Stamping semi-module of forming die

A molding die and molding technology, applied in the direction of molding tools, metal processing equipment, manufacturing tools, etc., can solve the problems of the difficulty of setting wire and the loss of blanks, and achieve the effect of improving the speed of mold clamping and the quality of product production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

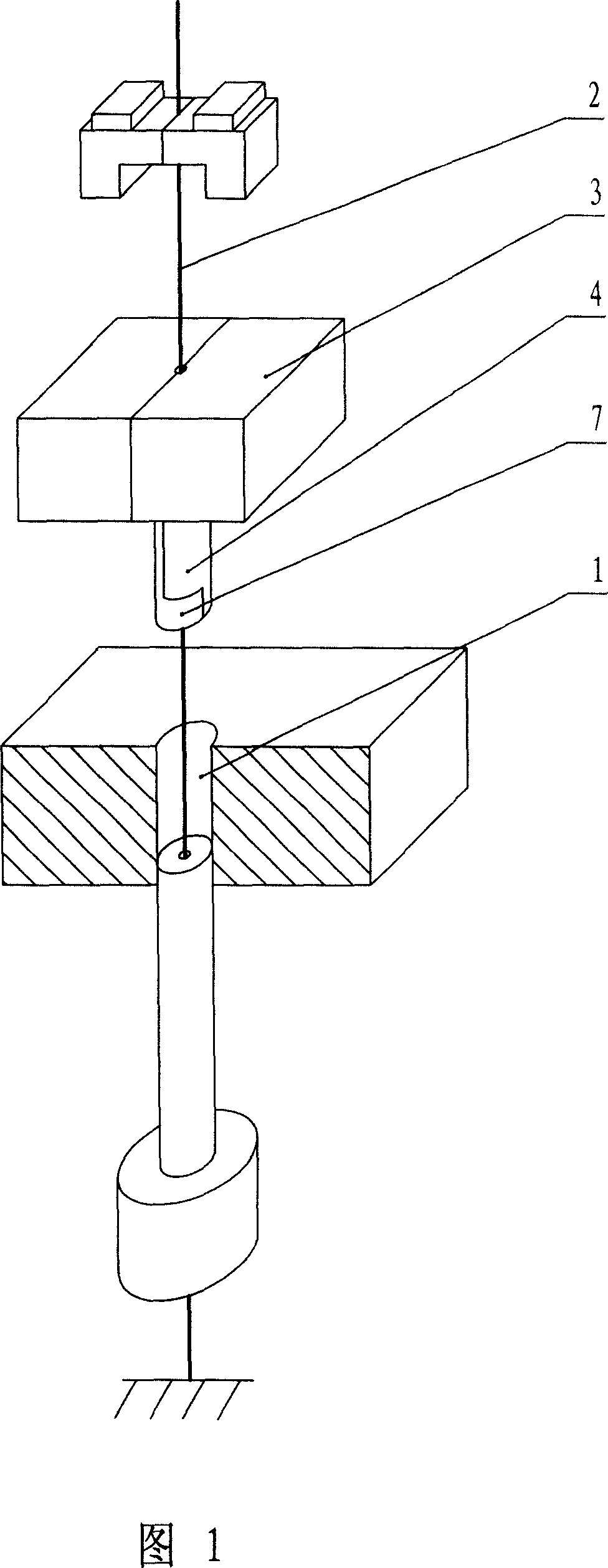

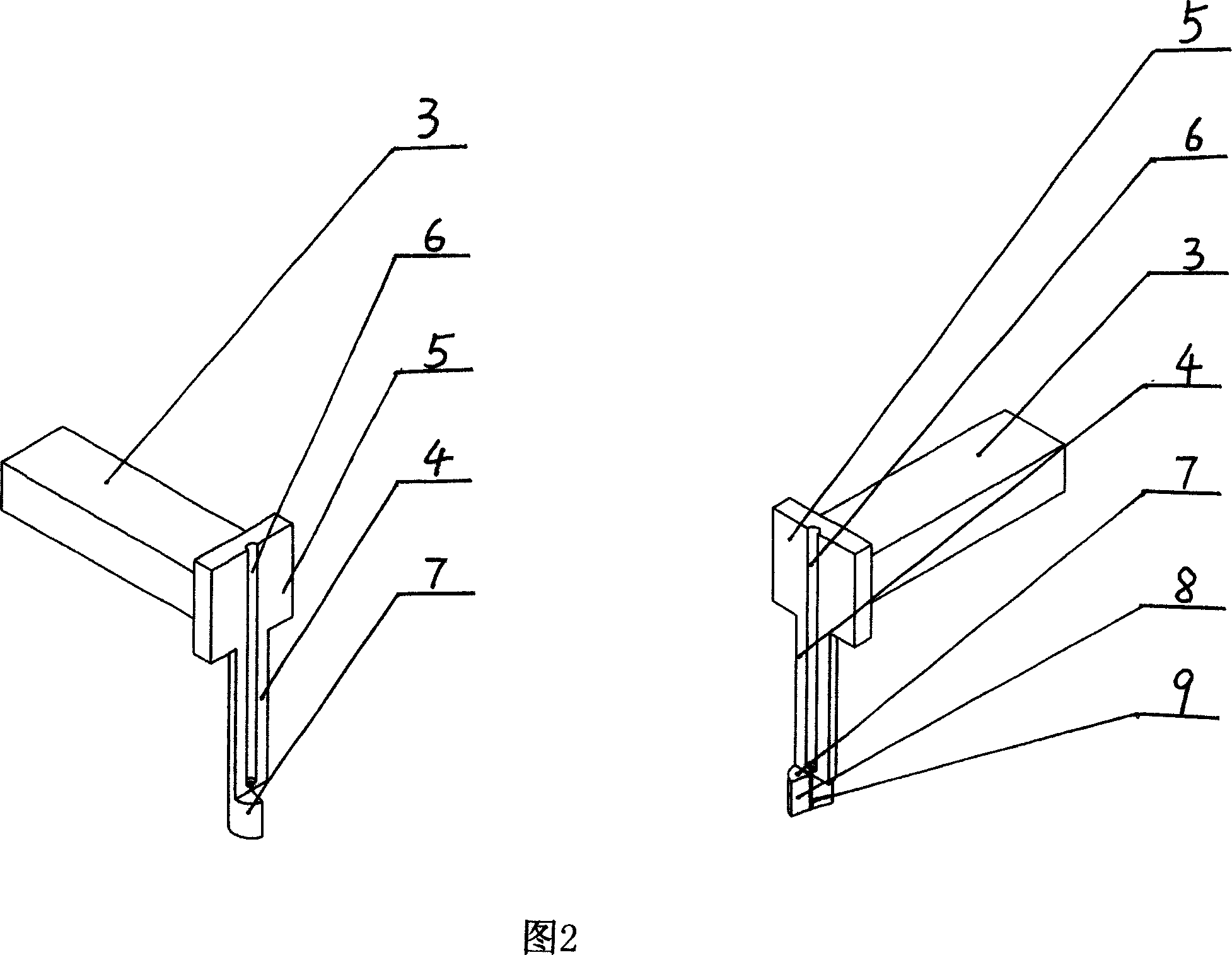

[0010] As shown in Figures 1 and 2, a stamping half-mold of a molding die includes a setting wire 2 pierced in the mold cavity 1, and a pair of opening and closing half-molds 3 arranged above the mold cavity 1. The two opening and closing halves The corresponding side ends of the mold 3 are respectively provided with a pair of half-molding rods 4 corresponding to each other, and the corresponding side planes 5 of the half-molding rods 4 are respectively provided with wire grooves 6 through up and down, and the ends of the half-molding rods 4 The half-molding heads 7 which are integrated with the half-molding rods 4 are respectively arranged, and the side planes 8 corresponding to the two halves of the molding heads 7 are also provided with wire grooves 9. The angle between the side plane 5 and the side plane 8 on the mold 3 can usually be between 90 degrees and 180 degrees at the same time, but in actual use, the angle is preferably between 92 and 150 degrees; in addition, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com