Tunnel large caliber steel tube conveyor system

A conveying device and large-diameter technology, applied in the field of trackless vehicles, can solve the problems of insufficient safety and high labor intensity, and achieve the effect of simple operation, low labor intensity and high automation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

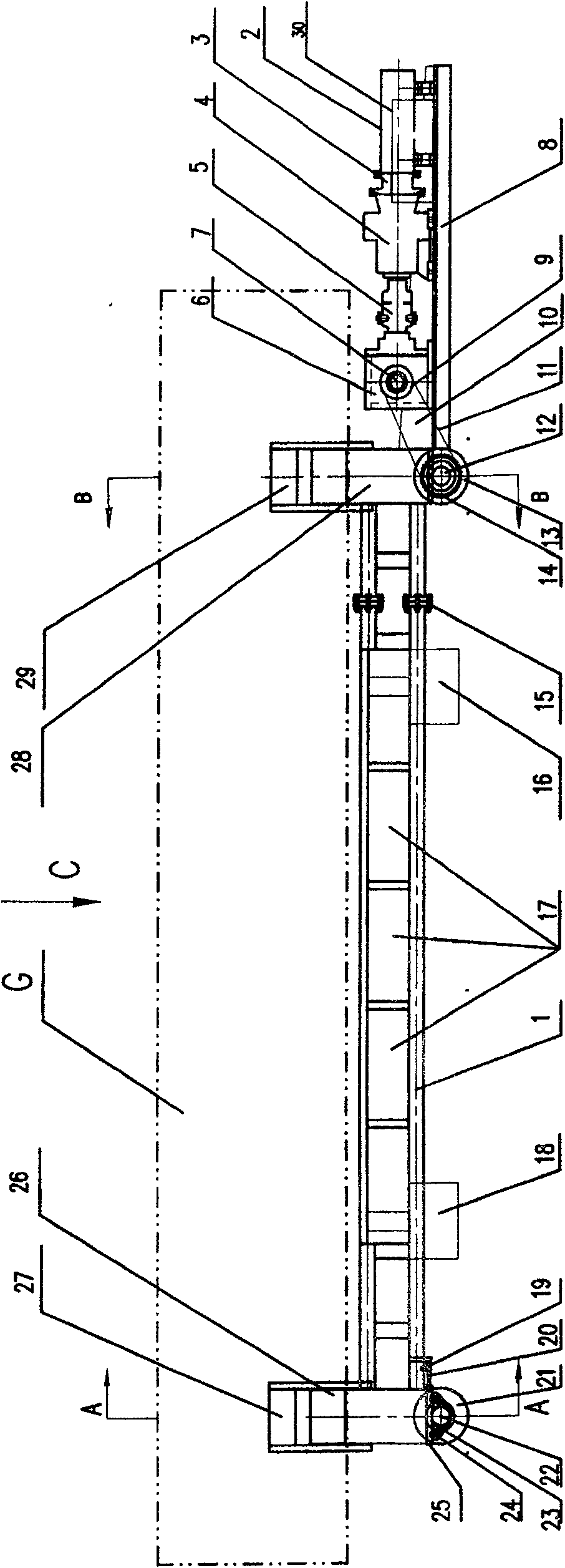

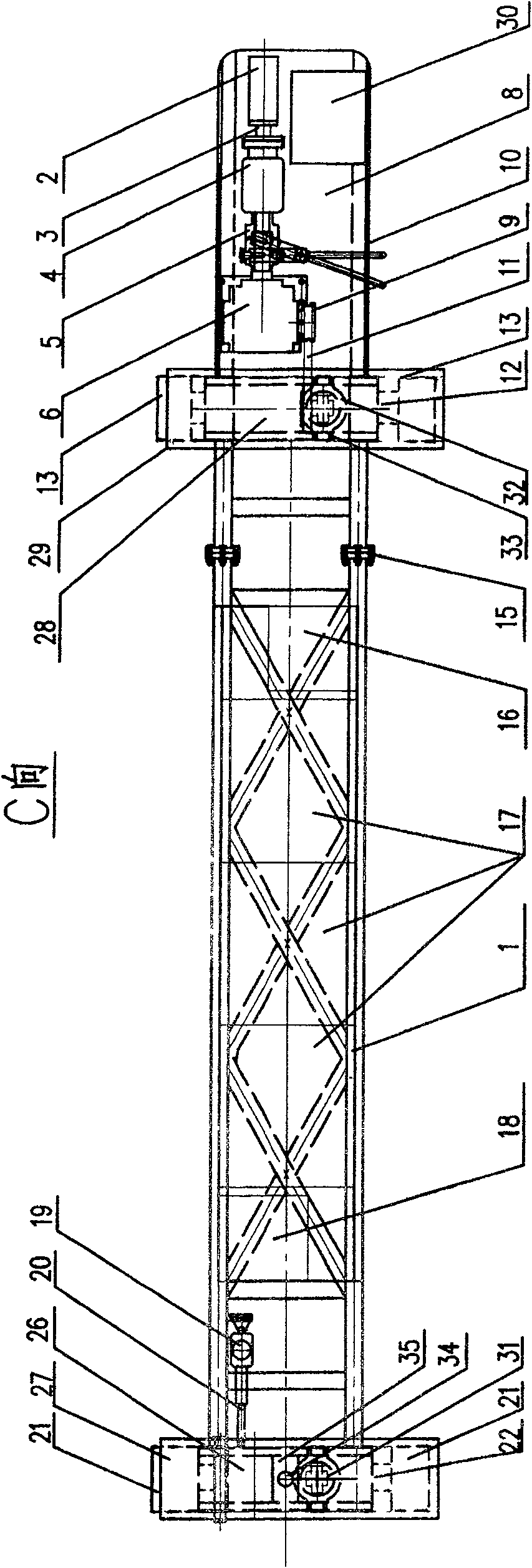

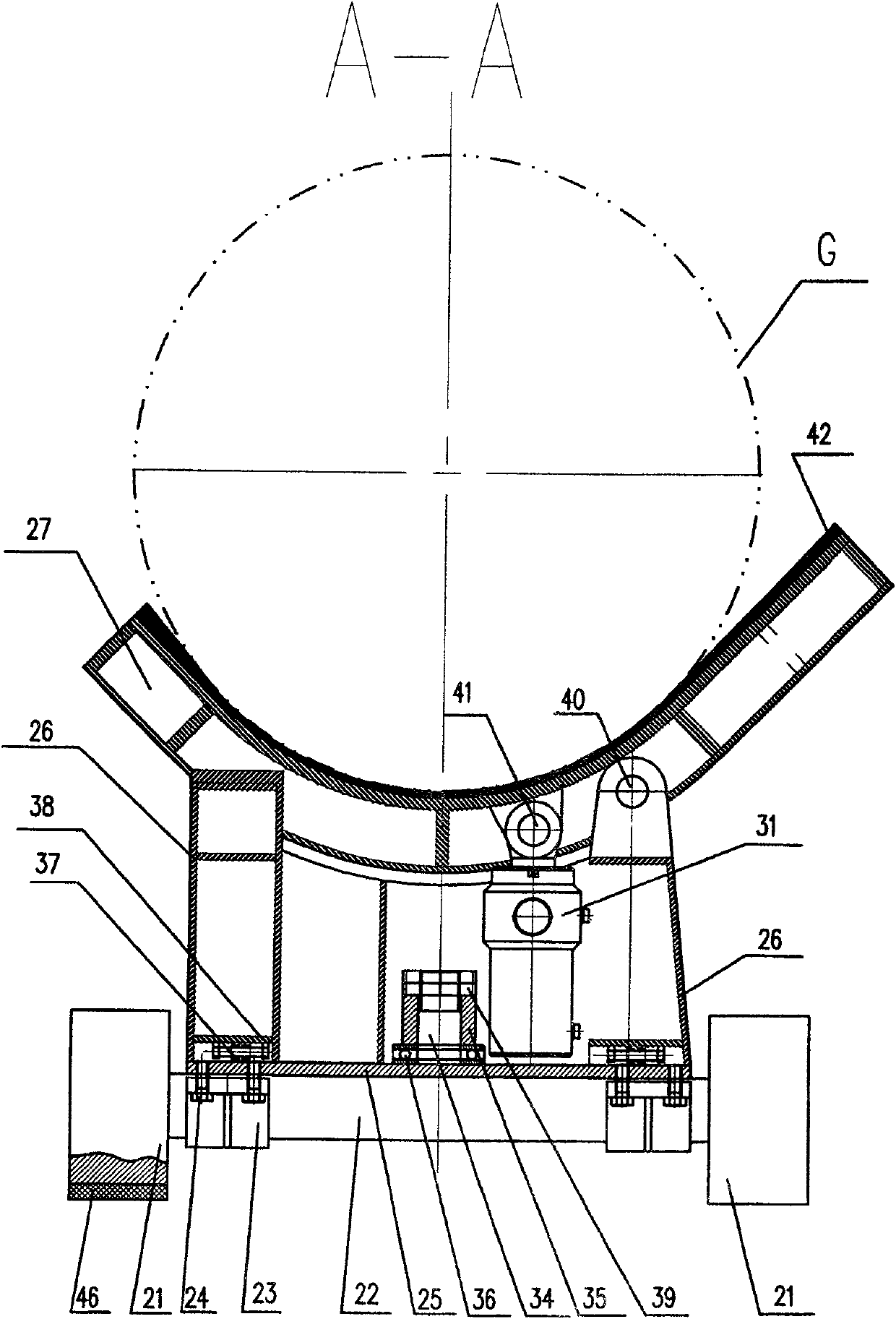

[0024] attached Figure 1~5 Among them, 1 is the frame, 2 is the DC motor, 3 is the coupling, 4 is the reducer, 5 is the clutch, 6 is the transmission reversing device, 7 is the driving sprocket axle, 8 is the supporting plate, and 9 is the driving chain Wheel, 10 is the second rib plate, 11 is the chain, 12 is the driving wheel shaft, 13 is the driving wheel, 14 is the passive sprocket, 15 is the joint flange assembly of the vehicle frame, 16 is the rear hydraulic source, 17 is Vehicle-mounted DC power supply, 18 is the front hydraulic power source, 19 is the steering motor, 20 is the electric push rod, 21 is the driven travel wheel, 22 is the driven travel wheel shaft, 23 is slips, 24 is slip bolts and nuts, 25 is steering Chassis, 26 and 28 are box-shaped supports, 27 is the front stinger frame, 29 is the rear stinger frame, 30 is the electric control box, 31 and 32 are the hydraulic cylinders, 33 is the hydraulic cylinder fixing sleeve, 34 is the steering center shaft, 35 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com