Camera calibration method and calibration apparatus thereof

A calibration device and camera calibration technology, applied in image analysis, instruments, television, etc., can solve the problems of unstable calculation of self-calibration method, difficult maintenance of three-dimensional control field, and difficulty in automation, so as to reduce manual intervention and achieve rapid automatic identification. , the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

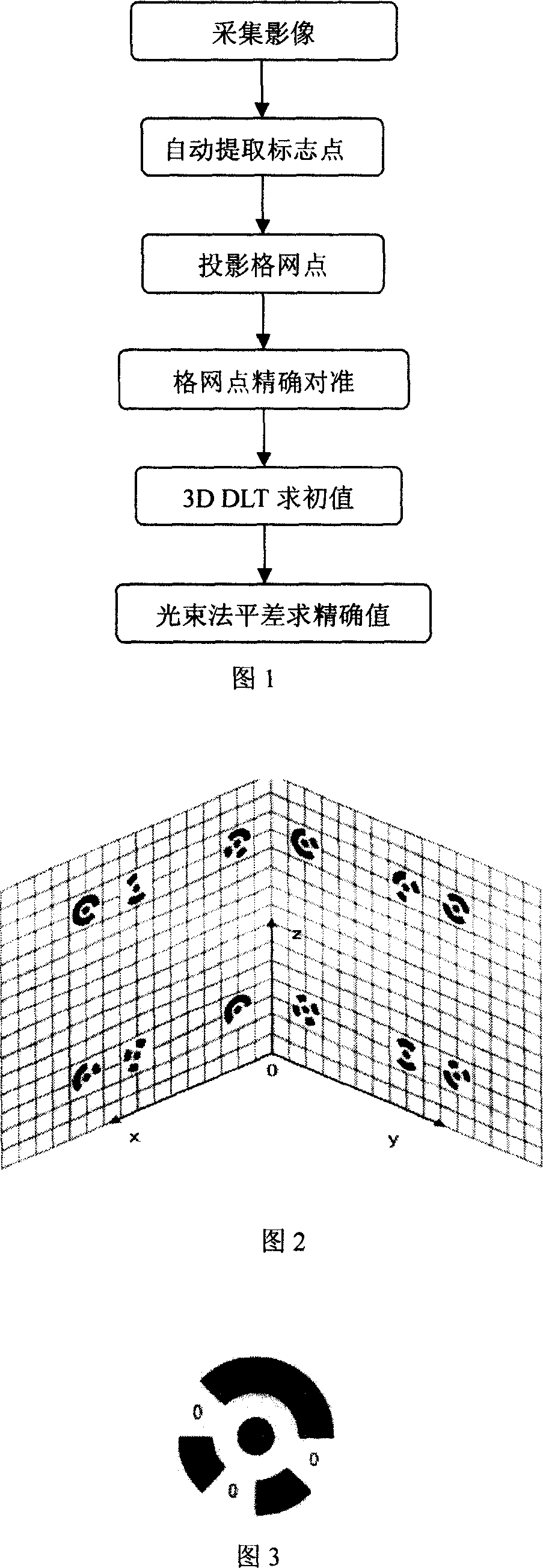

Method used

Image

Examples

Embodiment Construction

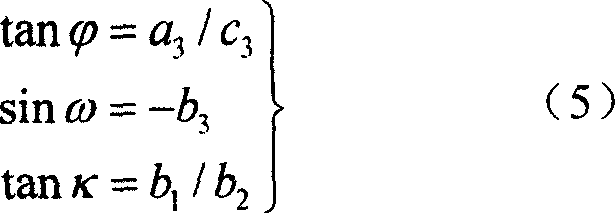

[0021] 1. Calibration device

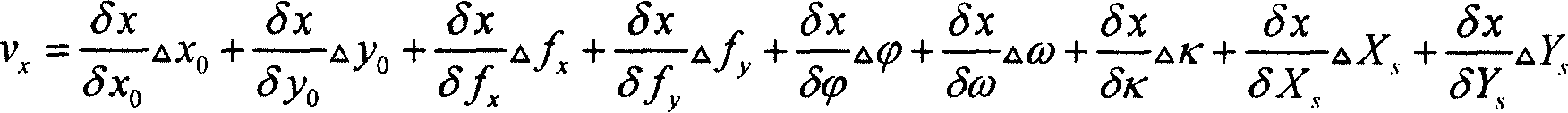

[0022] Referring to Fig. 2, the present invention relates to the calibration device that two mutually perpendicular planes form, and mark uniform grid on two planes (grid is made up of two groups of parallel straight lines perpendicular to each other, and the intersection point of straight line is grid point). In order to enable one-to-one correspondence between the coordinates of the image point and the coordinates of the object space point, each grid point is numbered: from the bottom to the top with the O point as the center, from the inside to the outside, the column number is represented by the ones and tens, and the hundreds and The thousands place represents the line number, the ten thousand place on the left plane is 1, and the ten thousand place on the right plane is 0. For example, 11211 represents the 12th row and 11th column of the left plane, and 706 represents the 7th row and 6th column of the right plane. Then a certain number of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com