Air filter

An air filter and air inhalation technology, which is applied in the direction of fuel air filter, dispersed particle filtration, chemical instruments and methods, etc., can solve the problems of accelerated deterioration of the first component, improve maintainability, and inhibit mesh clogging , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments are described below with reference to the drawings.

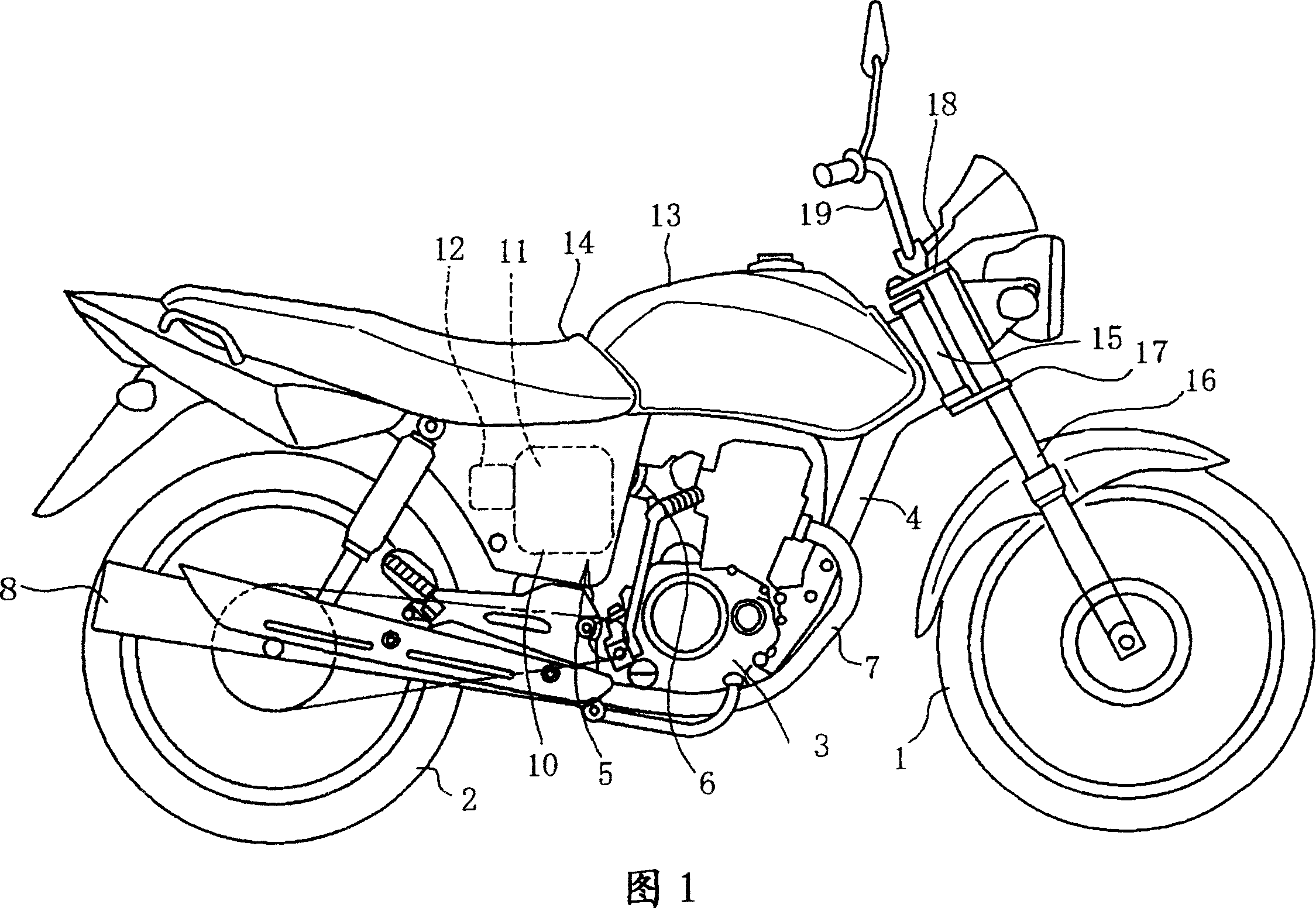

[0026] Fig. 1 shows the right side of a motorcycle equipped with the air cleaner device of the present invention.

[0027] An engine 3 disposed between the front wheels 1 and the rear wheels 2 is supported by a vehicle body frame 4 . Clean air is supplied to an intake port of the engine 3 from an air cleaner 5 arranged at the rear of the vehicle body through a connecting pipe 6 .

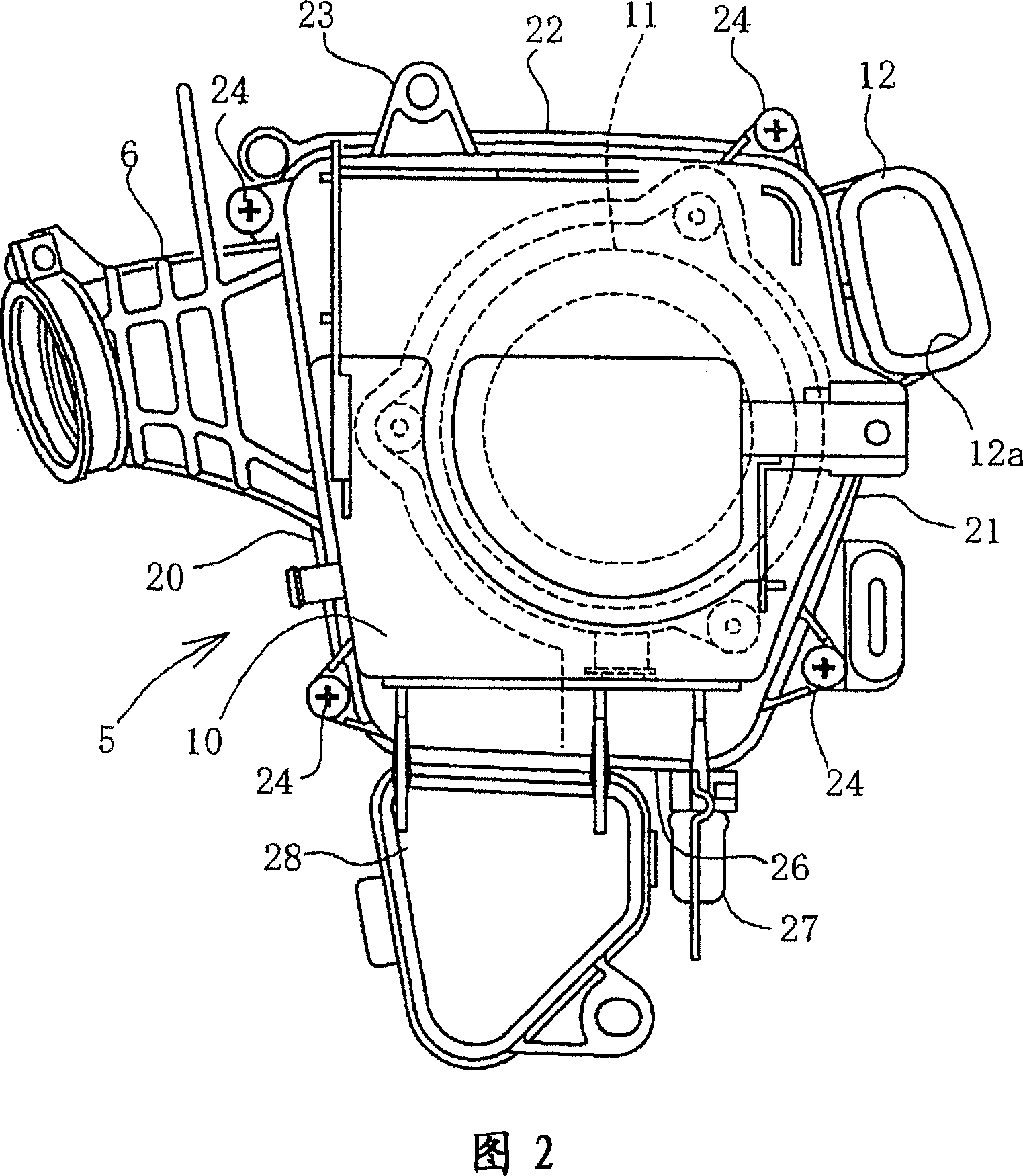

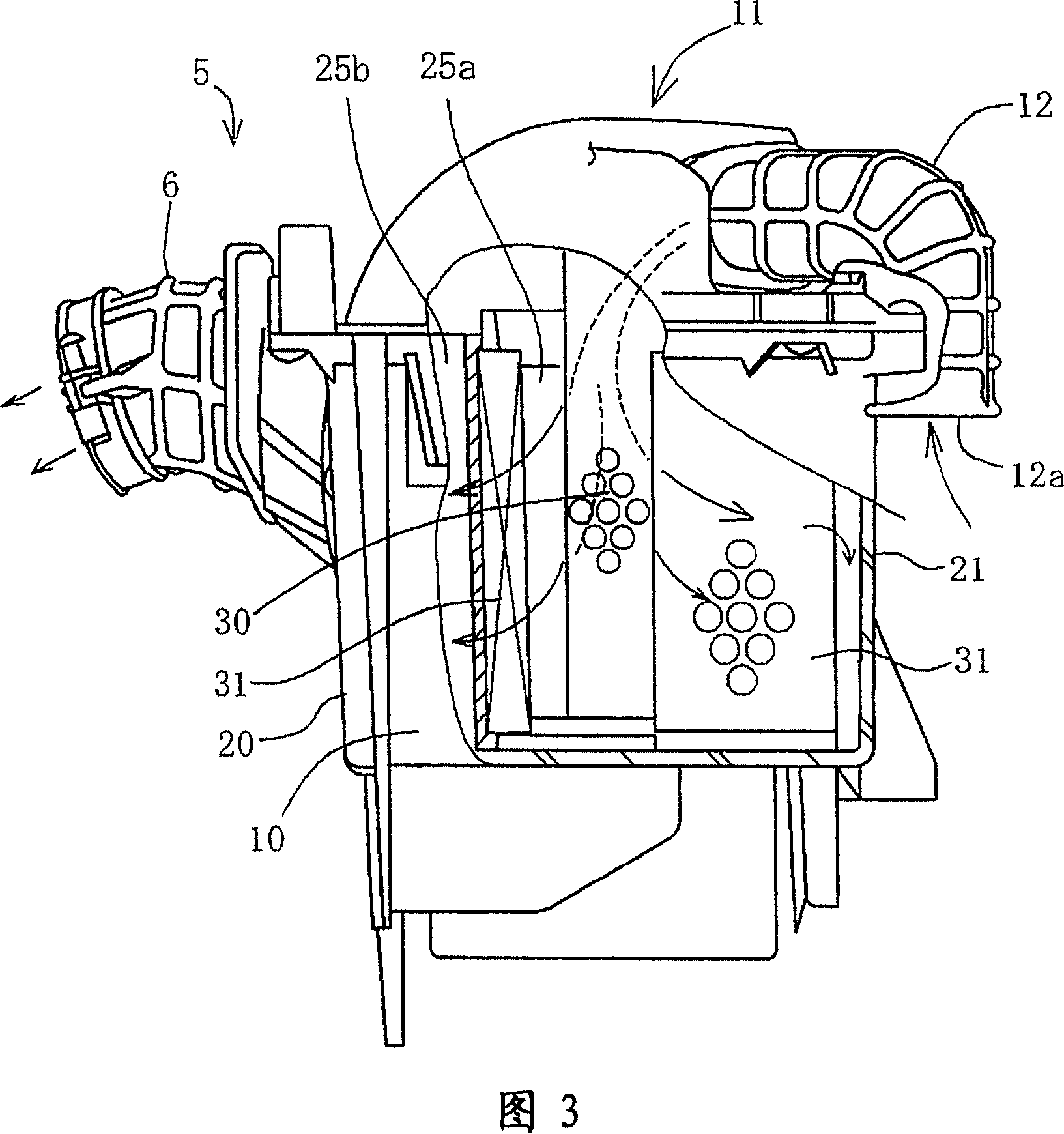

[0028] An exhaust pipe 7 protruding from an exhaust port of the engine 3 extends rearward through the bottom of the engine 3 and is connected to a muffler 8 arranged on the side of the rear wheel 2 . 10 is an air cleaner box of the air cleaner 5, 11 is an air cleaner cover, and 12 is a suction duct. The suction duct 12 faces the rear of the air cleaner box 10 and is opened inside the vehicle body, and sucks outside air into the air cleaner 5 from the rear of the vehicle body.

[0029] A fuel tank 13 is arranged above the eng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com