Small harvester

A harvester, small technology, applied in harvesters, headers, cutters and other directions, can solve the problems of complex structure, unstable walking, inability to rotate, etc., to achieve a flexible and reliable operating system, obvious economic benefits, compact and reasonable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

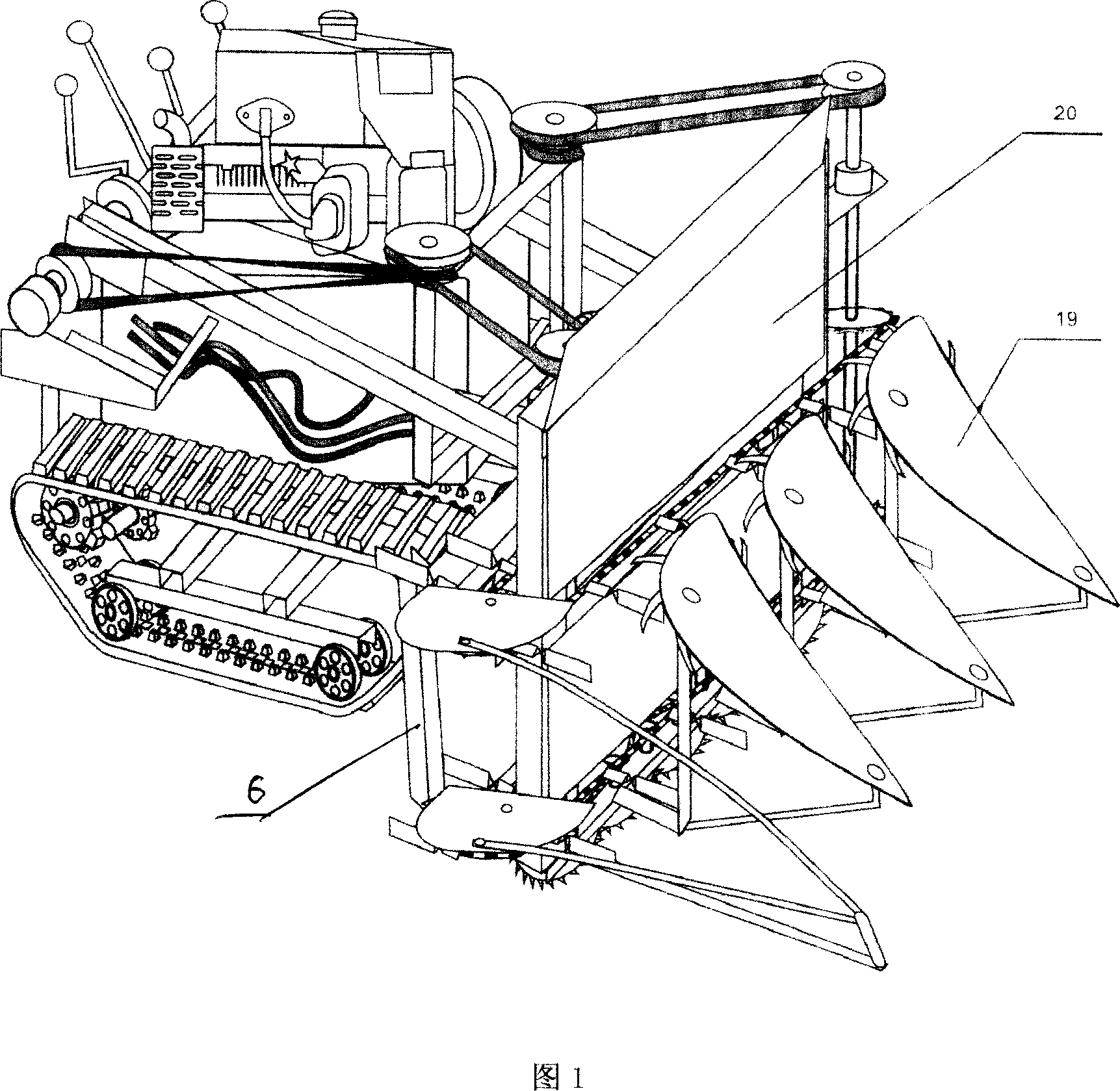

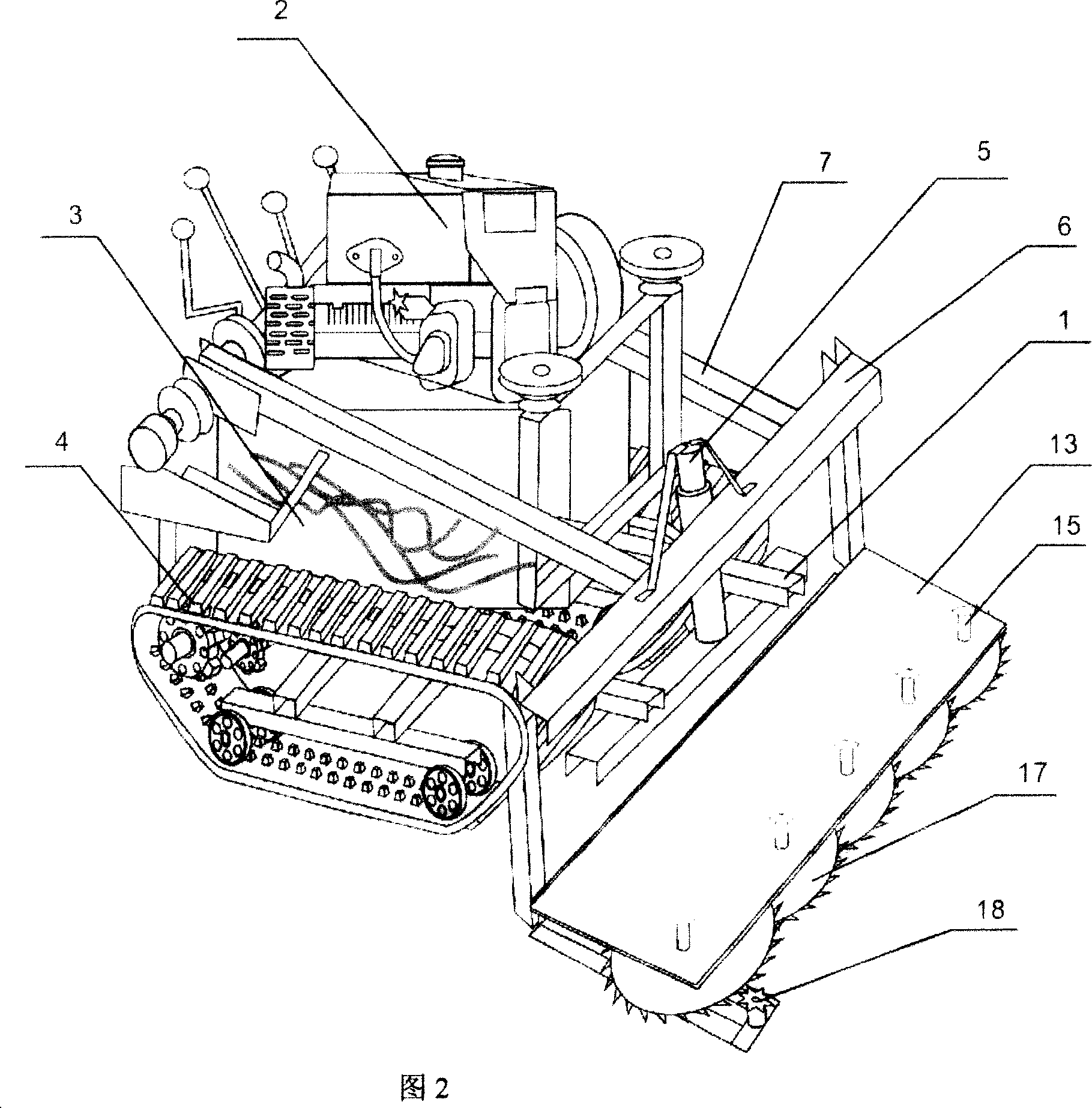

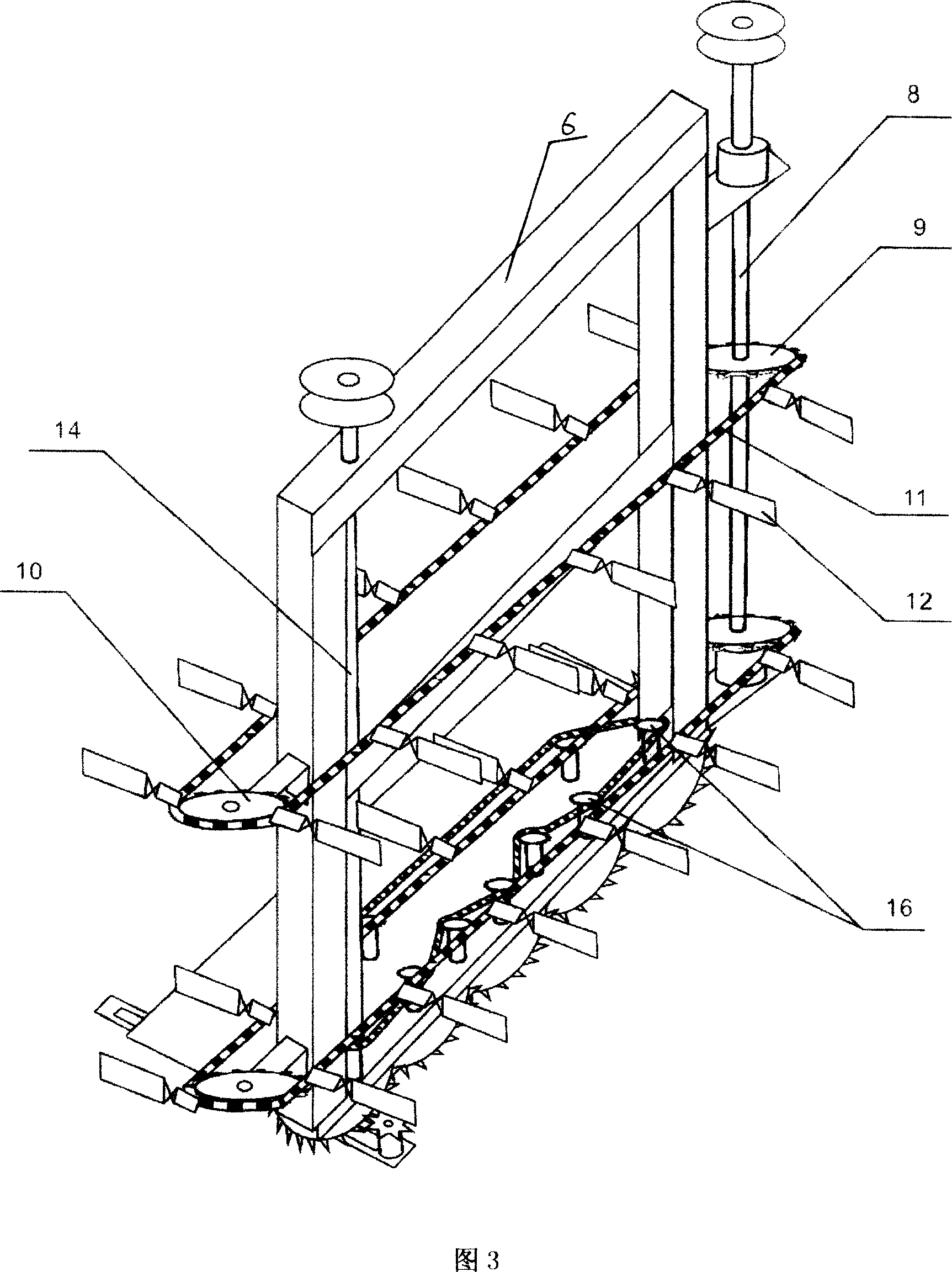

[0012] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS: The structure of the small harvester will be described in detail in conjunction with the accompanying drawings.

[0013] A 4.1kW diesel engine power unit 2 is installed on the chassis 1 of the harvester bracket. The output shaft of the diesel engine is connected to the transmission device 3 of the gear transmission. The hydraulic device 5 at the front end of the chassis 1 is also equipped with a joystick, and the above-mentioned power device 2, transmission device 3, crawler belt traveling device 4 and hydraulic device 5 all adopt the prior art; Movable arm 7 is equipped with on both sides of movable support 6, and the other end of movable arm 7 is contained on the support chassis 1; Transmission vertical shaft 8 is housed on the outside of one end of the outer frame of movable support 6, and belt pulley is housed at the top of transmission vertical shaft 8, and belt pulley is with transmission Belt is connected with th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap