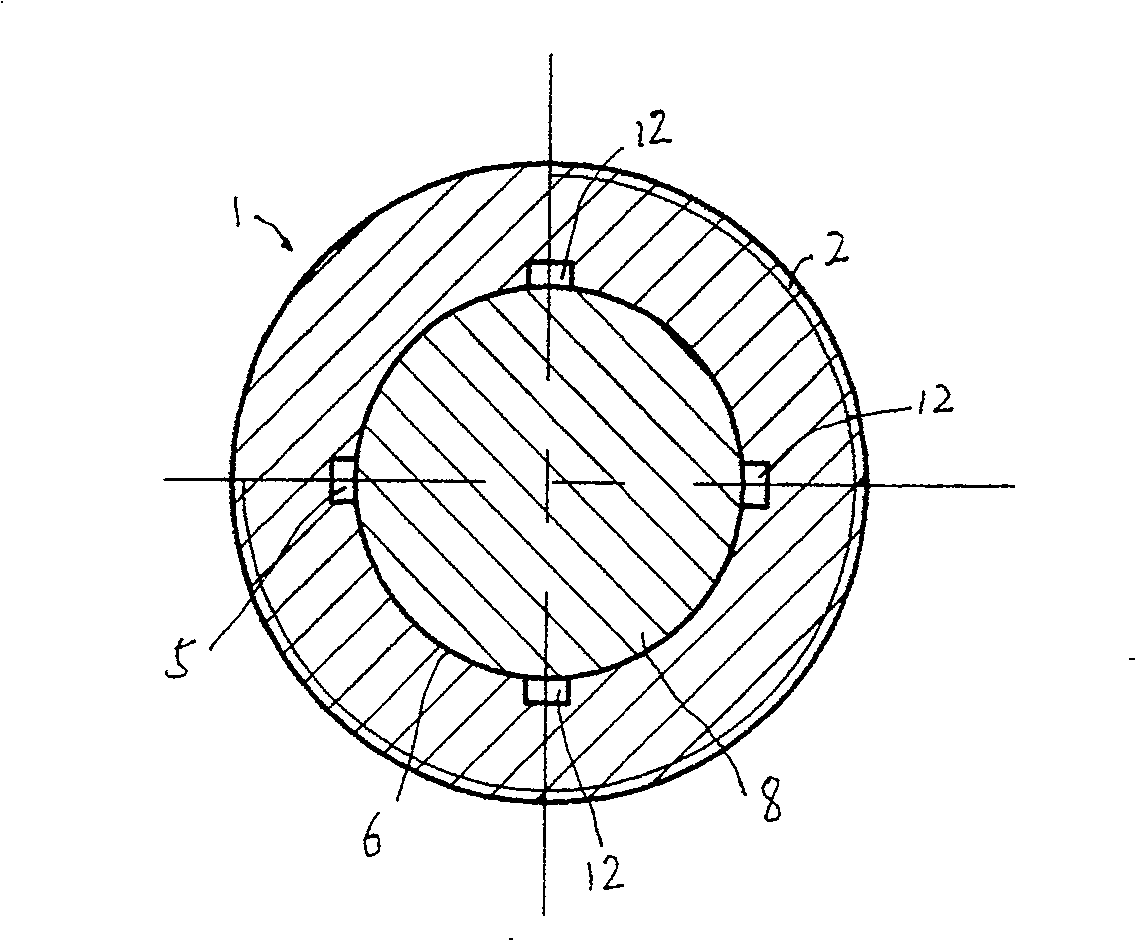

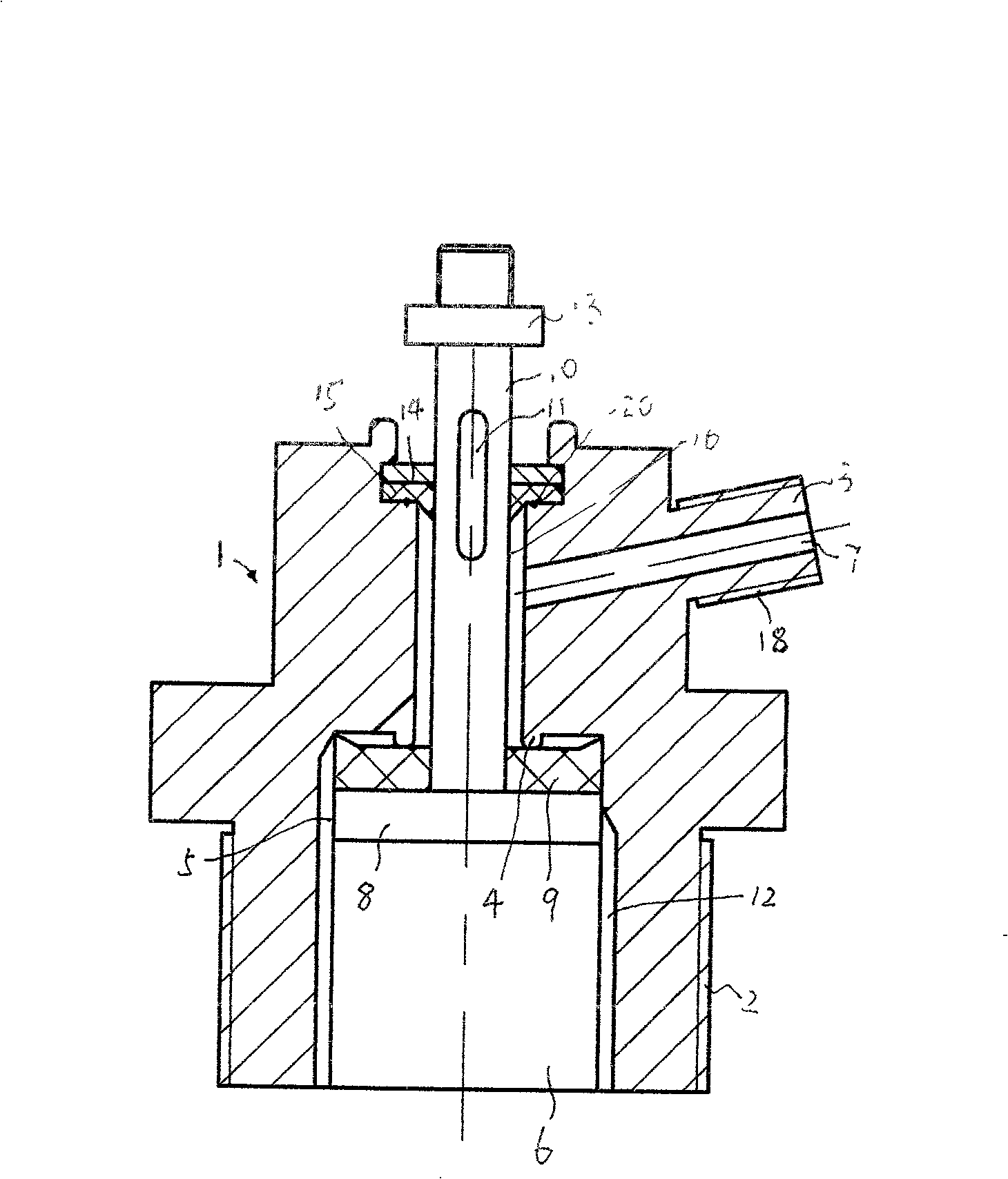

[0018] See figure 1 with figure 2 , An air compressor unloading check valve, including a valve body 1, the lower part of the outside of the valve body 1 is provided with an external thread 2 connected with the air compressor tank or the scorpion pump joint, in the valve body The upper part of 1 is provided with an intake pipe joint 3 integrated with the valve body 1. The intake pipe joint 3 is connected with the compressor through the external thread 18; the middle part is provided with an unloading check valve to facilitate the installation of the unloading check valve in the air compressor storage. The hexagonal end face l9 on the joint of the gas tank or the scorpion air pump.

[0019] The valve body 1 is provided with an air inlet chamber 16 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com