Artificial flowers and its processing method

A production method and technology of artificial flowers, applied in artificial flowers, applications, clothing, etc., can solve problems such as loss of luster, unnatural viewing, easy fading, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

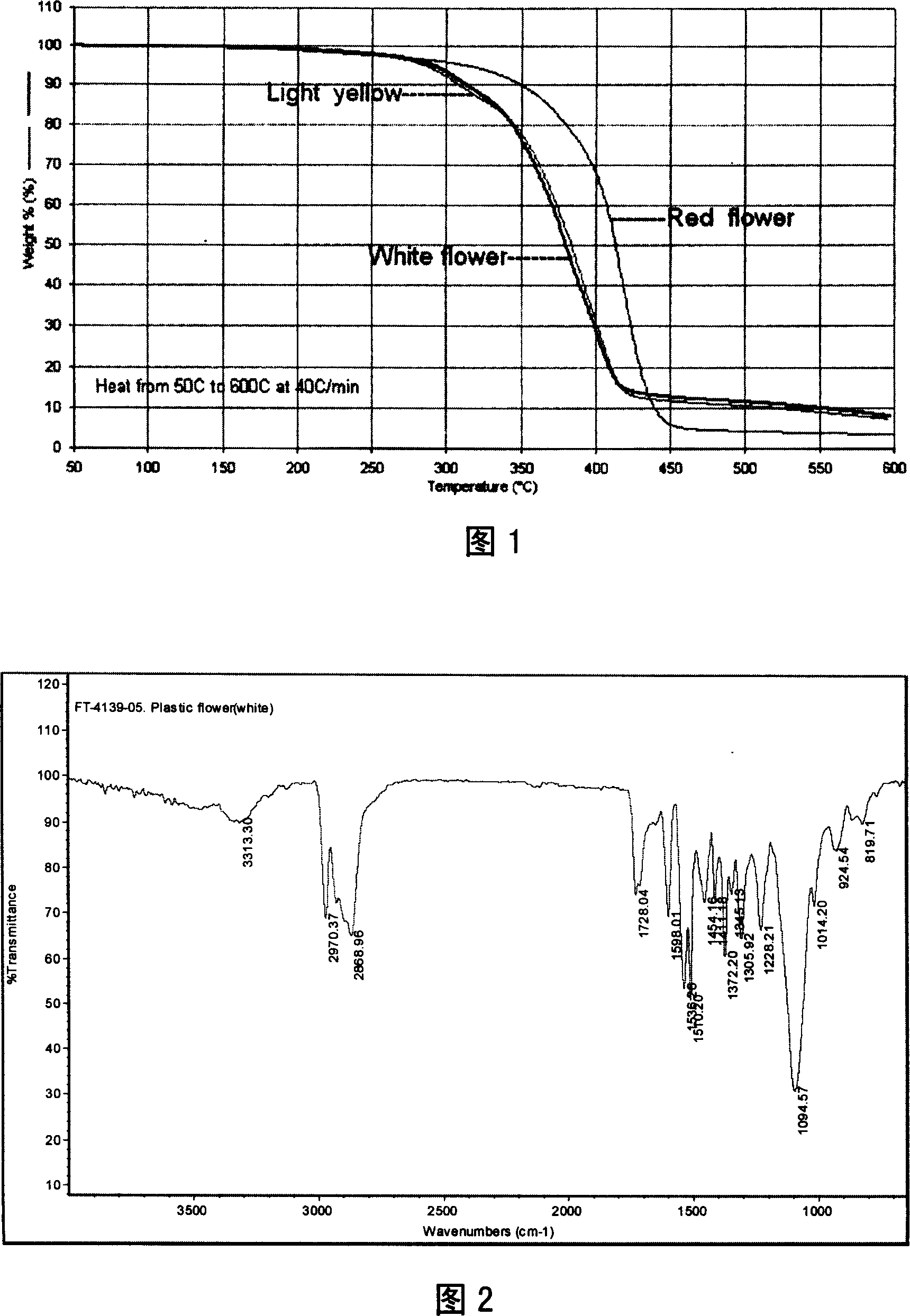

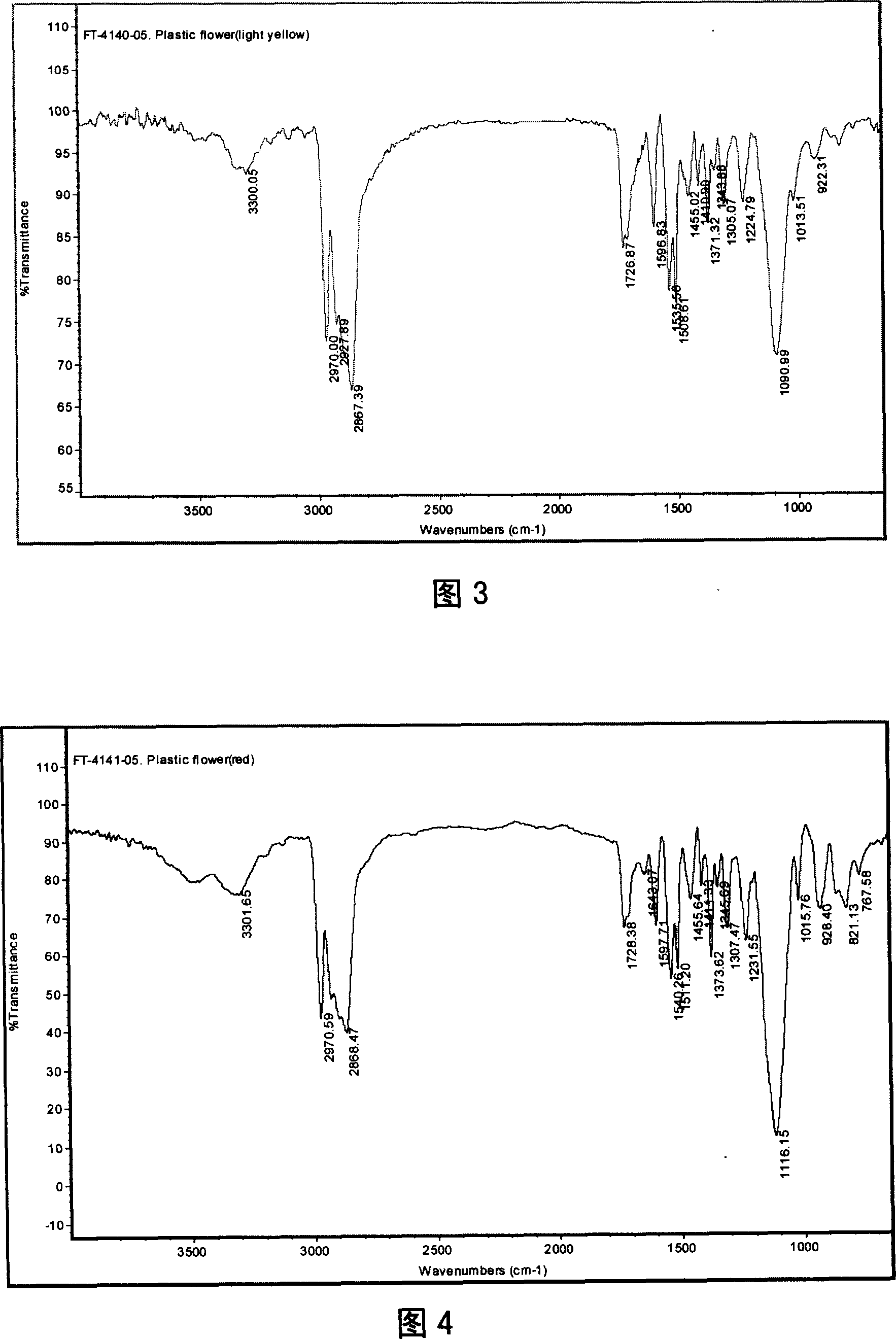

[0041] Example 1: White lilies (including stems)

[0042] Element:

[0043] As a typical example of this invention, the white lily is made as follows:

[0044] The ingredients for making petals are divided into Group A and Group B. Group A consists of the following materials: 80% polyether, 3% crosslinking agent, 2% stabilizer, 1.5% catalyst, 4% water, 4.2% foaming agent, 1.3% color paste. The components of group B are composed of the following materials: 18% of skin-forming isocyanate, 36% of elastic isocyanate, and the weight percentage of components of group B is calculated based on the total weight of components of group A. In this example, the weight of component A for making artificial lilies is 20 kg. In group B, the weight of skinning isocyanate is 3.6 kg, and that of elastic isocyanate is 7.2 kg.

[0045] The ingredients for making flower stems are also divided into Group A and Group B: Group A consists of the following materials: 50% polyether, 25% grafted polyet...

example 2

[0057] Example 2: Light yellow artificial flowers

[0058] Element:

[0059] Group A components: 70% polyether, 6% crosslinking agent, 4% stabilizer, 0.5% catalyst, 14% water, 4.2% foaming agent, 1.3% color paste.

[0060] Group B components: 10% skinning isocyanate, 45% elastic isocyanate, the weight percentage of group B components is calculated based on the total weight of group A components.

[0061] The use of the specific compound is the same as in Example 1, and the production process is also the same as in Example 1. But a yellow color paste was used, mixed with the ingredients of Group A.

example 3

[0062] Example 3: Red PU artificial flowers

[0063] Element:

[0064] Group A components: 90% polyether, 2% crosslinking agent, 3% stabilizer, 1% catalyst, 2% water, 1.2% foaming agent, 0.8% color paste.

[0065] Components of group B: 60% skin-forming isocyanate, the proportion of components in group B is determined by the total weight of group A.

[0066] The use of the specific compound is the same as in Example 1, and the production process is also the same as in Example 1. But a red color paste was used, mixed with the ingredients of Group A.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com