Mechanical expansion shaft and method for hoisting coil material

An expansion shaft and expansion shaft technology, which is applied in the field of mechanical expansion shafts and the lifting of coiled parts by using them, can solve the problems of large maintenance, poor reliability, and inability to bear heavy loads, etc., and achieves convenient operation, strong practicability, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

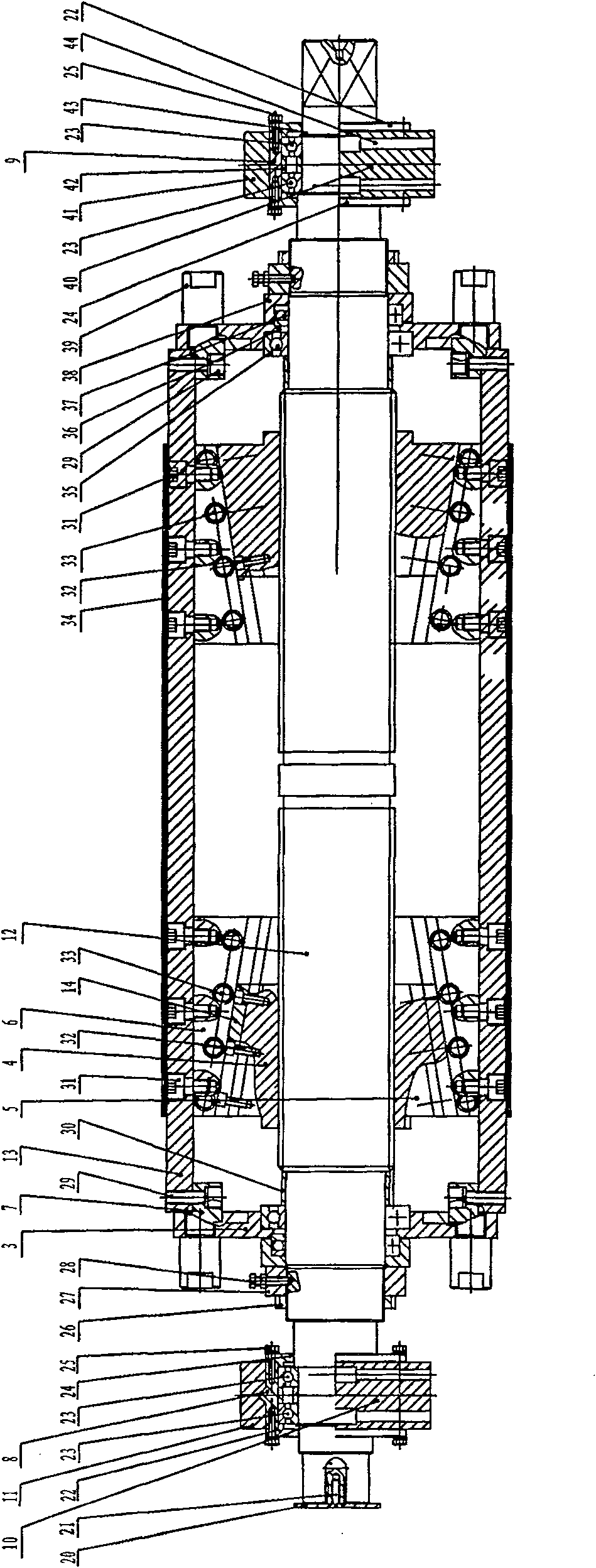

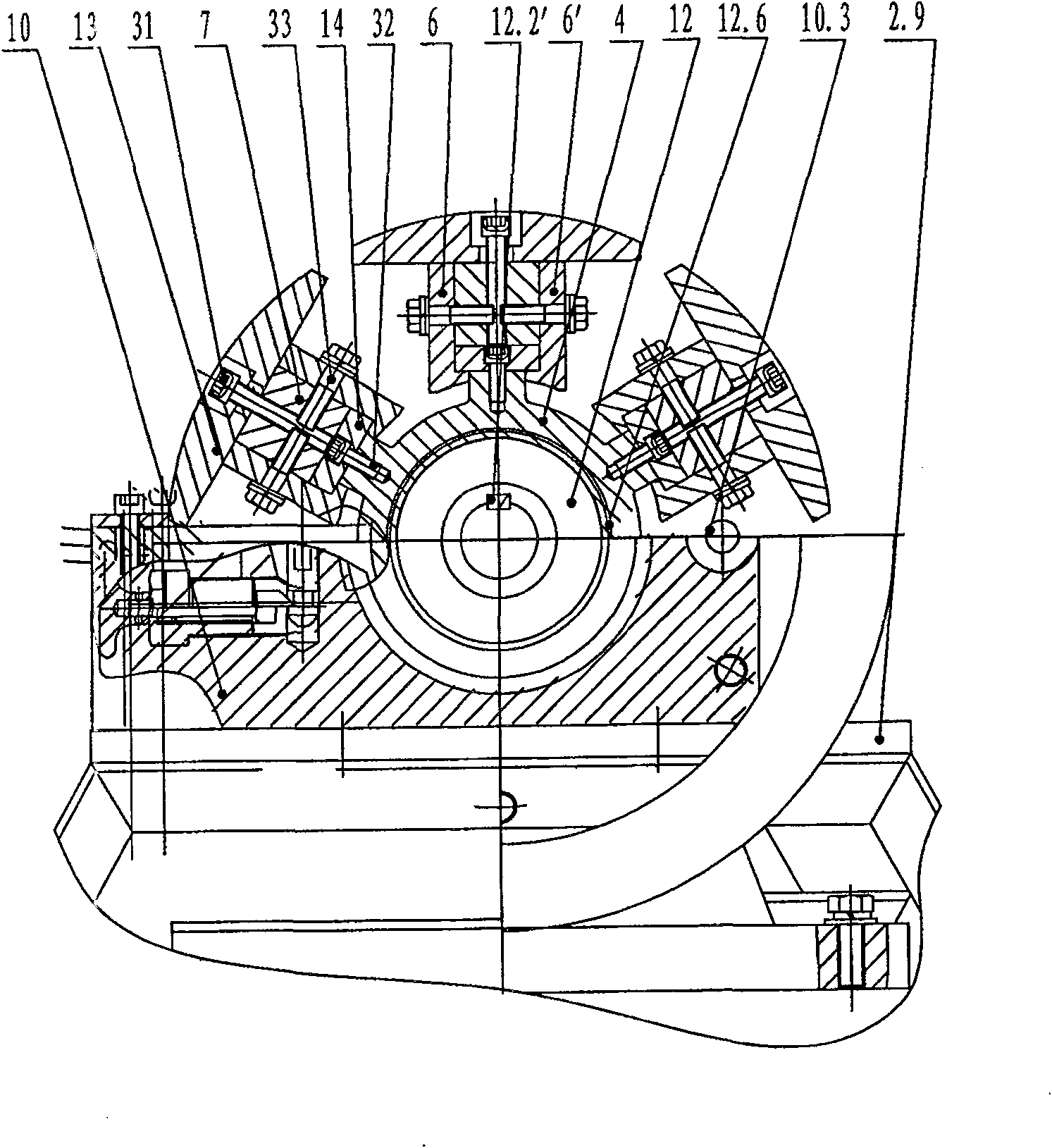

[0049] A specific embodiment of the mechanical expansion shaft of the present invention, such as figure 1 and figure 2 as shown, figure 1 is a longitudinal sectional view of the mechanical expansion shaft of the present invention, figure 2 It is a transverse sectional view of the mechanical expansion shaft of the present invention. As can be seen from the figure, its main structure is as follows:

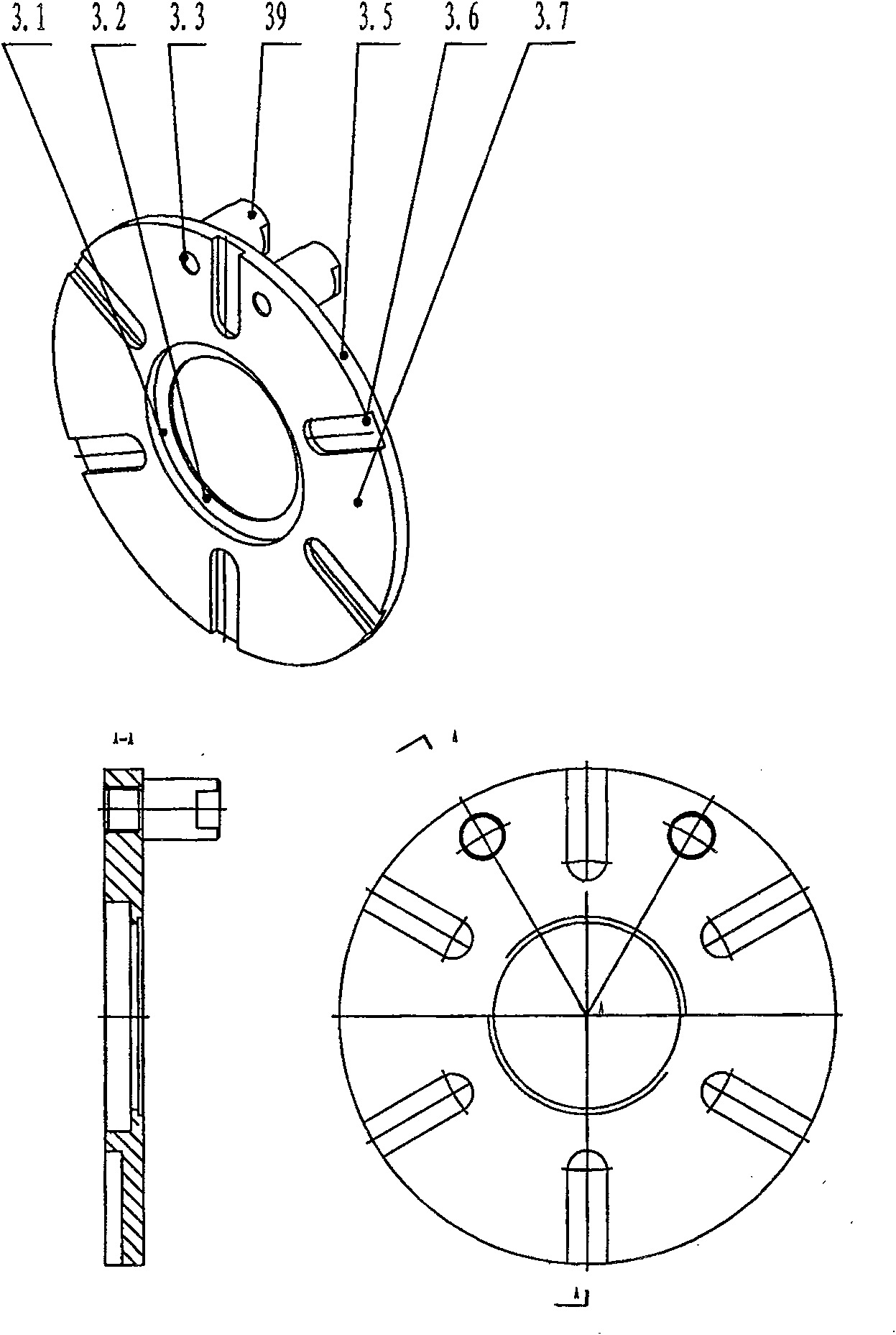

[0050] The mechanical expansion shaft in this embodiment includes a mandrel 12 and an expansion shaft support plate 13. One end of the mandrel 12 is provided with a square block, and the middle part of the mandrel 12 is symmetrically provided with two sections of external threads with opposite directions of rotation. An expansion shaft nut 4 is sleeved respectively. The overall expansion shaft nut 4 is in the shape of a truncated cone. The inner wall of the expansion shaft nut 4 is provided with an internal thread corresponding to the external thread on the mandrel 12. The out...

Embodiment 2

[0068] A specific embodiment of the mechanical expansion shaft of the present invention has the following structure:

[0069] A mechanical expansion shaft, including a mandrel and an expansion shaft support plate, one end of the mandrel is provided with a square block, and the middle of the mandrel is symmetrically provided with two sections of external threads with opposite rotation directions, and each external thread is respectively sleeved with an expansion thread The outer wall of the expansion shaft nut is a cone-column structure, and the inner wall is provided with an internal thread corresponding to the external thread on the mandrel. The two expansion shaft nuts are arranged symmetrically. The outer wall of the expansion shaft nut is equipped with multiple Tilt sliding mechanism on the silk nut.

[0070] The structure of the inclined sliding mechanism in this embodiment is as follows: a plurality of inverted T-shaped grooves are arranged on the outer wall of the expan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com