Method for measuring screen mesh form breaking point

A technology of bubble breaking point and screen mesh, which is applied in the field of measuring the bubble breaking point of the screen used in the propellant management device of the satellite surface tension storage tank, can solve the problems of large measurement data errors, achieve reliable data, scientific measurement methods, and solve The effect of large errors in measurement data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with specific embodiment, further illustrate the present invention.

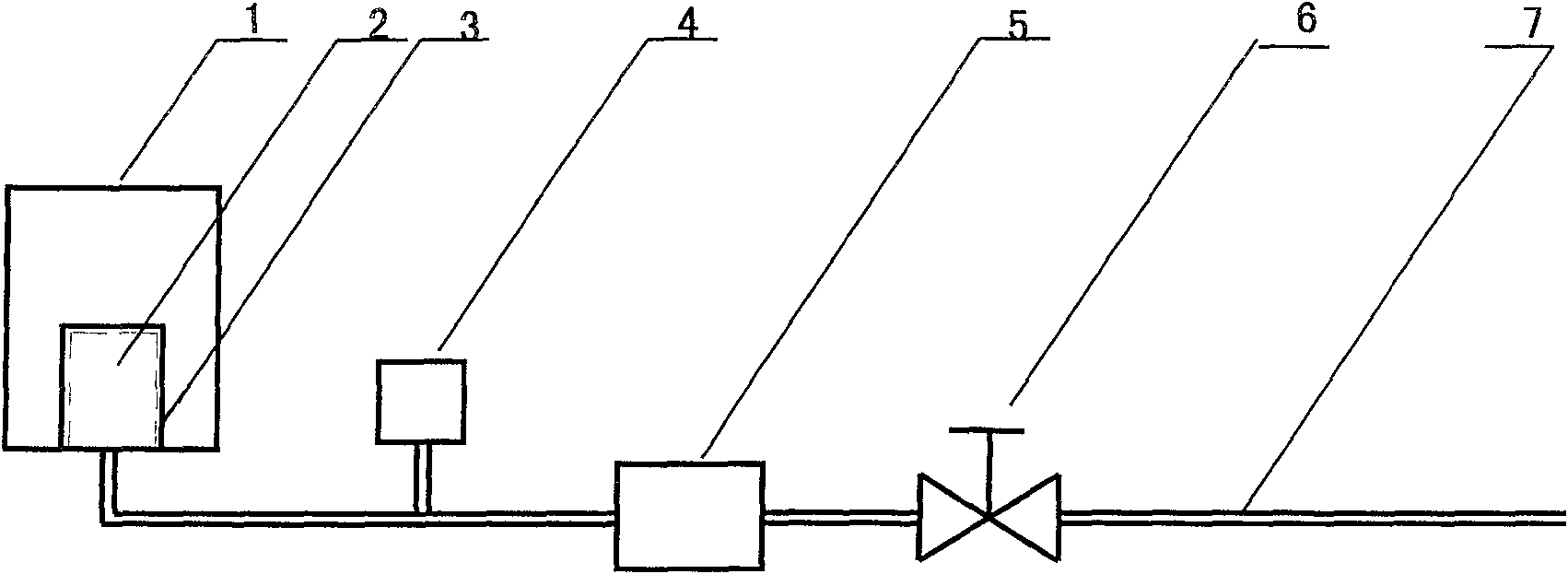

[0017] refer to Figure 1~2 , the measurement object among the present invention is the screen cloth 3 in the cavity 1, and the screen cloth 3 surface covers liquid film 2, and cavity body 1, screen cloth 3 constitute a closed space; Measuring device consists of pressure gauge (or pressure sensor) 4, The gas flow regulating valve 5, the shut-off valve 6, and the booster pipeline 7 are composed of the booster pipeline 7 connected with the confined space, and the pressure gauge (or pressure sensor) 4, the gas flow regulating valve 5, and the shut-off valve 6 are sequentially connected in series to the booster. Pressure line 7.

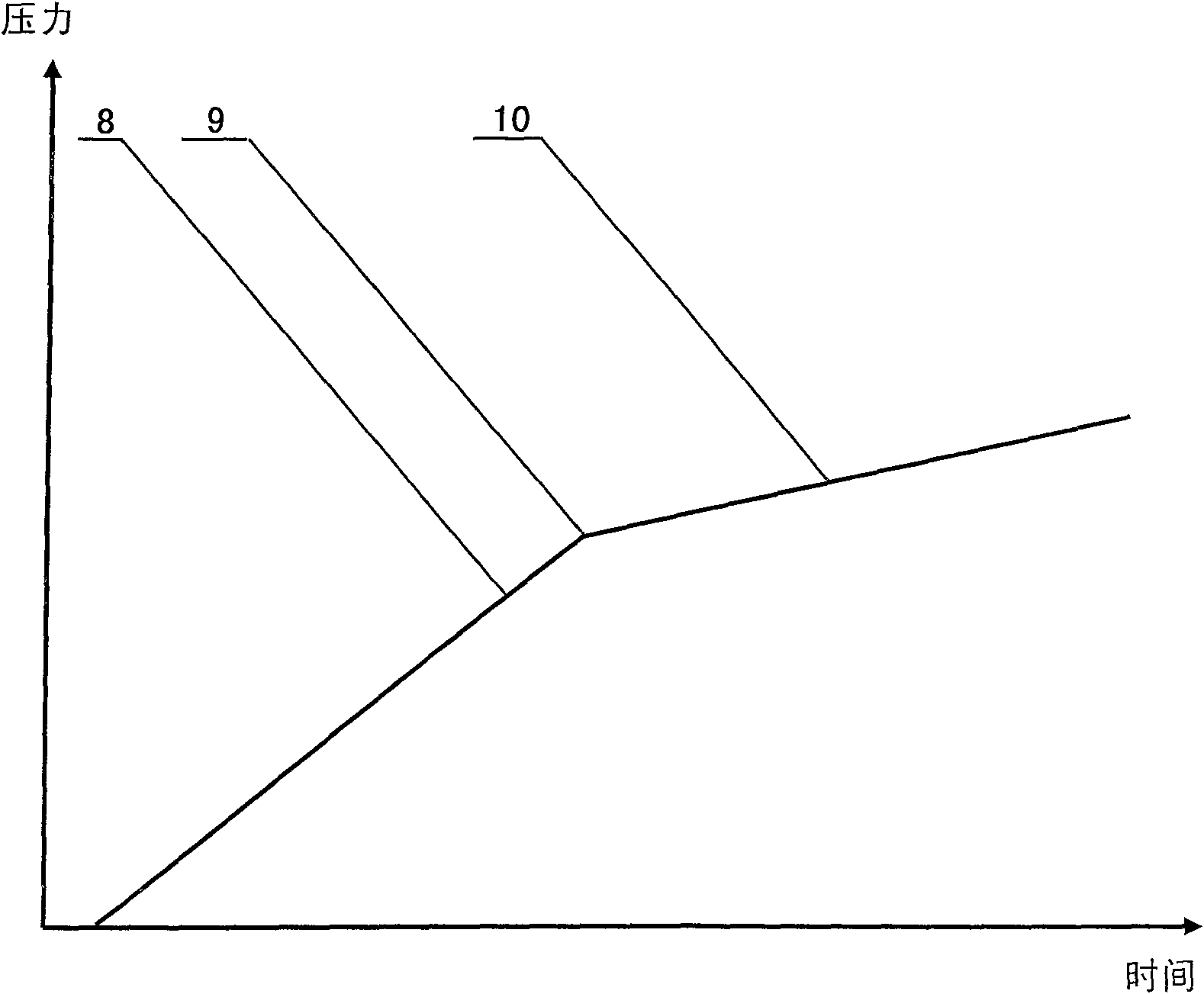

[0018] The screen to be tested is a stainless steel screen with a specification of 325 mesh × 2300 mesh, the liquid is isopropanol, the allowable error of the bubble breaking point measurement result is ±100Pa, the range of the pressure sensor is 10000Pa, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com