Backlight module

A backlight module and light guide plate technology, applied in optics, nonlinear optics, instruments, etc., can solve problems such as light leakage from the light guide plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

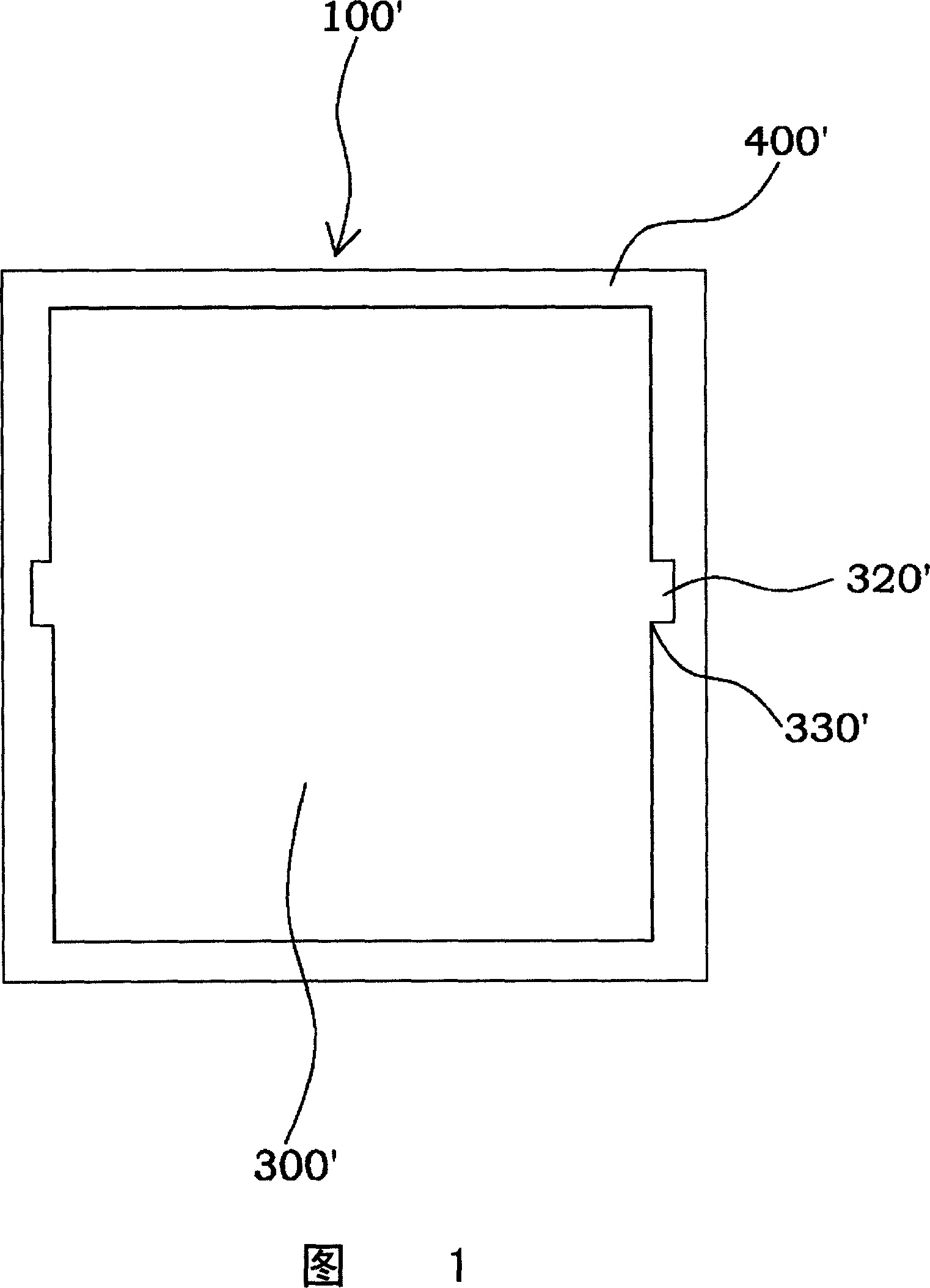

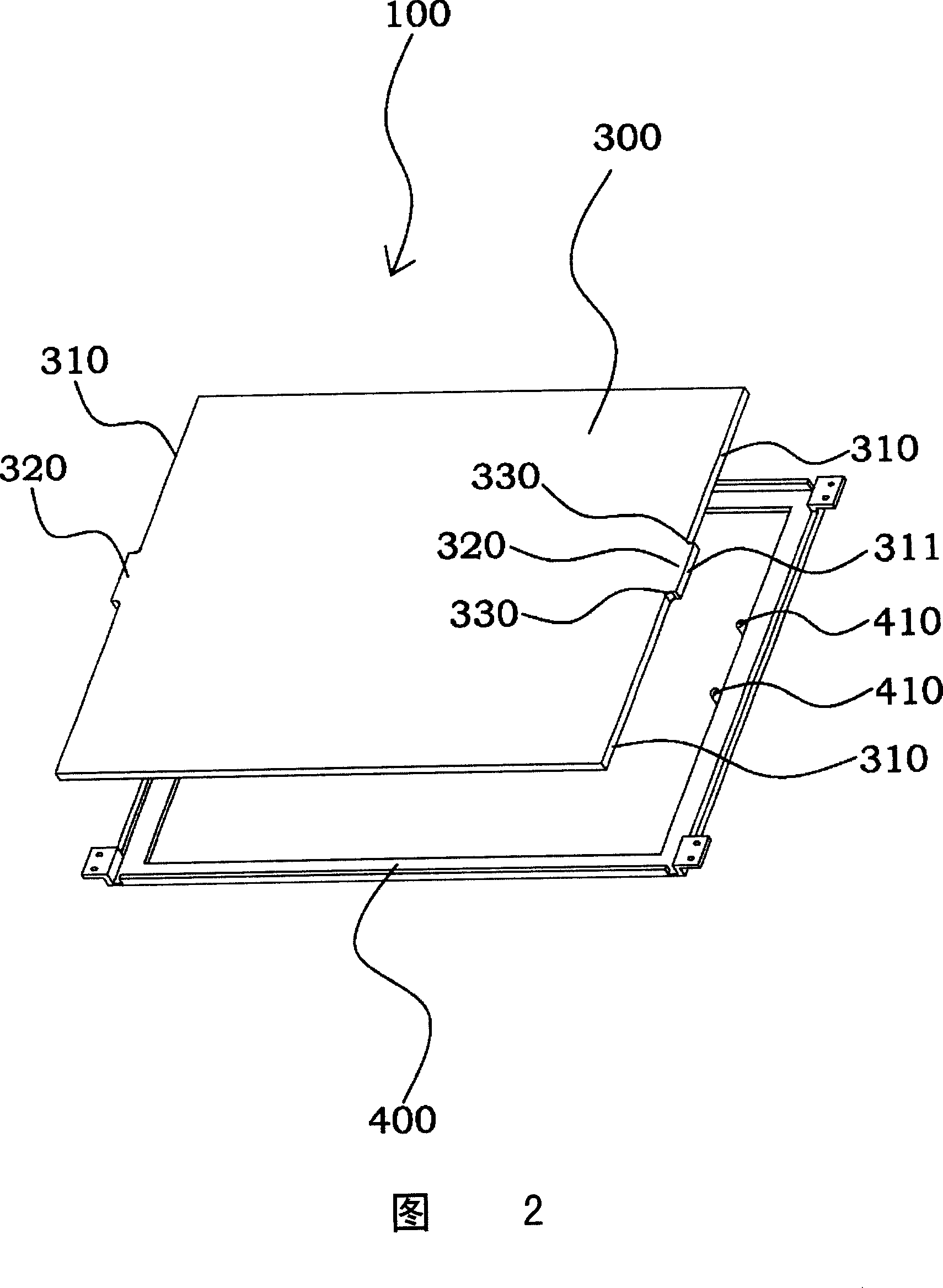

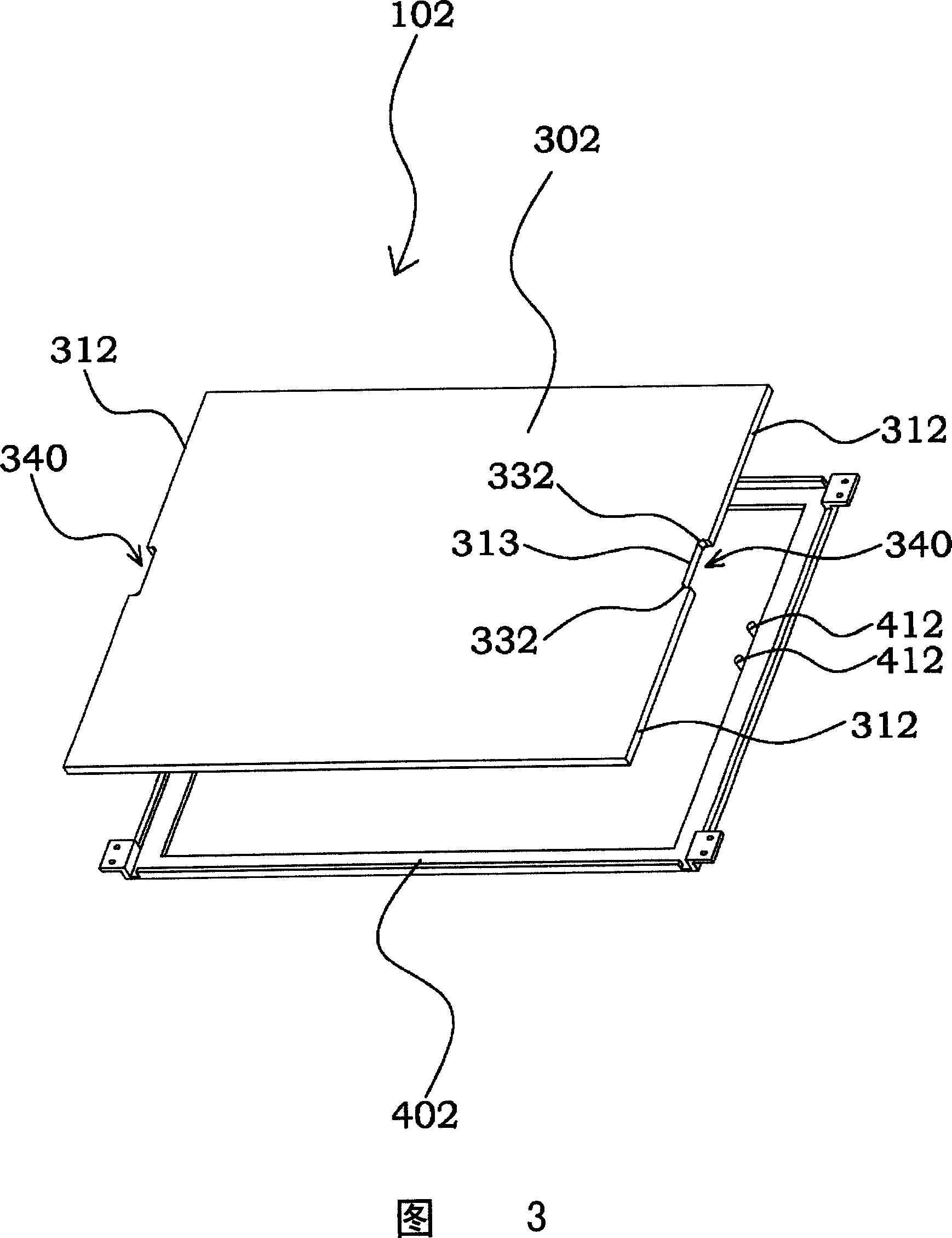

[0011] Please refer to FIG. 2 . FIG. 2 is a perspective view of a backlight module according to an embodiment of the present invention. In this embodiment, the backlight module 100 includes a light guide plate 300 and a corresponding outer frame 400 . Wherein, the light guide plate 300 includes a first peripheral edge 310 and a second peripheral edge 311, and the connection between the first peripheral edge 310 and the second peripheral edge 311 forms a guide angle 330, such as an arc-shaped guide angle. In one embodiment, the second The two peripheral edges 311 and the chamfer 330 define a protrusion 320 protruding from the first peripheral edge 310 . And in one embodiment, the protrusion 320 is located on the non-light-incident side of the light guide plate, so that the optical image is minimal. Next, an outer frame 400, such as a back plate, surrounds at least the first peripheral edge 310 and the second peripheral edge 311 of the light guide plate 300, and includes at lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com