Compensation test self-positioning bionic manipulator

A manipulator and self-positioning technology, used in manipulators, chucks, manufacturing tools, etc., can solve the problems of low rigidity, uneconomical, and long use time, and achieve the effect of improving work efficiency, not damaging materials, and grasping and kneading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

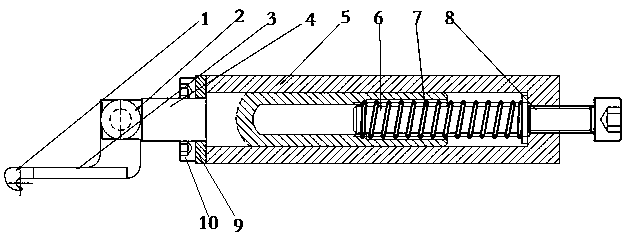

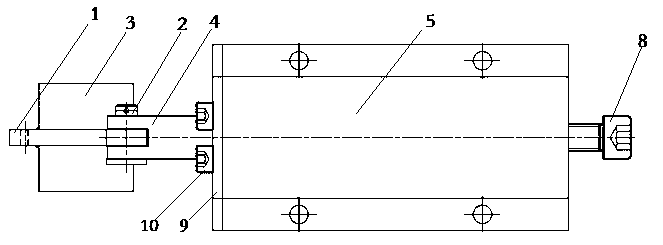

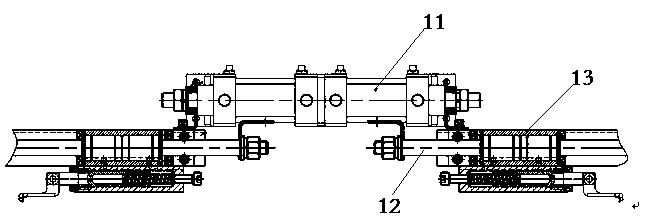

[0011] The present invention includes a mantis hand 1, a mantis arm 4 and a body 5. The front and rear sides of the body 5 are processed with circular through-holes, the periphery of the guide counterbore on the left end of the body 5 is processed with threaded counterbores, and the left end of the body 5 is guided to the bottom of the counterbore. There is a threaded hole connecting the right end face. The right arm body of Mantis Arm 4 is processed with a counterbore with steps. There is a circular through hole on the side of the groove of the head of the connecting rod on the left side of Mantis Arm 4. One end of Mantis Arm 1 is the one extending downward. Arc-shaped grab hook, the other end of the mantis 1 is a vertical rectangular steel plate processed with a circular through hole, the two sides of the mantis 1 are welded with a limit plate 3, and the counterbore of the steps is equipped with a compression spring 7 and a mandrel 6. Insert the body of the 4 arm into the gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com