A positioning mechanism of a polarizer laminating machine

A technology of positioning mechanism and laminating machine, applied in optics, nonlinear optics, lamination auxiliary operation, etc., can solve problems such as affecting the quality of finished products, inability to align polarizers, etc., to ensure accuracy and quality of finished products, and avoid deviations , Fast and accurate automatic positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

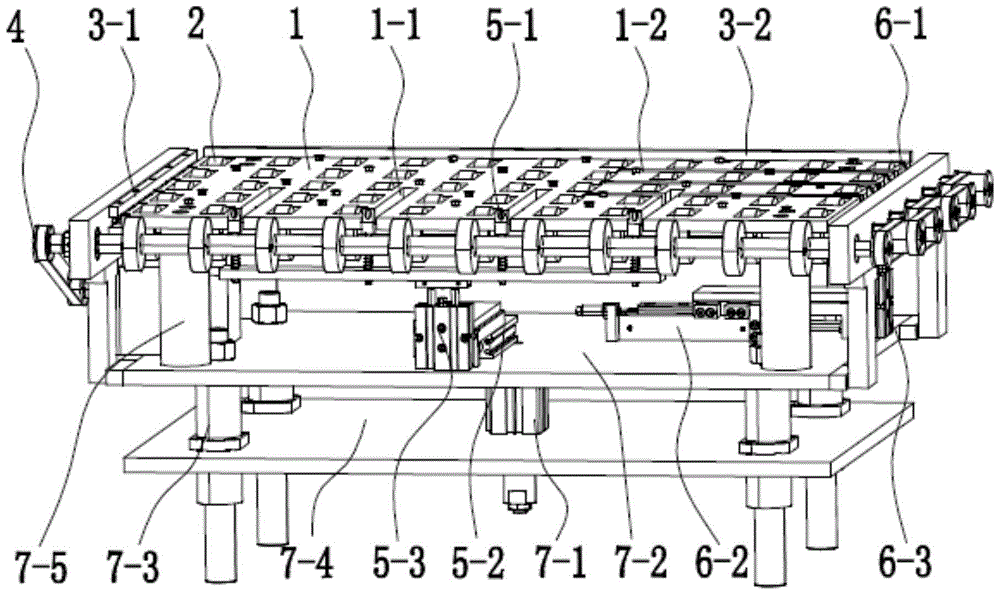

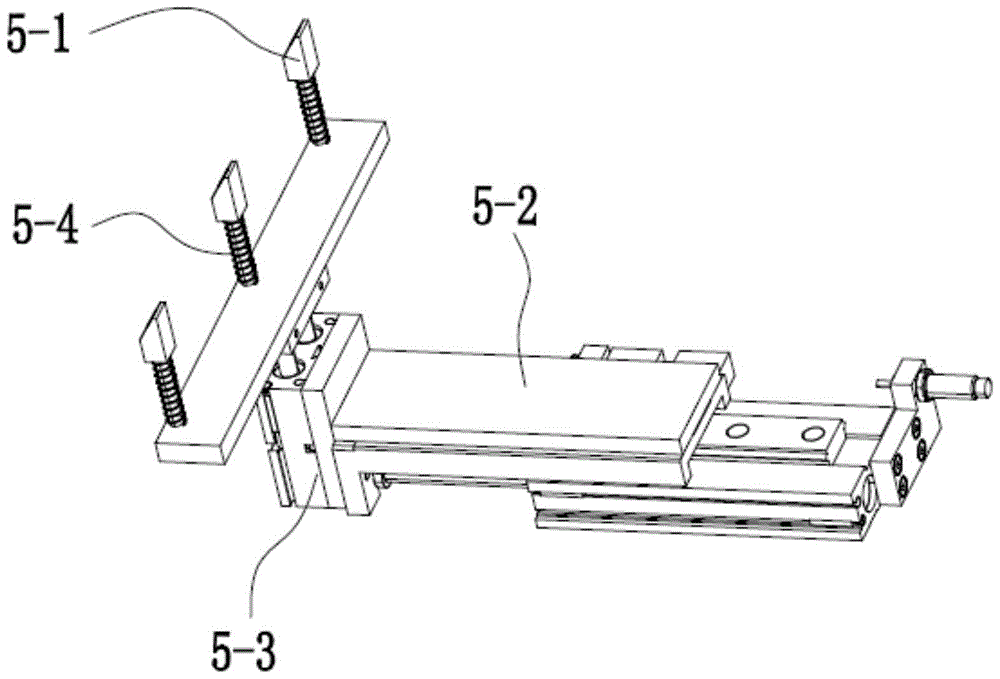

[0016] refer to figure 1 , a positioning mechanism of a polarizer laminating machine, including a supporting plate 1, a roller 2, a retaining bar, a stepping motor 4, an X-axis positioning device, a Y-axis positioning device and a flat lifting device; the stepping motor 4 drives the rollers 2 drive the glass substrate, the pallet 1 lifts the glass substrate under the drive of the flat lifting device; the X-axis positioning device and the Y-axis positioning device respectively drive the glass substrate toward the stopper at its corresponding position; The bar 3 moves so that the glass substrate is positioned against the bar 3;

[0017] The glass substrate enters the positioning mechanism, the stepping motor 4 drives the roller 2 to move the glass substrate to the position to be positioned, and the flat lifting device lifts the supporting plate 1 to make the glass substrate The contact of the substrate with the roller 2 becomes the contact with the pallet 1 . At this time, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com