Sealing press piston type drink soaking device having protection equipment

A protective device and piston-type technology, which is applied in the field of sealed and spring-pressed piston-type brewers, can solve problems such as cumbersome operation, scalding the human body, and unsanitary conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

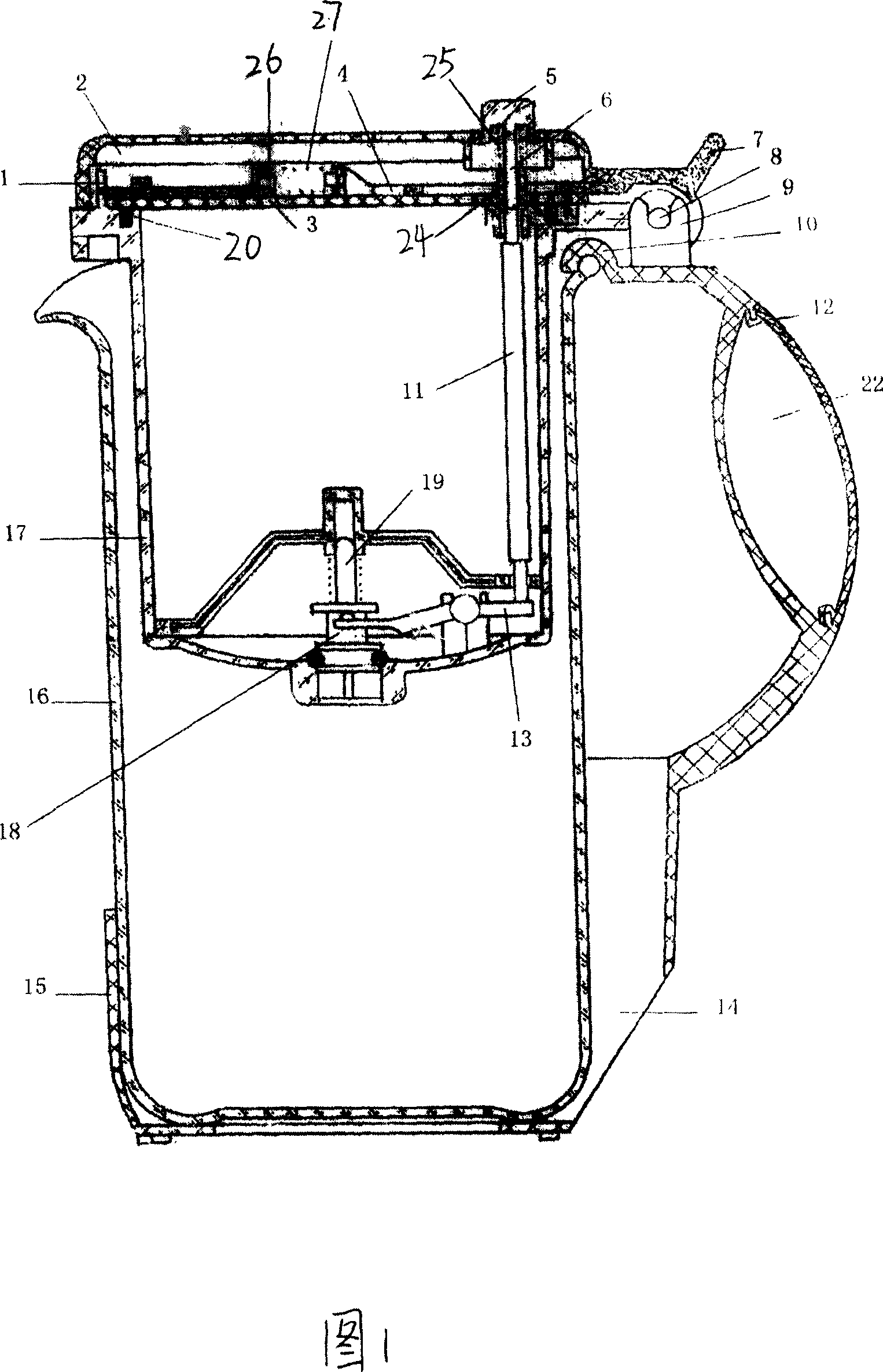

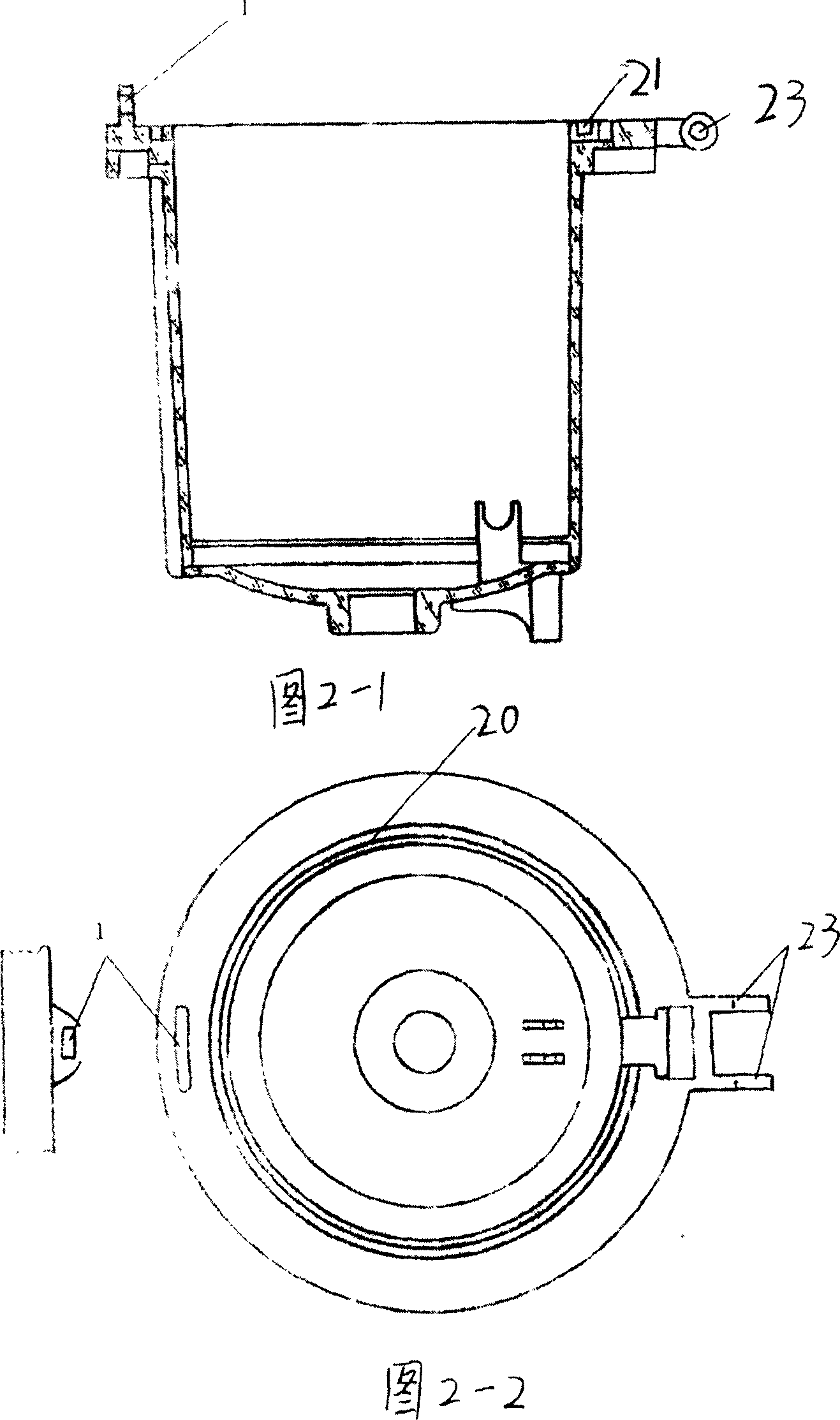

[0023] As shown in Fig. 1, the present invention is a kind of sealed elastic piston brewing device with a protective device, including a mother cup 16 and a sub-cup 17 sleeved in the mother cup and covered in the sub-cup The cup cover 2 above has a water outlet at the bottom of the sub-cup, a handle 12 is provided on one side of the mother cup, a snap-press ejector 6 is provided in the cup cover, and a ejector 11 is provided in the sub-cup close to the cup wall , the top of the ejector rod is flush with the mouth of the sub-cup, and is in contact with the elastic ejector rod provided in the cup cover, a spring 25 is arranged in the cup cover, and the elastic ejector rod is set in the cup In the spring, the top of the spring push rod is provided with a spring push button 5, and the spring push button protrudes from the cup cover; the bottom of the cup is provided with a valve core 18 and a rocker 13 connected with the valve core , the bottom of the spool is set at the water out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com