Automatic plane screen printer with turned plate

A technology of printing machine and cloth plate, applied in the field of reverse cloth plate automatic flat screen printing machine, can solve the problems of affecting the popularization and application of automatic printing machine, large influence on printing quality, low work efficiency, etc. Easy to adjust and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

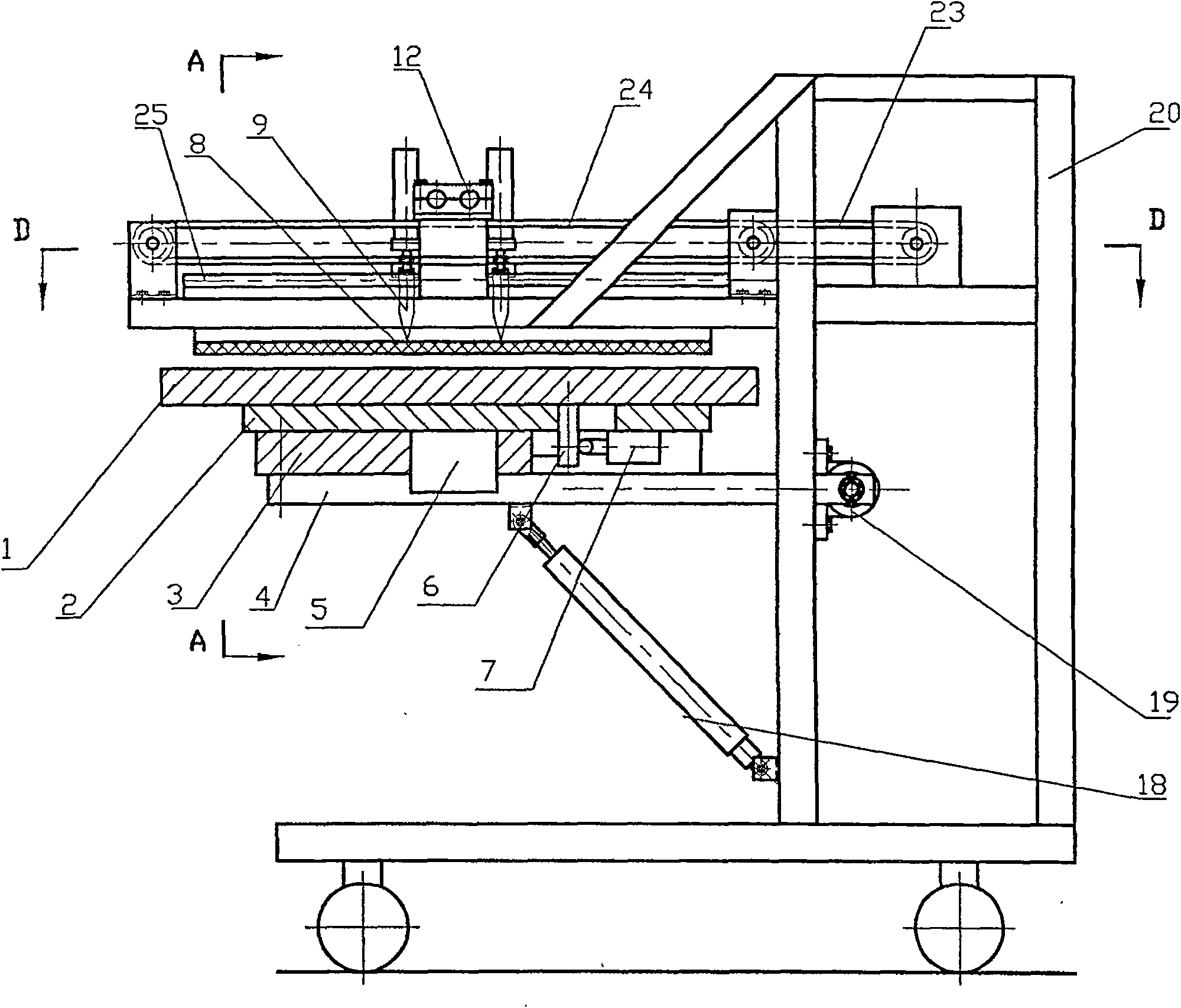

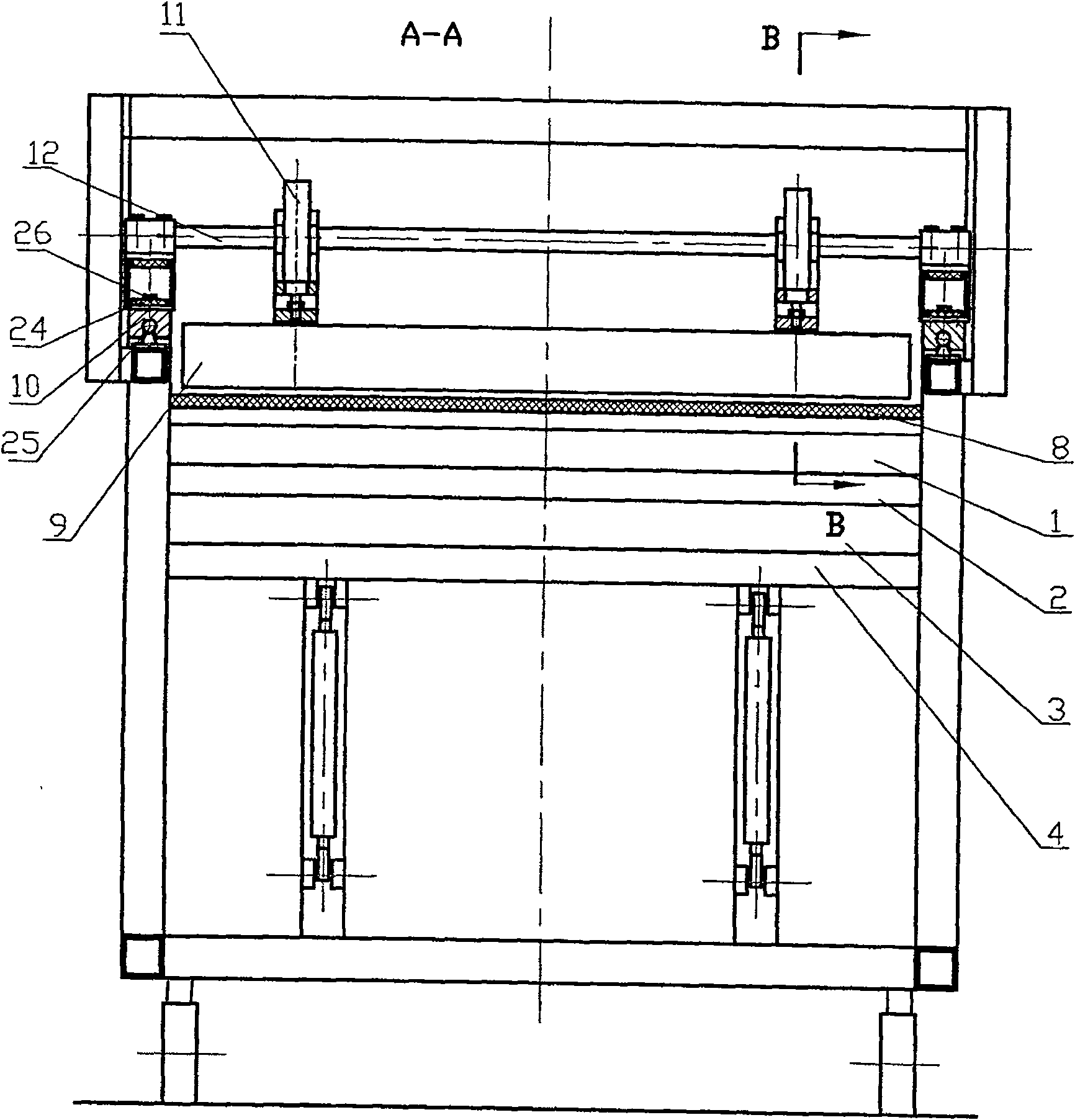

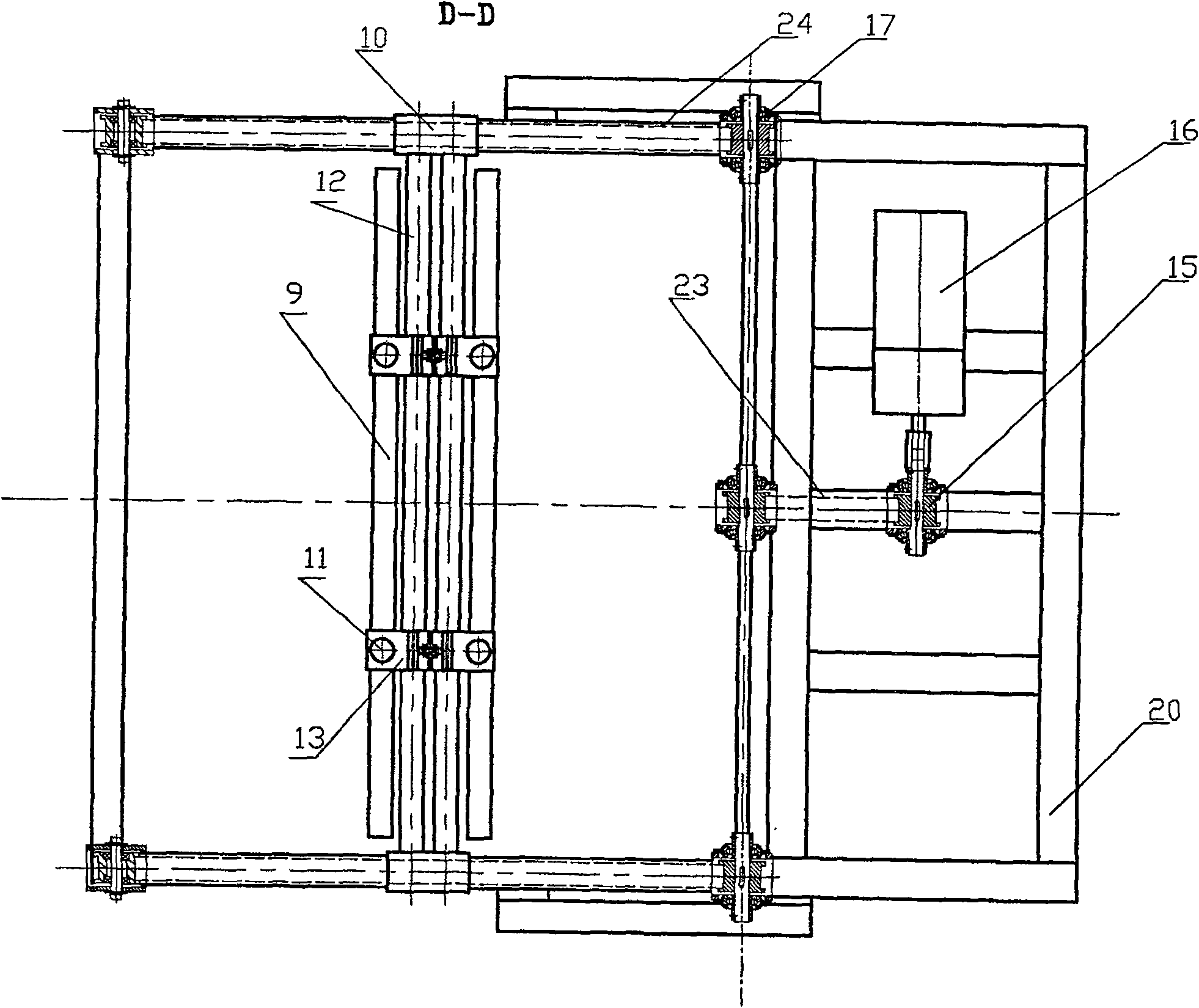

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, it includes a pressurizing mechanism for installing two scrapers 9 on the main frame 20, a moving mechanism, a silk screen 8, and a rotating mechanism for the cloth plate 1.

[0018] The slider 10 makes a linear reciprocating motion on the linear guide rail 25. The bottom of the slider 10 and the bottom of the synchronous belt 24 are connected together by bolts 26. Two pressurized cylinder fixing rods 12 are installed on the top of the slider 10; each pressurized cylinder Pressurized cylinder fixed frame 13 is installed respectively by screw 14 on the fixed rod 12, pressurized cylinder 11 is connected as a whole with pressurized cylinder frame 13 by the screw thread of its cylinder body lower end, and the piston rod extension end of pressurized cylinder 11 passes thread and Scraper spl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com