Coconut cutting machine

A cutting machine, coconut technology, applied in the direction of metal processing, etc., can solve the problems of imbalance, high labor cost, low efficiency of machete cutting, etc., and achieve the effect of speeding up and cutting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

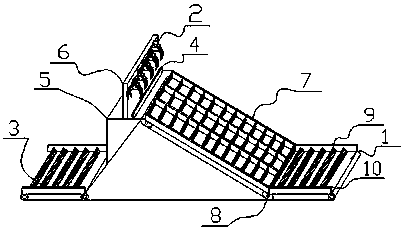

[0023] Embodiment 1, with reference to Figure 1-3 Shown, a kind of coconut cutting machine mainly comprises first conveyer belt, second conveyer belt, the 3rd conveyer belt and cutting platform, described first conveyer belt contacts with second conveyer belt, and described cutting platform is connected with the 3rd conveyer belt, described A pillar is installed on the cutting platform, and a plurality of clamping devices are installed on the pillar, and an electric saw is installed on the cutting platform, and the electric saw is located directly below the clamping device.

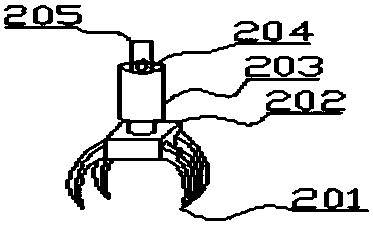

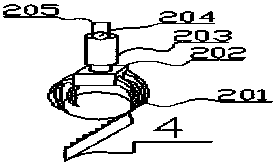

[0024] Specifically, the pneumatic gripper includes: a claw head, a connecting block, a cylinder, a bending shaft and a telescopic rod, the claw head is connected to the connecting block, the connecting block is connected to the cylinder, the cylinder is connected to the bending The shaft is connected, and the curved shaft is connected with the telescopic rod.

[0025] Specifically, a through hole is op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com