Branched chain nesting three-freedom moving platform continuously turning parallel connection robot mechanism

A degree of freedom and robot technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of large operating range and flexibility, small equipment installation space, difficult to realize operation, etc., to expand the application field and scope of application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Describe the present invention in detail below in conjunction with embodiment and accompanying drawing. The examples are based on the technical solutions of the present invention, giving detailed implementation and process, but the scope of protection of the claims of the present invention is not limited to the following examples.

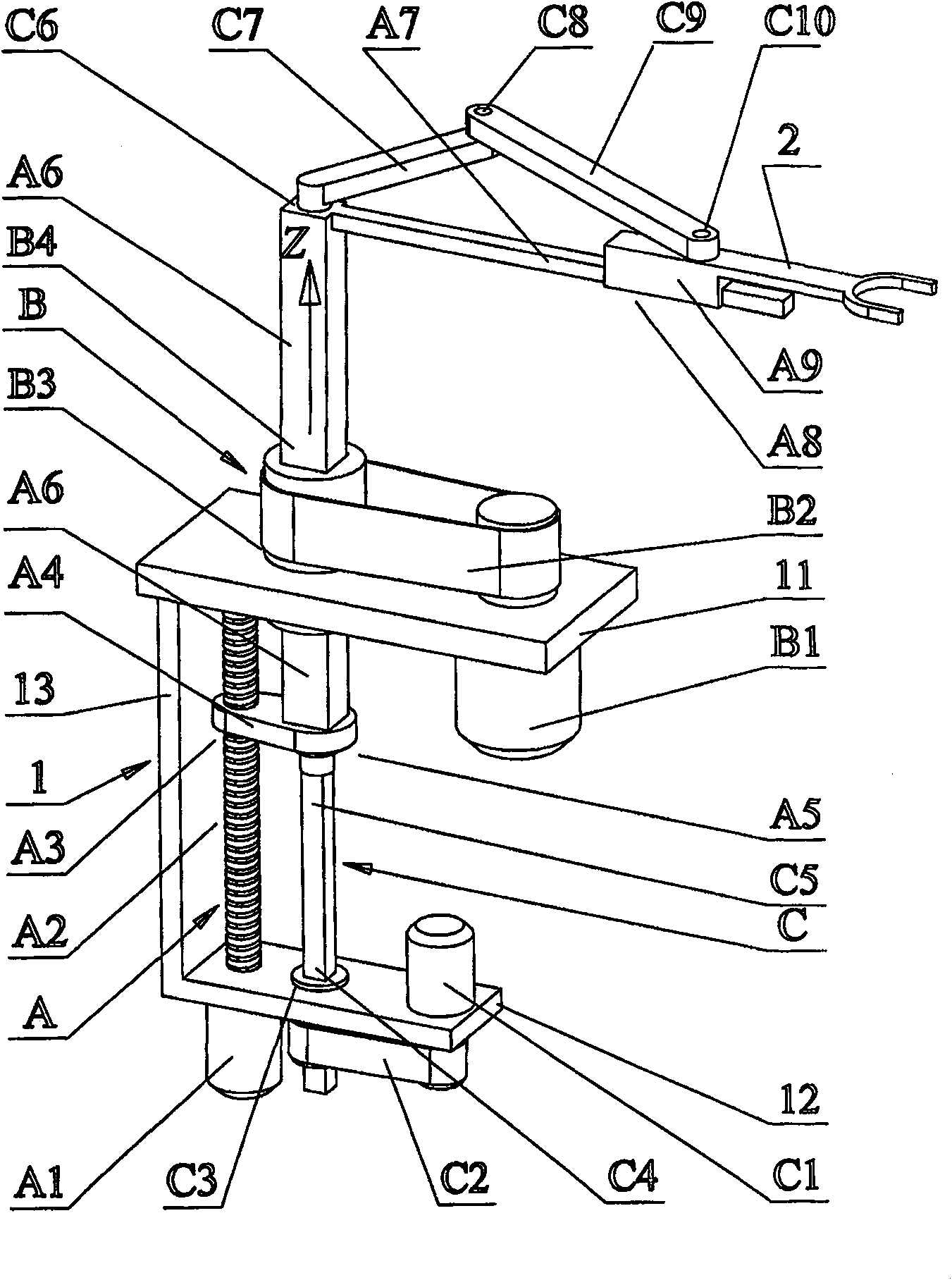

[0009] The parallel robot mechanism designed by the present invention (hereinafter referred to as mechanism, see figure 1 ), which is characterized in that the mechanism includes a base 1 and a moving platform 2, and a first kinematic branch chain A, a second kinematic branch chain B and a third kinematic branch chain fixedly connected between the base 1 and the moving platform 2 and nested together. Motion branch chain C; the base 1 includes a horizontal upper plate 11 and a lower plate 12 and a vertical plate 13 connecting the upper plate 11 and the lower plate; the first motion branch chain A includes: installed on the base 1 The first m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com