Plasma display device

A plasma display and plasma technology, applied in the direction of tube structure parts, mixed gas absorption, solid cathode parts, etc., can solve the problem that impurity gas cannot be completely eliminated, discharge start voltage characteristics, driving voltage characteristics and gray scale characteristics. Adverse effects, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, preferred embodiments of the present invention will be described in more detail with reference to the accompanying drawings.

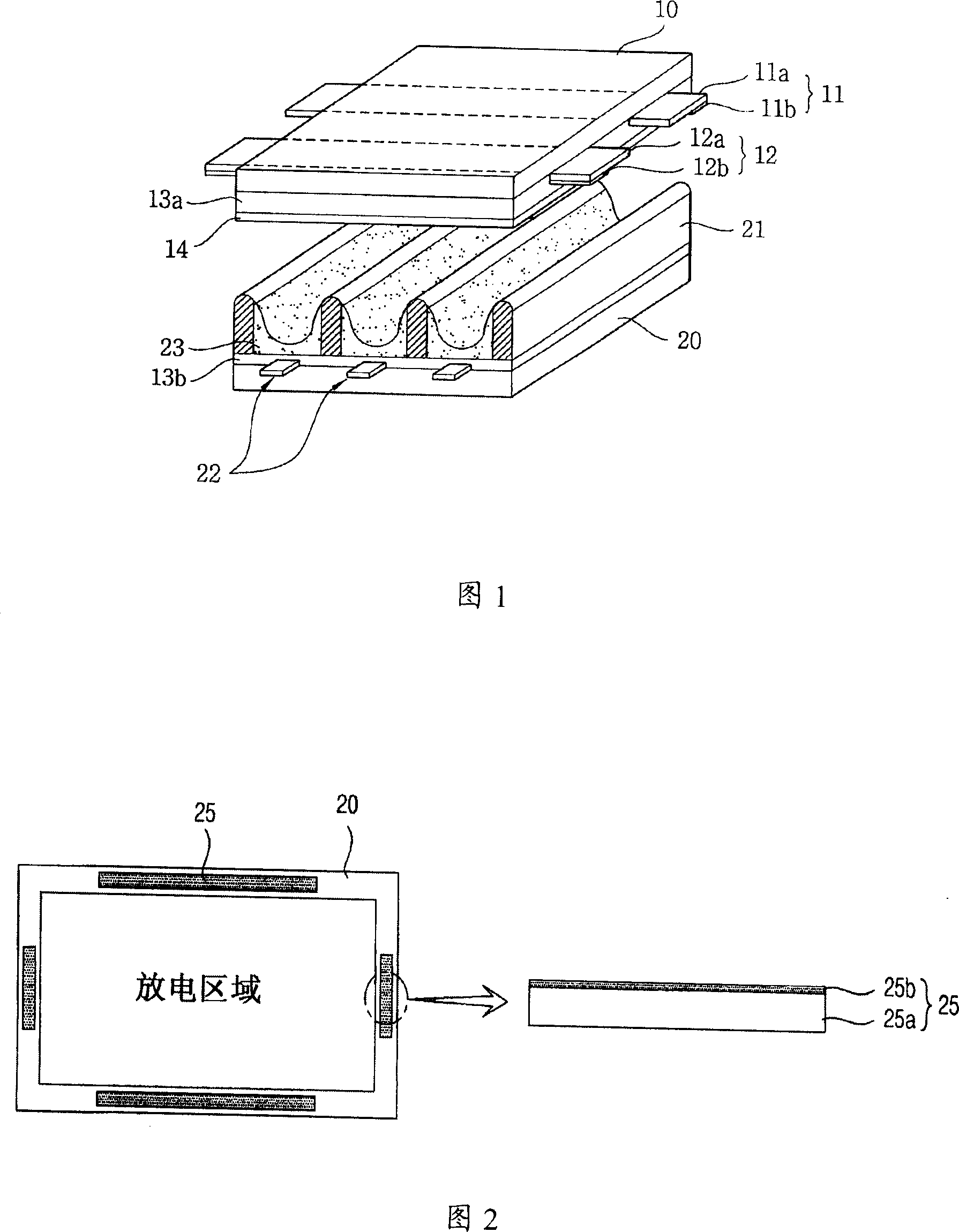

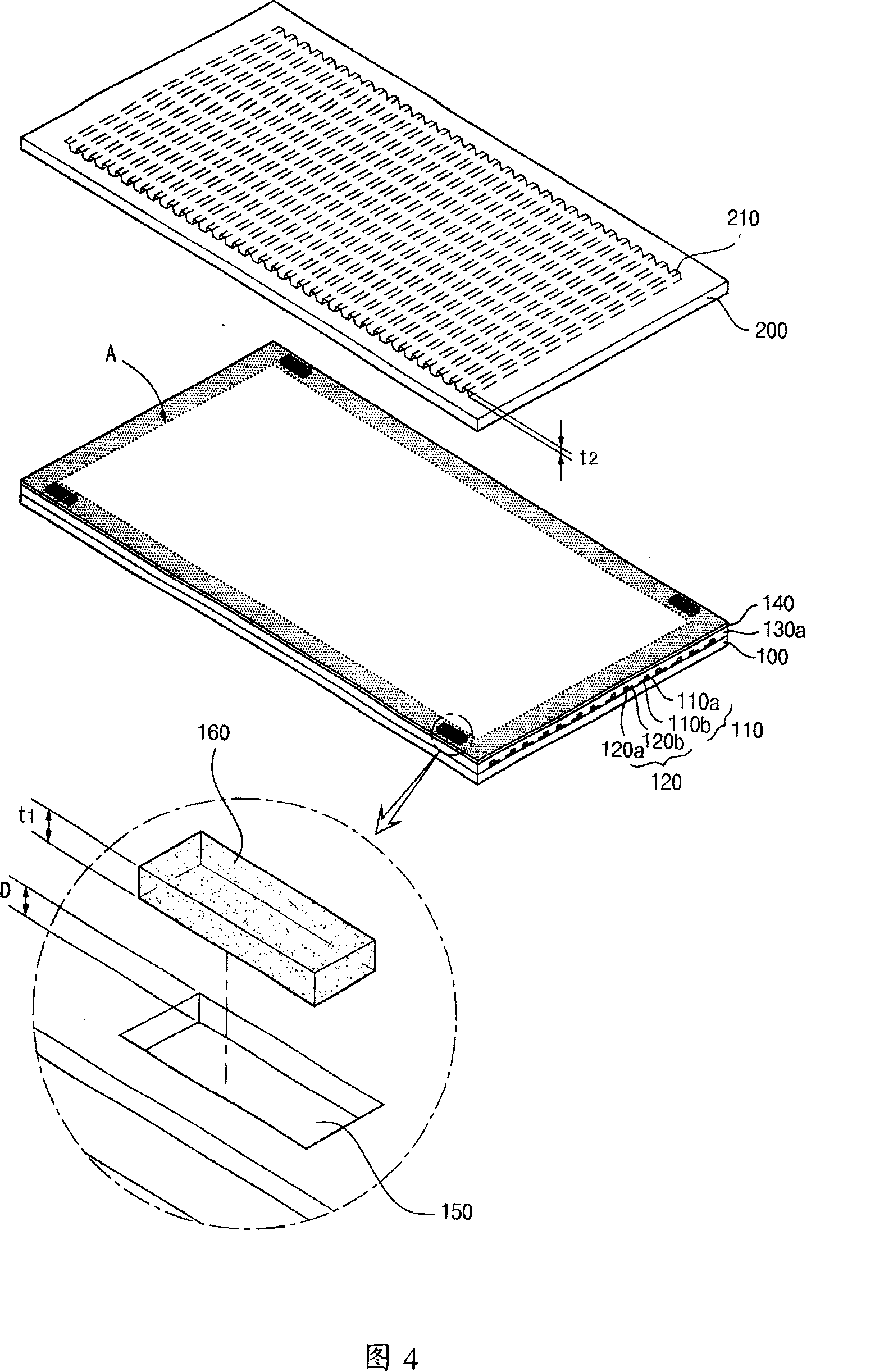

[0039] Fig. 4 is an exploded view of the PDP of the present invention. As shown in FIG. 4 , the PDP according to the present invention is the same as the prior art, and is formed by parallel bonding of the front glass plate 100 and the rear glass plate 200 of the display pixel by means of frit glass (not shown) at a certain distance.

[0040] The front glass plate 100 is composed of the following two parts: the sustain electrodes 110, 120 that rely on the mutual discharge of a pixel below to maintain the unit to emit light, that is, the transparent electrodes 110a, 120a formed by transparent ITO material; the bus electrodes 110b made of metal materials, Sustain electrodes 110, 120 at 120b. The protective layer 140 with the following functions is formed on the sustain electrodes 110, 120: form wall charges, maintain the discharge by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com