Voltage reference source adopting technique deviation compensation structure

A technology of voltage reference source and process deviation, applied in the direction of adjusting electrical variables, control/regulating systems, instruments, etc., can solve problems such as characteristic deviation of pnp transistors, and achieve the effect of high initial precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings.

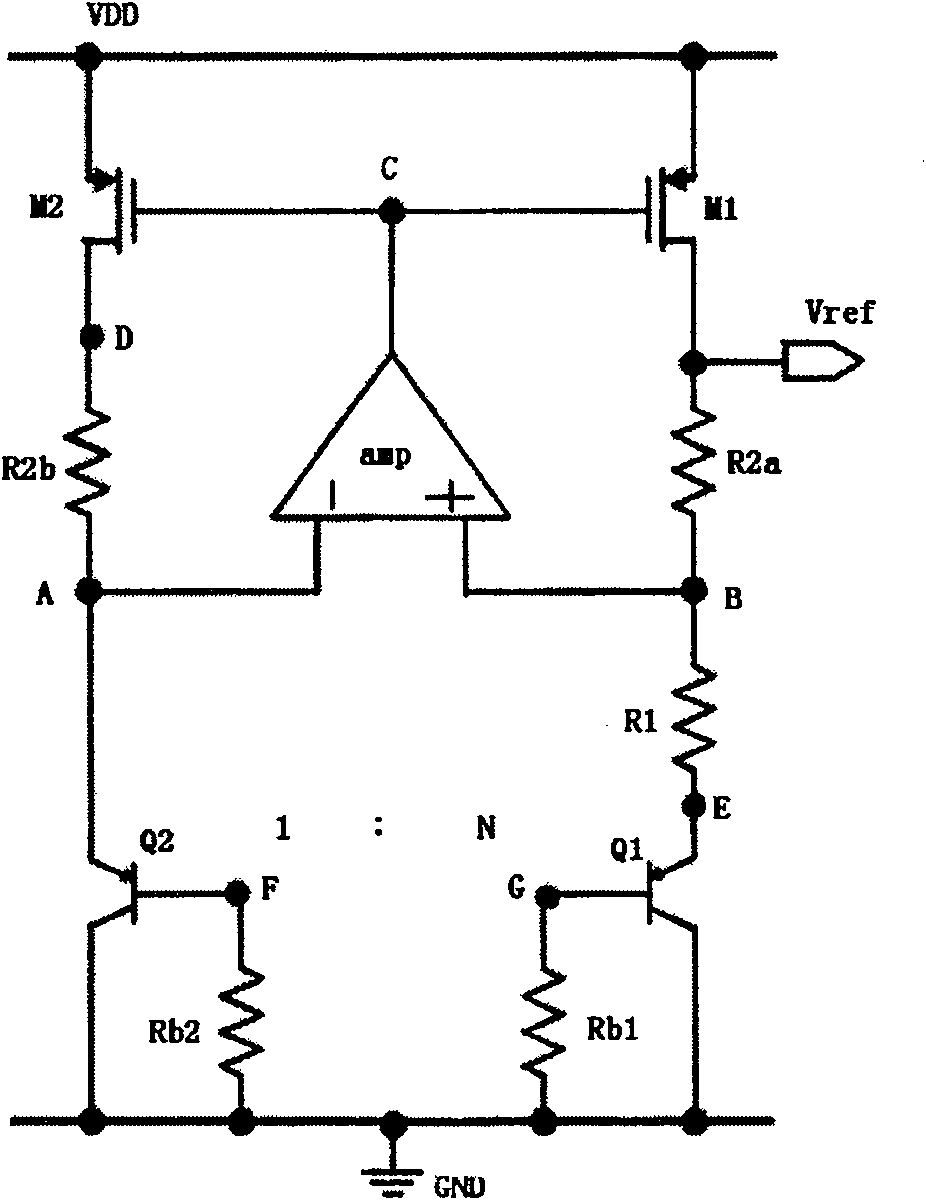

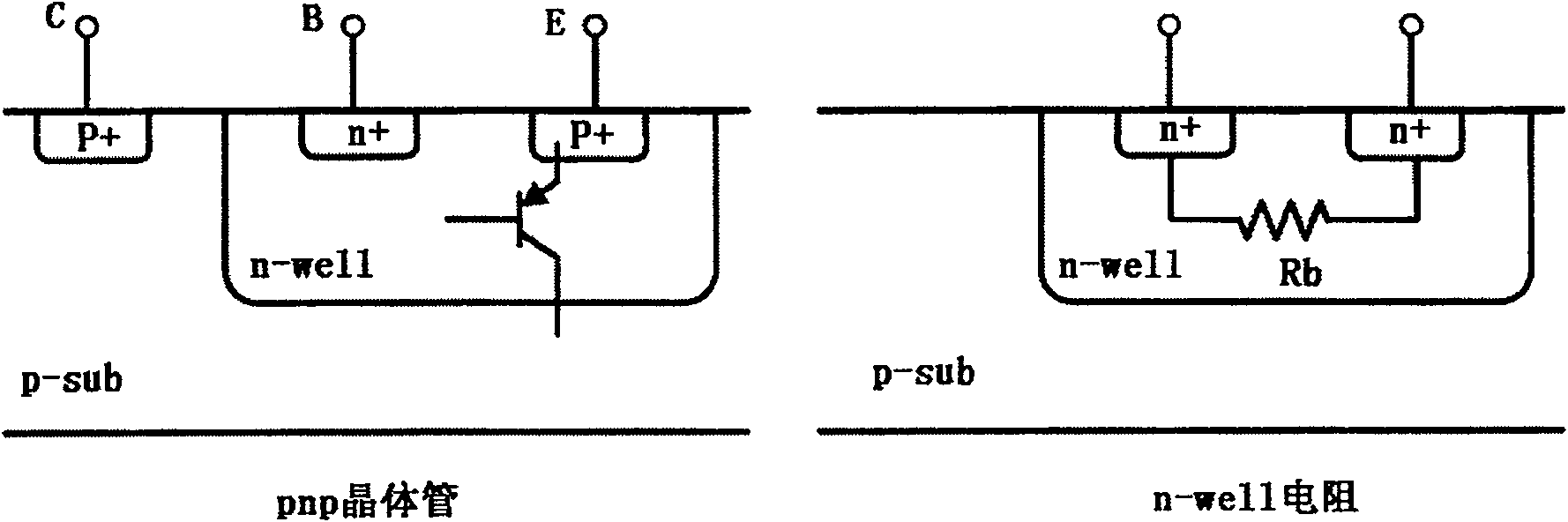

[0044] see figure 1 , the present invention includes MOS transistors M1 and M2, the source of MOS transistor M1 is connected to node VDD, the gate is connected to node C, the drain is connected to node Vref, the source of MOS transistor M2 is connected to node VDD, and the gate is connected to Node C, drain connected to node D, proportional resistor R 2a Connected between node B and node Vref, matching resistor R 2b Connected between node A and node D, the positive input of the error amplifier amp is connected to node B, the negative input is connected to node A, the output is connected to node C, and the transistor base-emitter dropout resistor R 1 Connected between node B and node E, the emitter of transistor Q1 is connected to node E, the base is connected to node G, and the collector is connected to node GND; the emitter of transistor Q2 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com