Double-cutterhead dynamic cutter tower seat structure

A technology of turret base and double cutter head, which is applied in the direction of tool holders, large fixed members, metal processing machinery parts, etc., can solve the problems of high cost, large space occupation, damage to tools and machines, etc., and achieve saving The effect of cost and machine equipment streamlining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

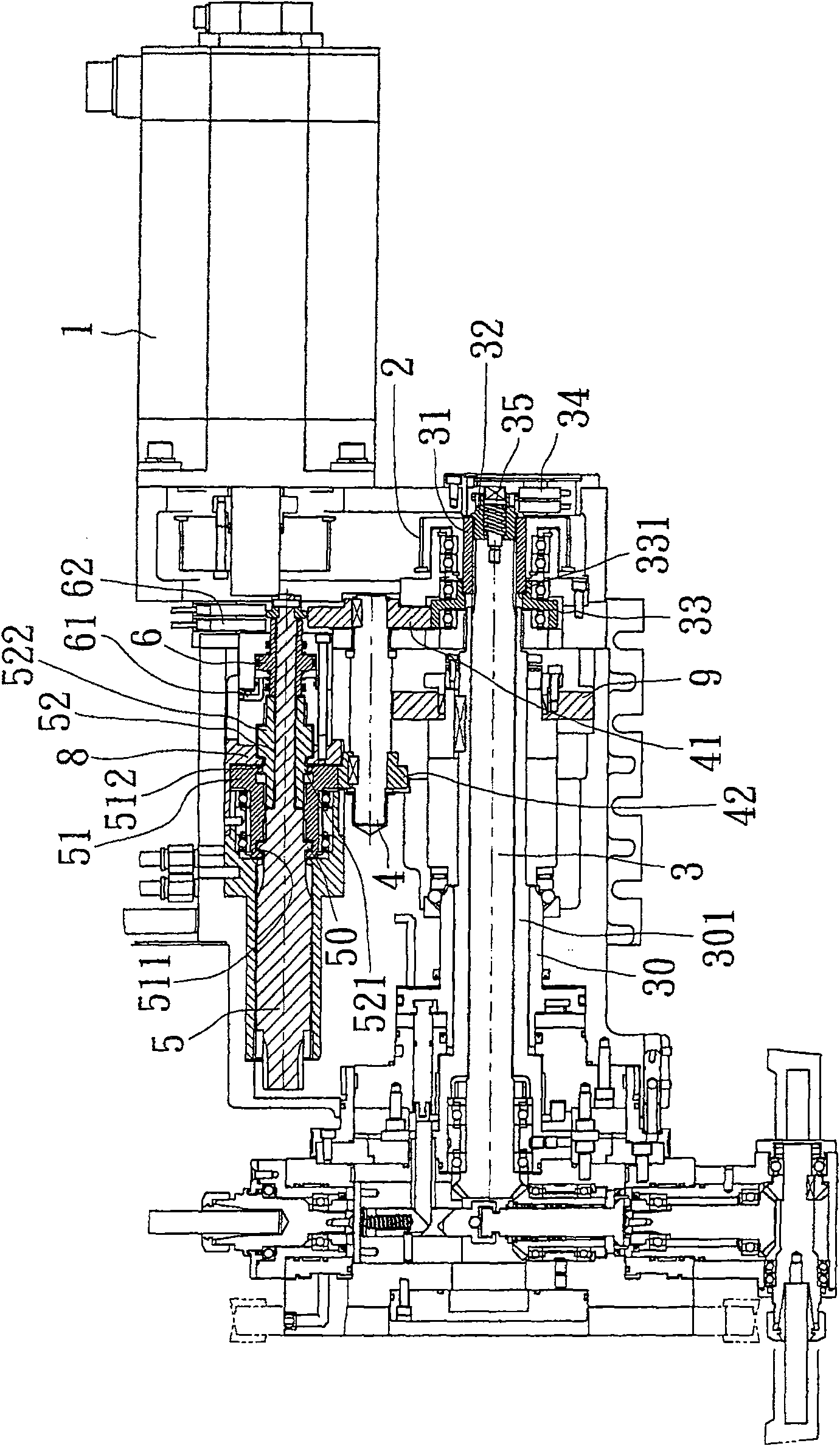

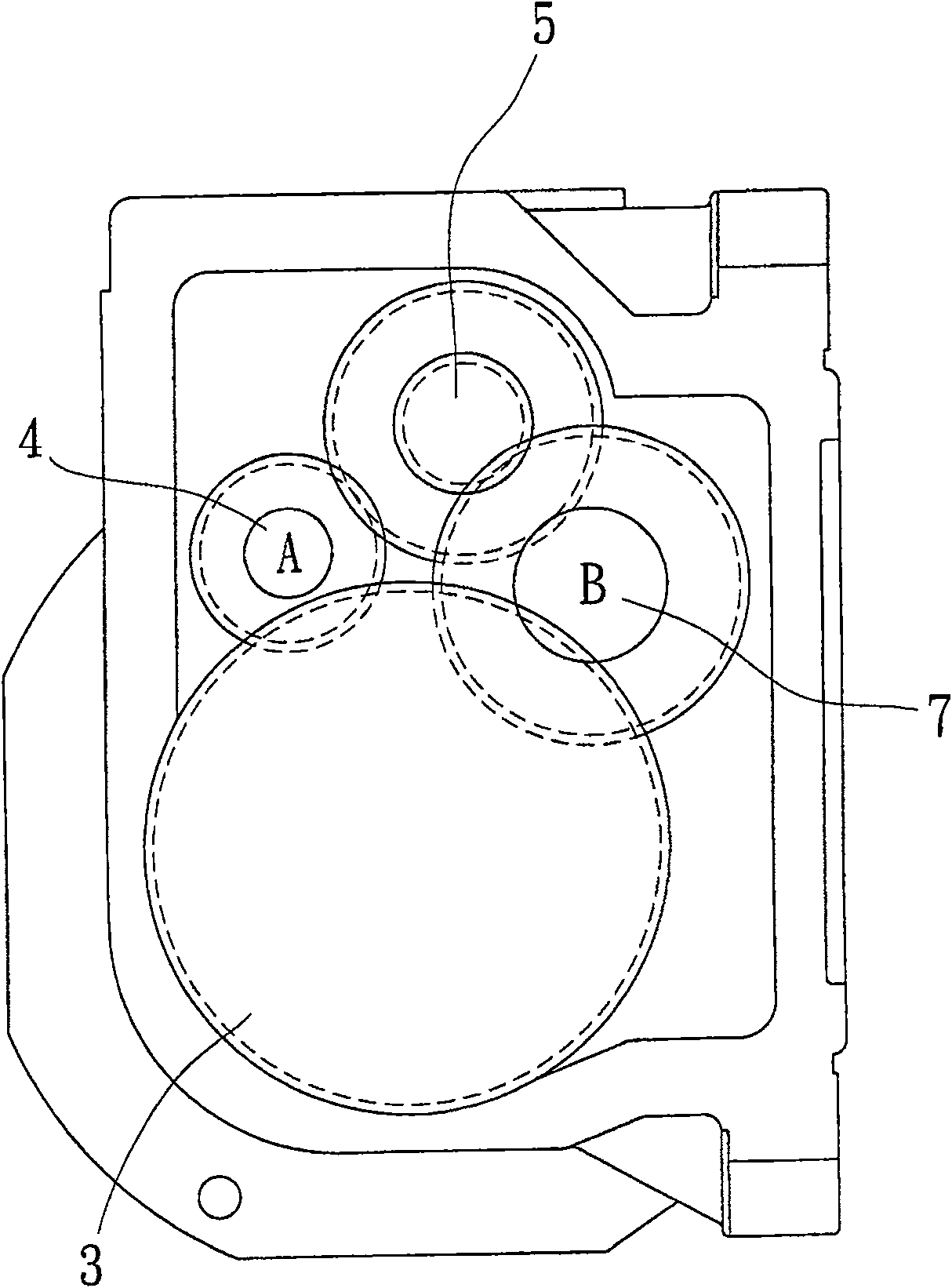

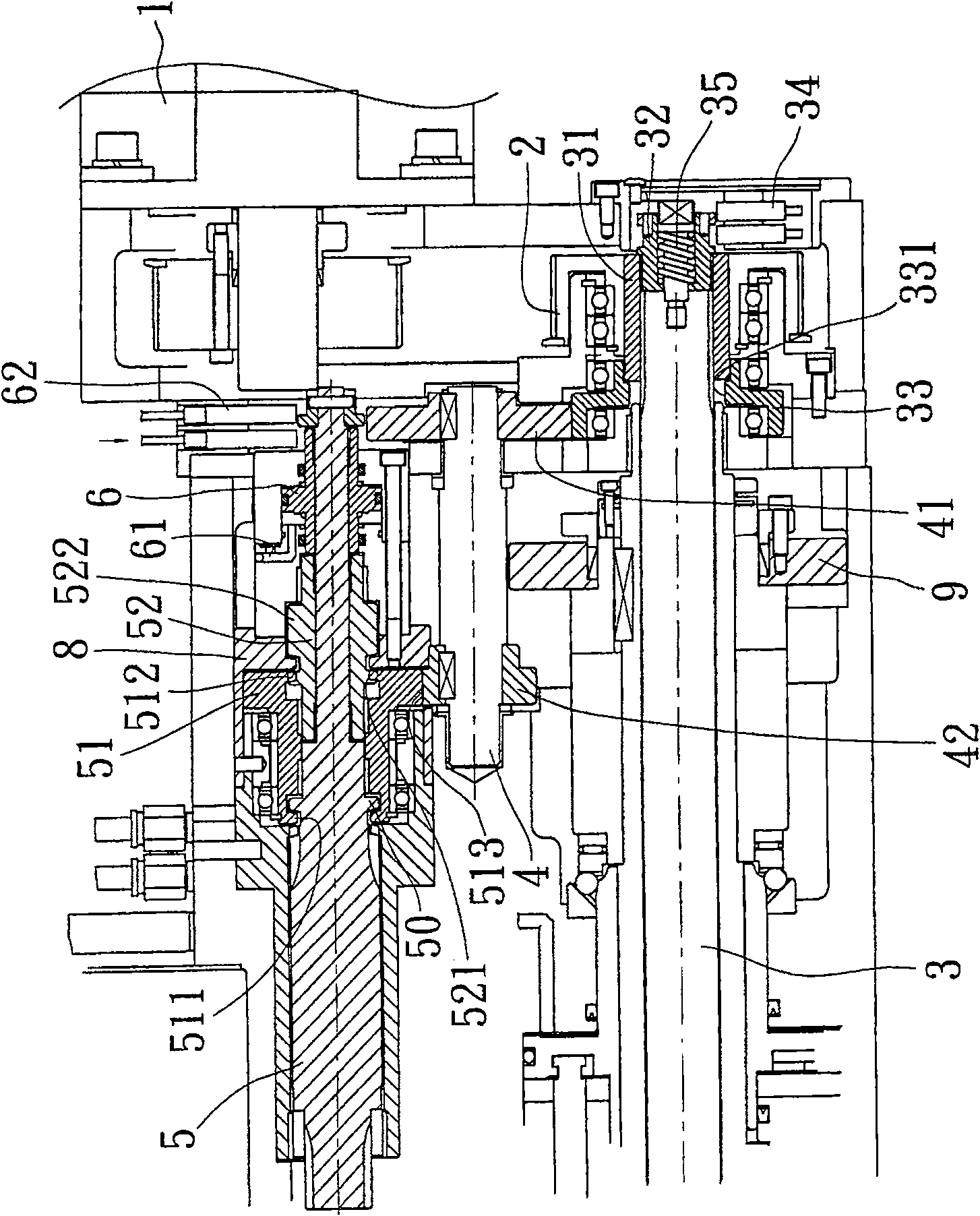

[0049] First, see figure 1 As shown, it is a schematic cross-sectional view of the whole structure of a double-blade power turret seat of the present invention. An active power source 1 is set on the machine, and the power is transmitted from the active power source 1 to the power group 2. 2 Link the gear ring 31 outside the main shaft 3 to transmit the power to the first rotating shaft 4, and let the tooth seat 42 of the first rotating shaft (A rotating shaft) 4 guide the power to the transmission member 51 on the inner knife rotating shaft 5 to drive Part 51 cooperates with the piston clutch part 6 to selectively drive the inner and outer cutter heads of the inner cutter shaft 5 or the second shaft (B shaft) 7 to drive and rotate respectively for tool selection operation and processing (please refer to figure 2 shown]; where:

[0050]Please also refer to image 3 As shown, a clutch seat 32 is provided at the end of the main shaft 3, and the clutch seat 32 can move to resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com