Bush cutter working head connection structure

A technology of connecting structure and working head, applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of laborious, laborious and inconvenient operation of the operator, and achieve convenient and easy use, convenient disassembly, assembly and replacement, and work efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The embodiments of the present invention will be described in detail below according to the above-mentioned drawings.

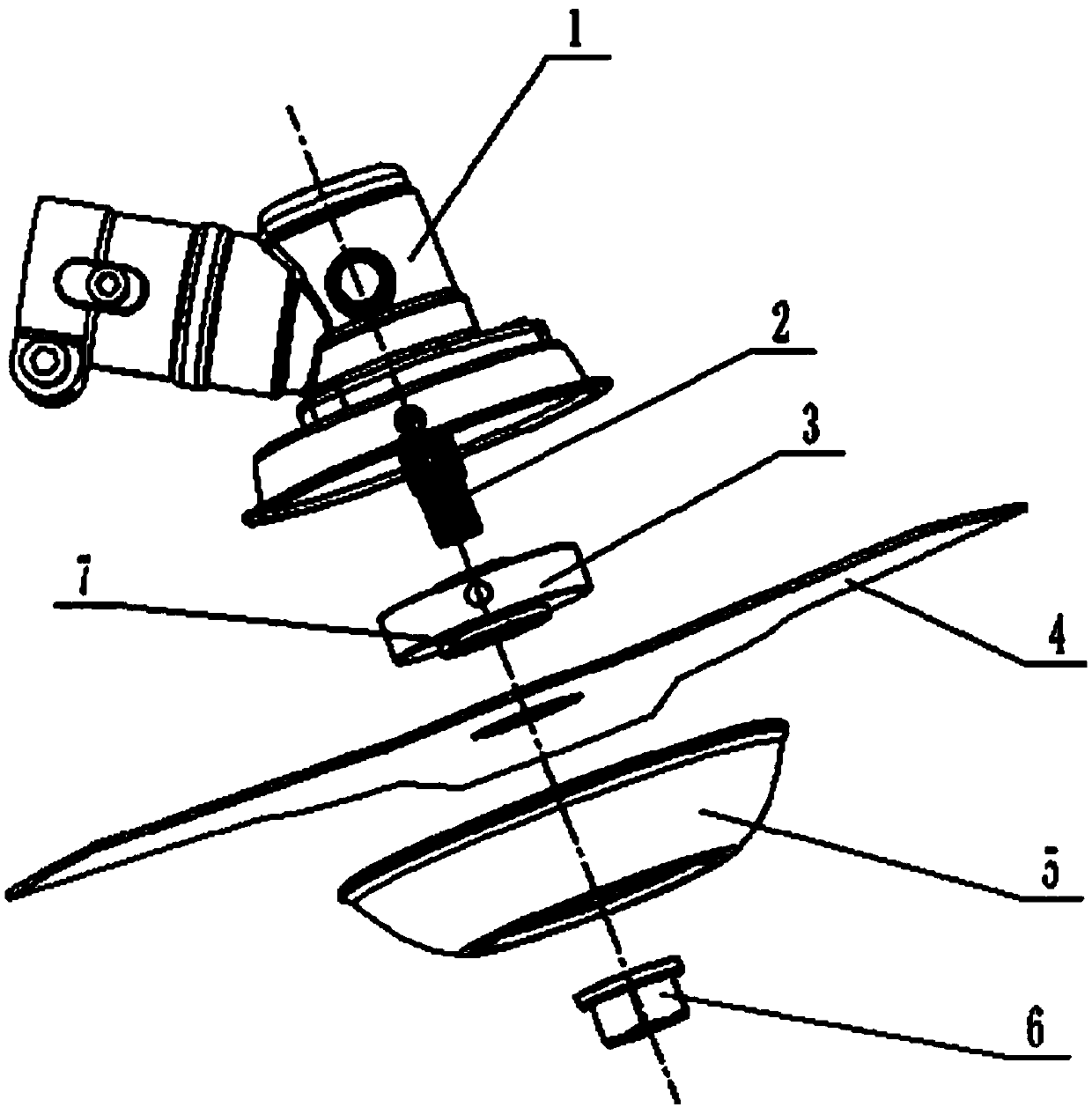

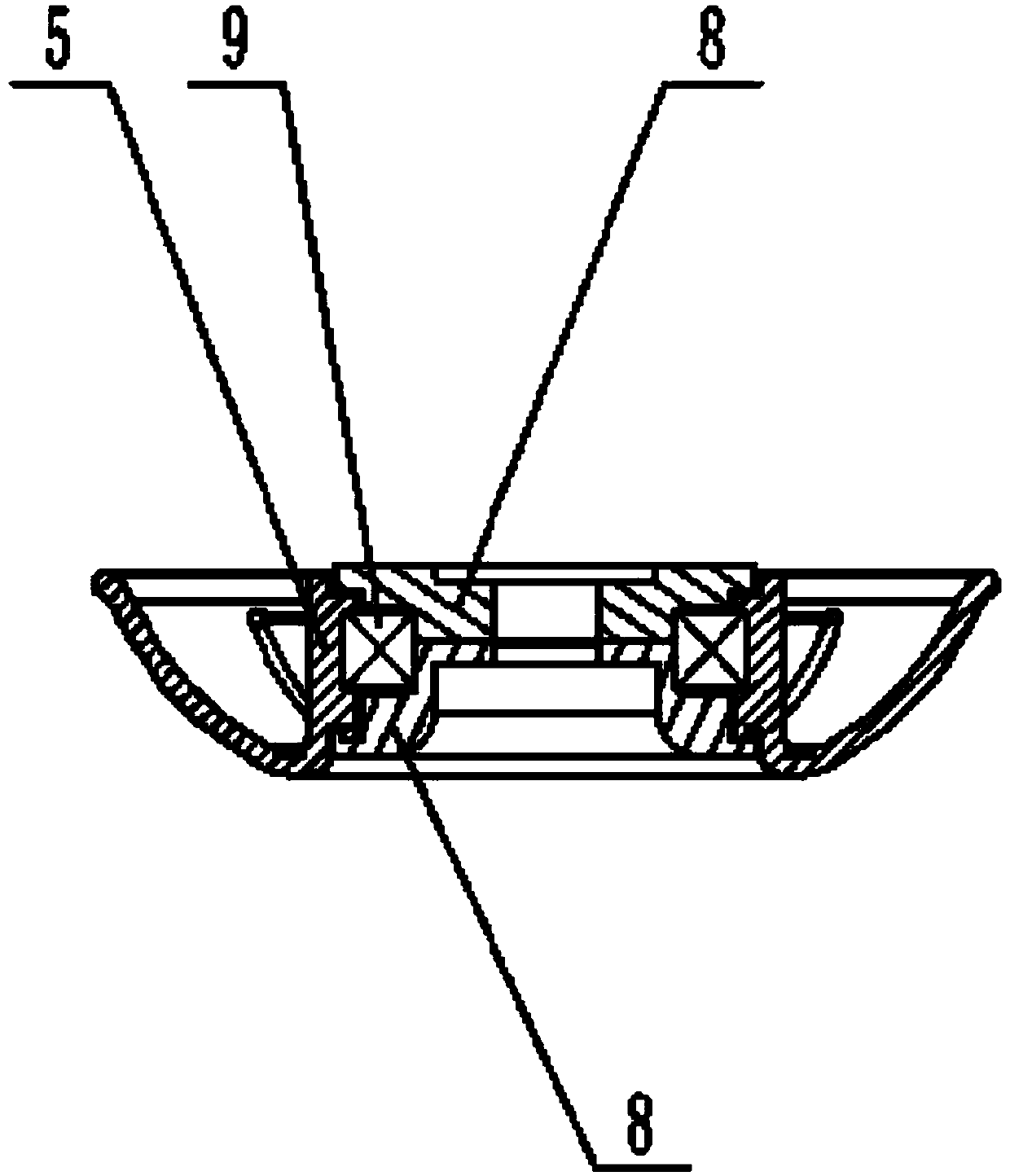

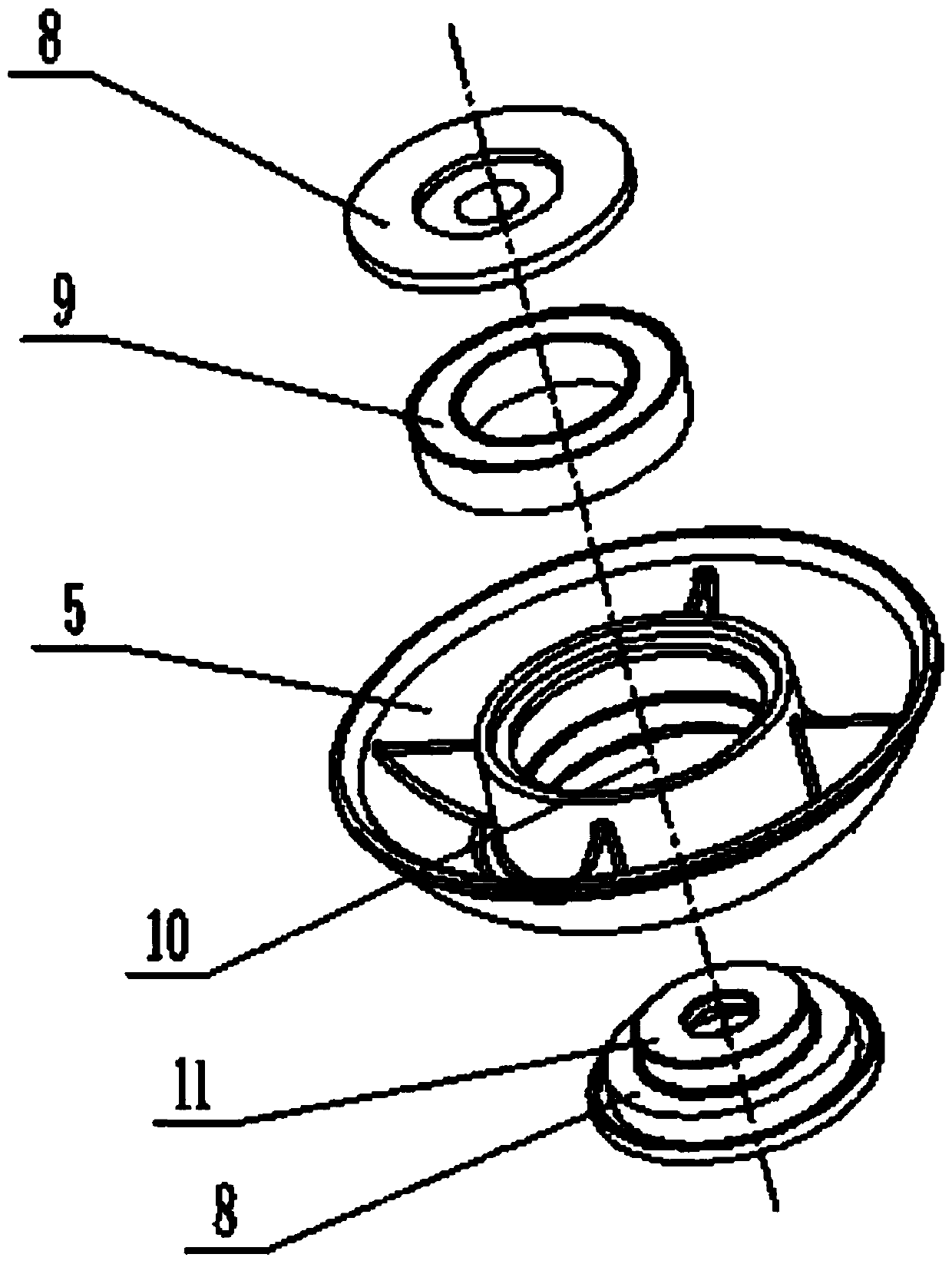

[0016] like Figure 1 ~ Figure 4 As shown, 1. Gear box, 2. Output shaft, 3. Support block, 4. Blade, 5. Shield, 6. Nut, 7. Mounting boss, 8. Pressure plate, 9. Bearing, 10. Connection hole, 11. Connect the boss.

[0017] The connection structure of the working head of the brush cutter, such as figure 1 As shown, it is mainly composed of a gear box 1, a bracket 3, a blade 4, a pressing plate 8, a shield 5 and a flange nut 6 and the like.

[0018] The rear end of the gear box 1 is connected to the operating lever (not shown) of the brush cutter, the gear box 1 is provided with a gear set, and the bottom of the gear box protrudes from the output shaft 2, which is formed by the external threaded shaft at the front end. and the external spline shaft at the rear end; the support block 3, the blade 4, the pressure plate 8 and the shield 5 are sequentially...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com