Automatic checking device for cell leakage

An automatic detection device and air-tightness technology, which is applied in the direction of liquid-tightness measurement by using liquid/vacuum degree, and by detecting the appearance of fluid at the leakage point, can solve the problems that are difficult to meet industrial mass production, low detection sensitivity, and operation Difficulty and other problems, to achieve the effect of prolonging the detection and observation time, accurate detection results, and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

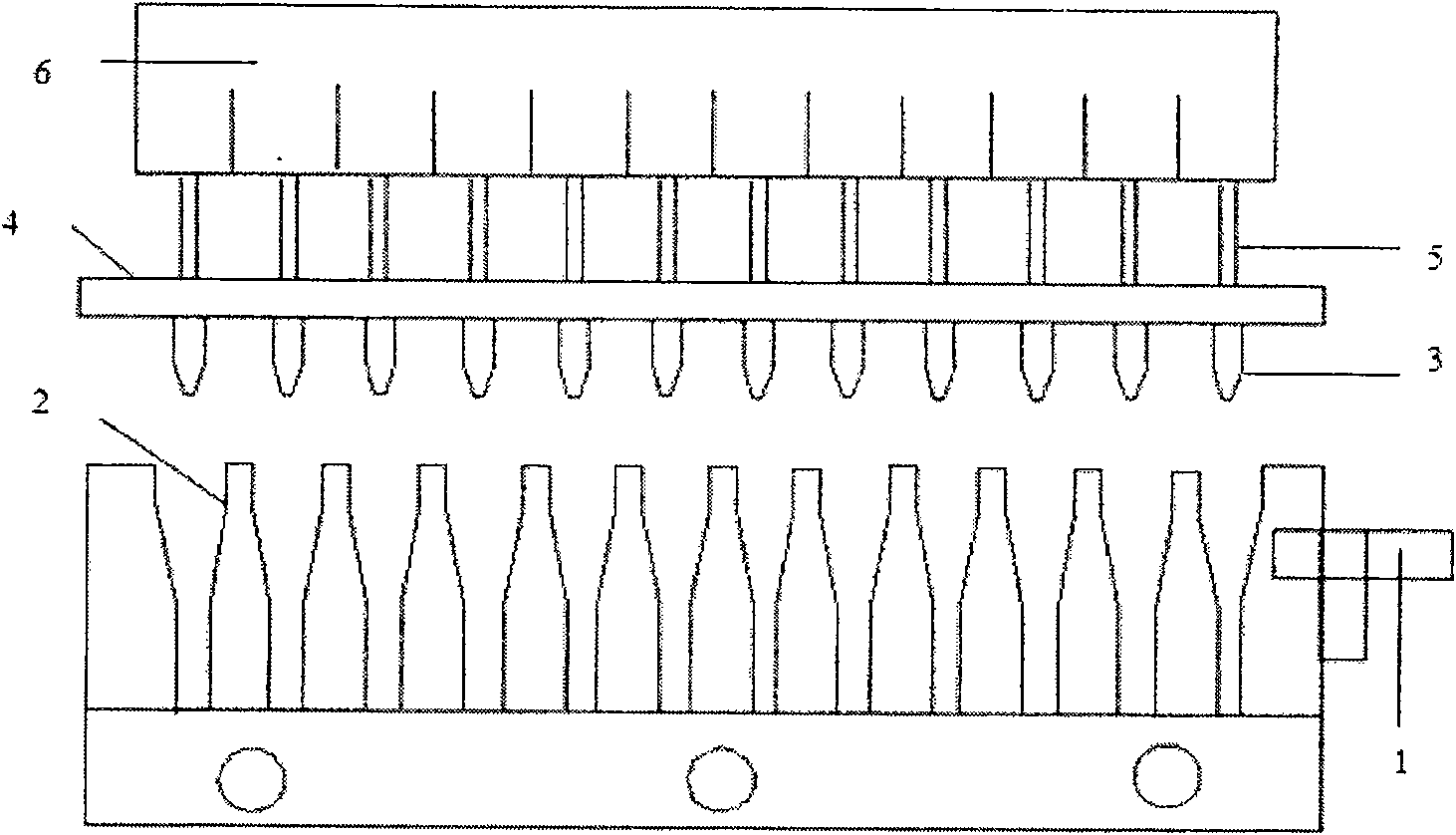

[0012] Such as figure 1 As shown, the battery air tightness automatic detection device of the present invention mainly includes a frame, a battery clamp, a detector 3, a workbench 4, a push plate, a water tank 6, an air extraction device, and a controller. The frame is L-shaped , The battery clamp is installed on the bottom frame of the rack. The lower part of the battery clamp is equipped with a stroke cylinder. The battery clamp is composed of an adjustable screw 1 and a positioning clamp 2. A push plate is provided on the outside of the bottom of the rack to push the battery, and the push plate is connected to the double cylinder cylinder; The upper part of the frame is provided with an adjustable cylinder, which is connected with a sliding rod, the workbench 4 is connected to the sliding rod, and a plurality of detectors 3 are installed on the workbench 4, and the detector 3 is composed of a suction nozzle and a suction cup; An air duct 5 and a suction duct connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com