Patents

Literature

37results about "Gas mixture absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

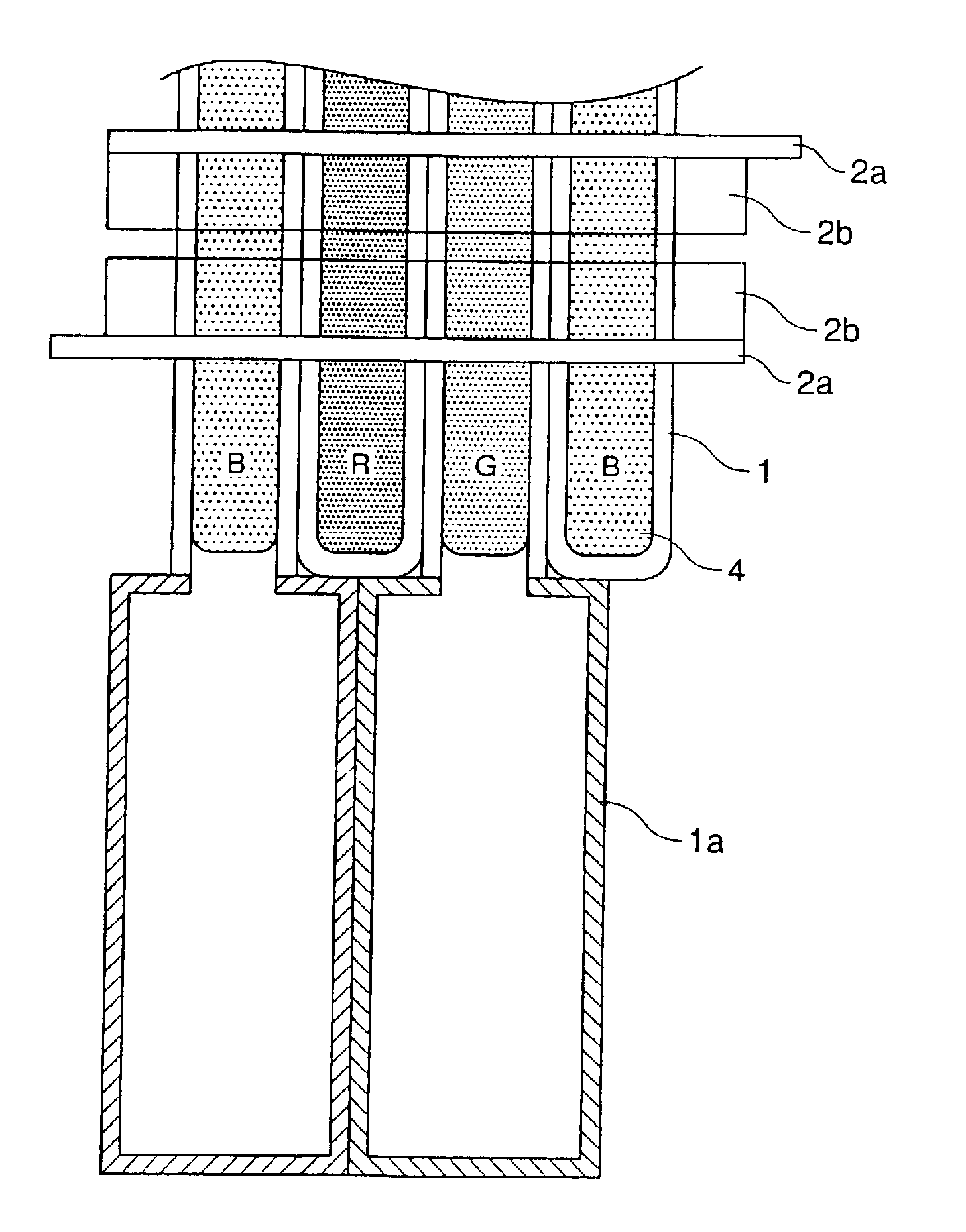

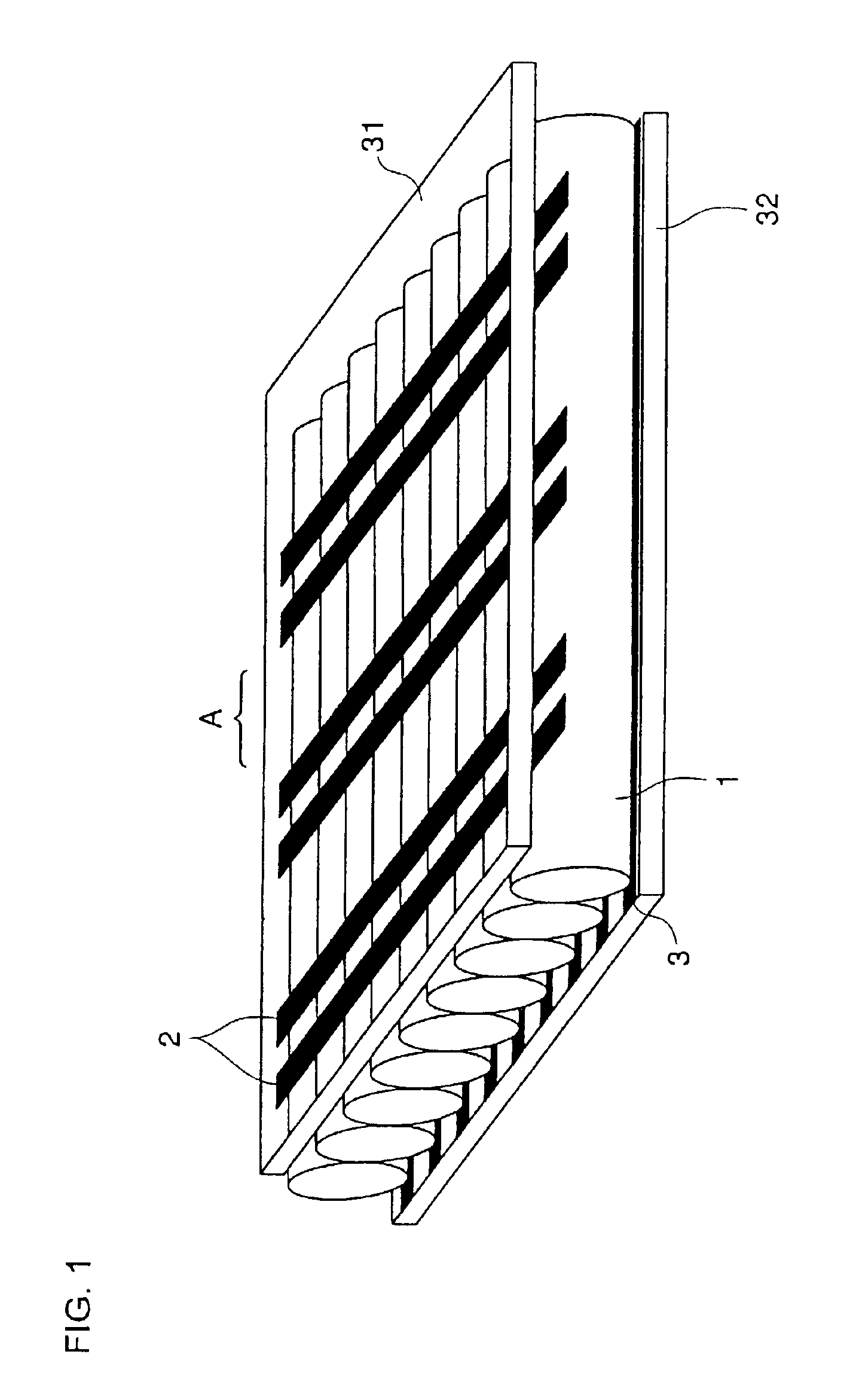

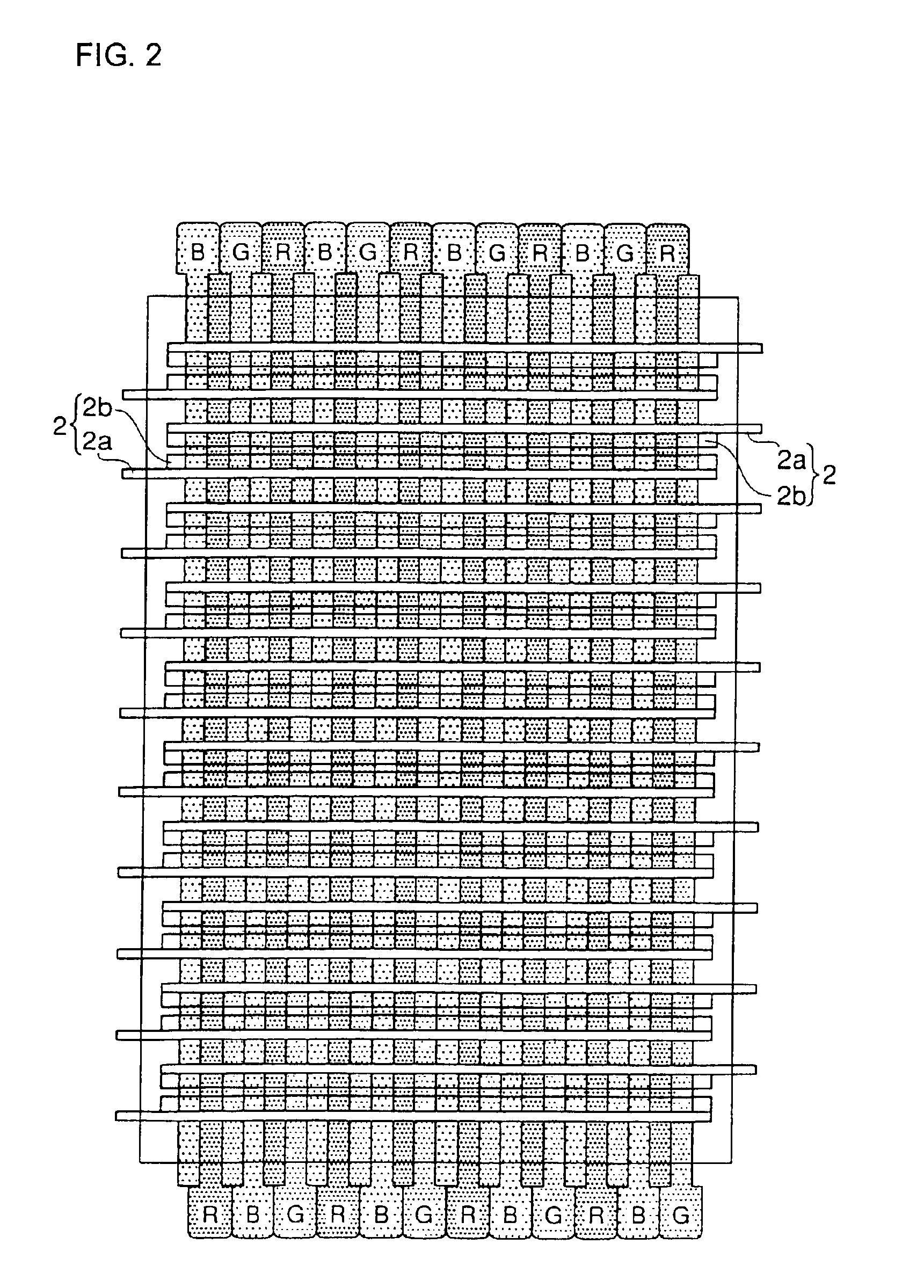

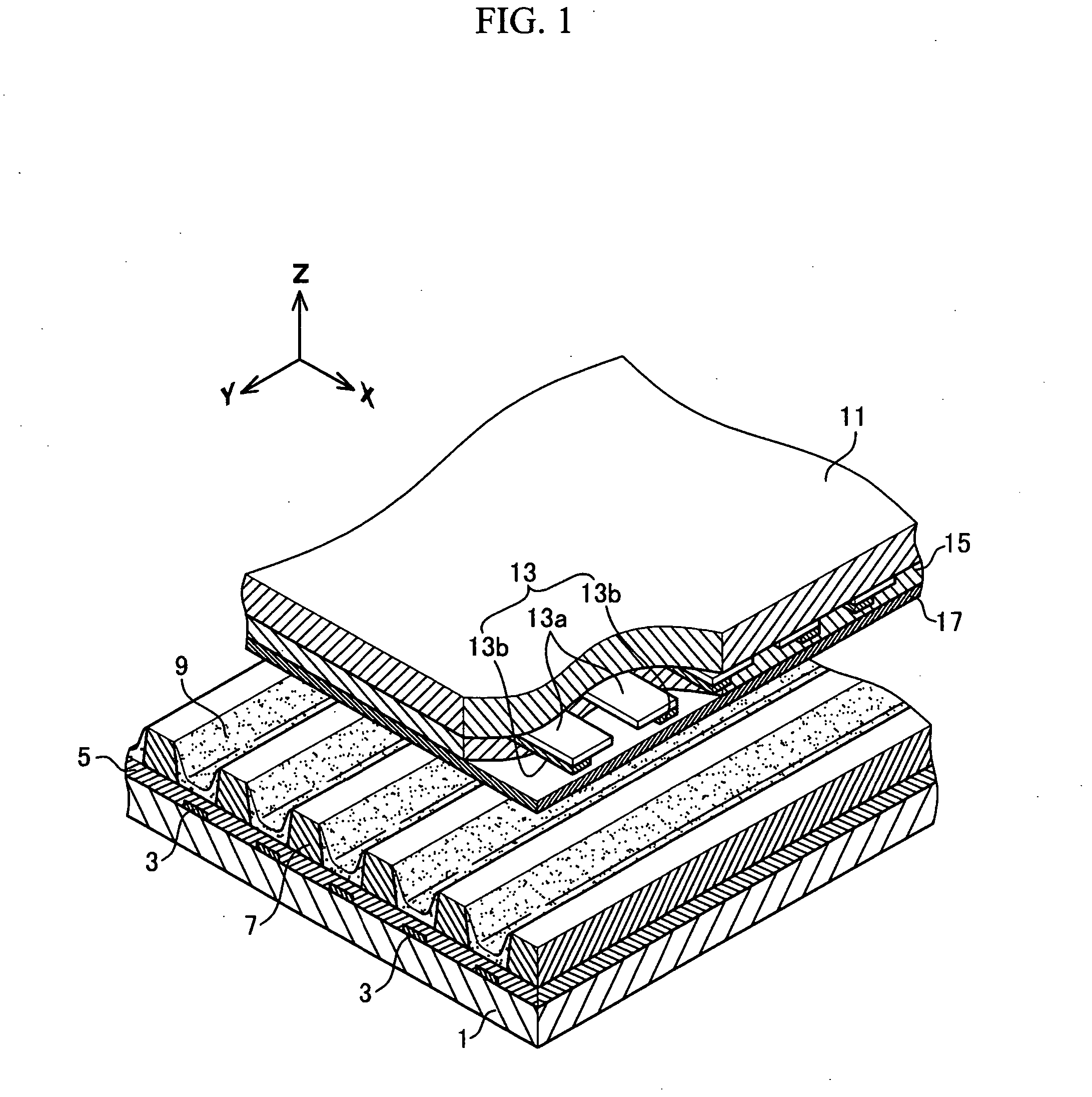

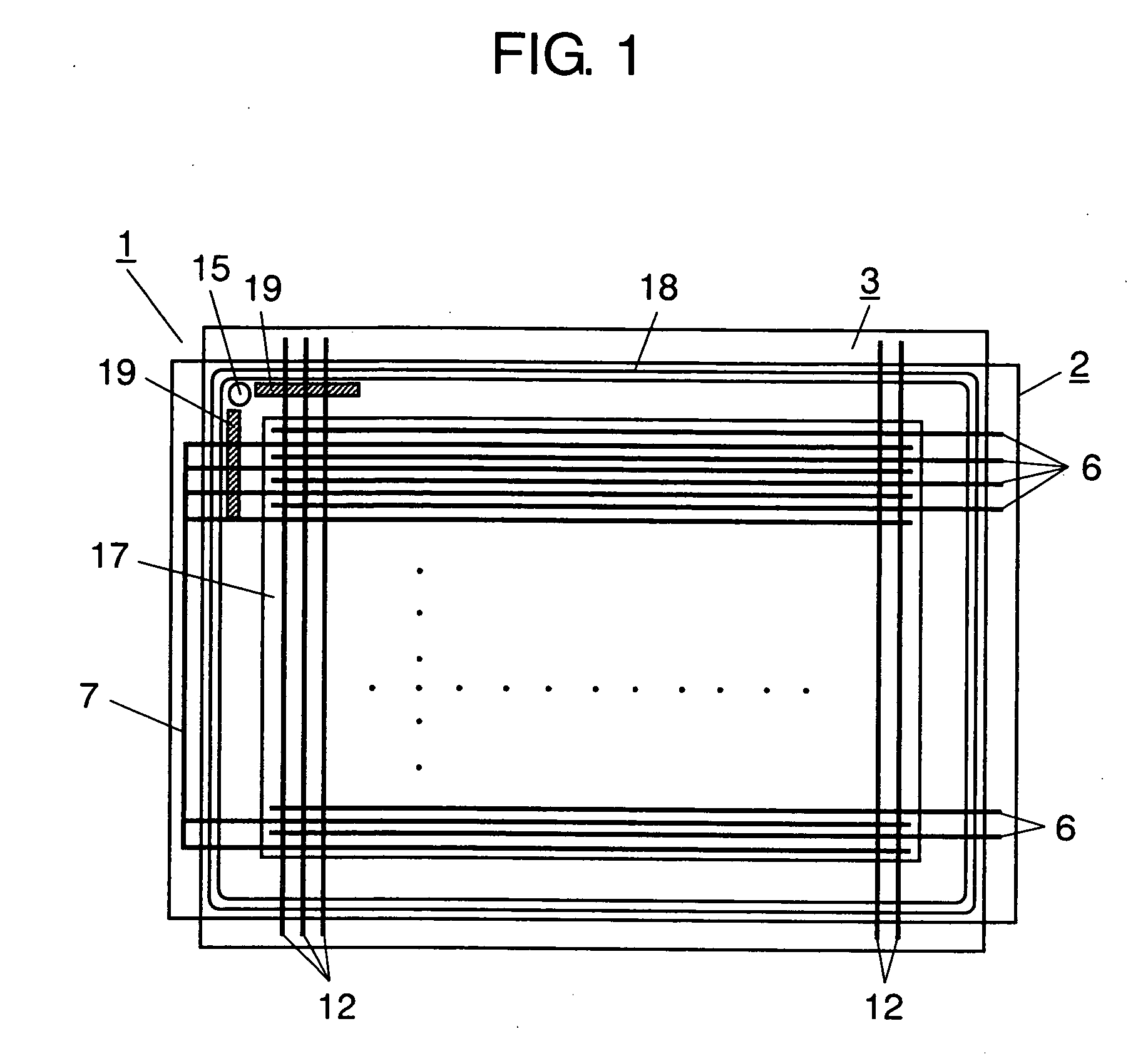

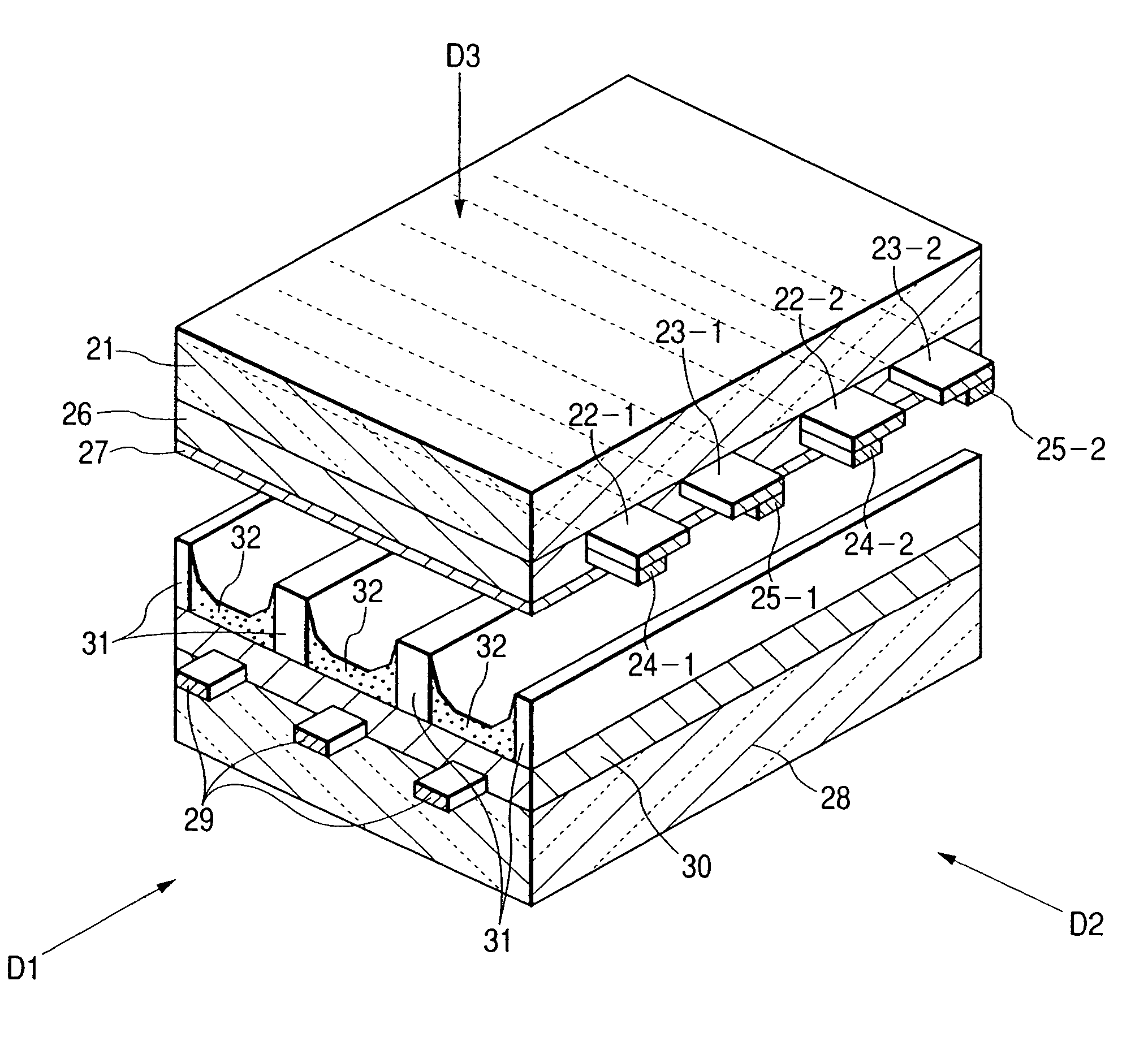

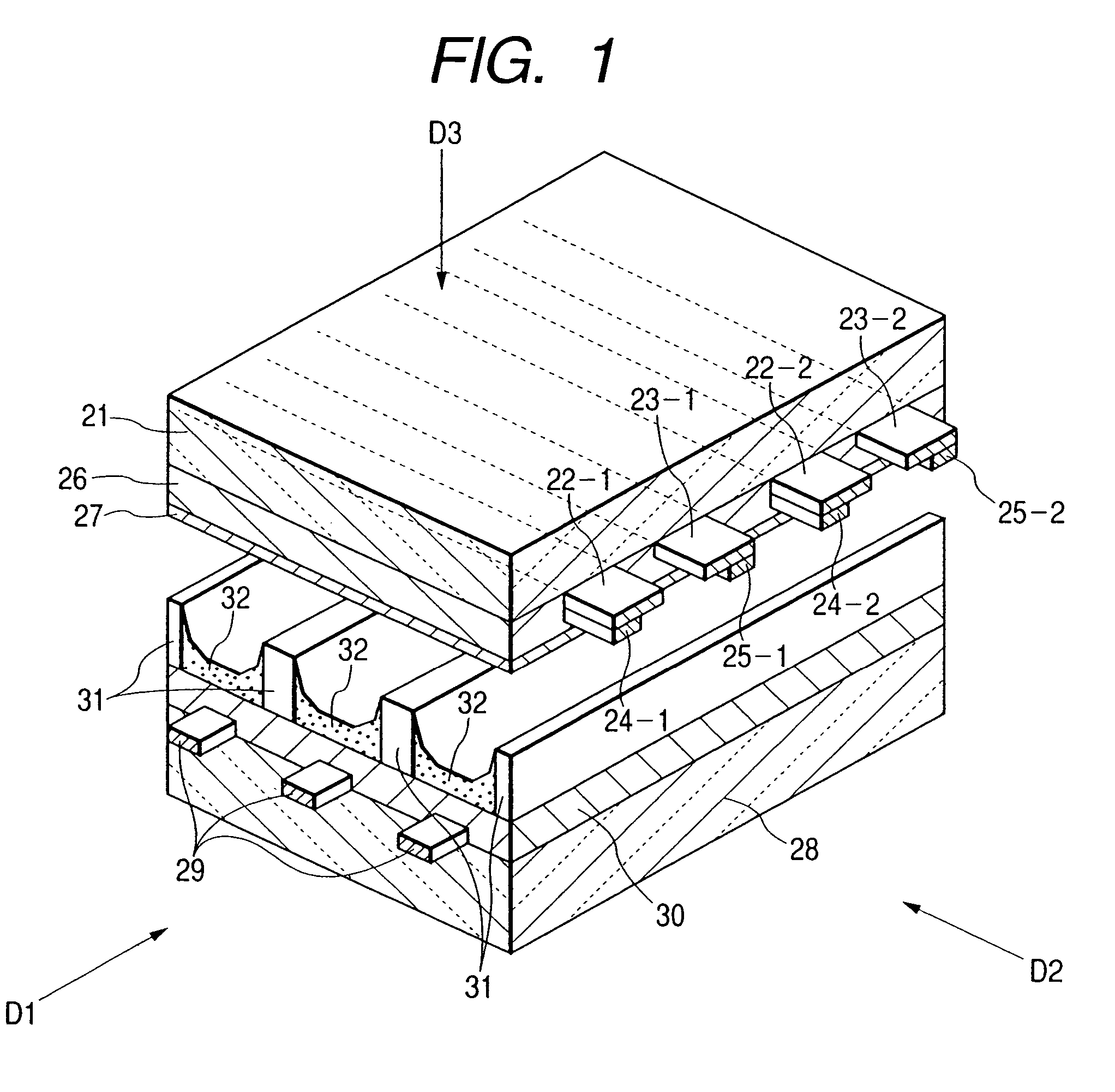

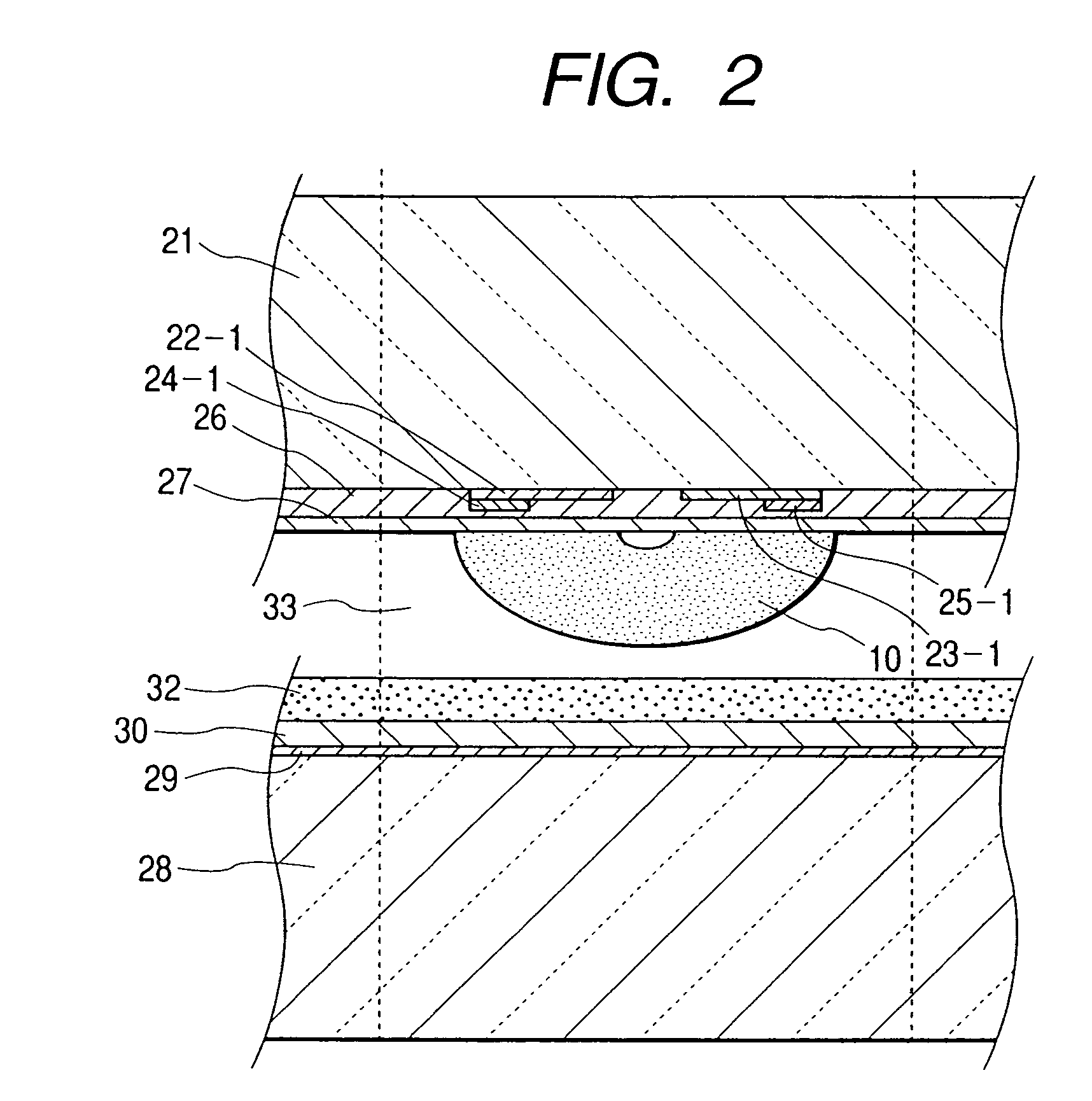

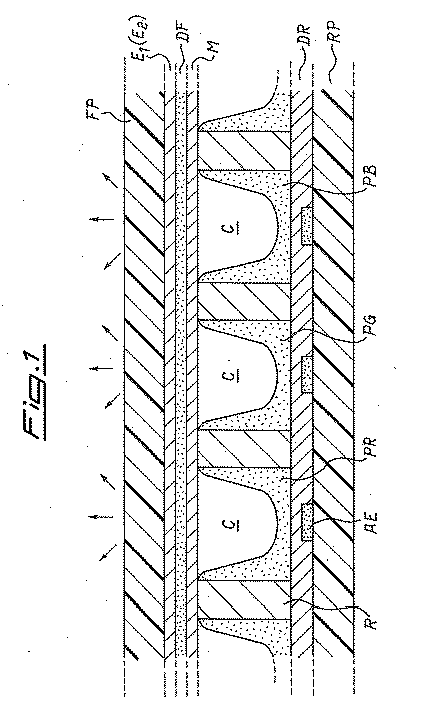

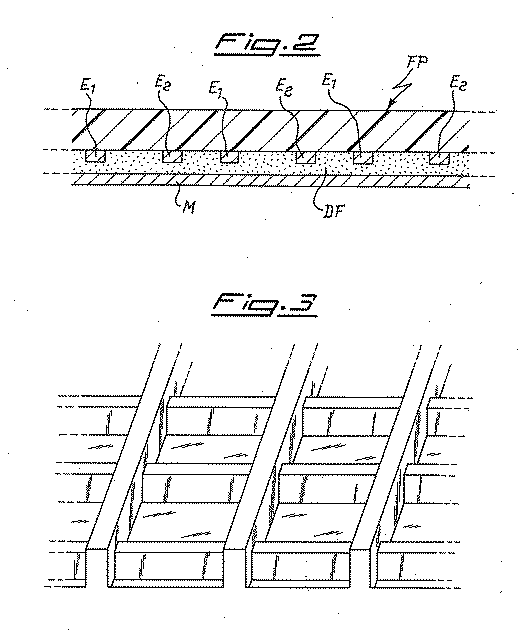

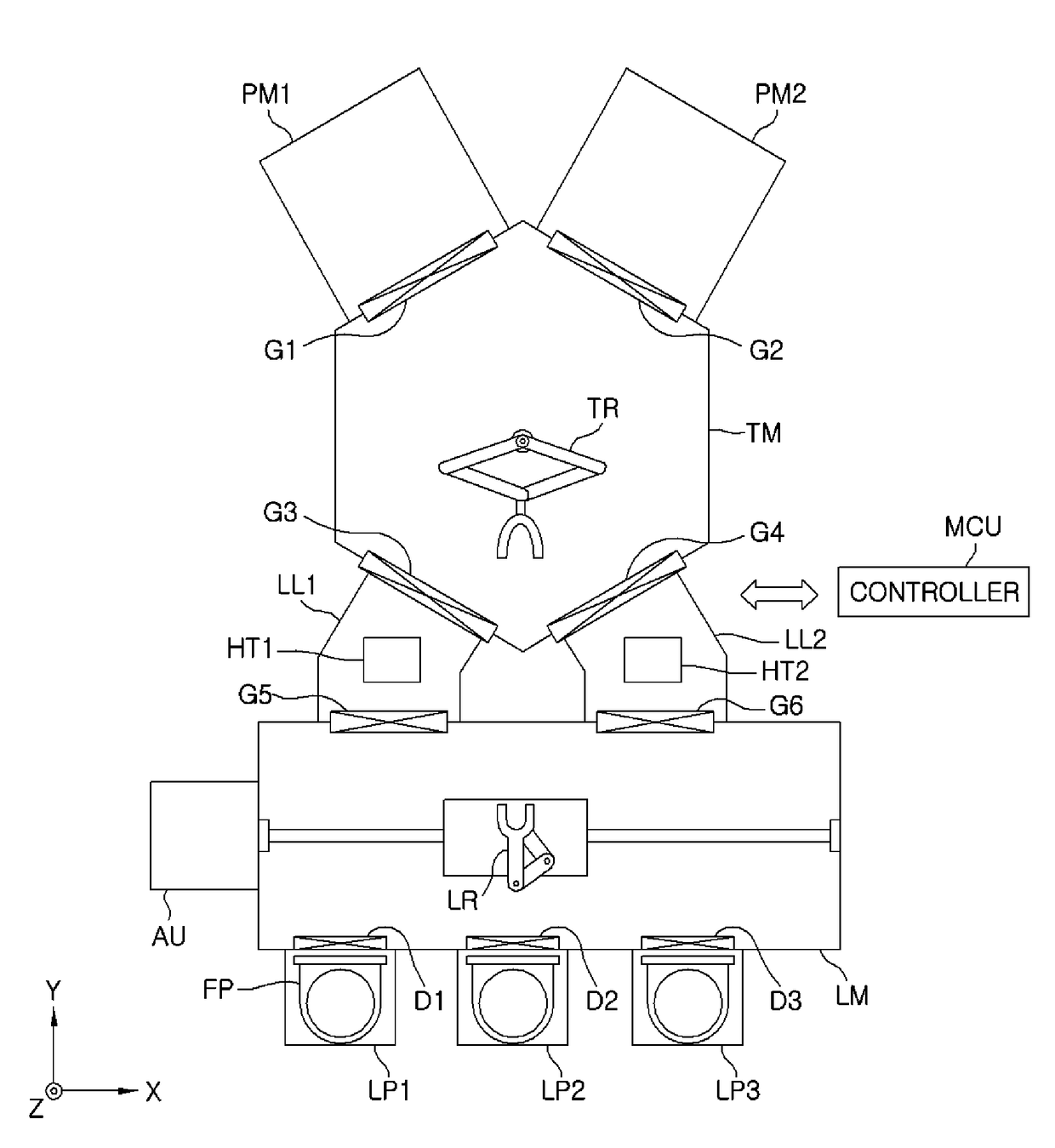

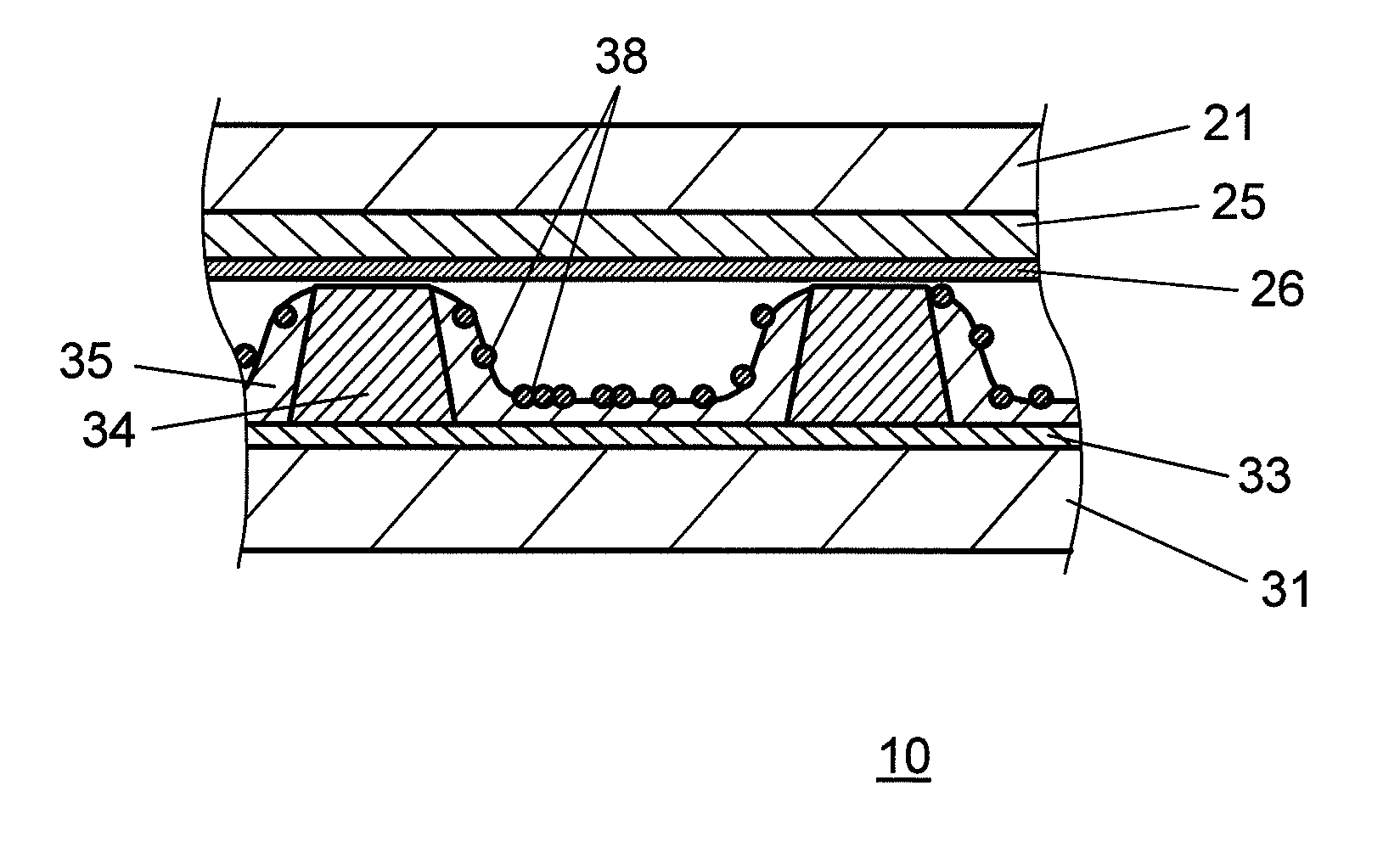

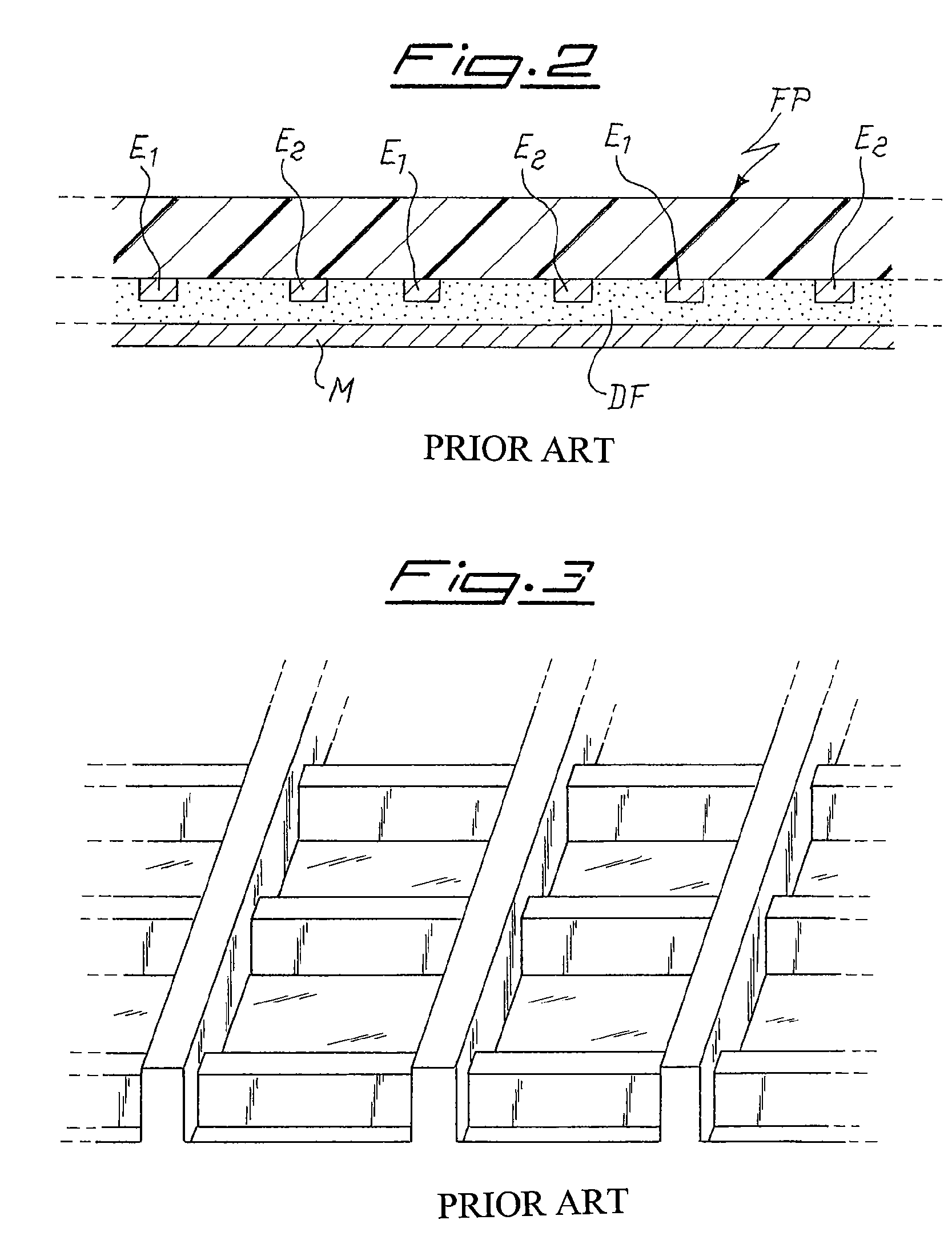

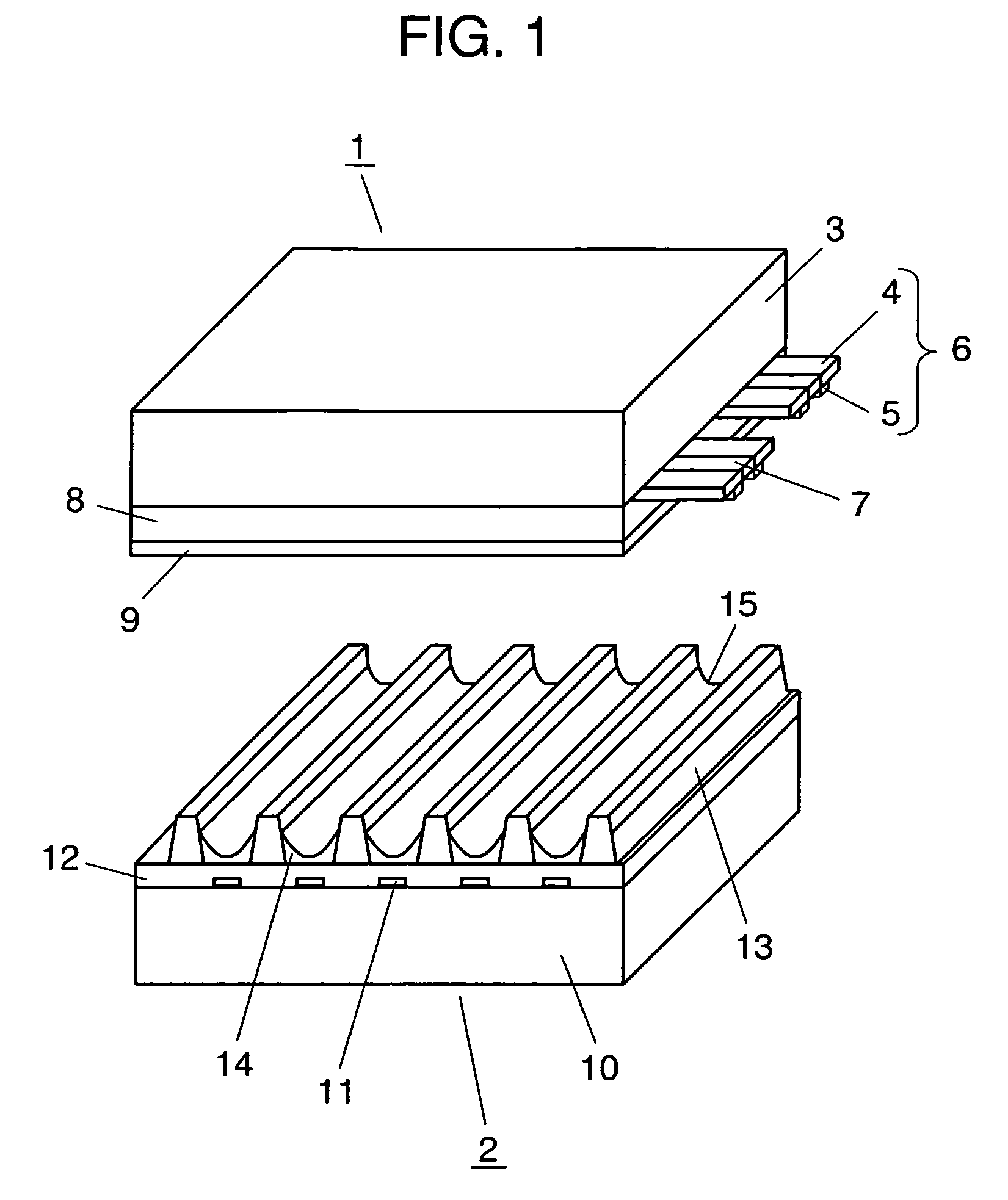

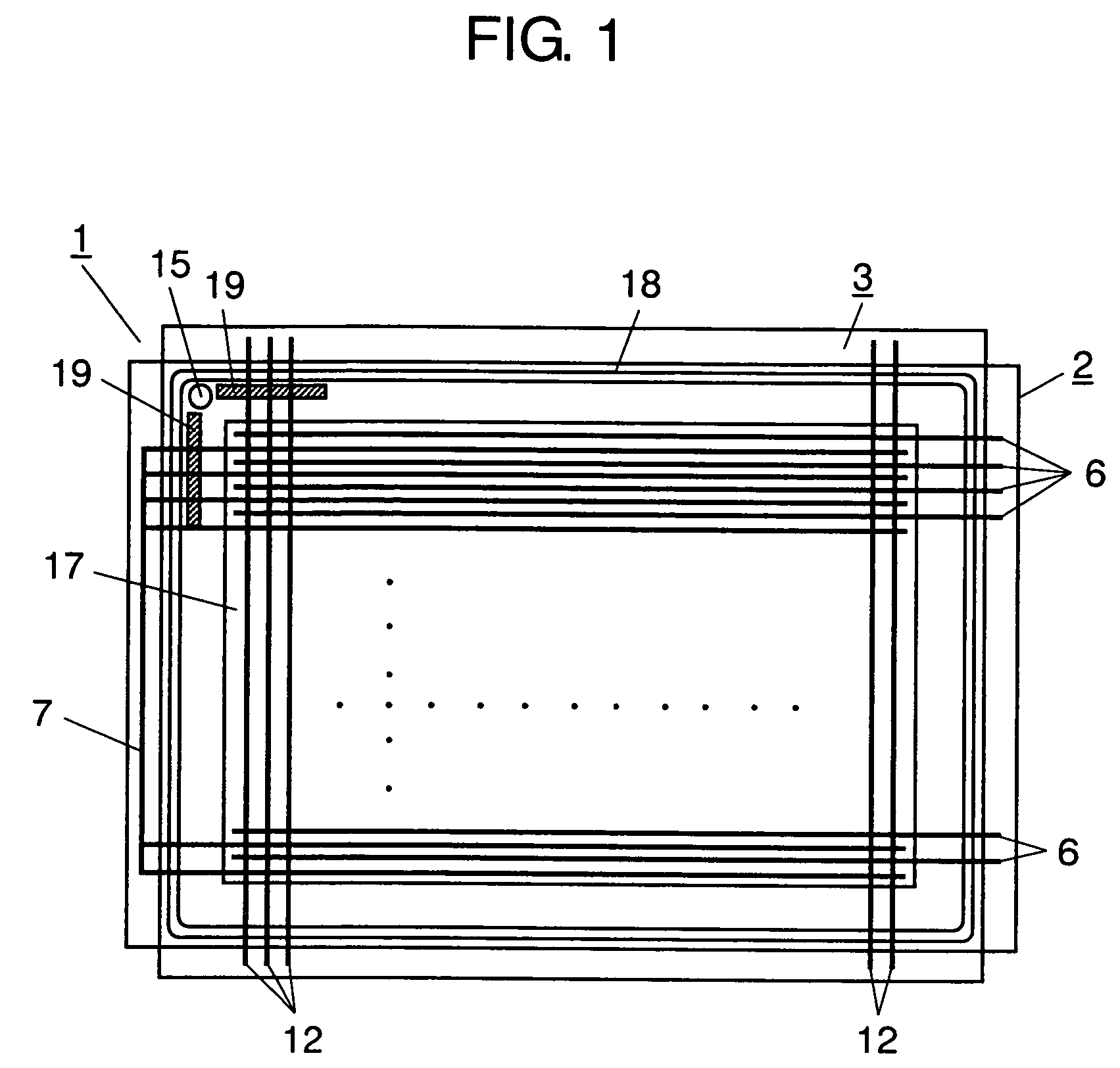

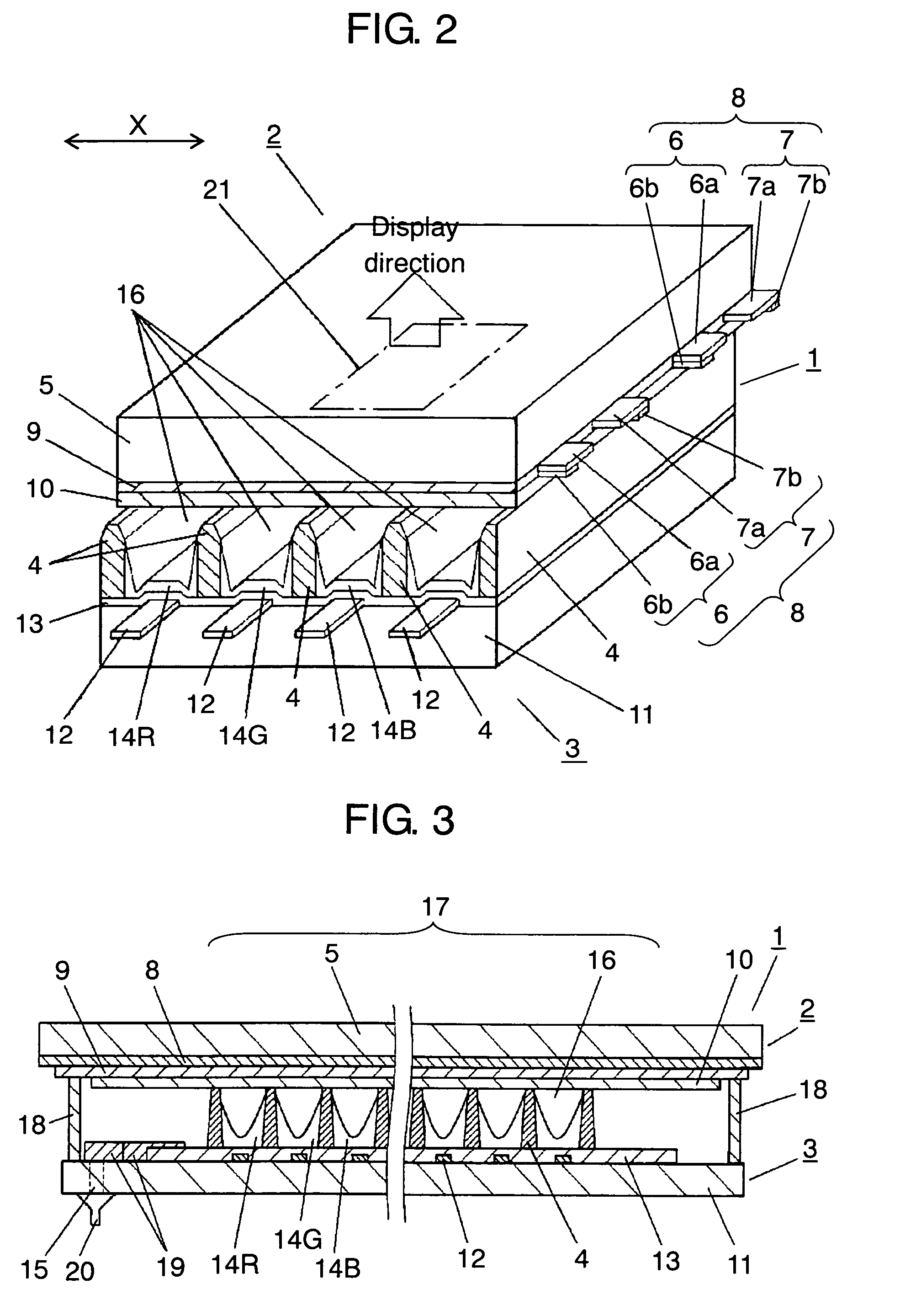

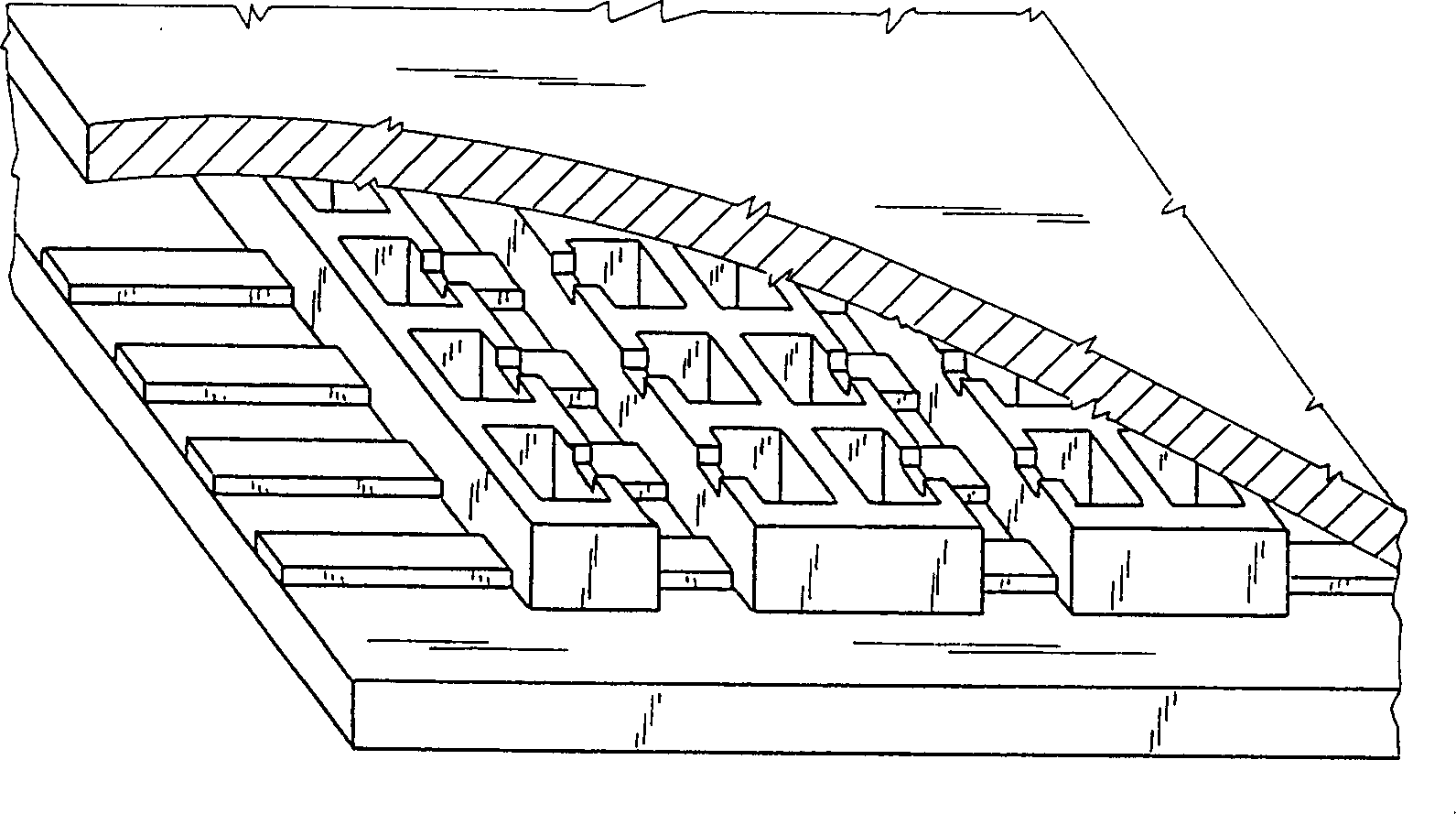

Display device employing gas discharge tubes arranged in parallel between front and rear substrates to comprise a display screen, each tube having a light emitting section as part of the display screen and a cleaning section connected to the light emitting section but displaced from the display screen

InactiveUS7049748B2Deterioration of discharge characteristic is preventedInhibit deteriorationAddress electrodesSustain/scan electrodesFluorescencePhosphor

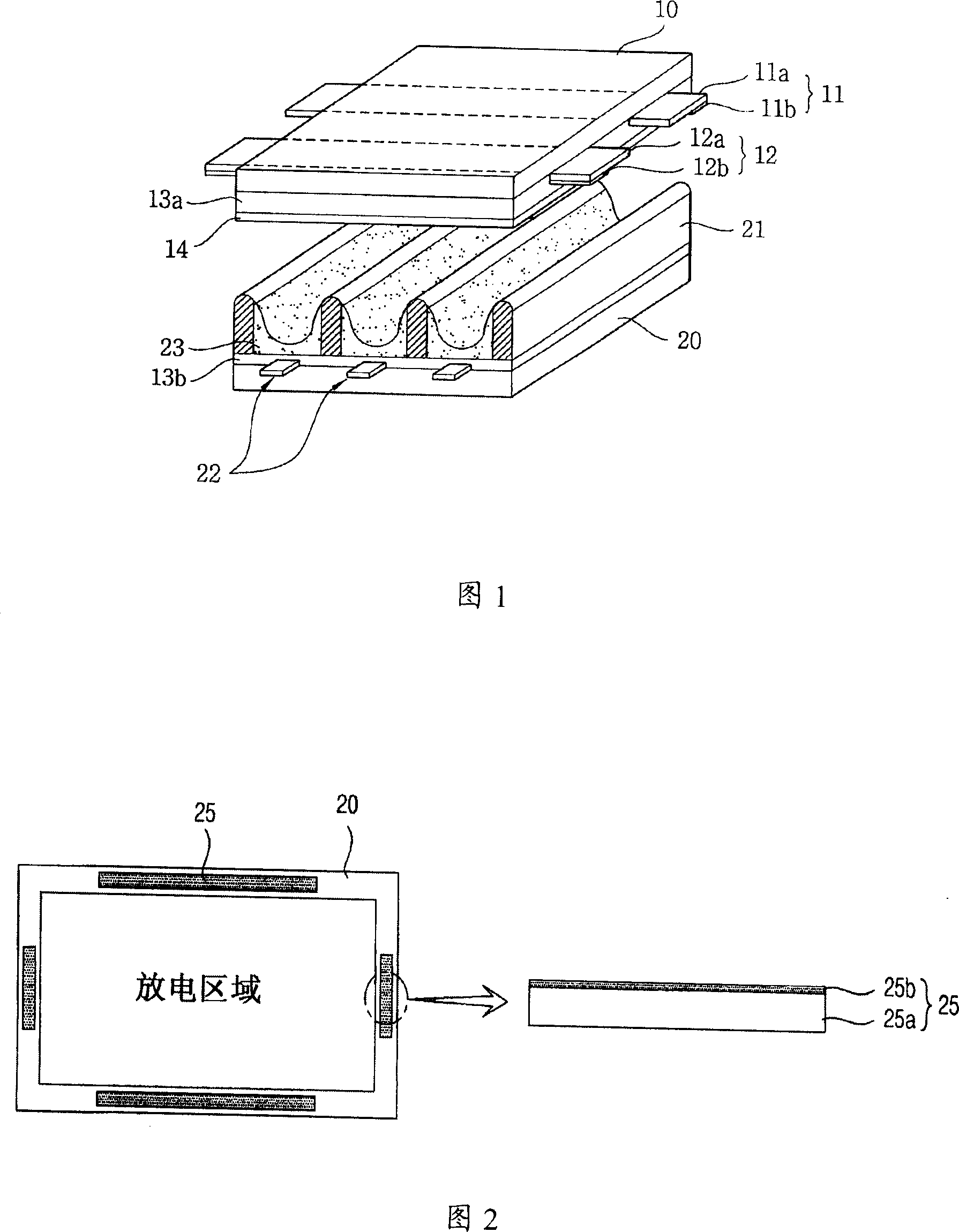

A gas discharge tube has a phosphor layer formed and a discharge gas enclosed within an elongated tube which is to serve as the gas discharge tube. The gas discharge tube includes a light-emitting section and a cleaning section for cleaning the discharge gas. The cleaning section is connected to the light-emitting section.

Owner:SHINODA PLASMA

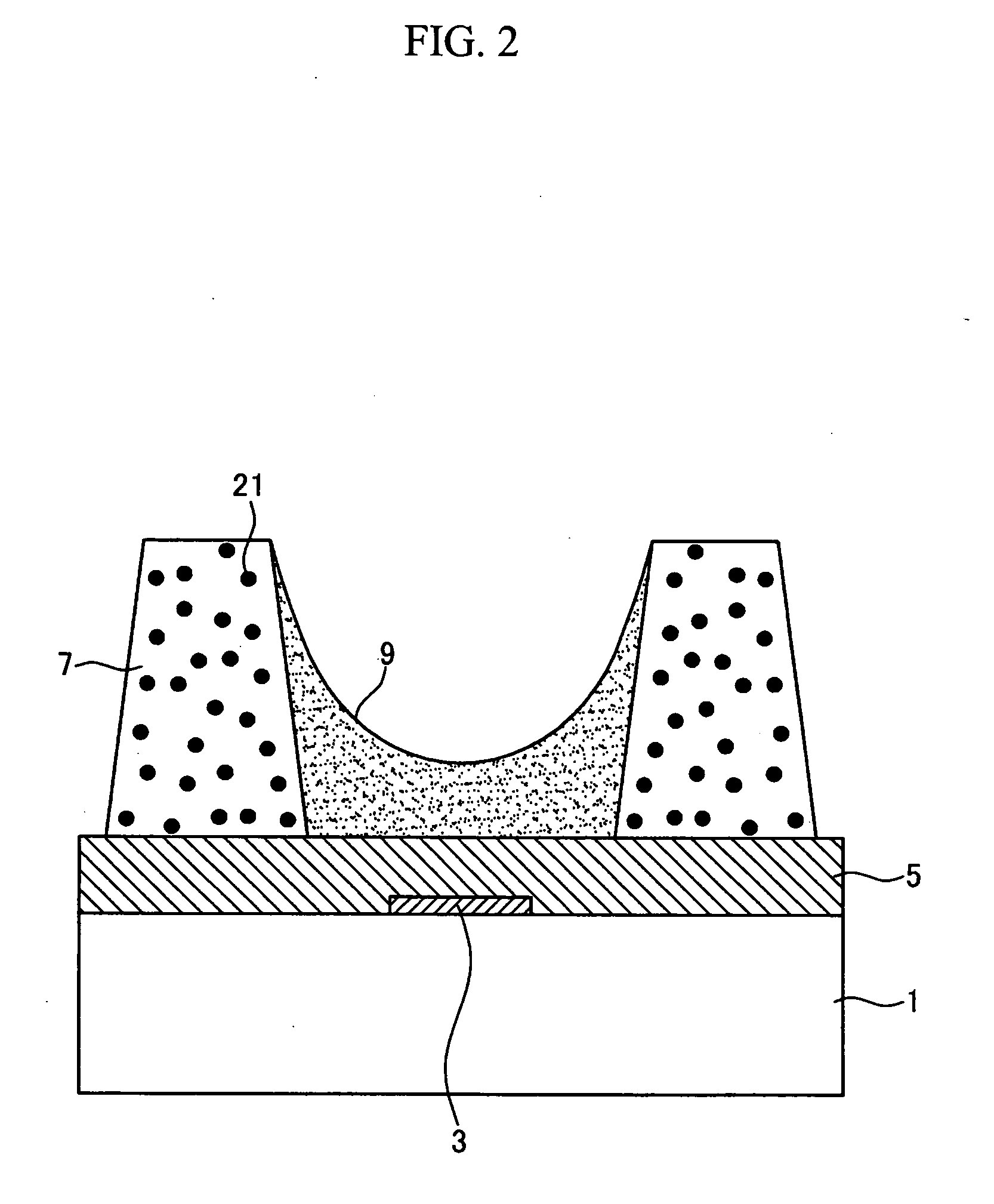

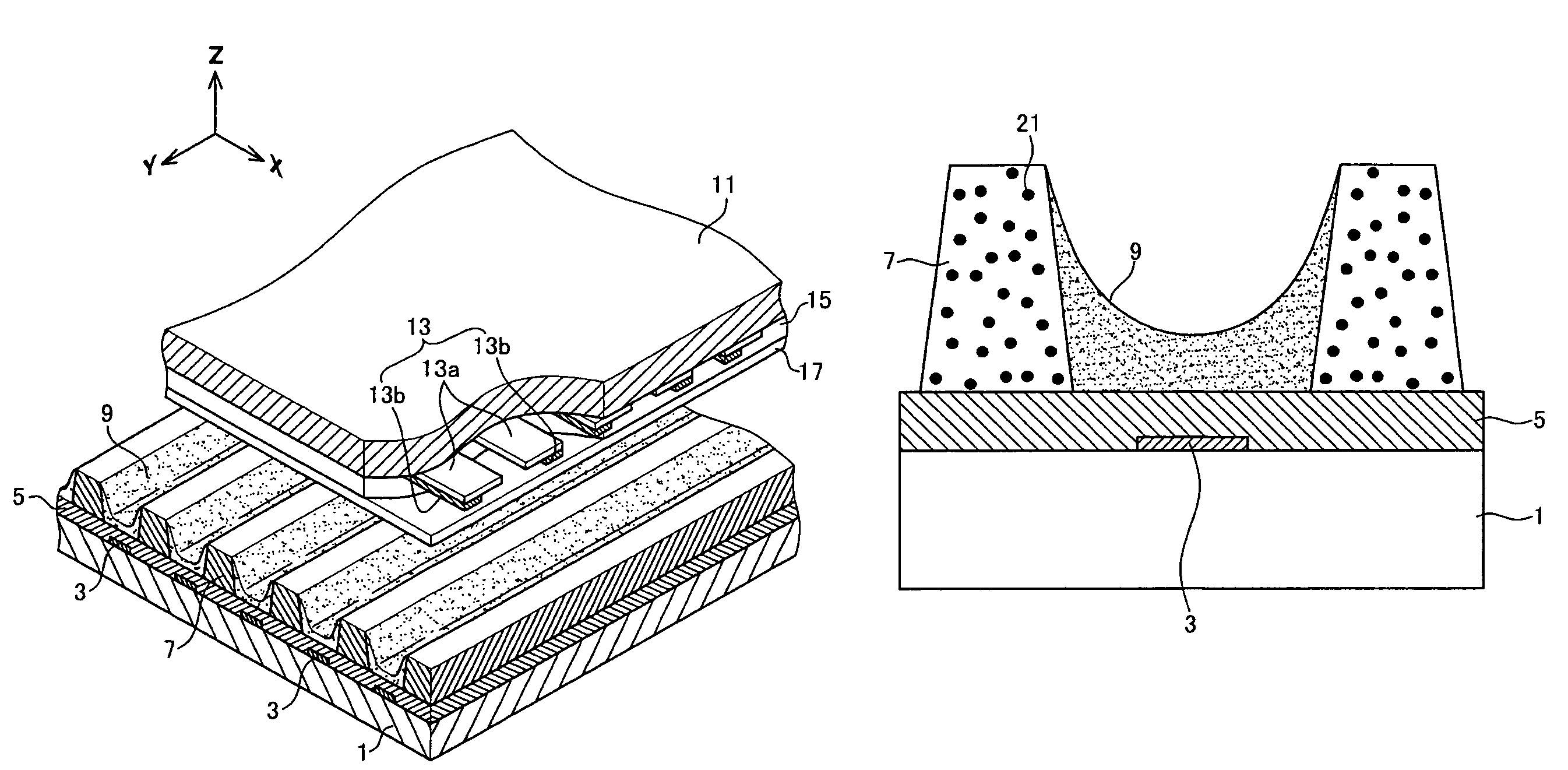

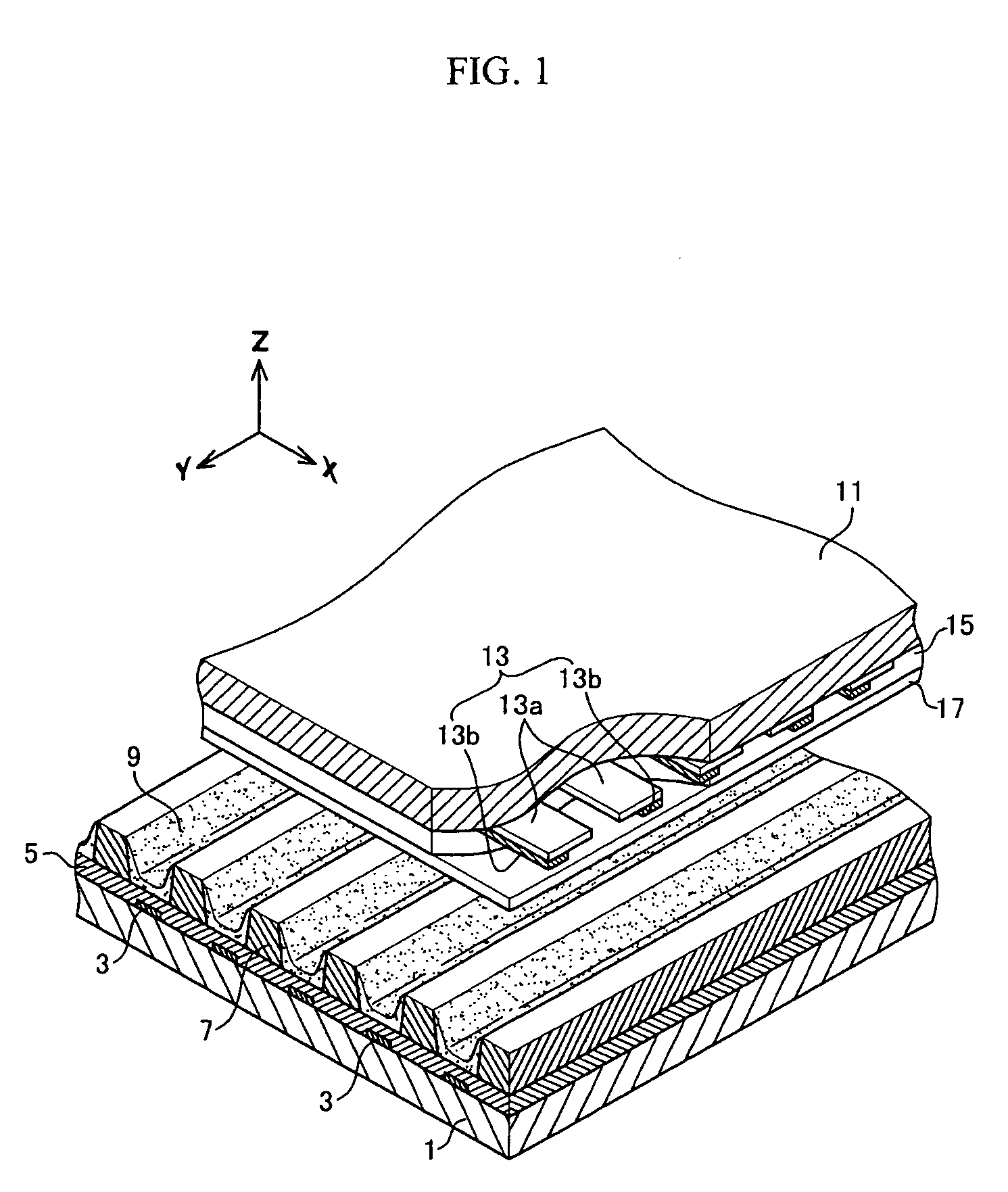

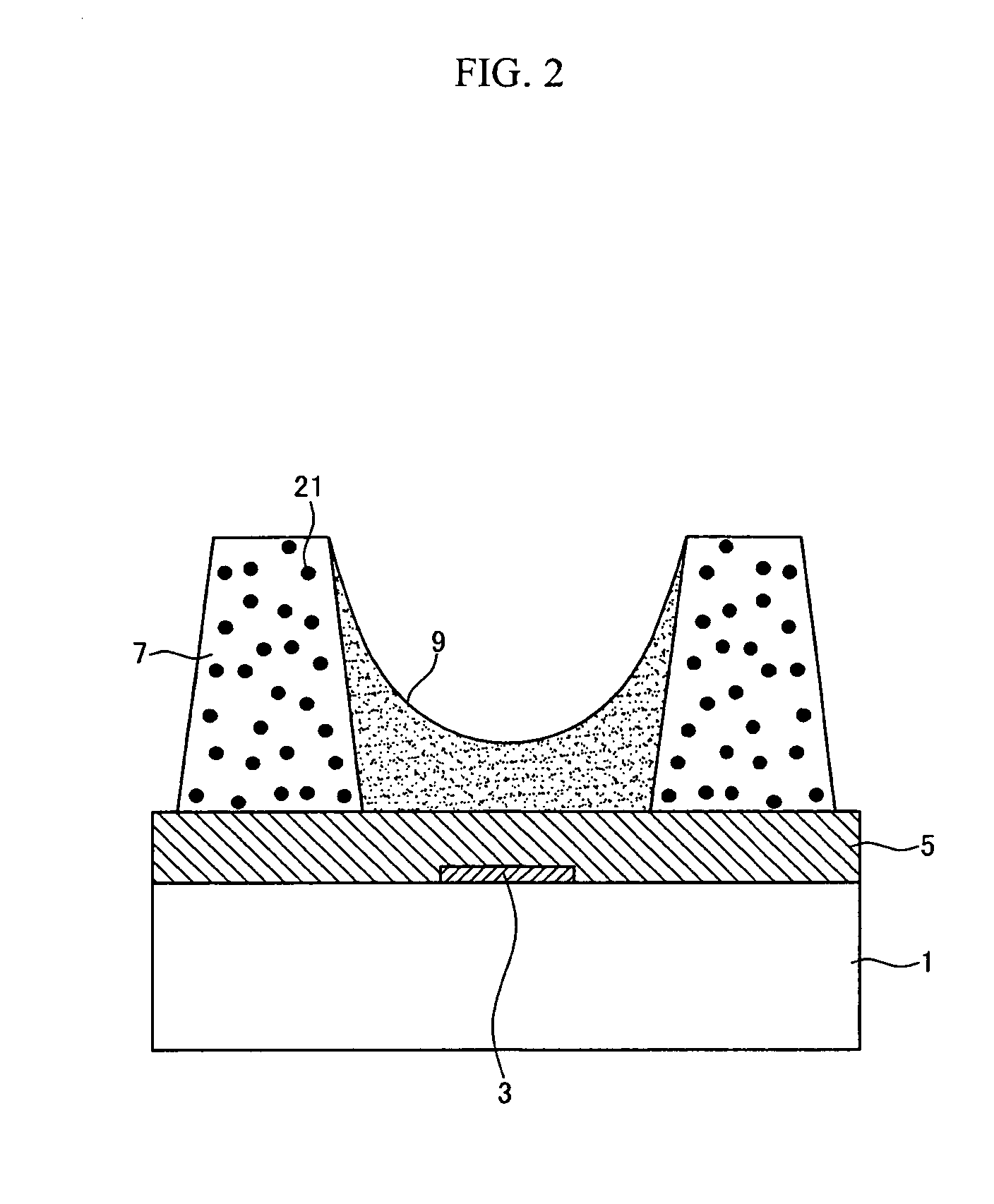

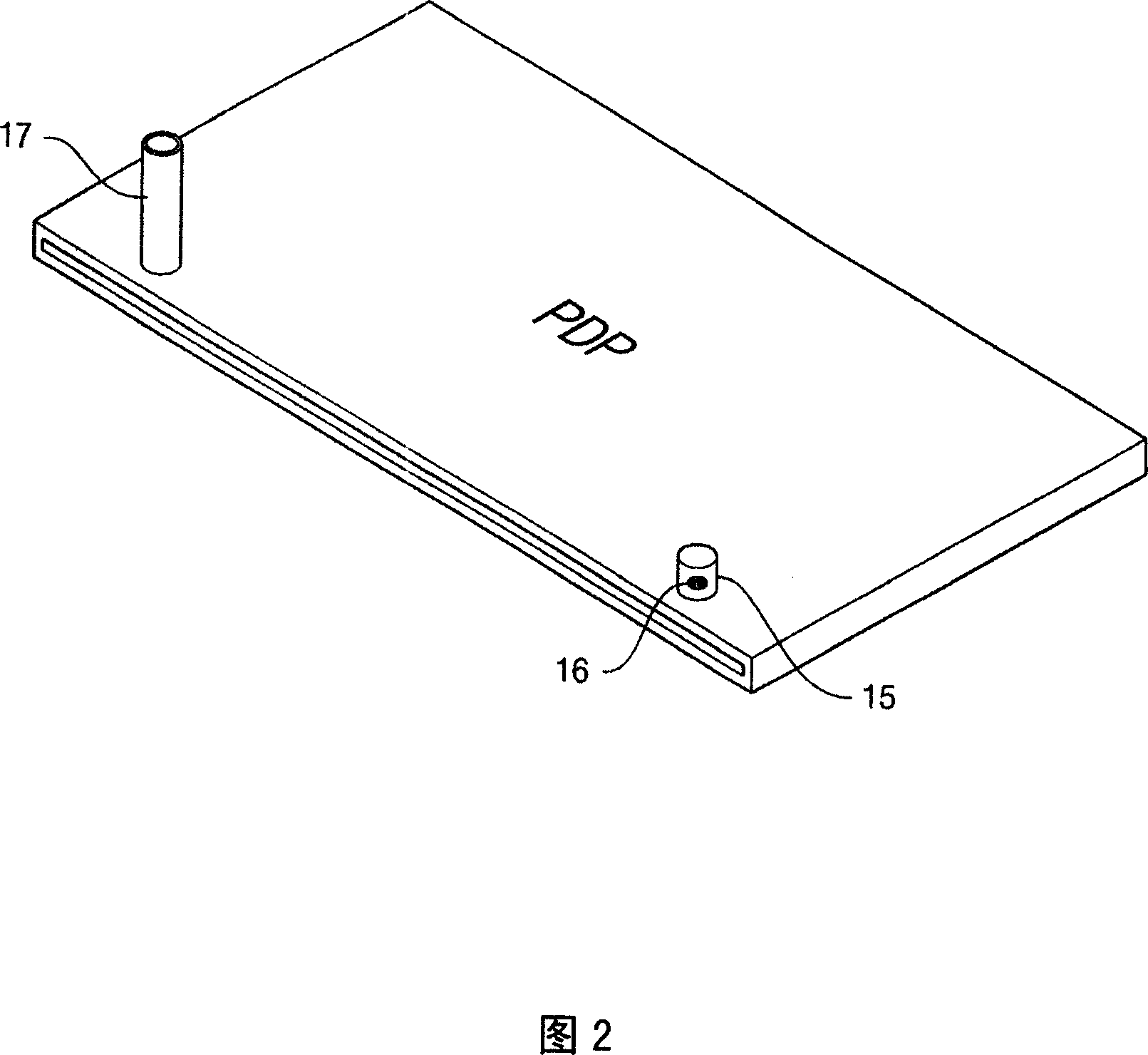

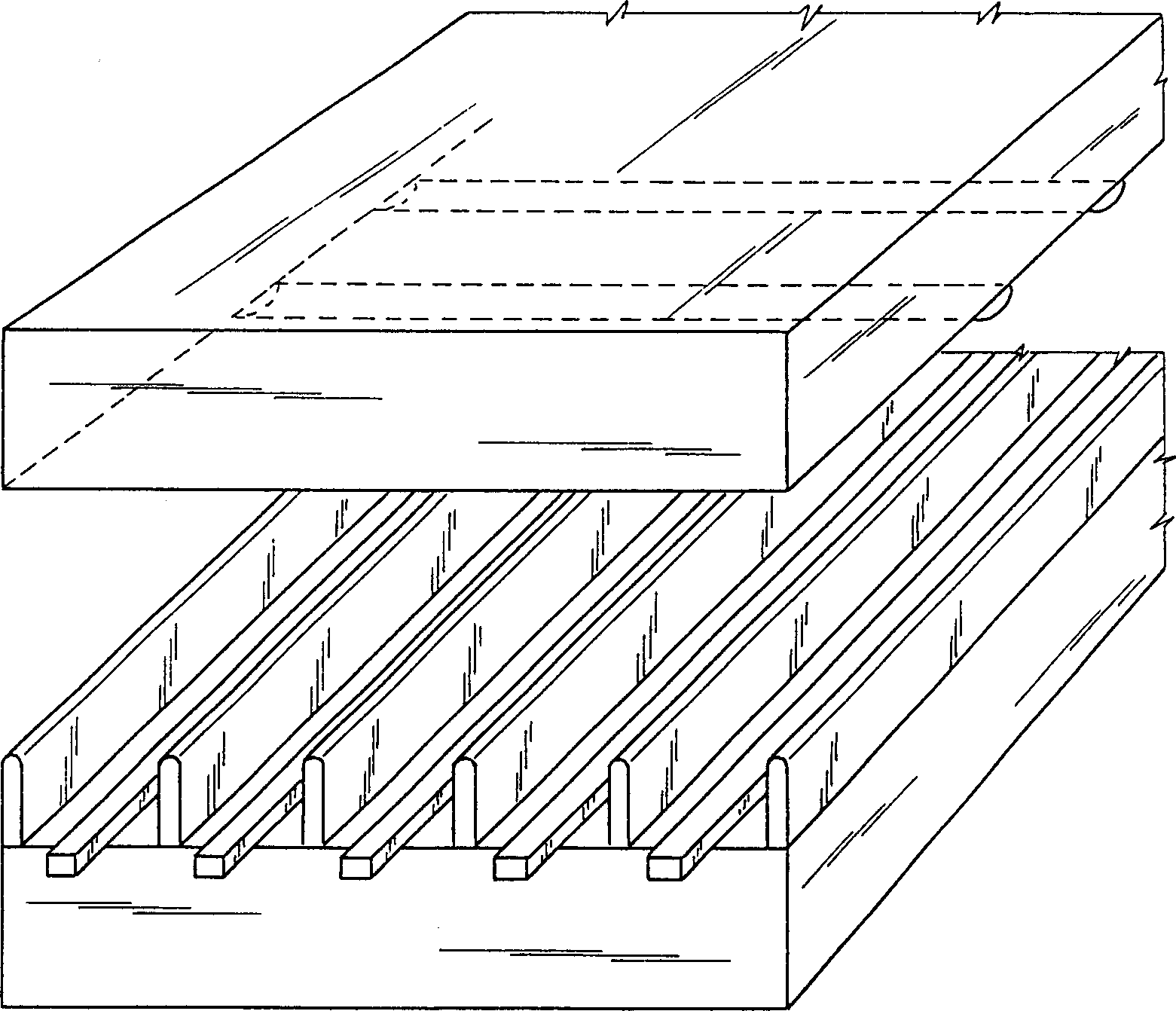

Plasma display panel

InactiveUS20070103058A1Efficient removalAddress electrodesSustain/scan electrodesDisplay boardPhosphor

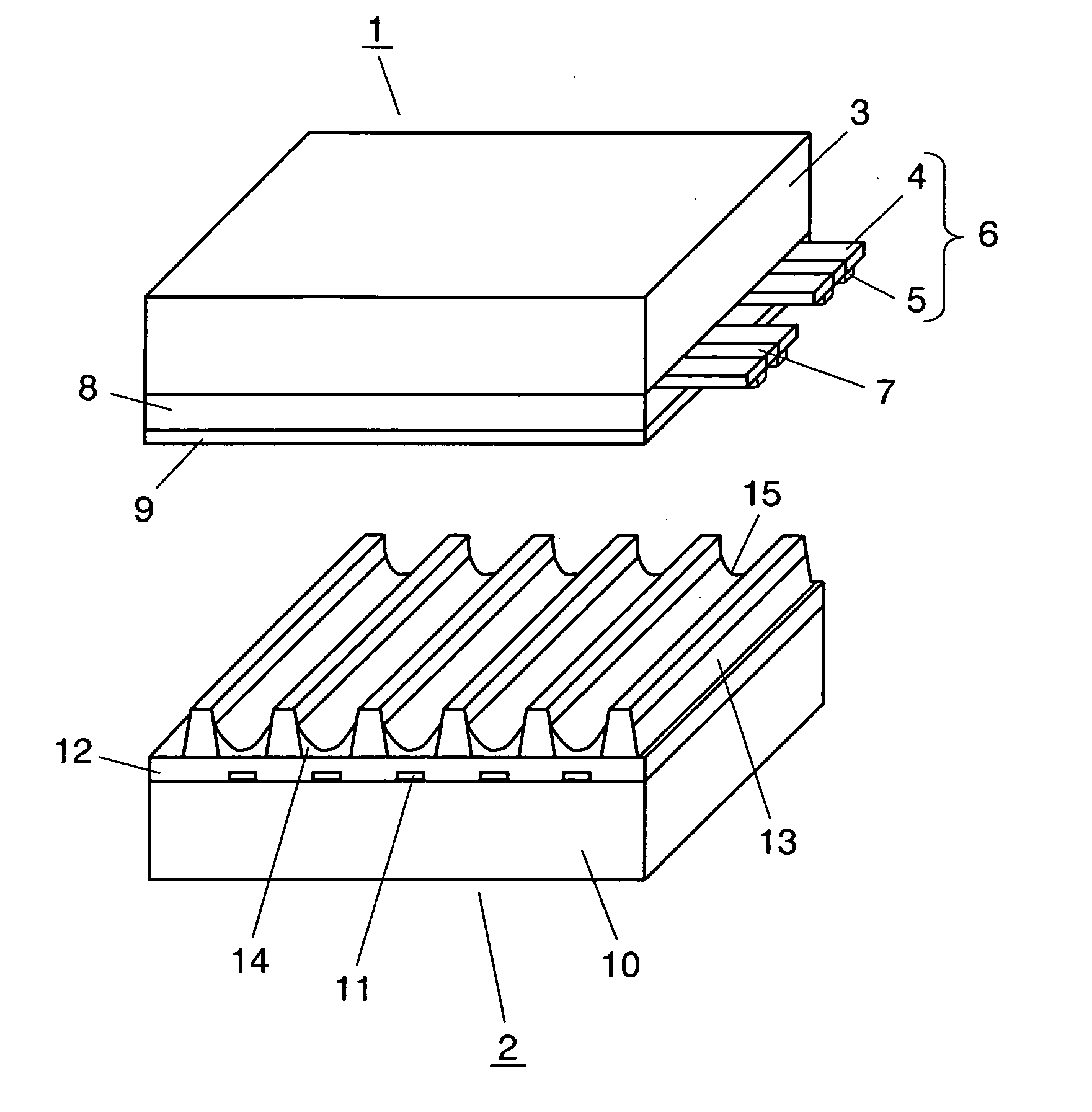

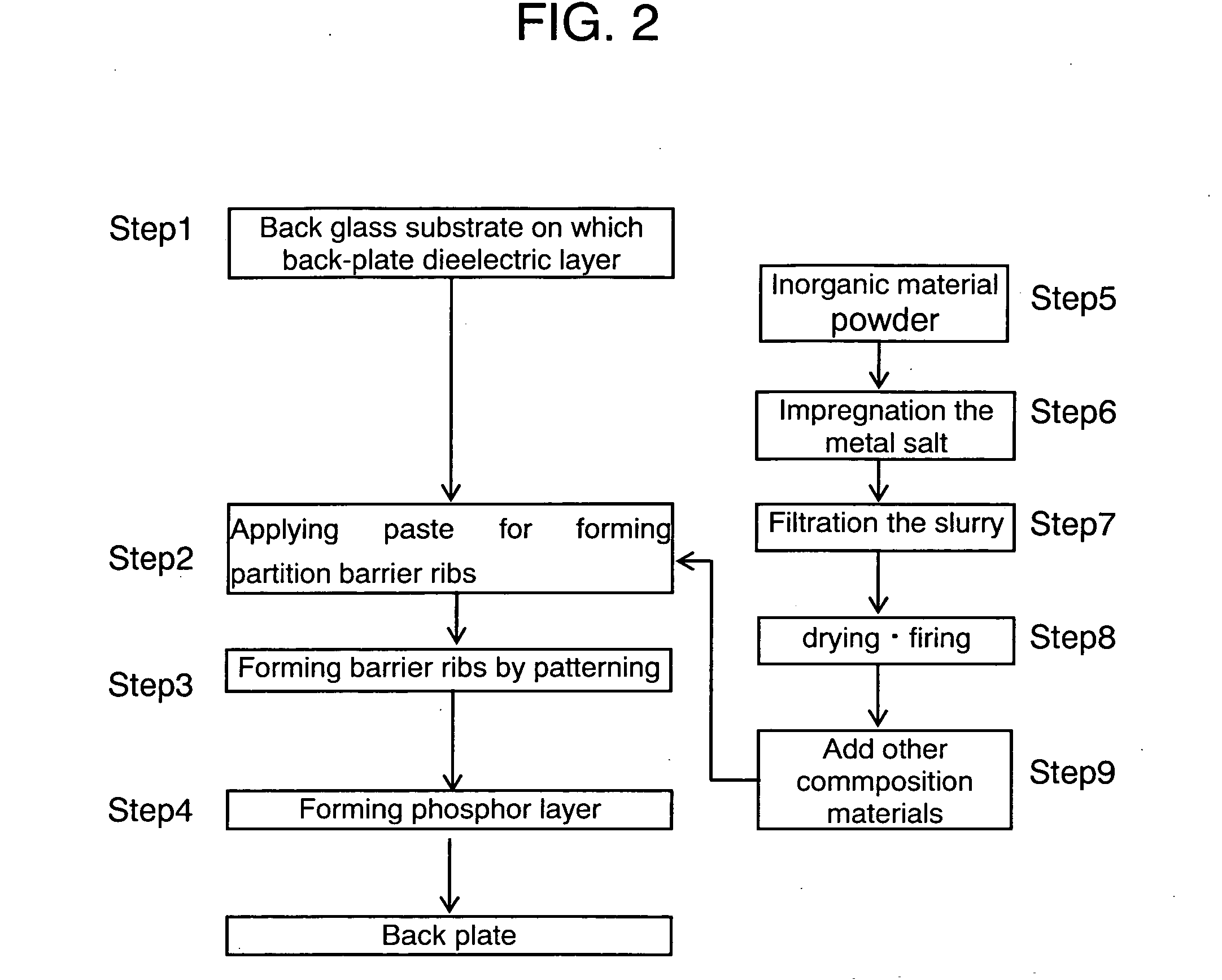

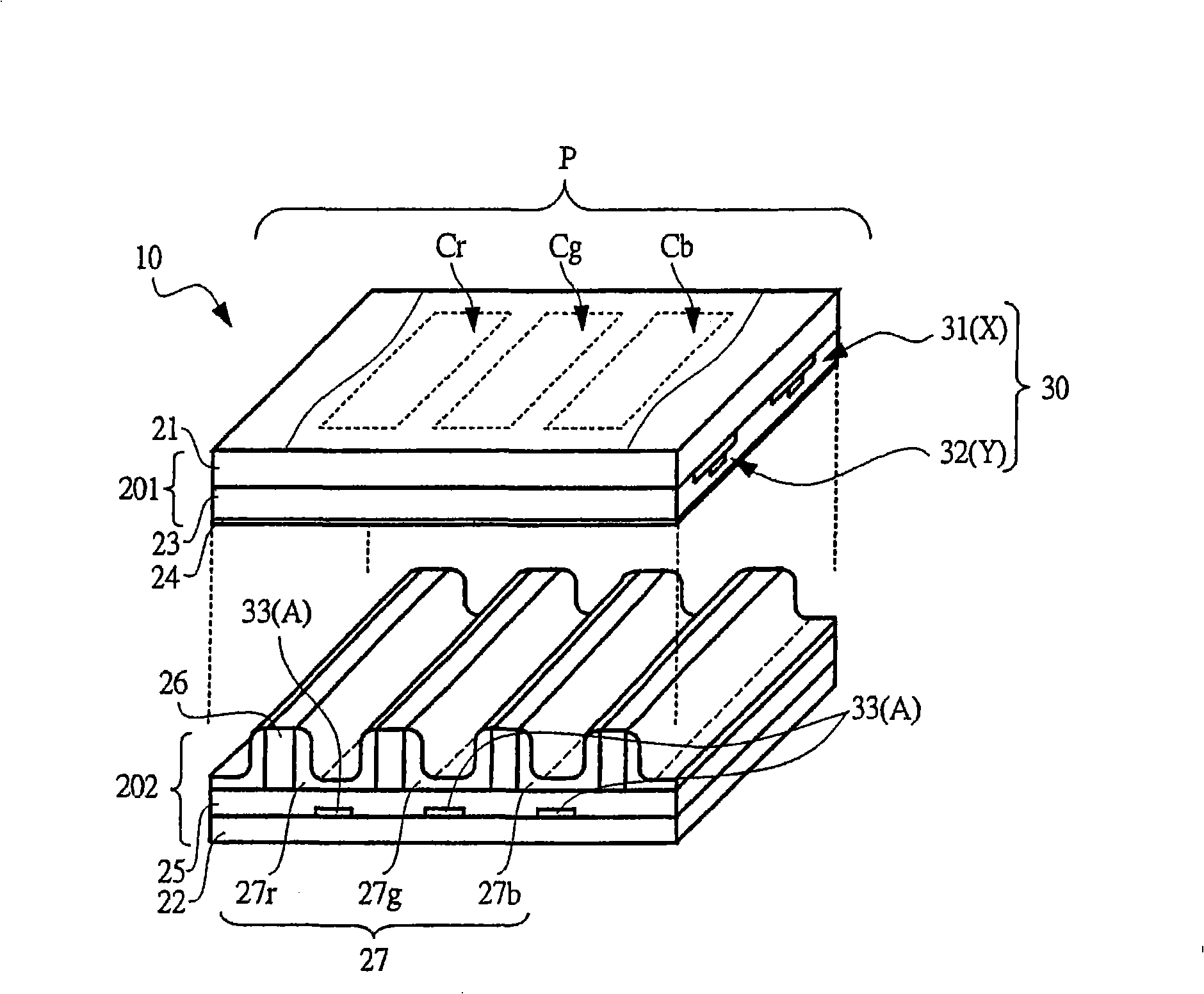

The present invention relates to a plasma display panel (PDP) that includes a first substrate, an address electrode formed on the first substrate, a dielectric layer formed on the first substrate and covering the address electrode, a barrier rib formed on the dielectric layer, a second substrate, a display electrode formed on the second substrate, a dielectric layer formed on the second substrate and covering the display electrode, and a protection layer formed on the dielectric layer of the second substrate. Discharge cells are defined by barrier ribs, and a phosphor layer is formed in the discharge cells. Barrier ribs contains inorganic adsorbent. When a PDP is operated for a long time, residual carbon or water is generated inside discharge cells, and thereby contaminates a discharge gas contained in the discharge cells. The inorganic adsorbent included in the barrier ribs absorb the residual carbon or water improving efficiency and lifespan of the PDP.

Owner:SAMSUNG SDI CO LTD

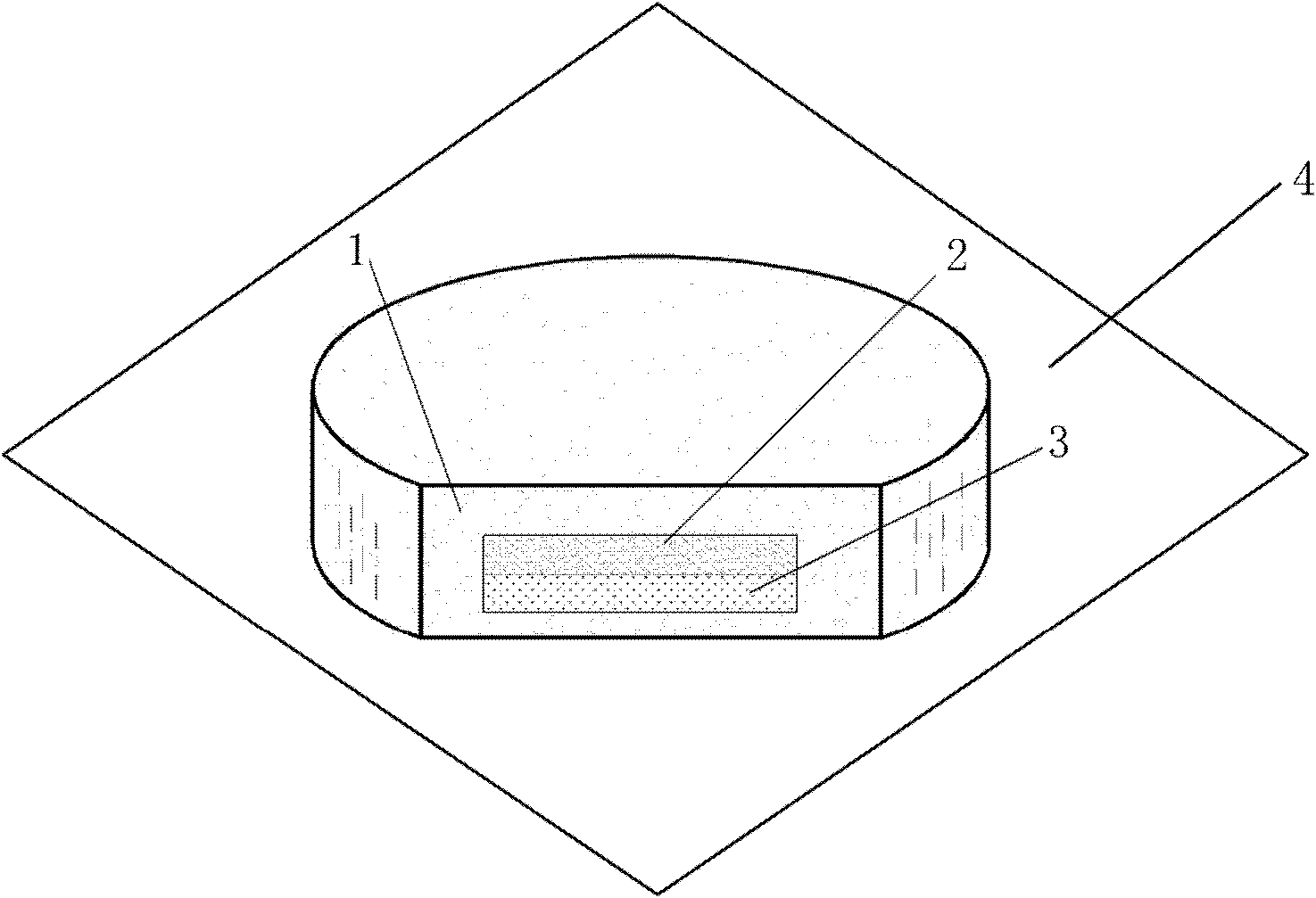

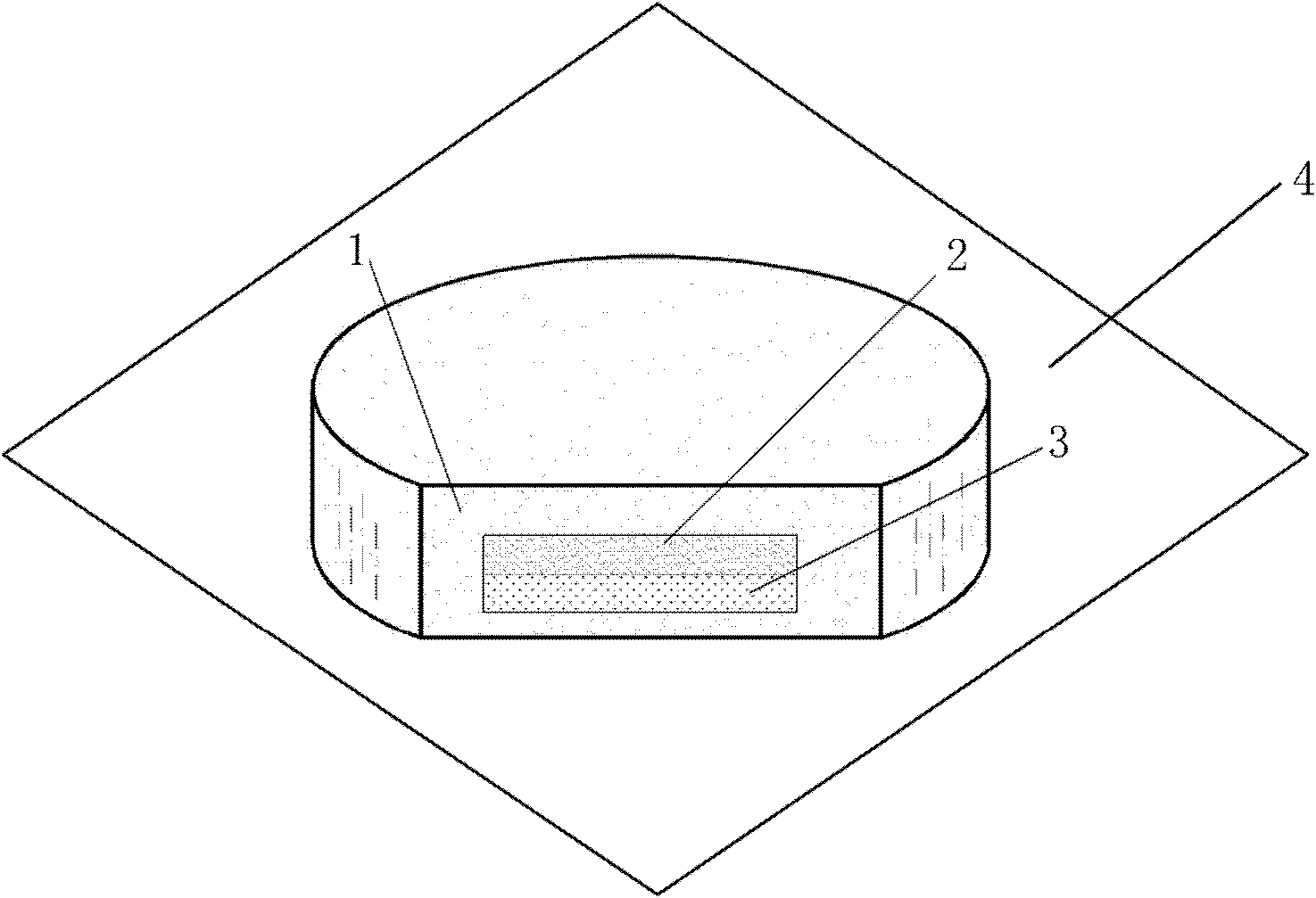

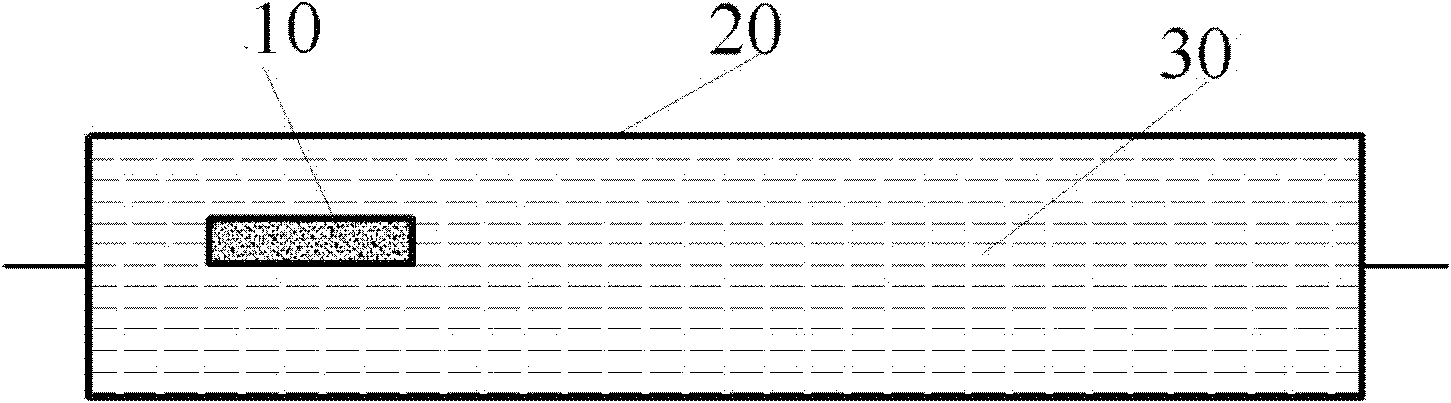

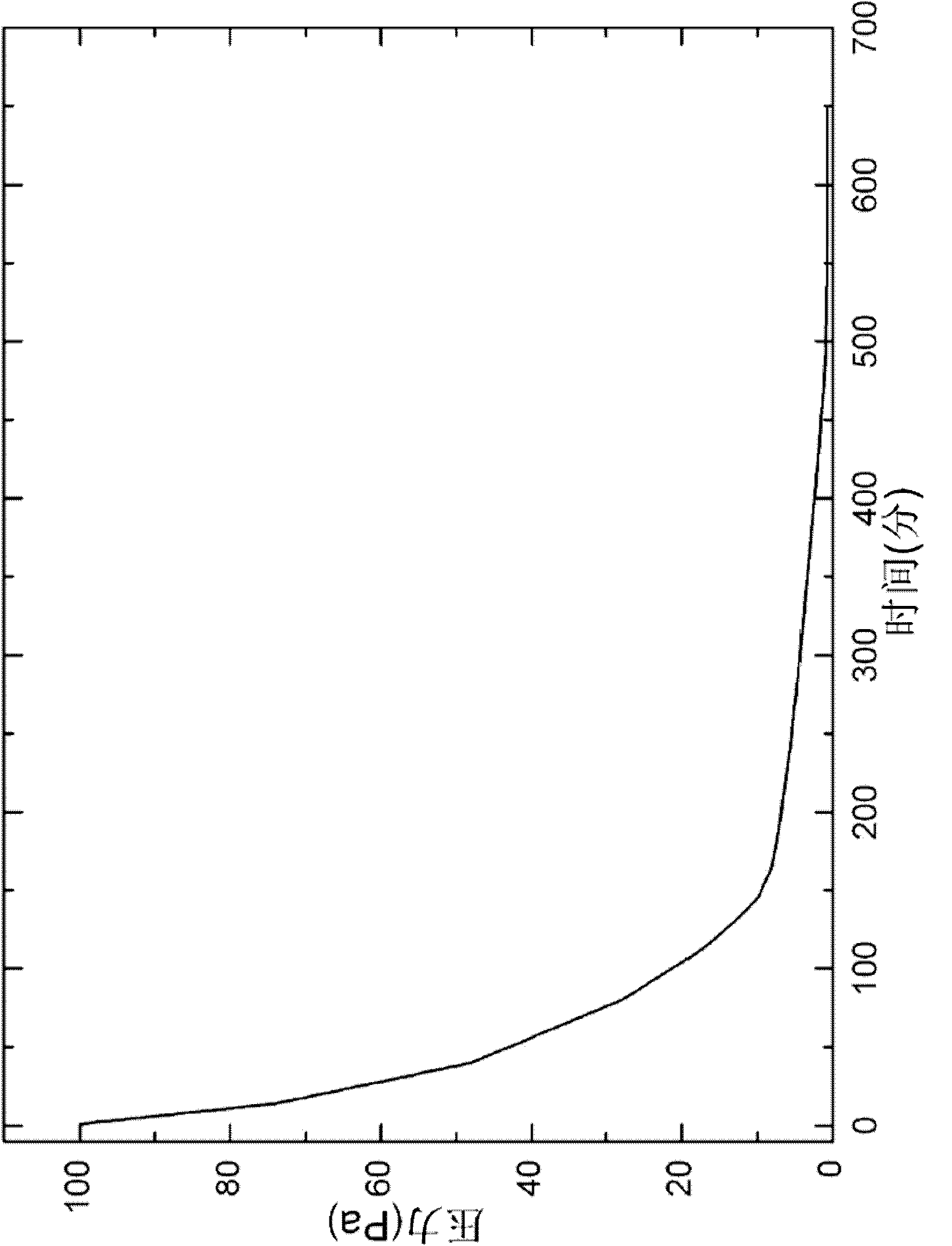

Composite getter for maintaining medium and low vacuum environment and preparation method thereof

ActiveCN102205228ASimple structureImprovement ingredientsOther chemical processesSemiconductor/solid-state device detailsLow vacuumPressure difference

A composite getter for maintaining medium and low vacuum environment and a preparation method thereof. According to the composite getter, gettering metal element powder and gettering alloy powder are disposed as two layers in an intermediate position of desiccant powder to form a core-spun structure body; the core-spun structure body is sealed in a plastic film; the gettering metal element powderis one of or a combination of at least two of iron powder, nickle powder, copper powder which are processed by reduction and have a particle size of 10-200 micrometers; the gettering alloy powder is one of or a combination of at least two of strontium lithium alloy powder, barium lithium alloy powder, barium magnesium alloy powder with a particle size of 50-500 micrometers; the desiccant powder is one of or a combination of at least two of calcium oxide powder, strontium oxide powder, barium oxide powder with a particle size of 20-200 micrometers; the plastic film can break by itself under the pressure difference of one atmospheric pressure. The service performance is not affected by temporary exposure in air.

Owner:FUJIAN SUPERTECH ADVANCED MATERIAL

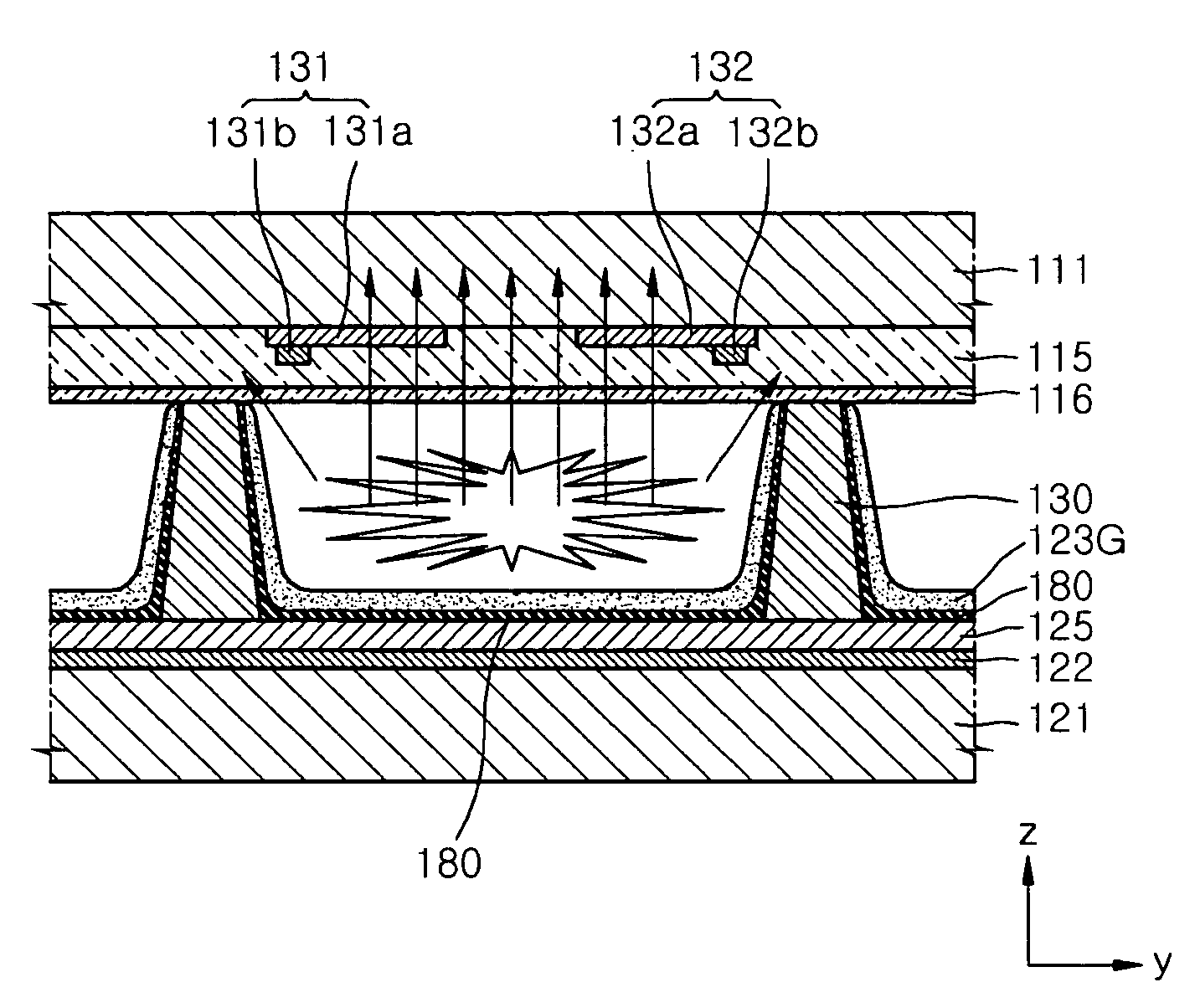

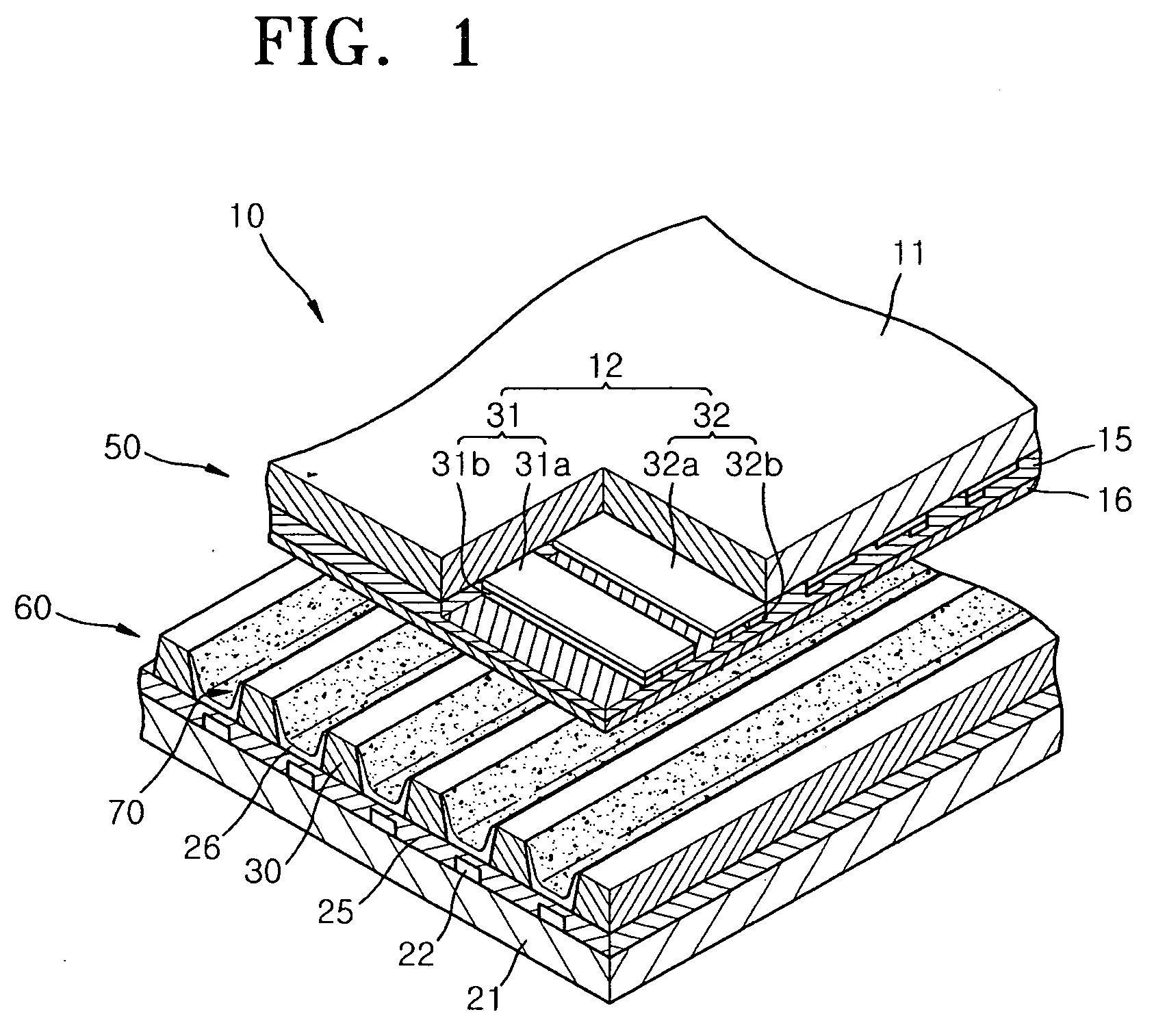

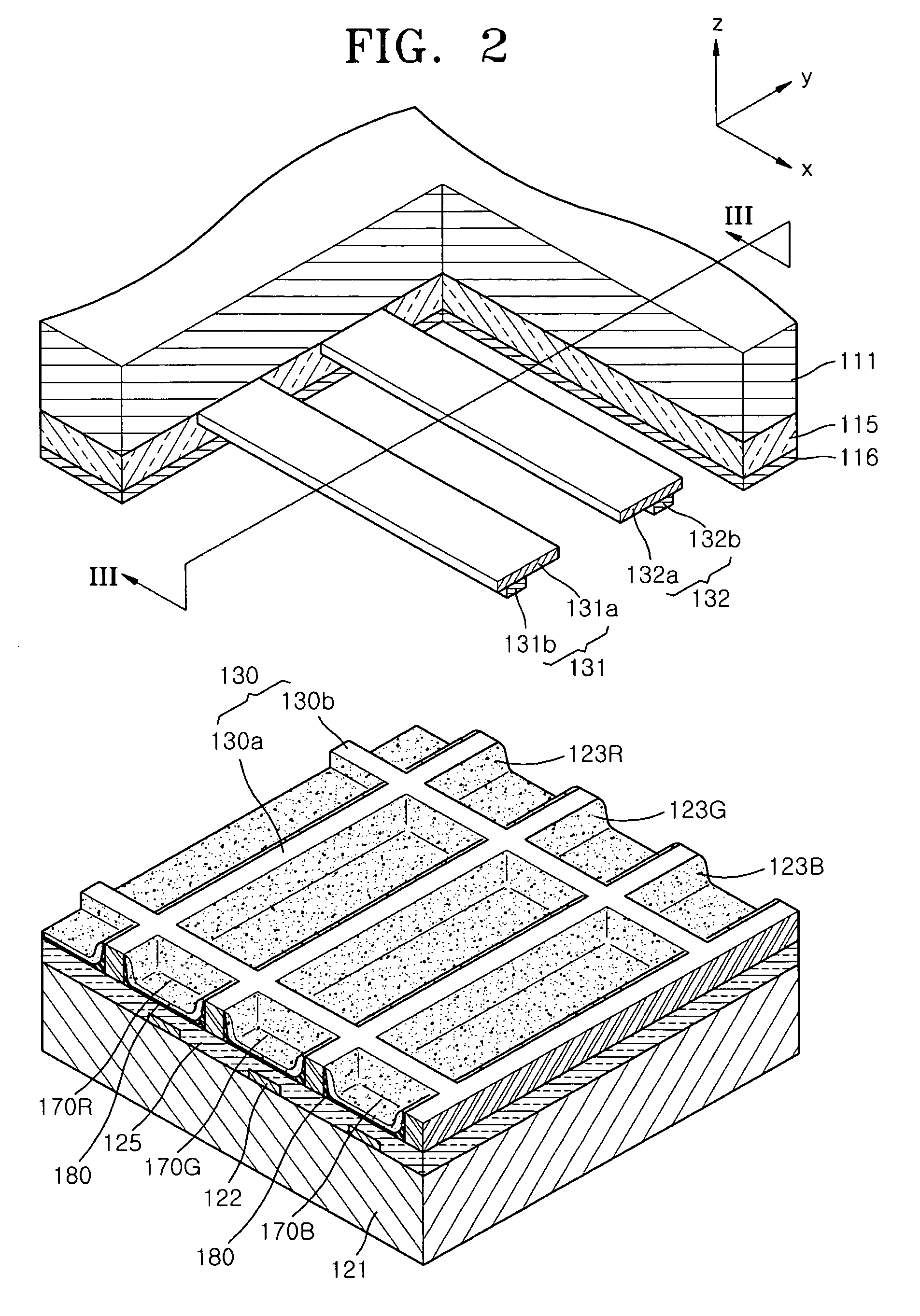

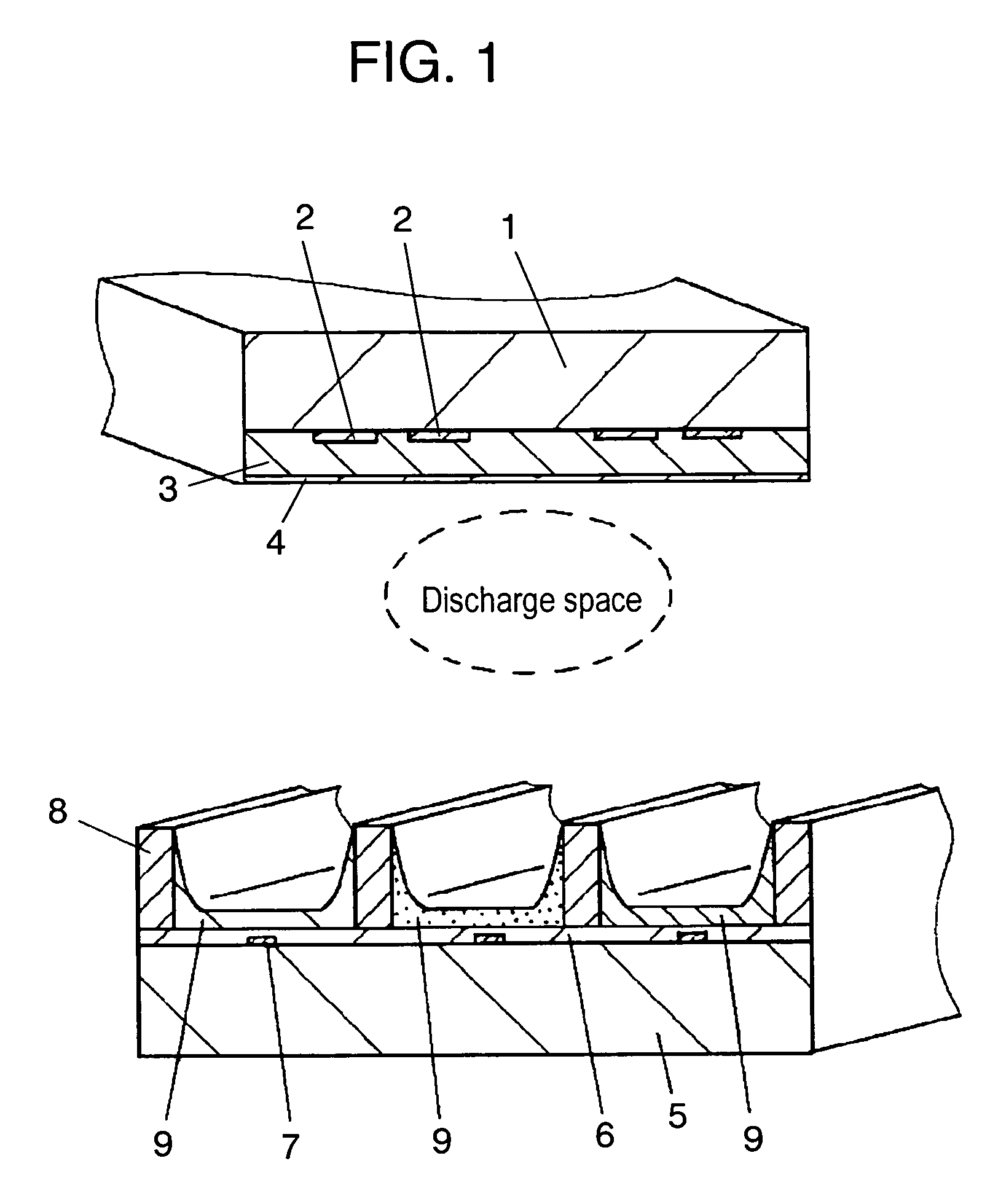

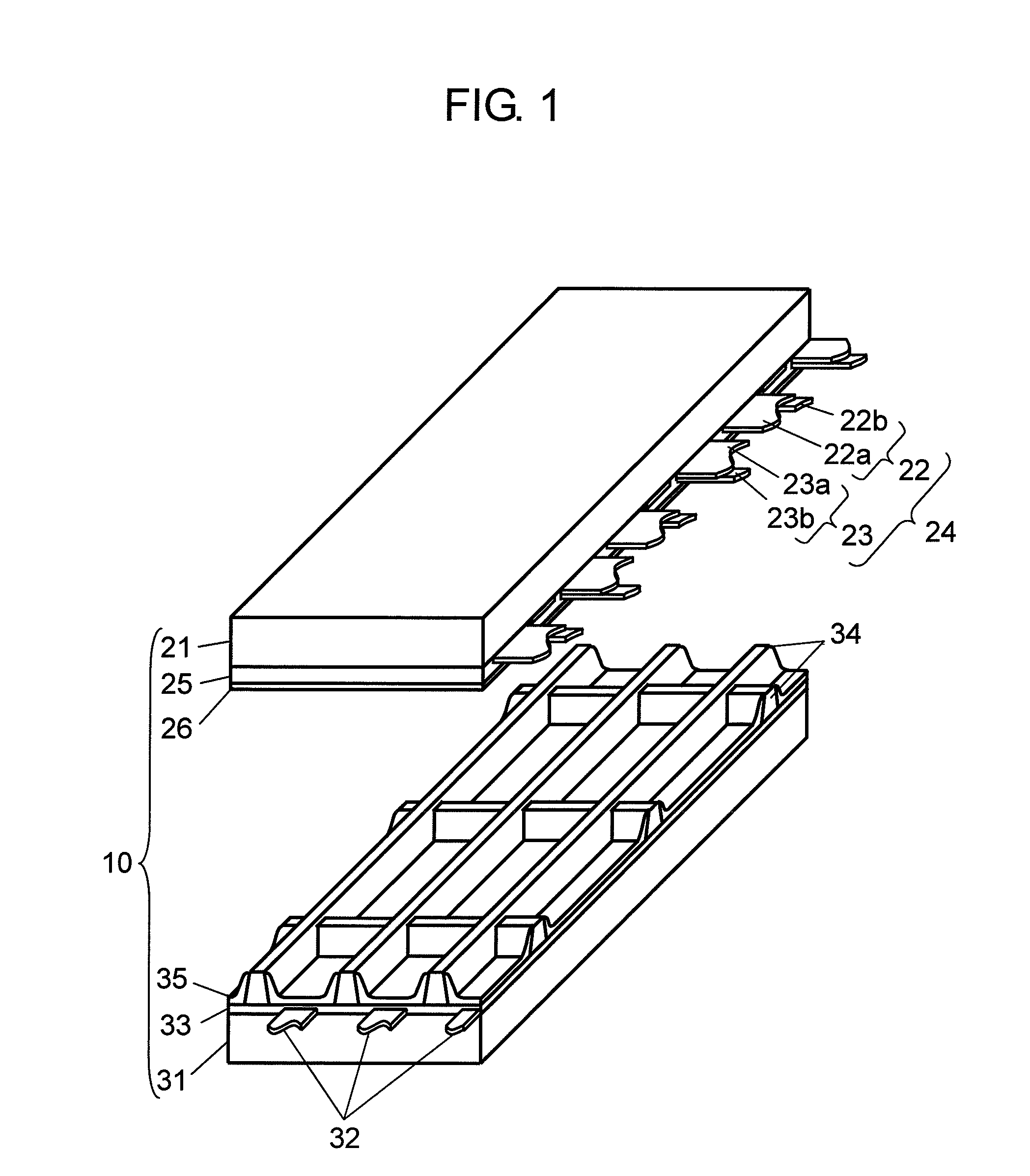

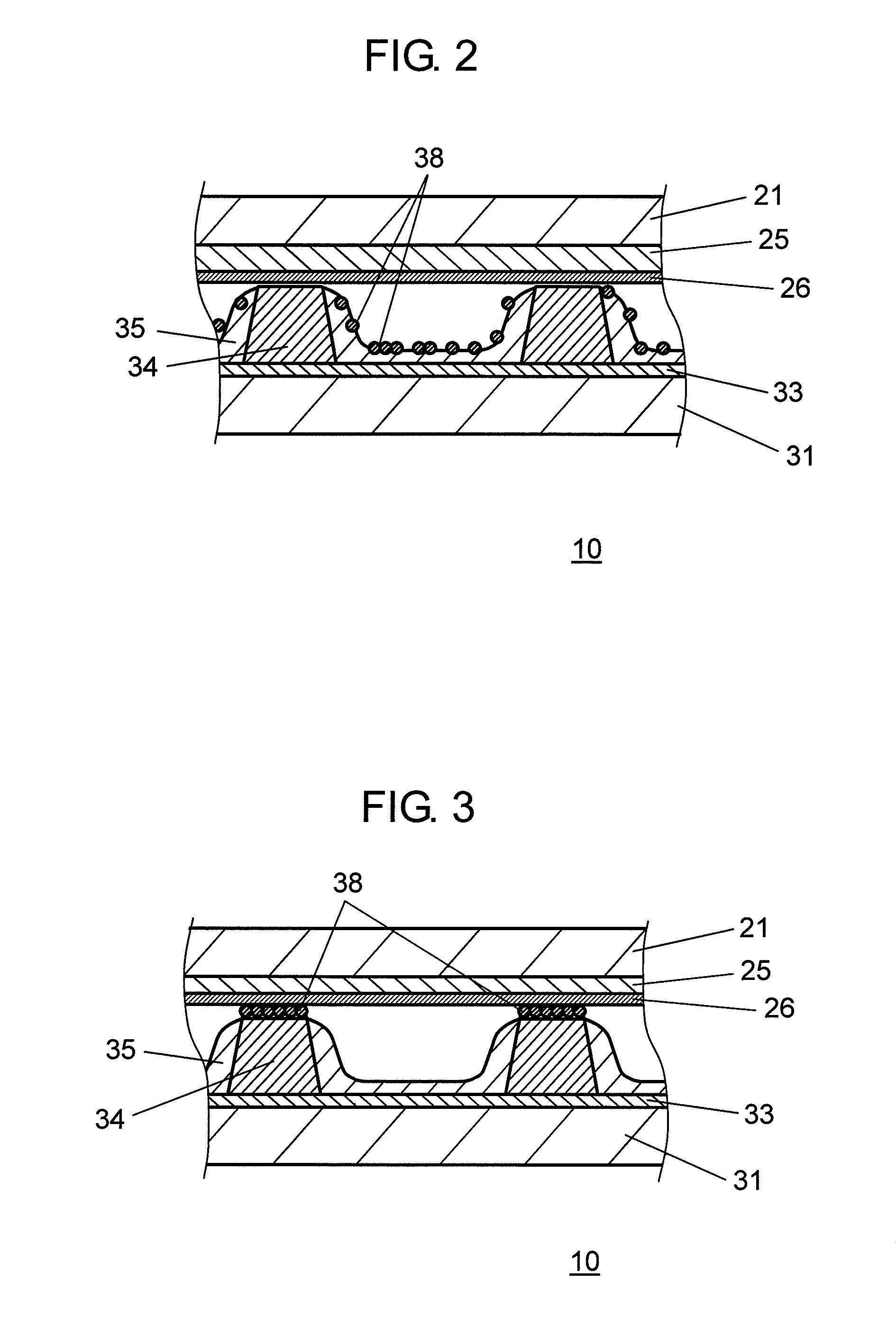

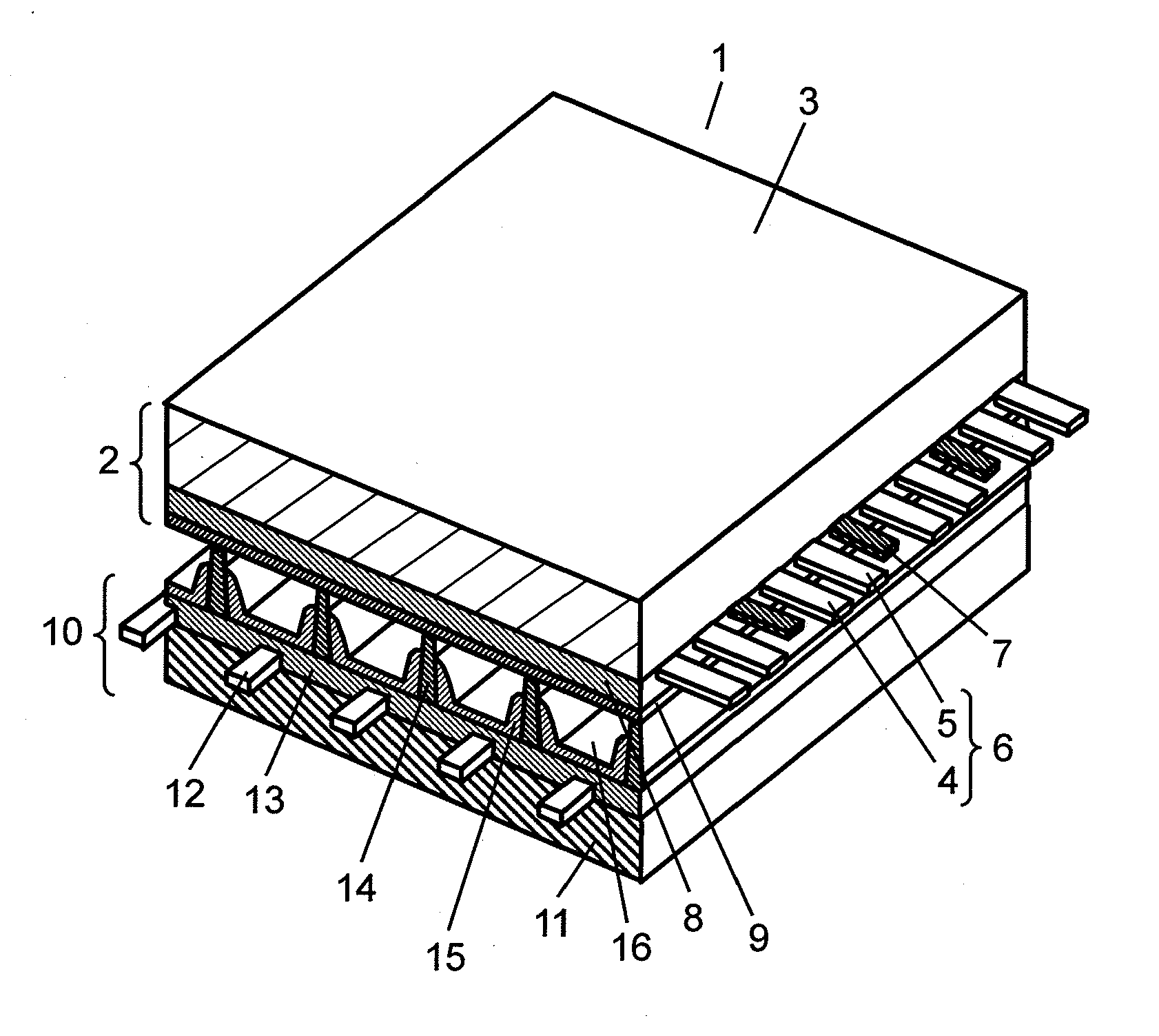

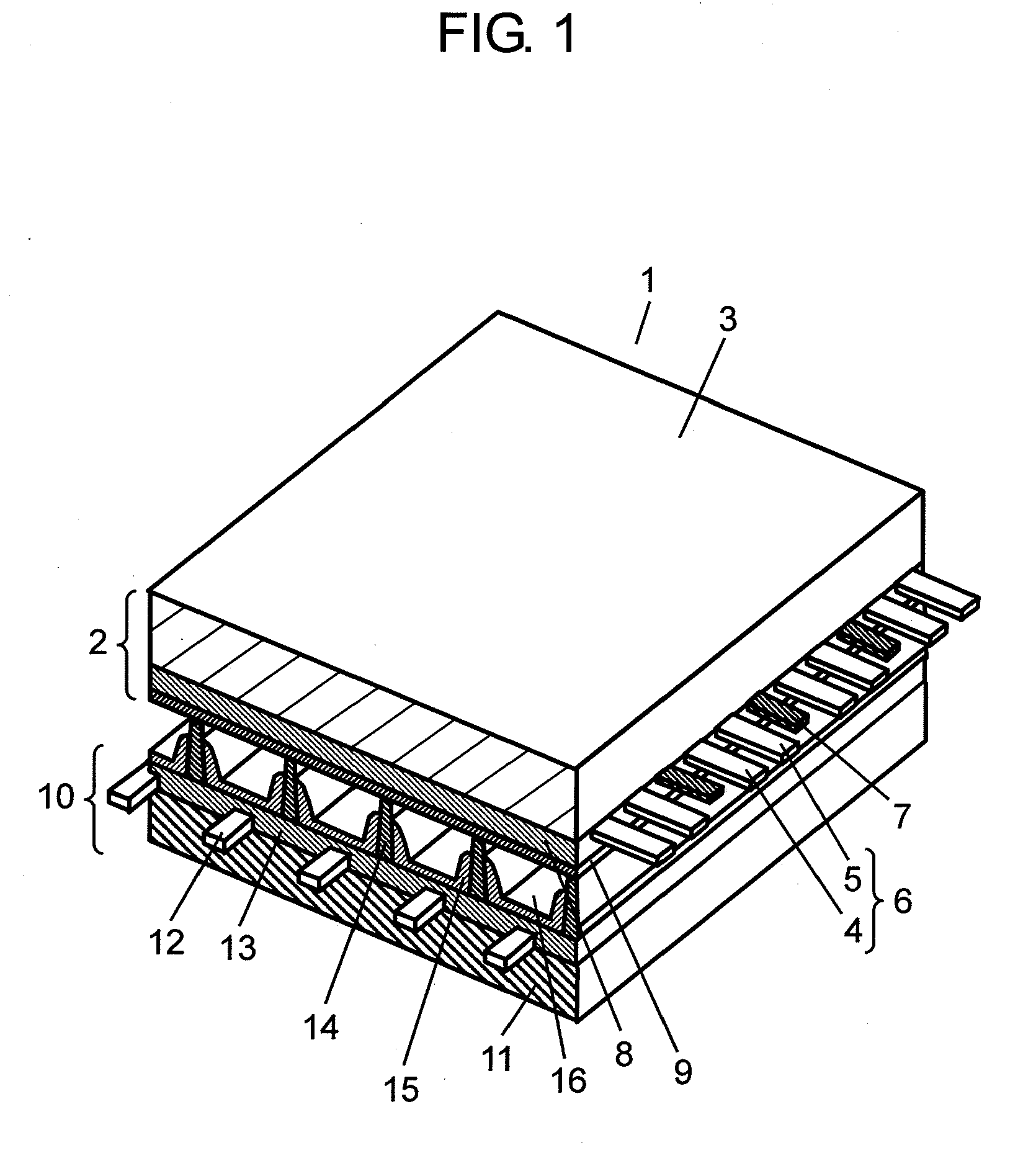

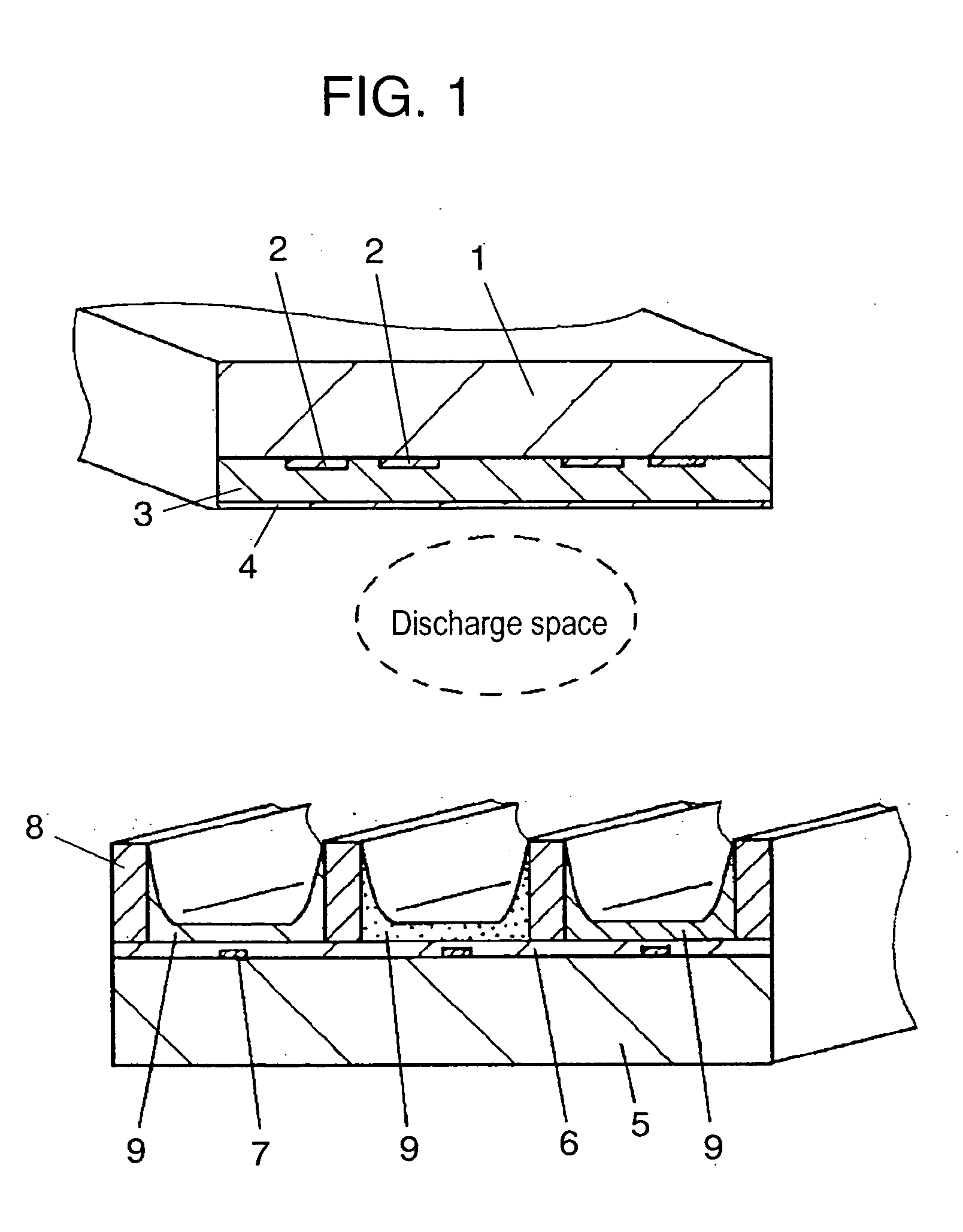

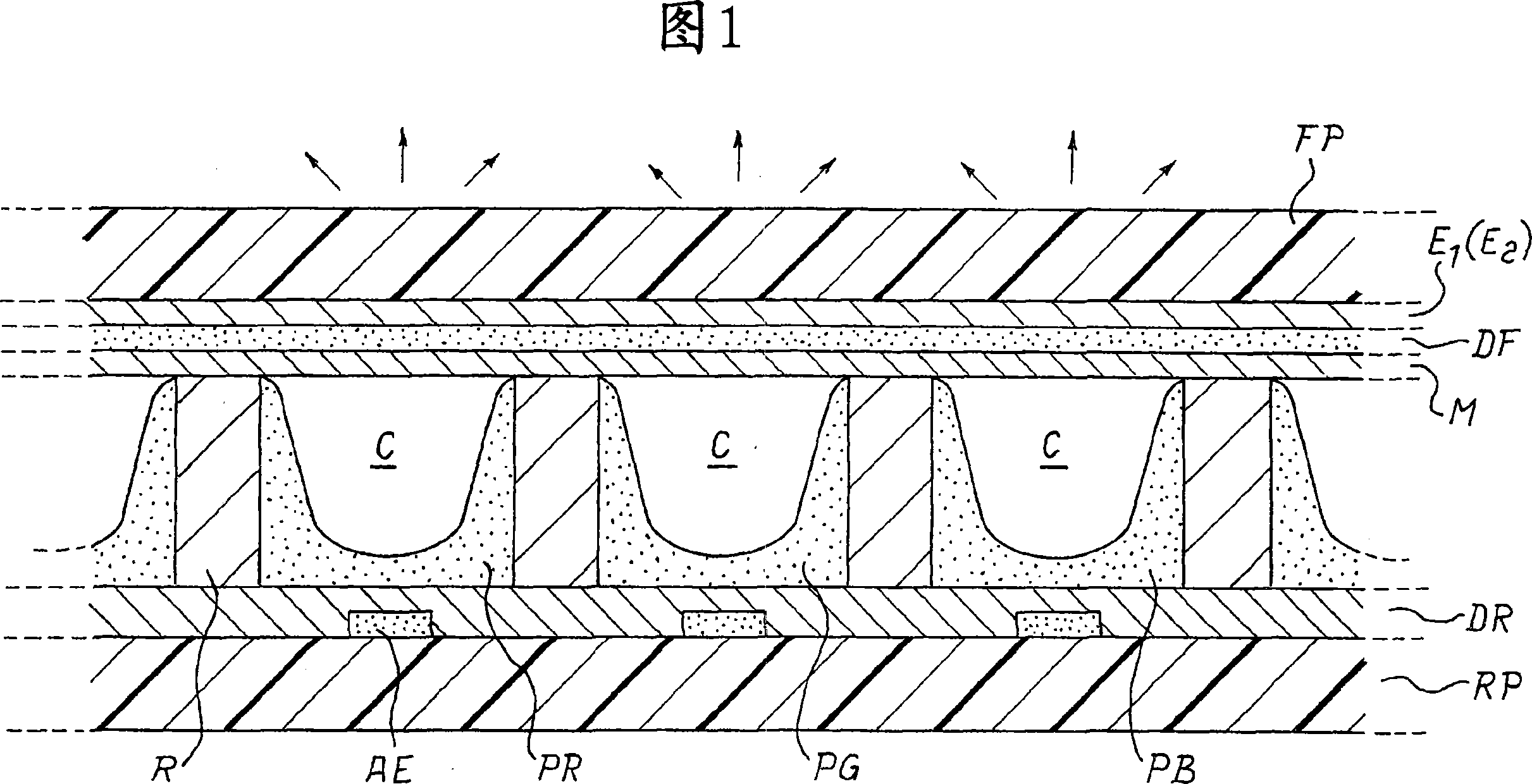

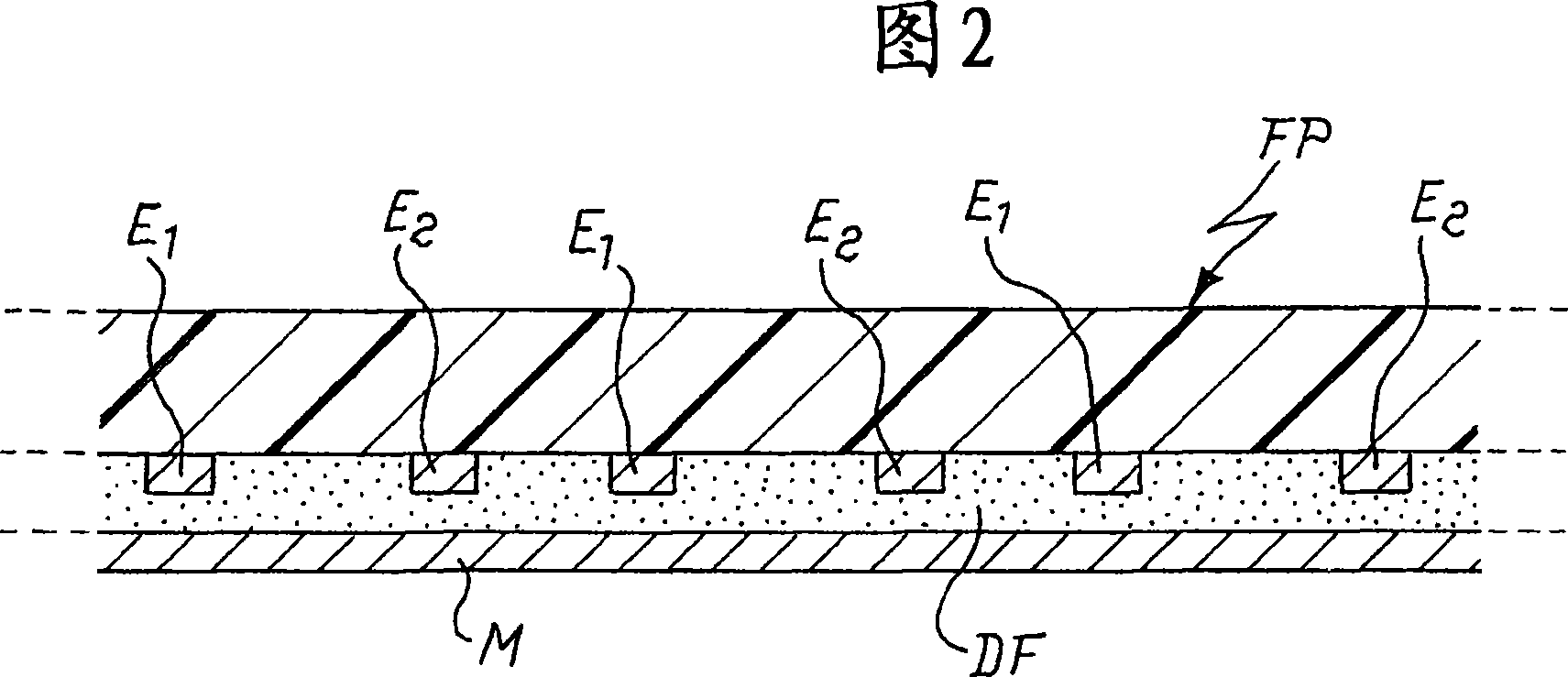

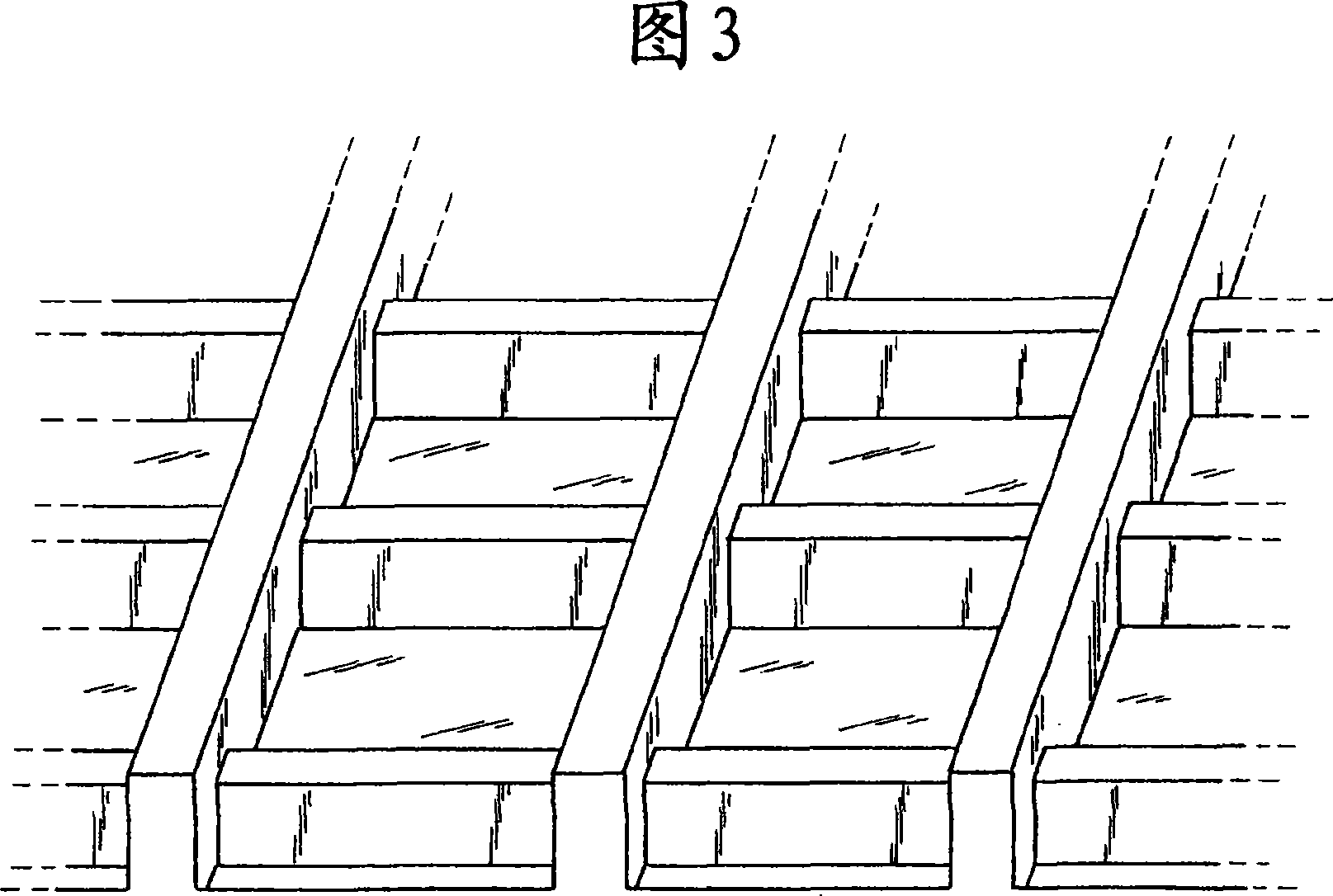

Plasma display panel

InactiveUS20070152591A1Discharge space can be preventedImprove discharge efficiencyElectric discharge tube/lamp manufactureAlternating current plasma display panelsPhosphorEngineering

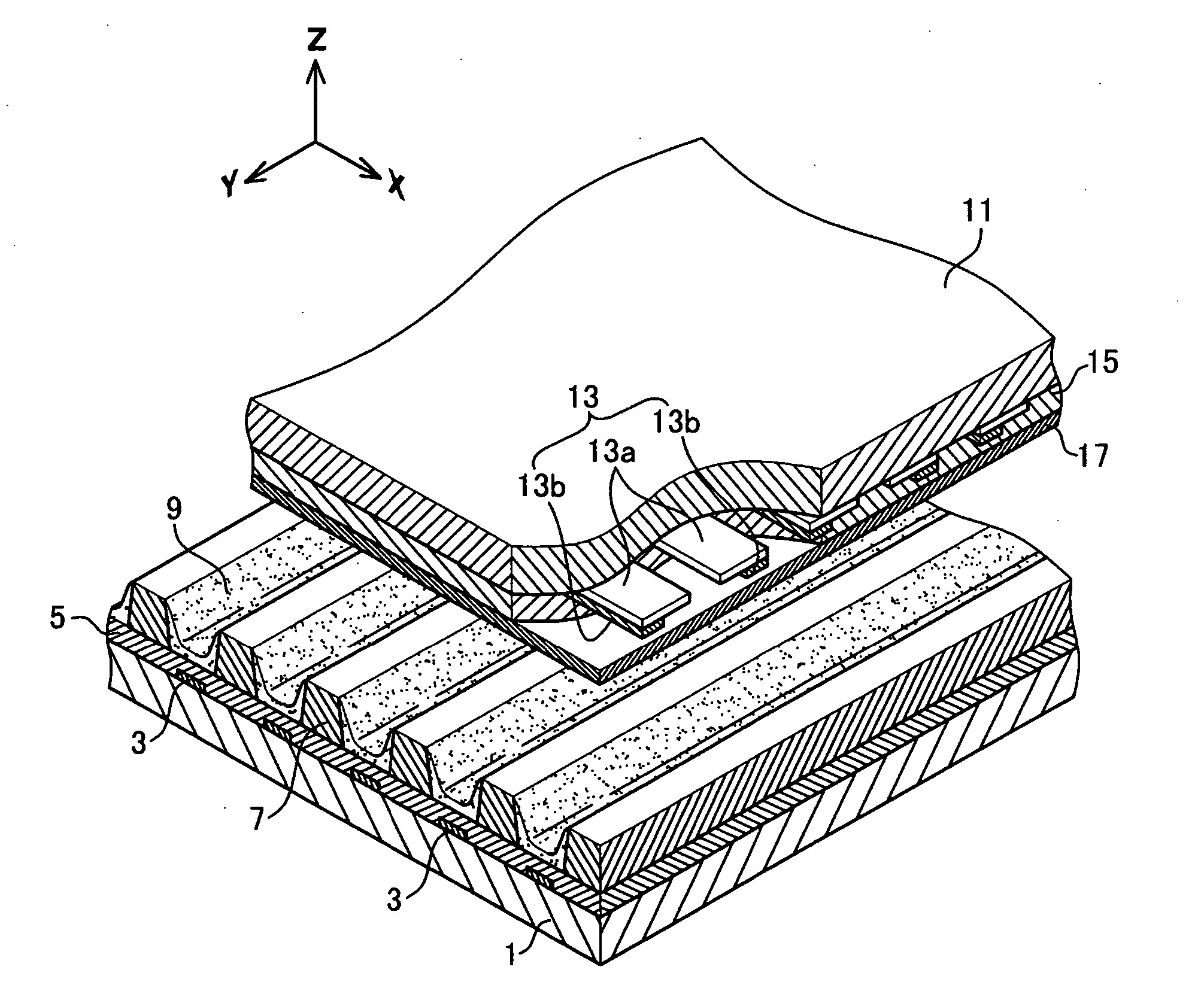

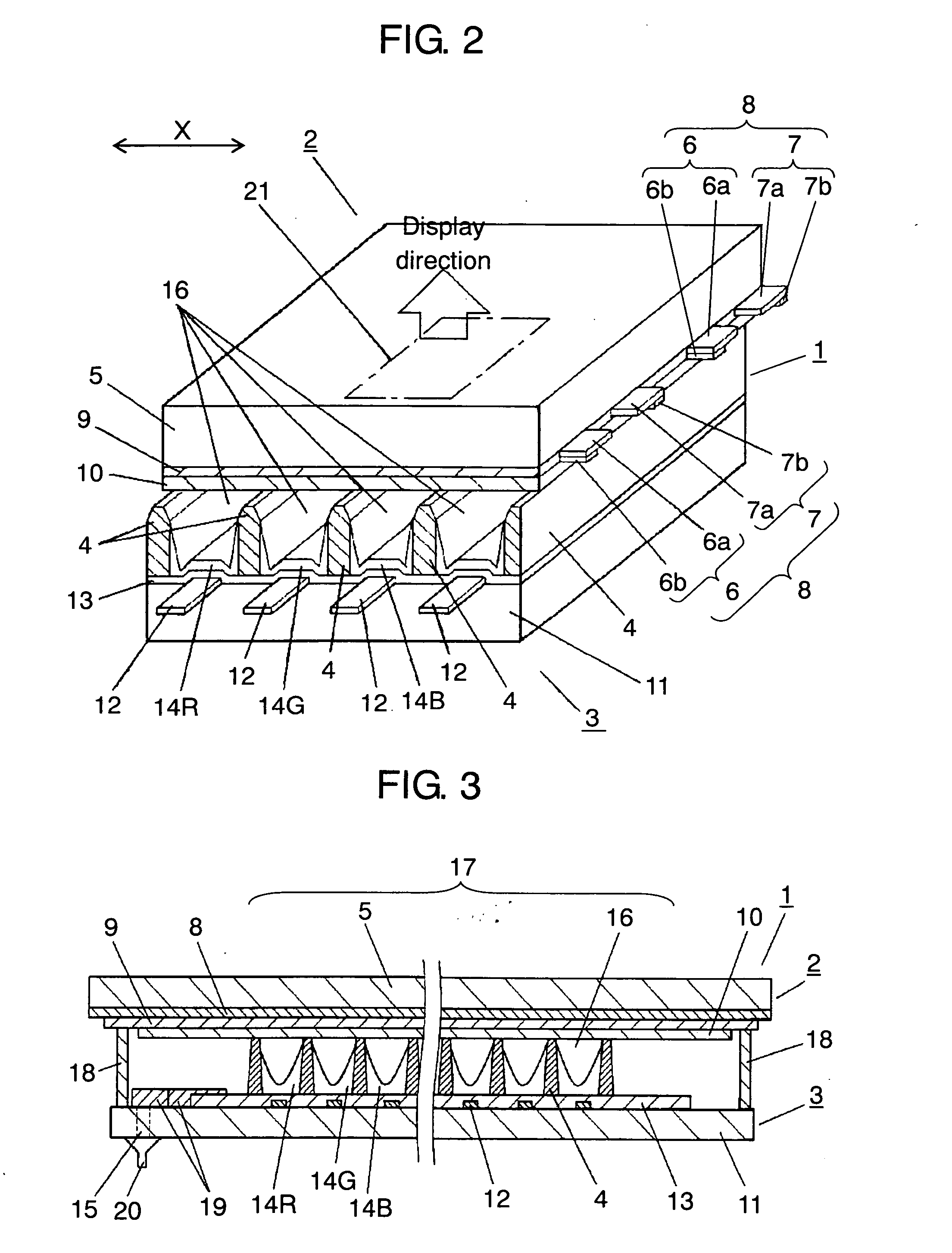

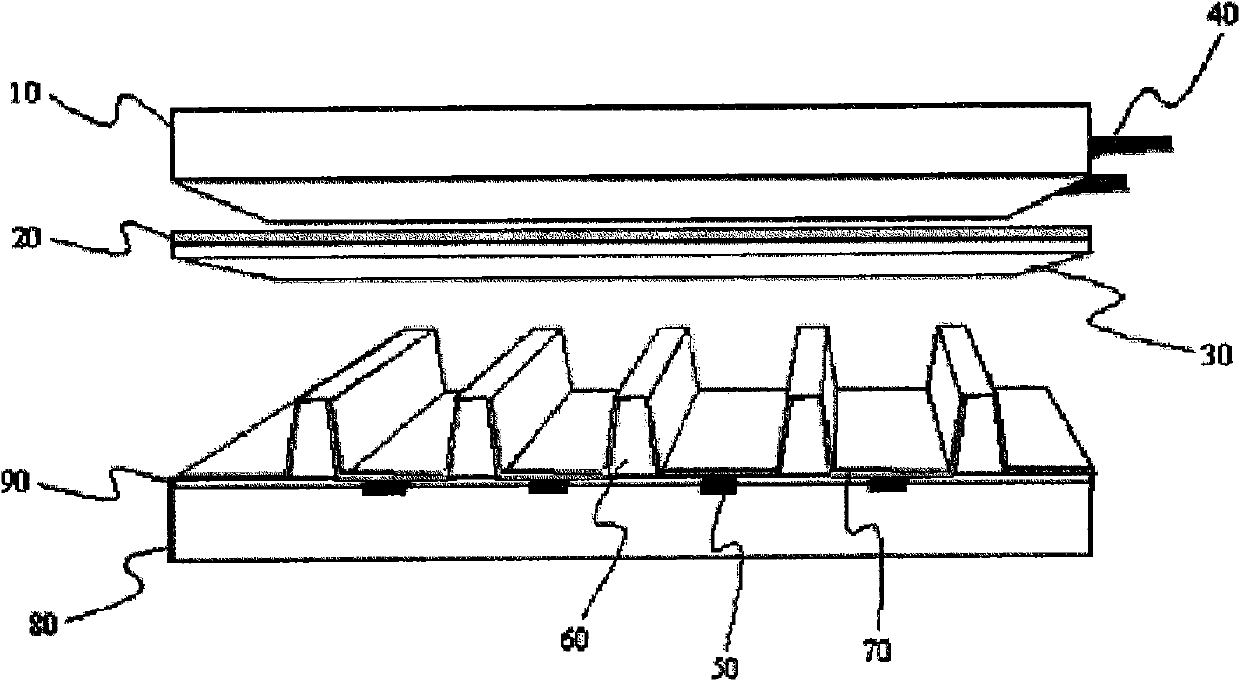

Provided is a plasma display panel that displays images using visible light emitted from phosphor layers formed in discharge cells as a result of discharges in the discharge cells. The plasma display panel includes a first substrate and a second substrate facing each other, a plurality of barrier ribs disposed to define a space into a plurality of discharge cells between the first and second substrates, sustain electrode pairs extending in a direction on the first substrate crossing the discharge cells, address electrodes crossing the sustain electrode pairs, a first dielectric layer covering the sustain electrode pairs, a second dielectric layer covering the address electrodes, phosphor layers formed in the discharge cells, and an adsorption layer formed in the discharge cells to adsorb impurity gasses and moisture in the discharge cells.

Owner:SAMSUNG SDI CO LTD

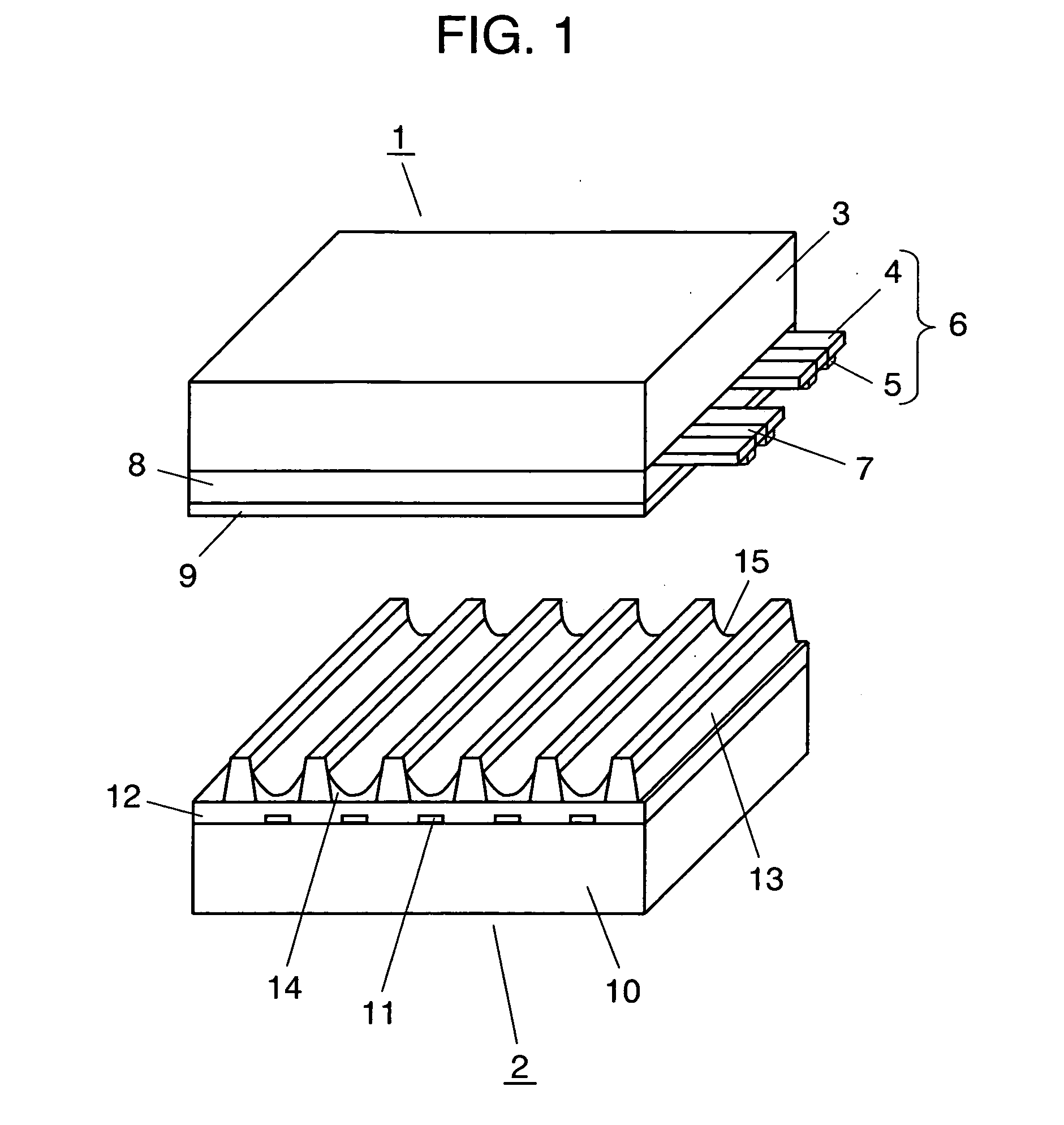

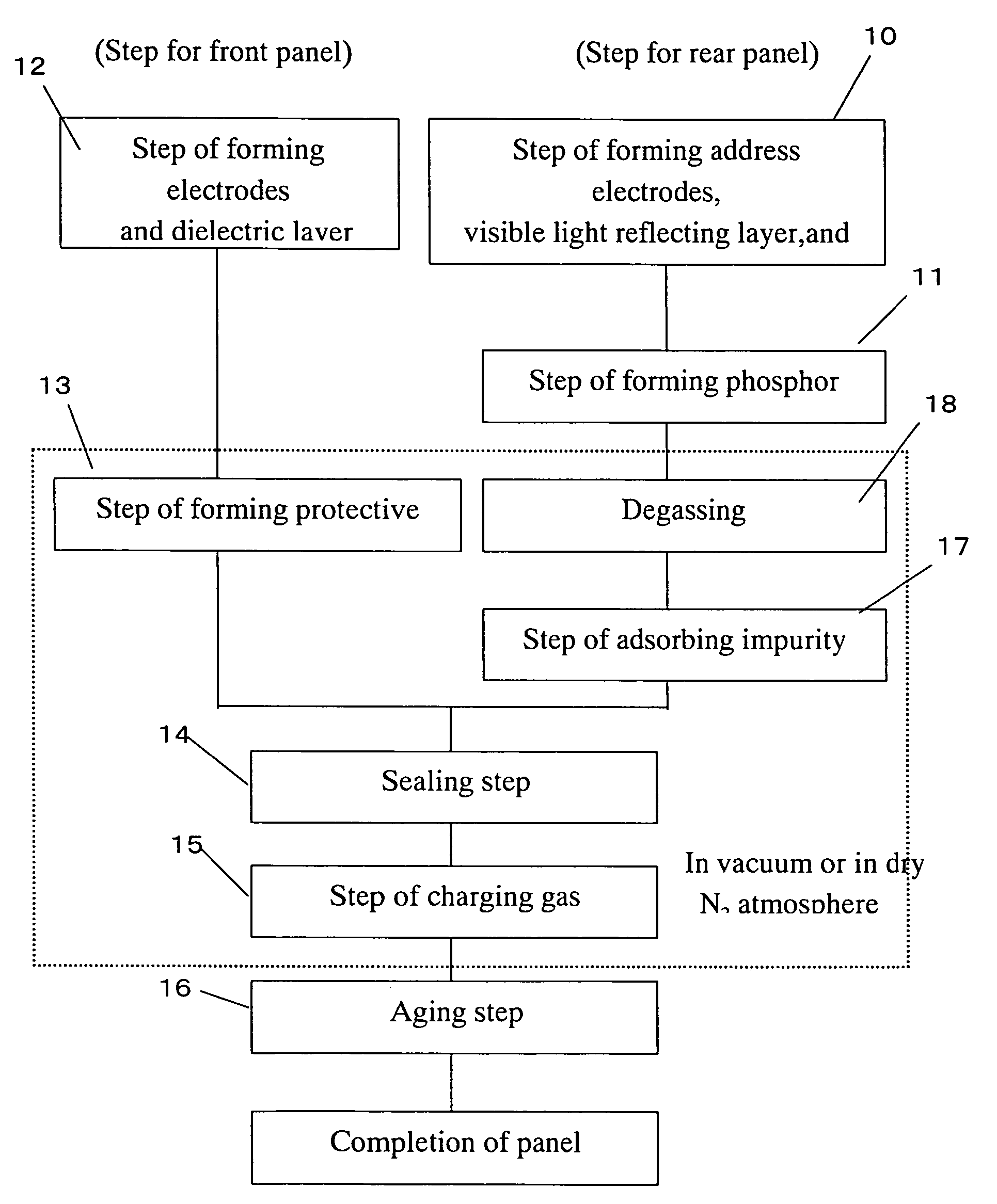

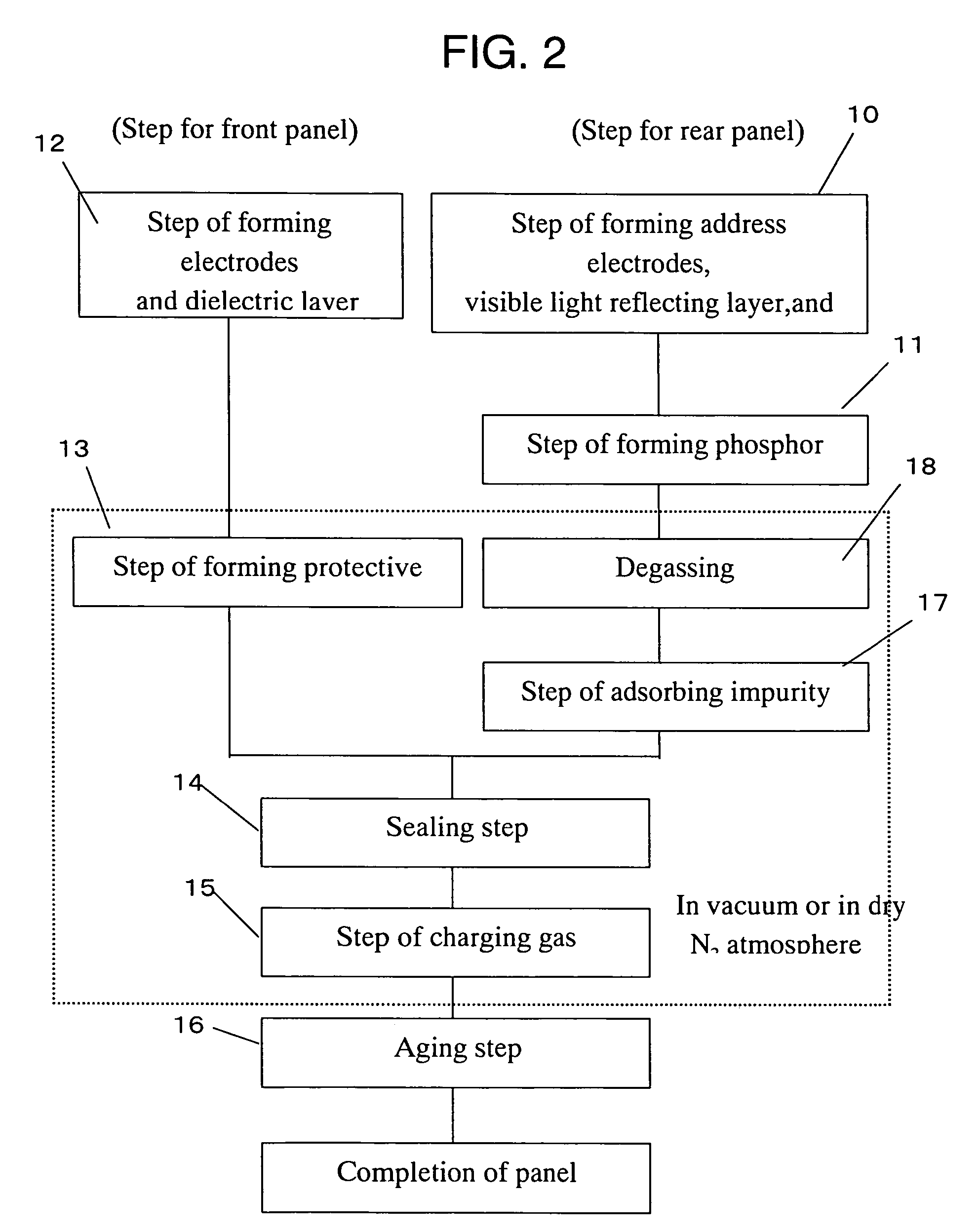

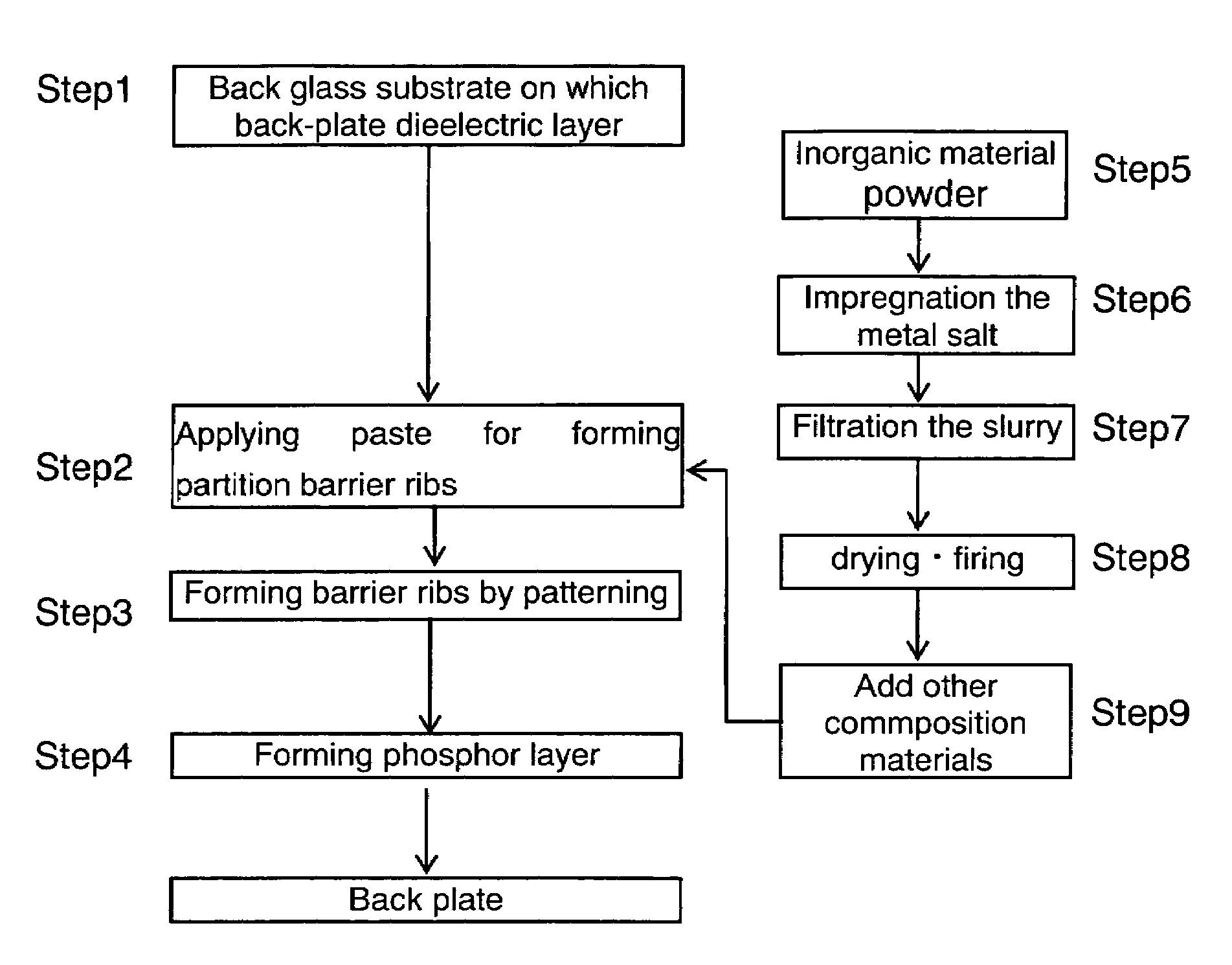

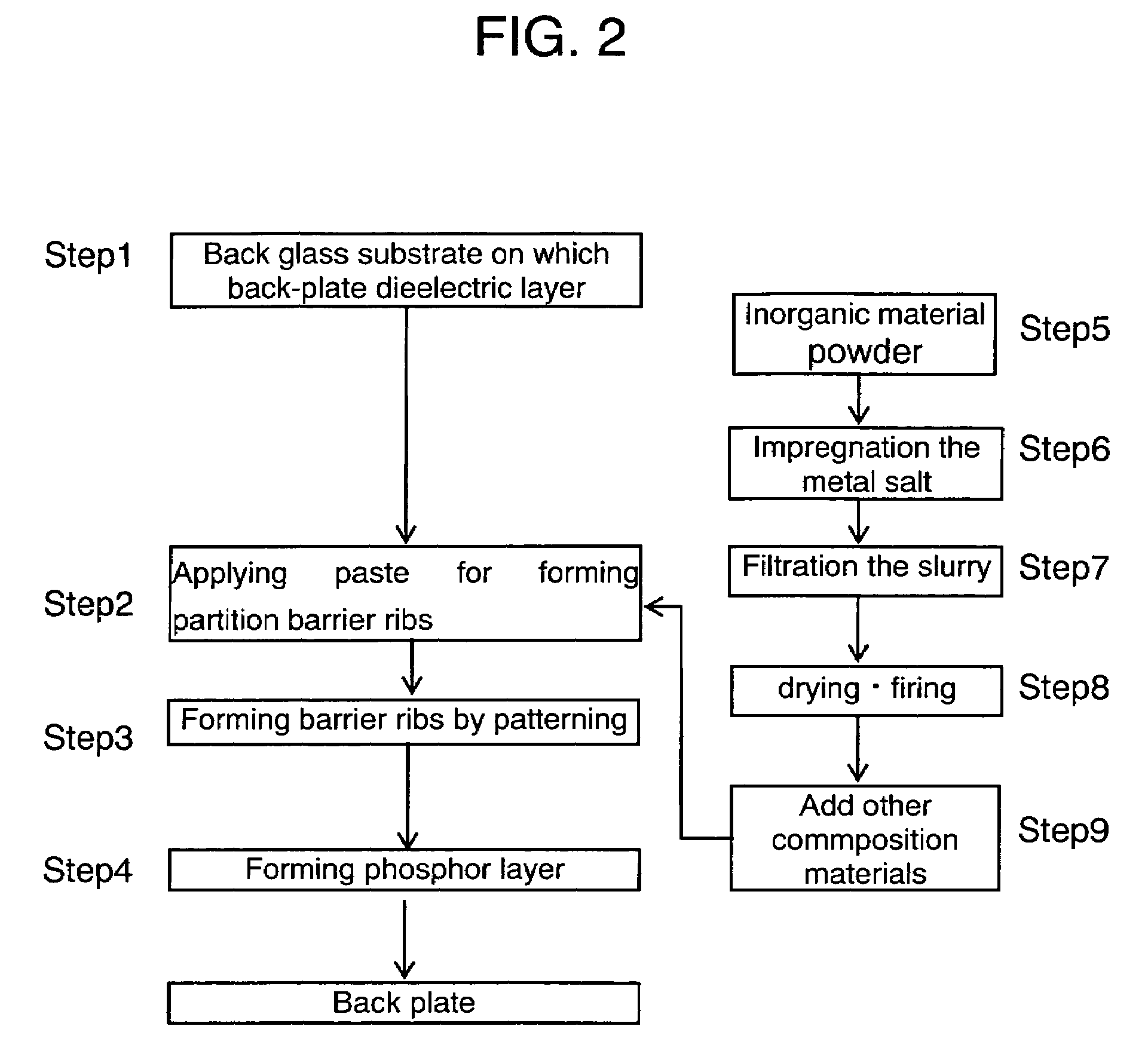

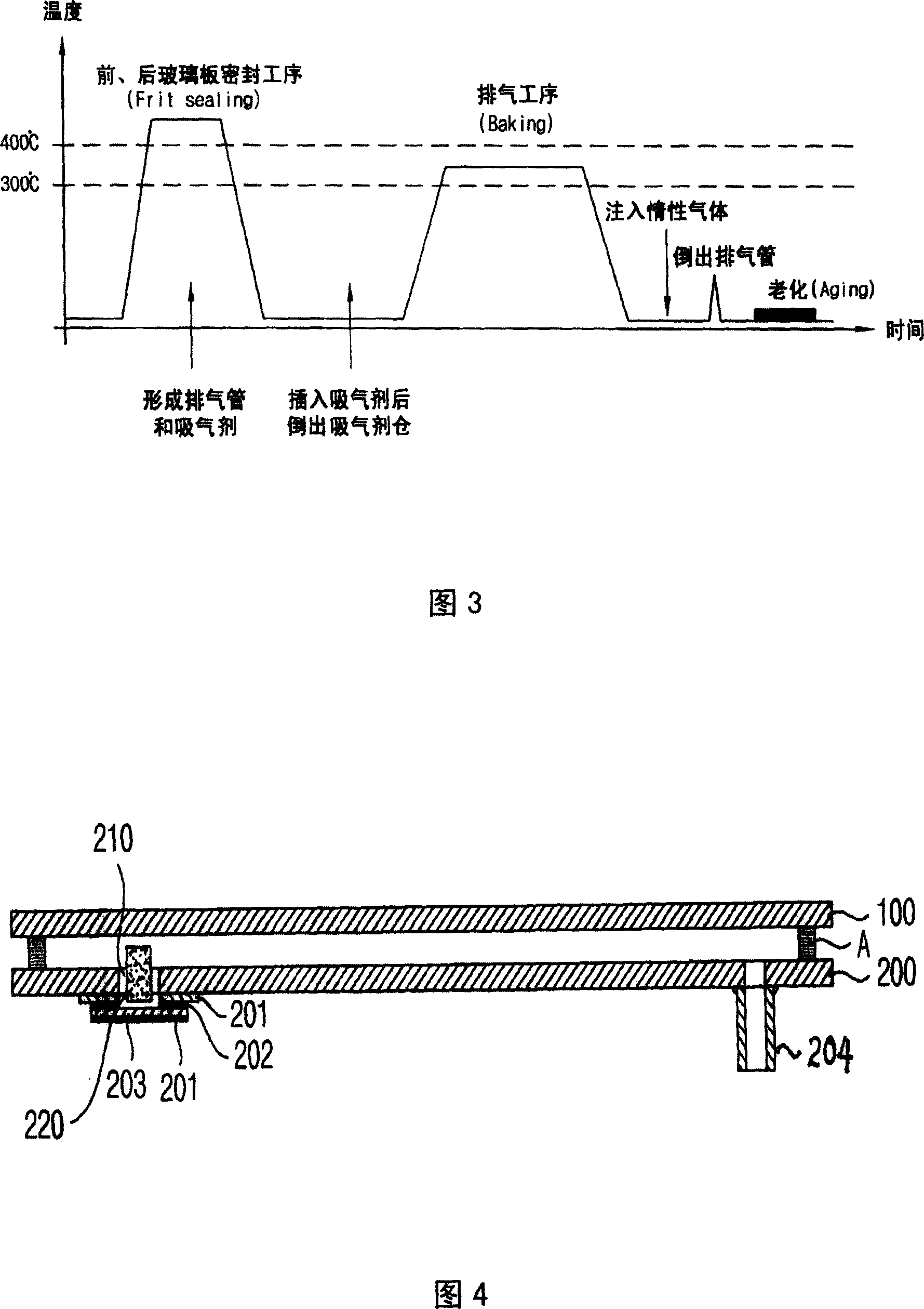

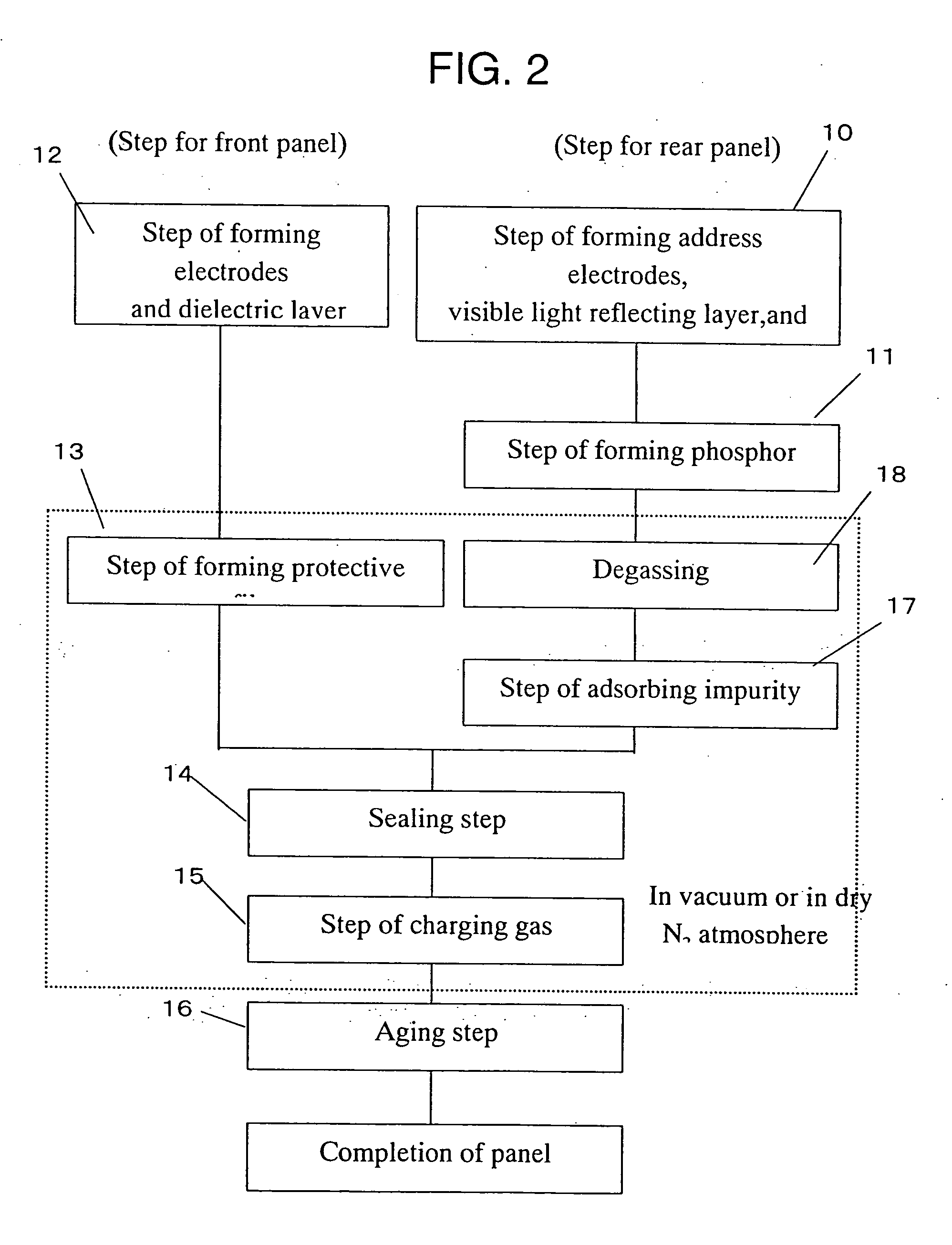

Plasma display panel manufacturing method

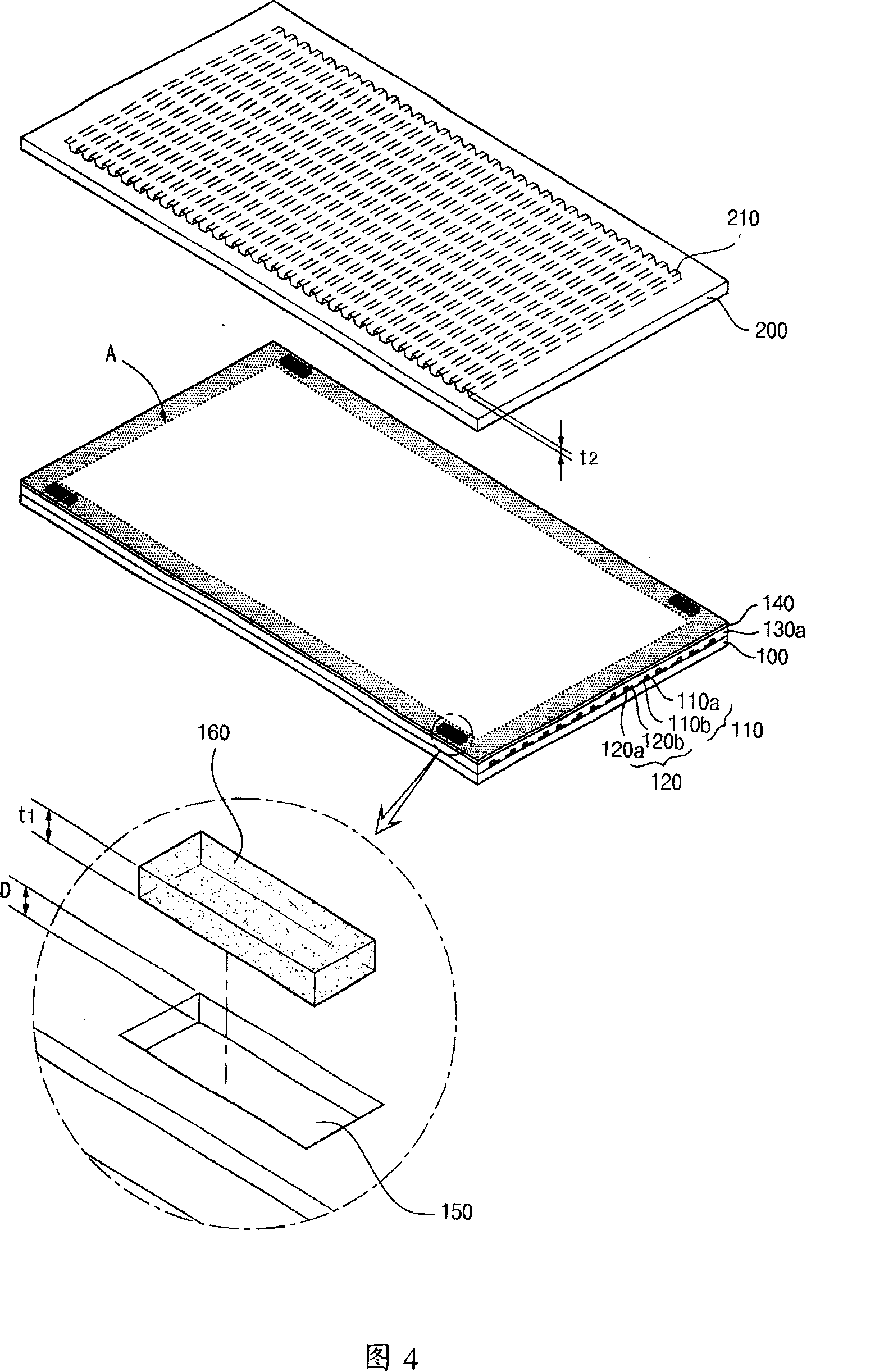

InactiveUS20050093774A1Static indicating devicesAlternating current plasma display panelsPhosphorFluorescence

A method of manufacturing a plasma display panel is disclosed. This method can collect impurity gas in the panel without an activation treatment at a high temperature. The method includes at least one of forming a dielectric layer on a principal face of a substrate, forming barrier ribs which partition a discharging space on the dielectric layer, and forming a phosphor layer between the barrier ribs. At least one of forming the dielectric layer, forming the barrier ribs, and forming the phosphor layer uses inorganic material into which solution including degassing material is impregnated.

Owner:PANASONIC CORP

Plasma display panel

InactiveUS20060152156A1Suppression of phosphor luminance degradationSuppress luminescenceAlternating current plasma display panelsGas mixture absorptionPhosphorEngineering

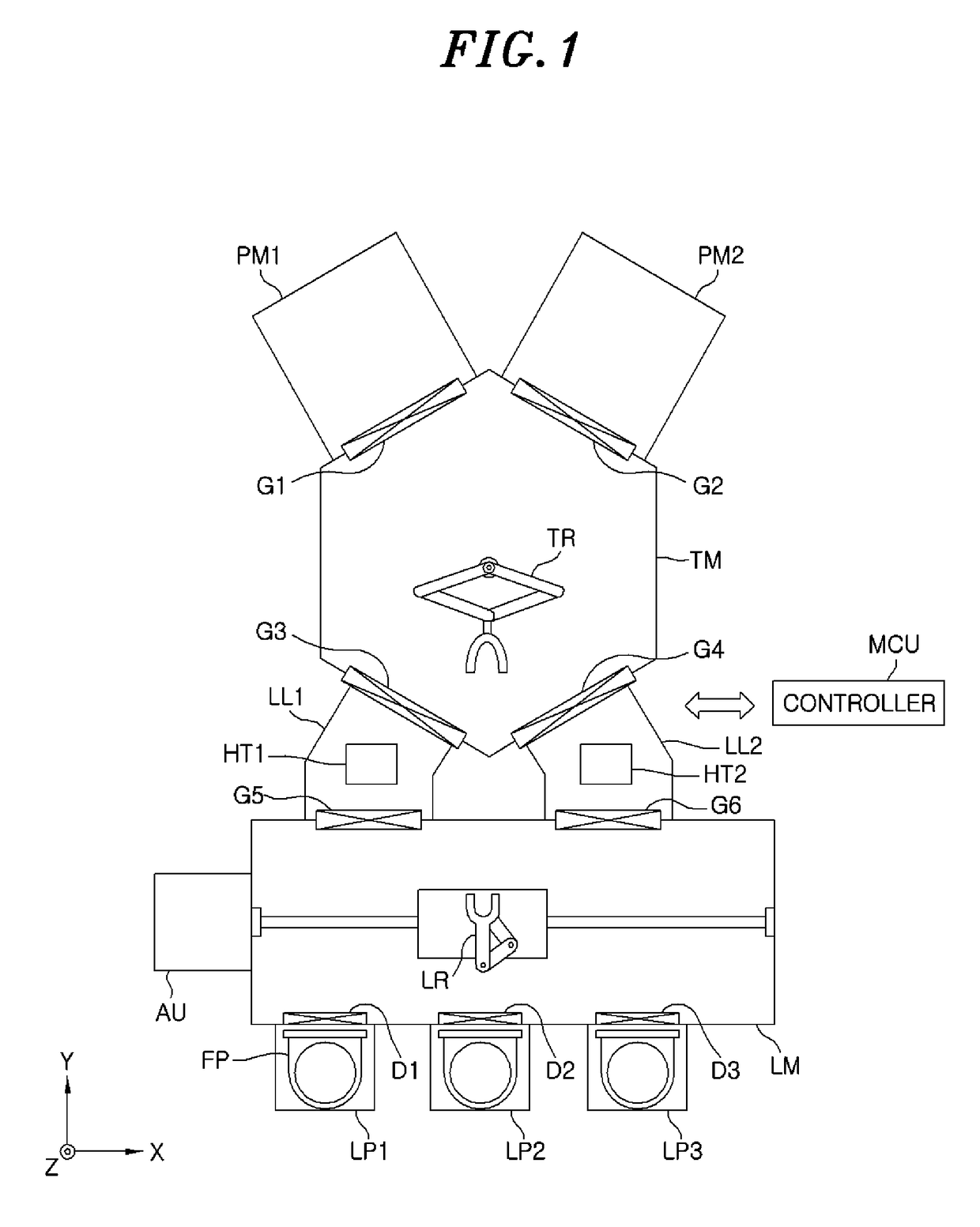

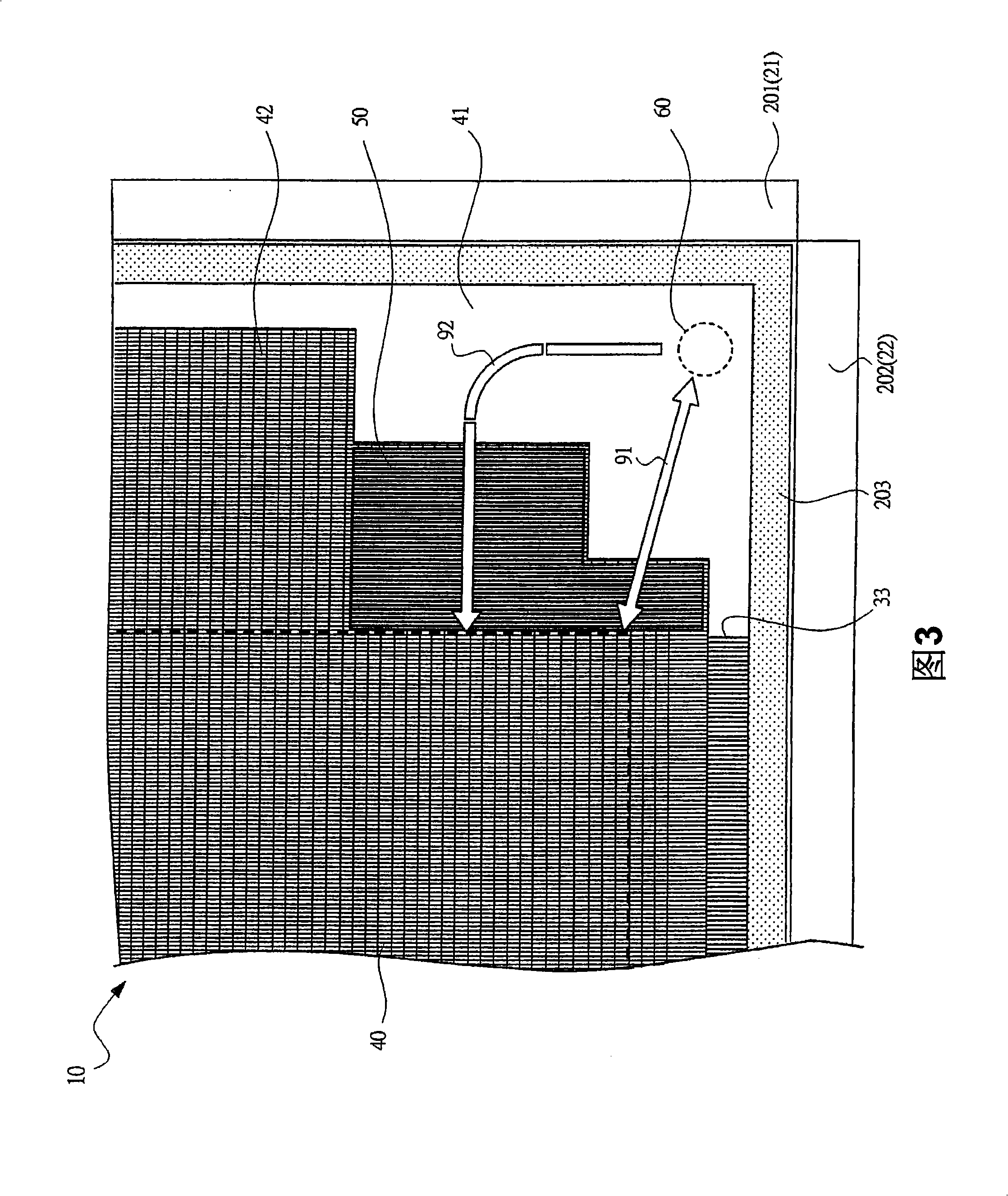

A highly reliable plasma display panel which suppresses degradation of phosphor characteristic by removing impurity gases inside the plasma display panel. A front board includes scanning electrodes and maintenance electrodes. A and rear board includes data electrodes; partitions disposed in parallel and an exhaust hole. The scanning electrodes and maintenance electrodes of the front board and the data electrode of rear board cross. A non-evaporating getter such as zeolite is disposed inside plasma display panel near the exhaust hole.

Owner:PANASONIC CORP

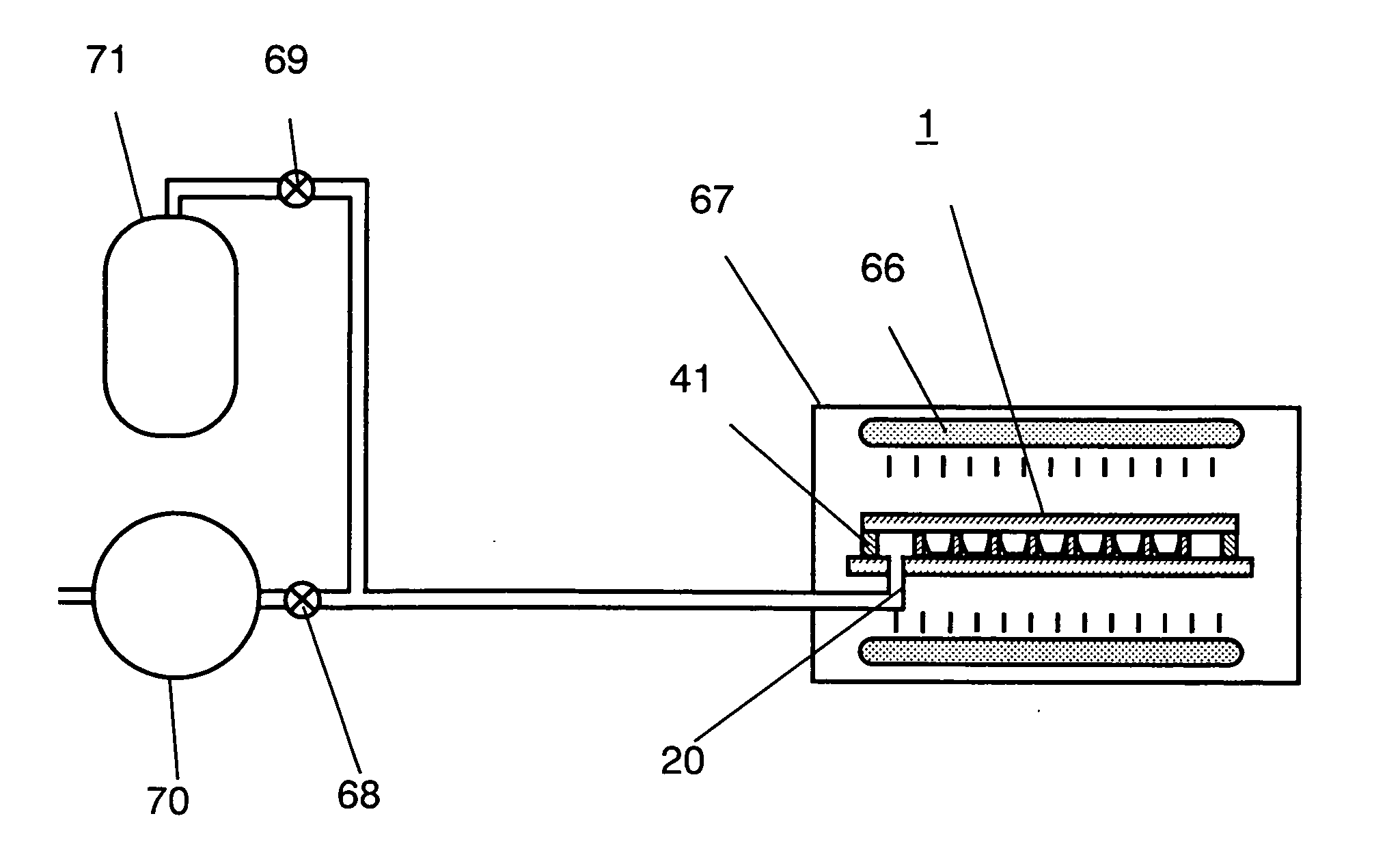

Method of manufacturing a plasma display panel with adsorbing an impurity gas

InactiveUS7037156B2Many of characteristicReduce voltageTube/lamp vessel degassingTube/lamp vessel fillingPhosphorHigh luminance

A plasma display panel capable of realizing improvement in the characteristics thereof, such as lower discharge voltage, more stable discharge, higher luminance, higher efficiency, and longer life. Before a step of sealing the periphery of substrates, impurity gas containing CO2, H2O and CH4 is other then inert gas is adsorbed by phosphor layers. The impurity gas is released into discharge gas and while the panel is lit. This method can realize improvement in characteristics, such as lower discharge voltage, higher luminance, higher efficiency, and longer life.

Owner:PANASONIC CORP

Plasma display panel

Owner:SAMSUNG SDI CO LTD

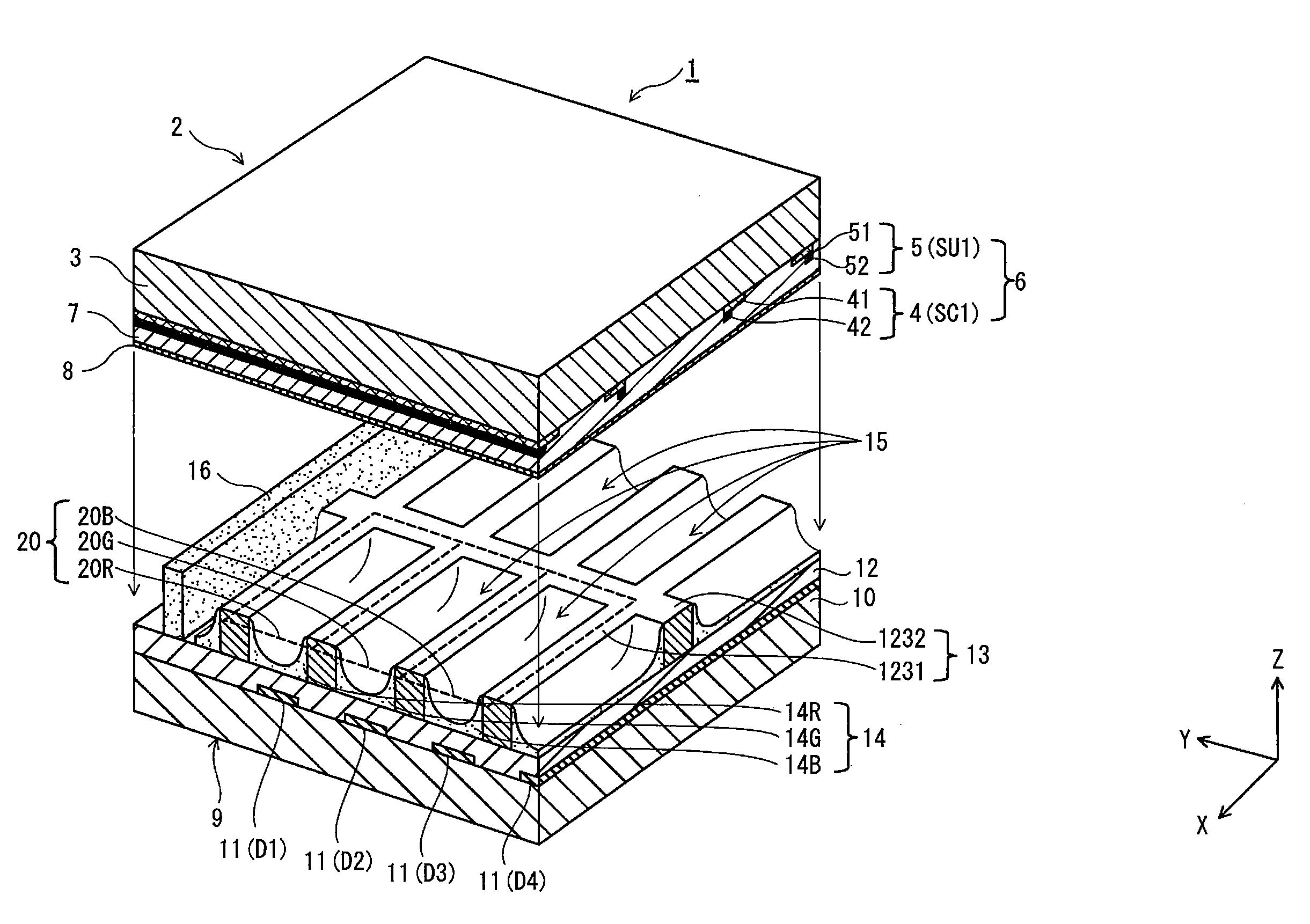

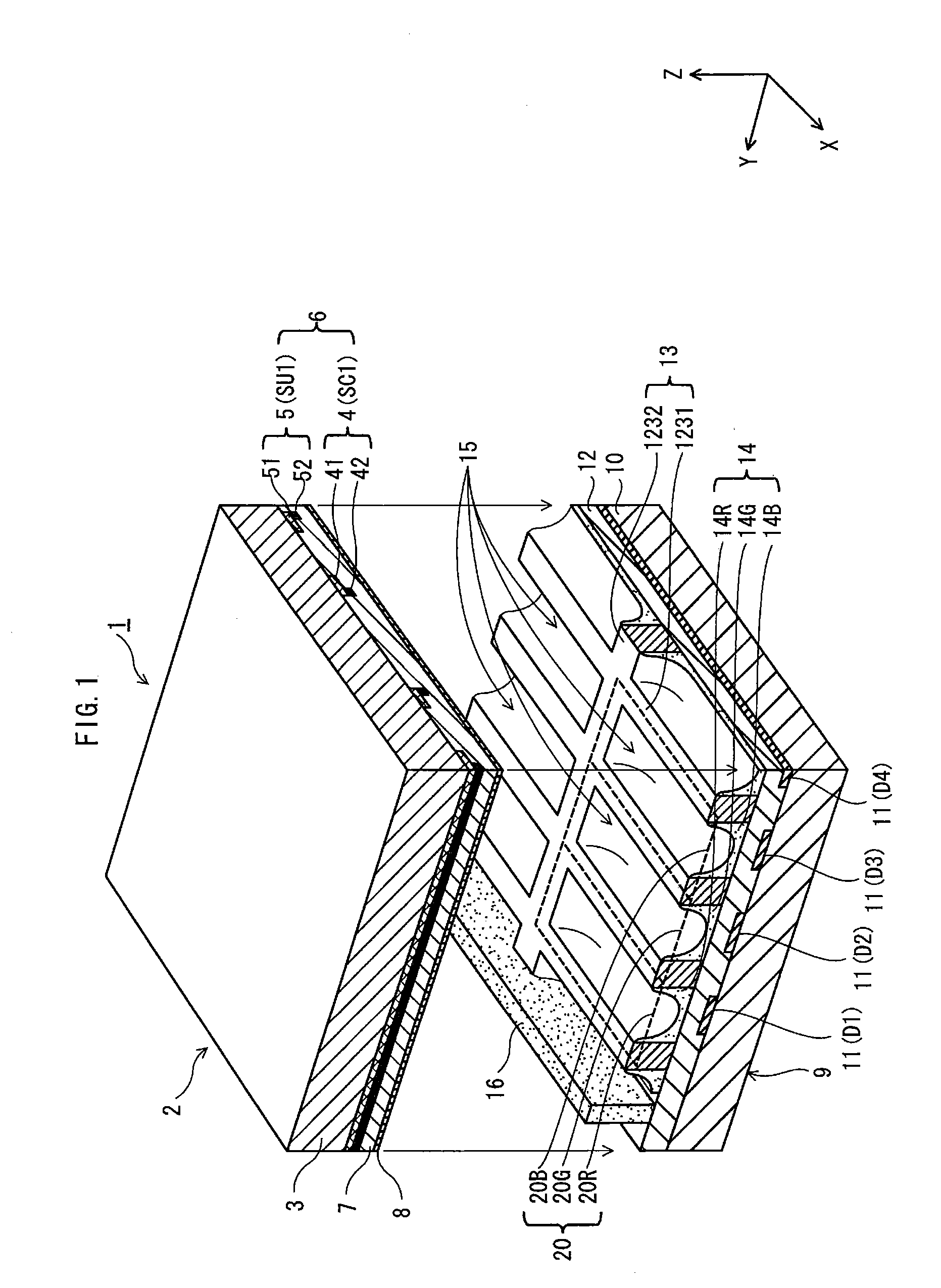

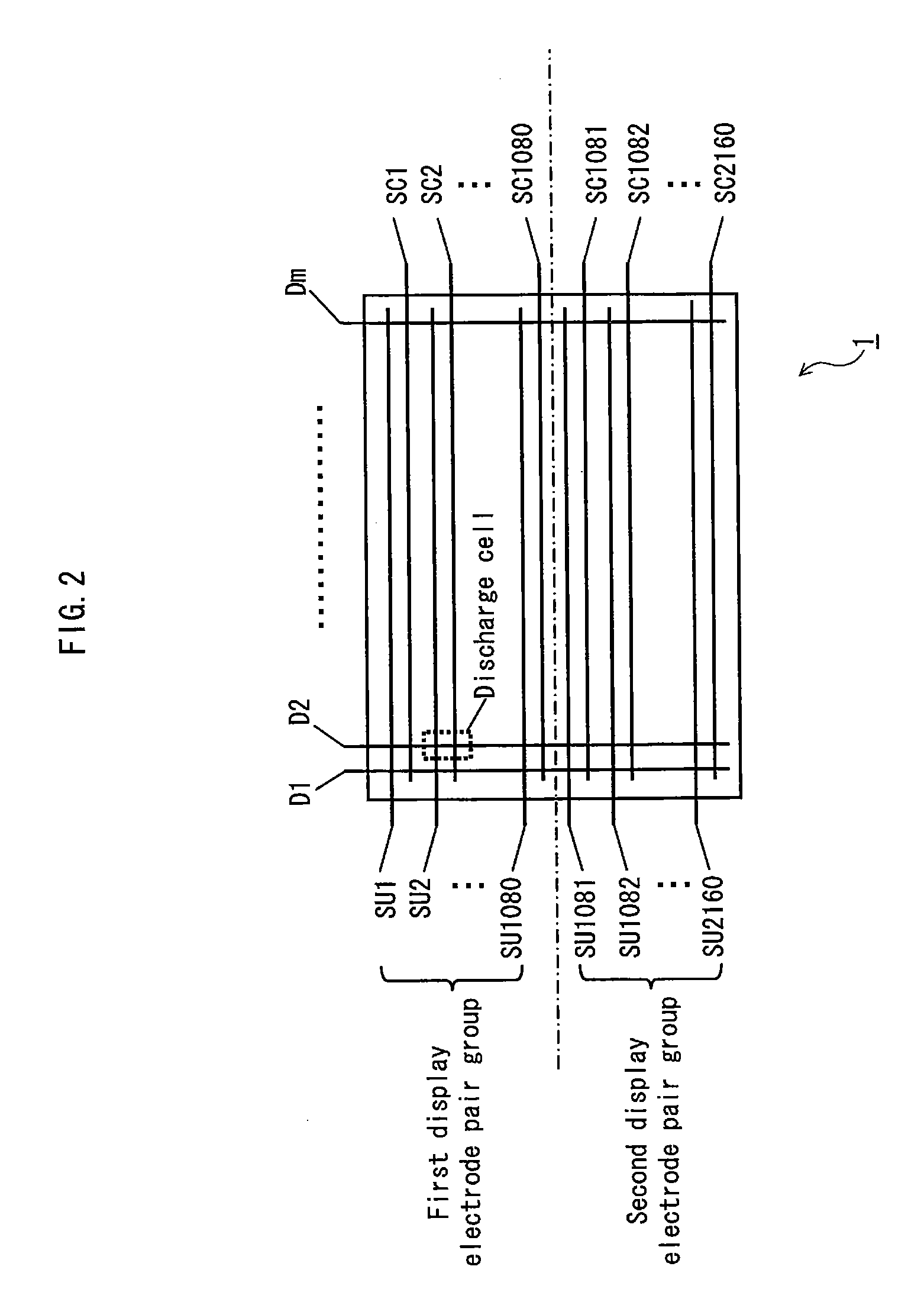

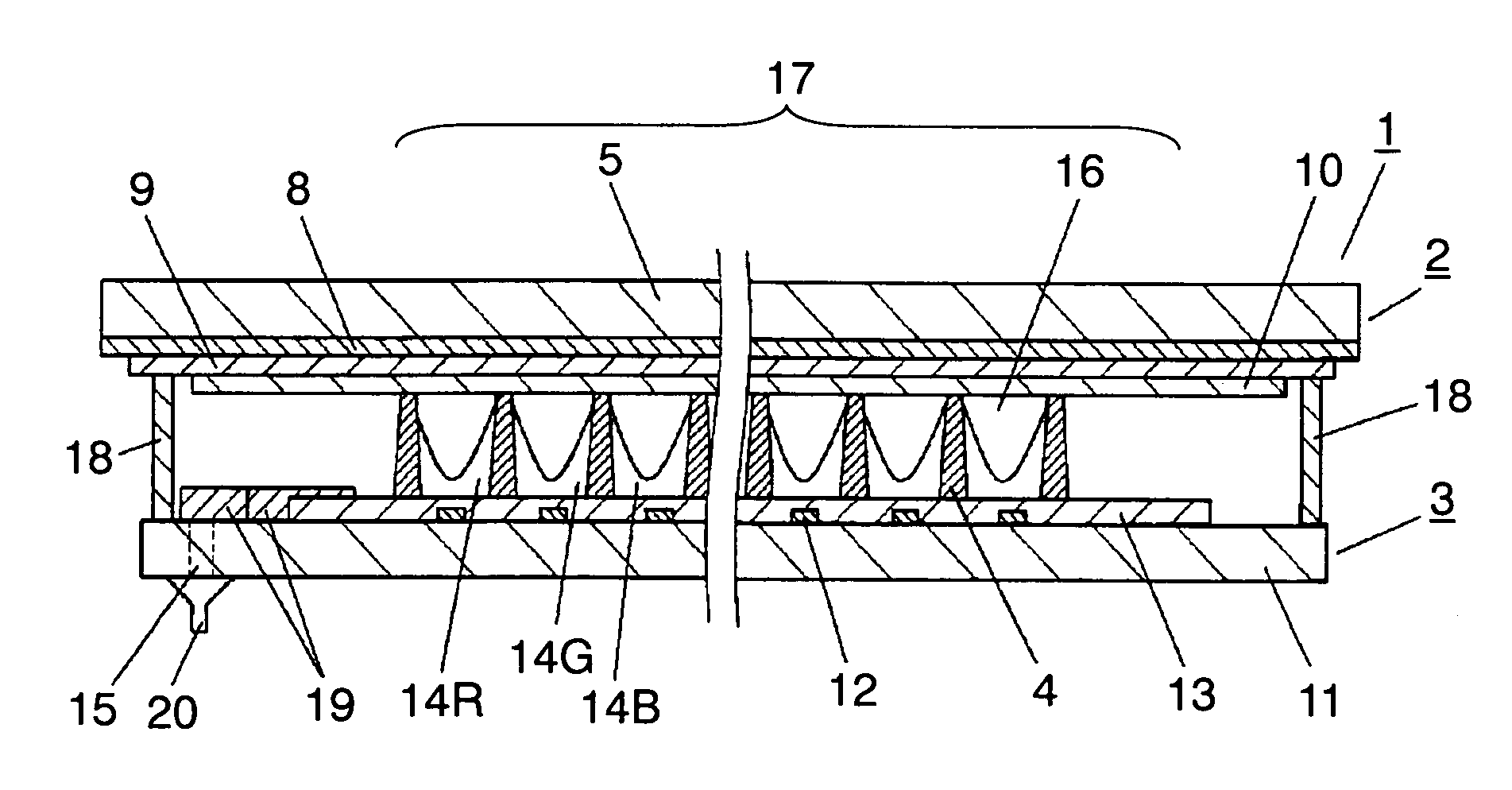

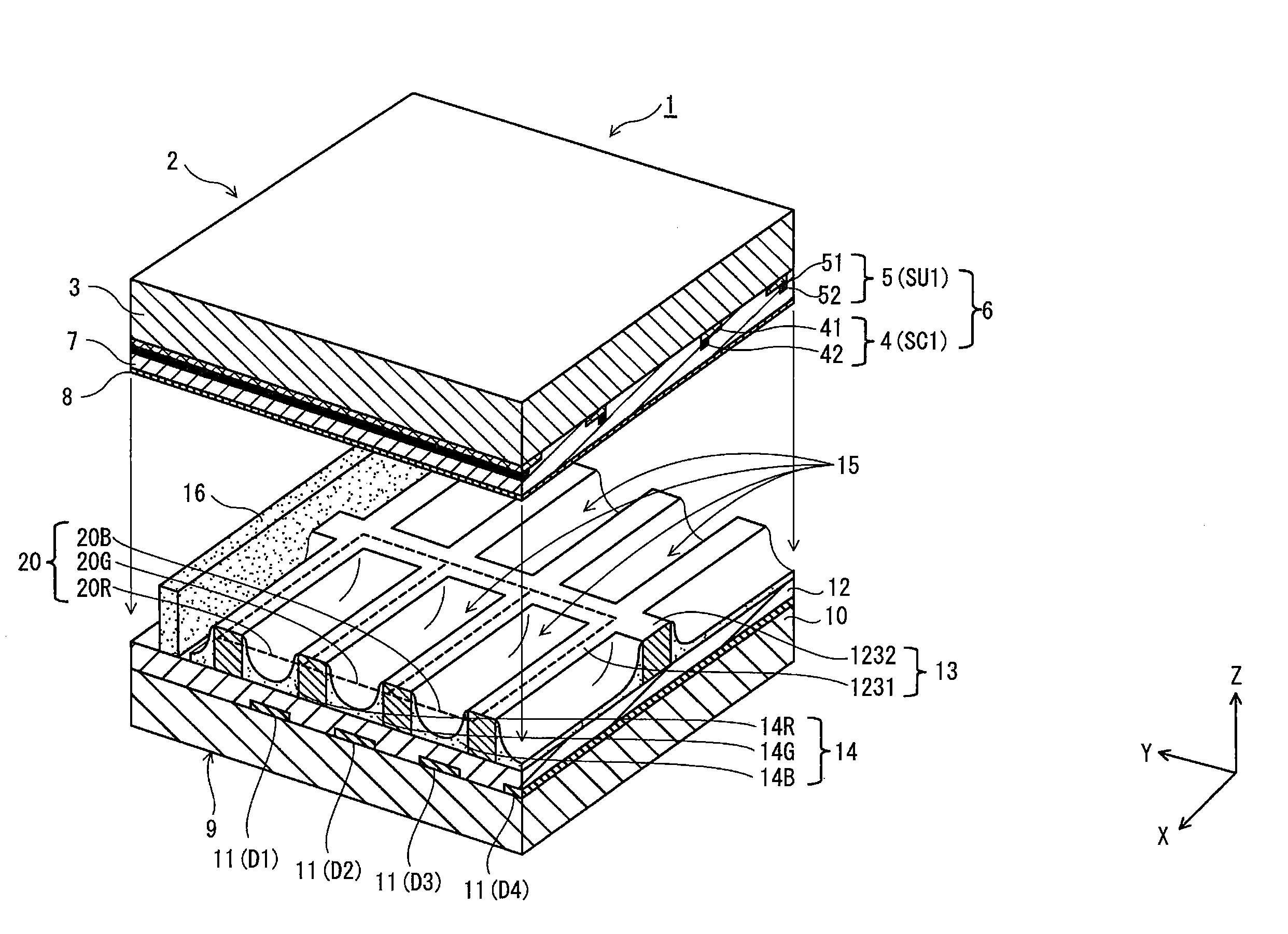

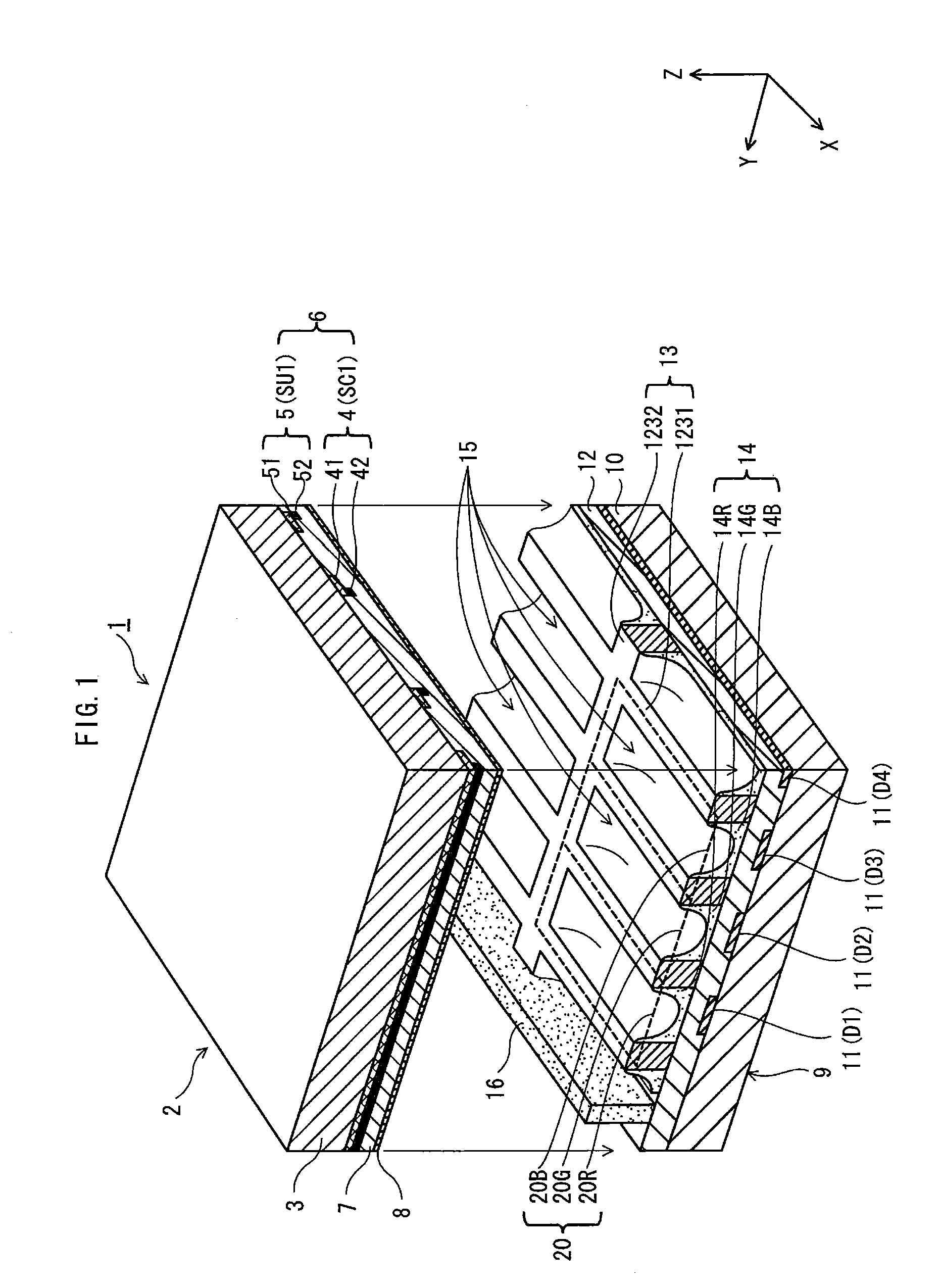

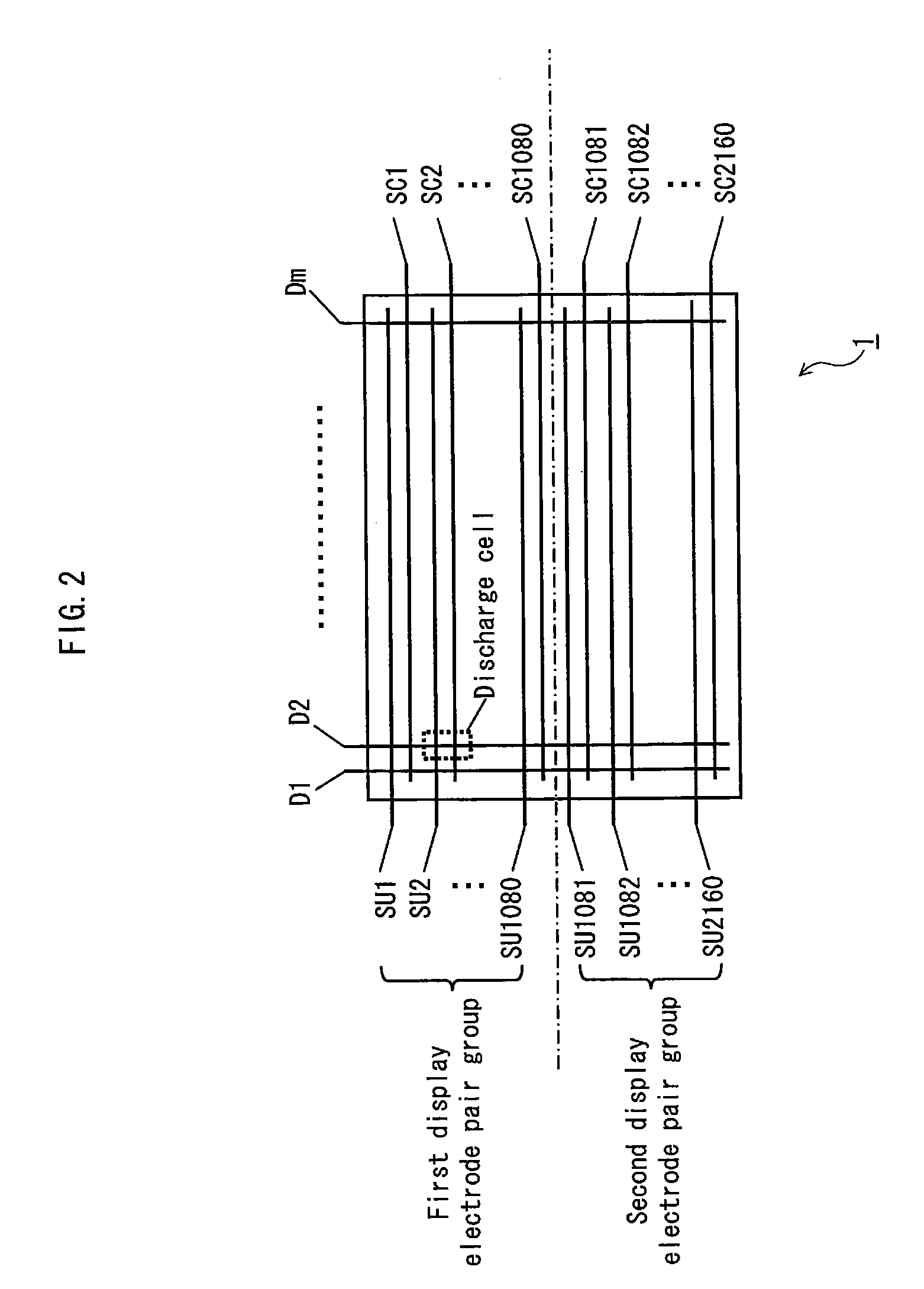

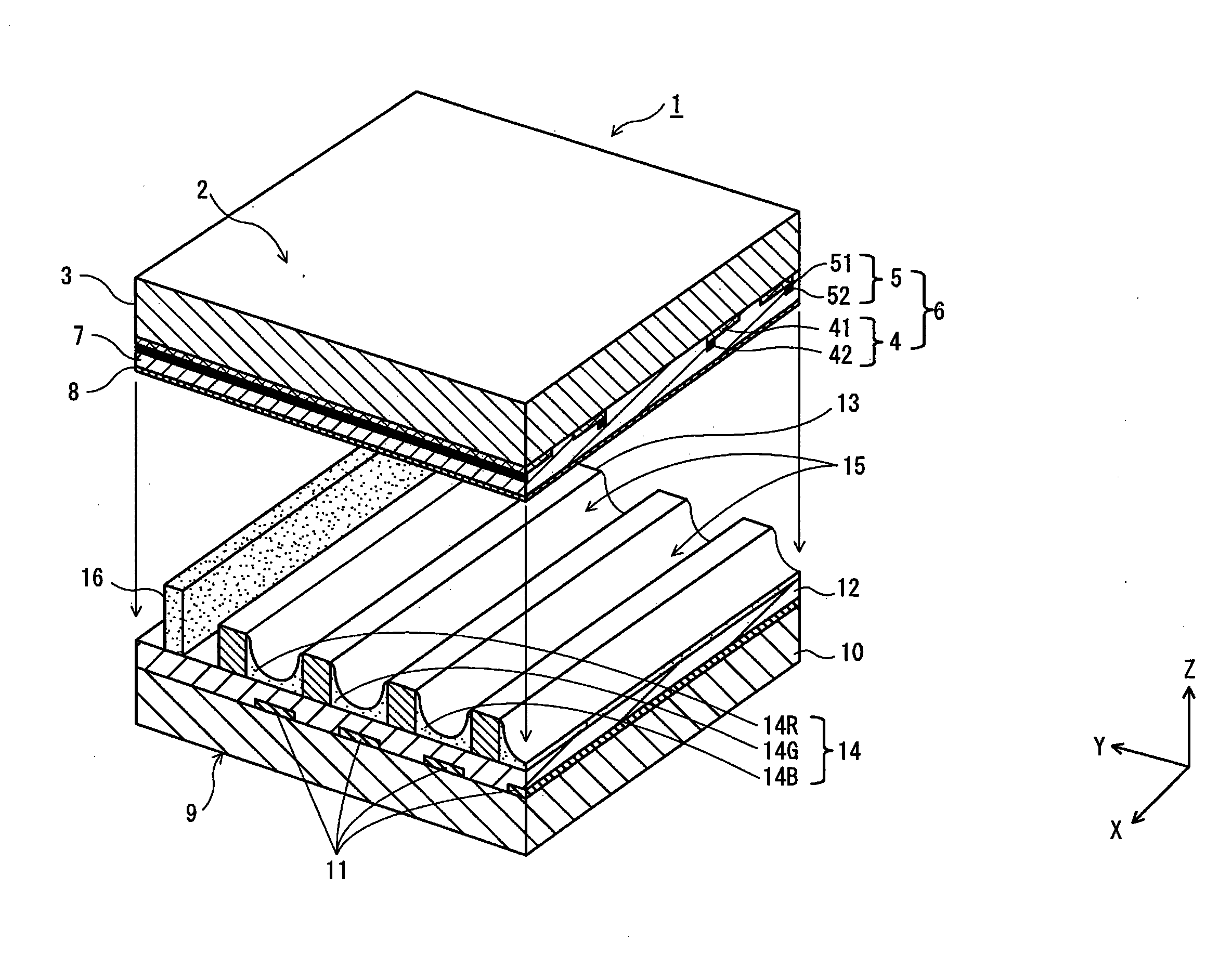

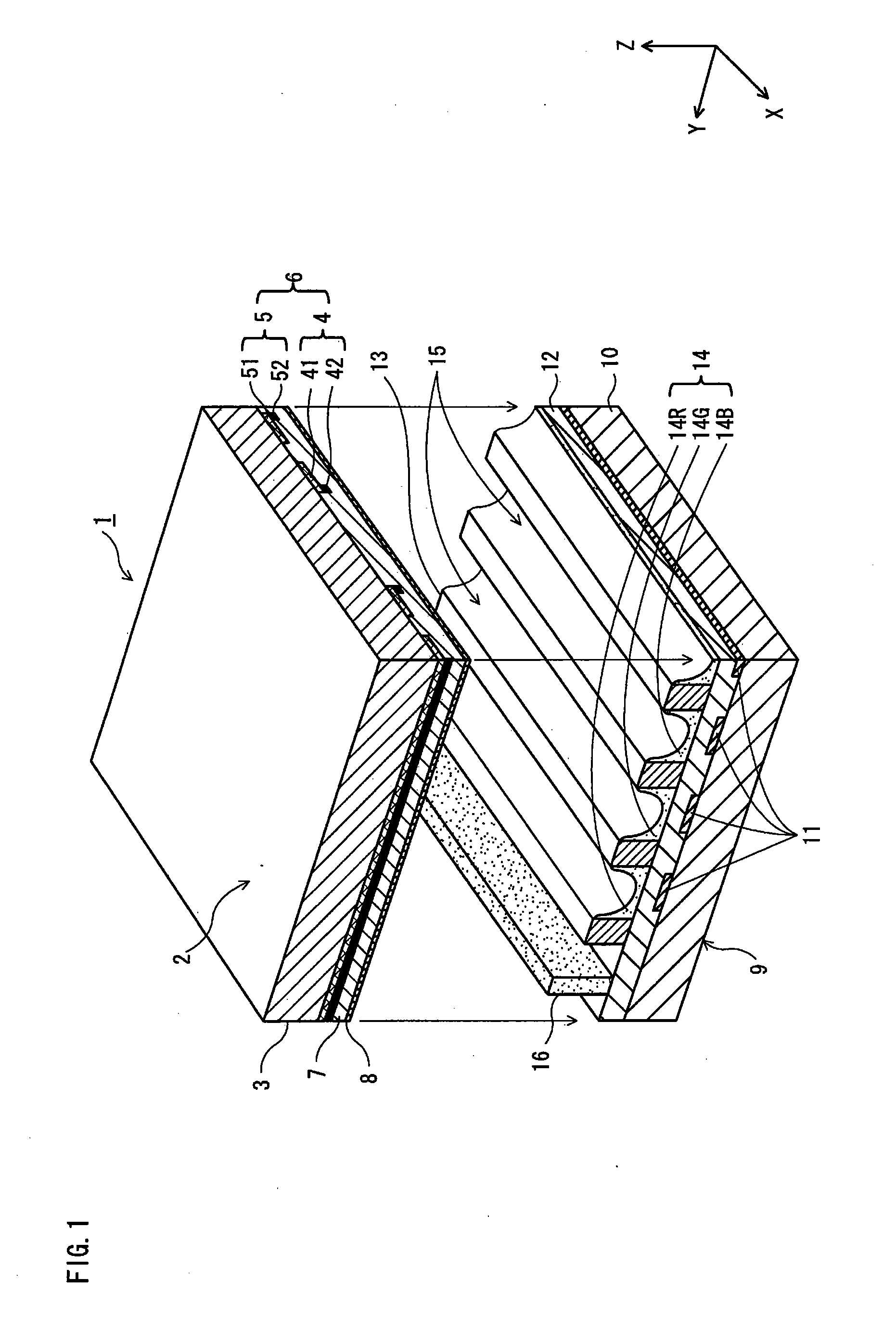

Plasma display panel and imaging device using the same

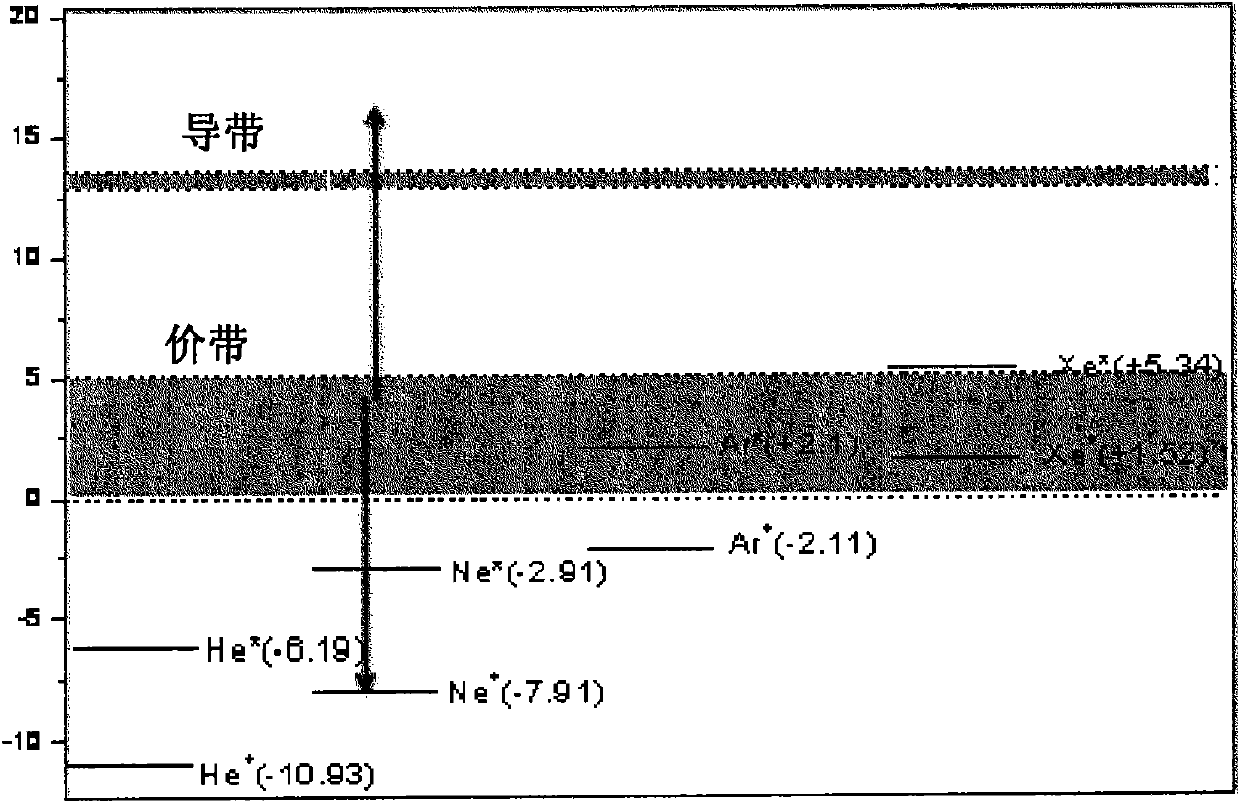

InactiveUS7071901B2Improve luminous efficiencyLong lastingAddress electrodesSustain/scan electrodesVoltage pulseTorr

Owner:MAXELL HLDG LTD

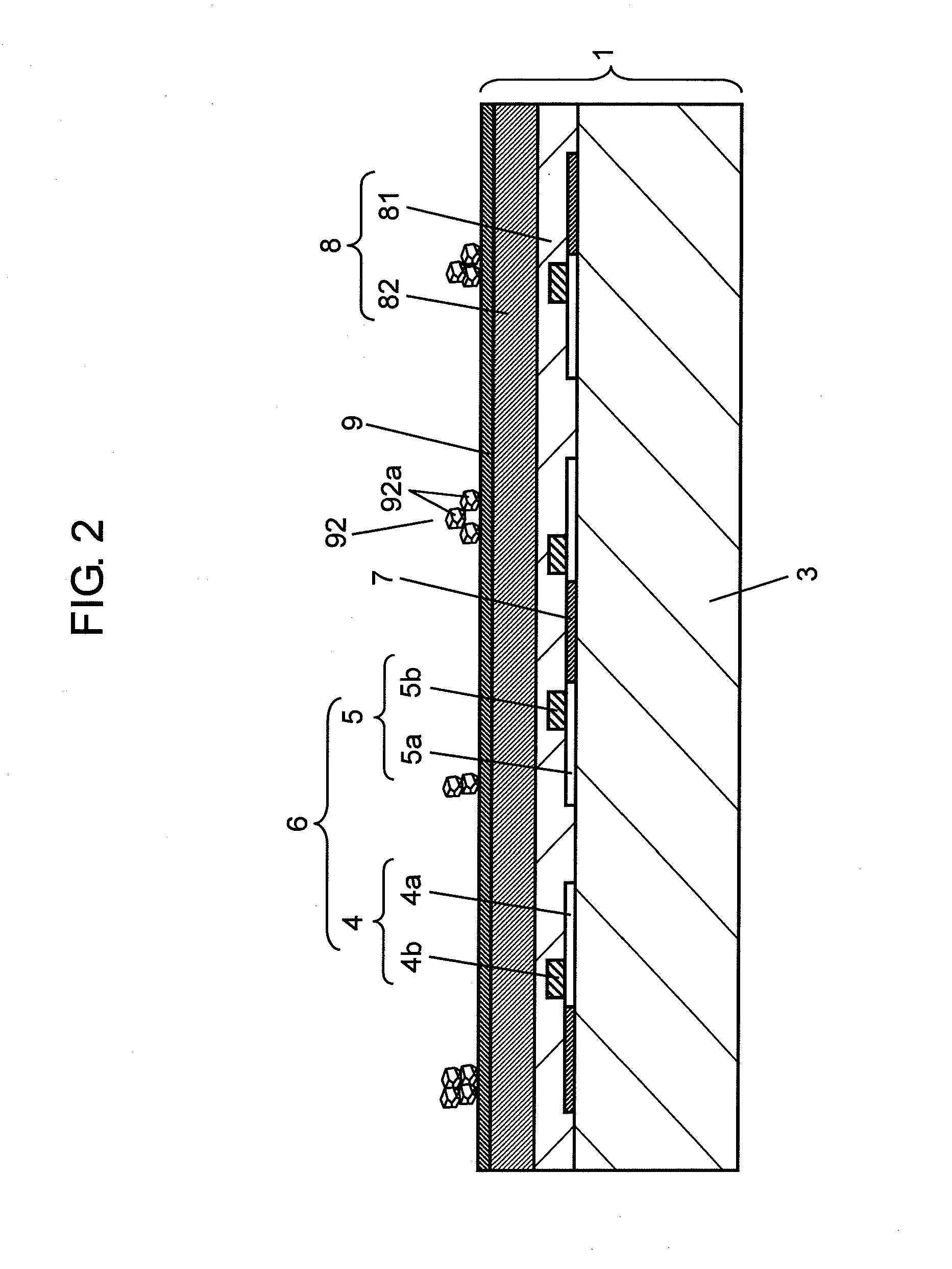

Process for the Production of Plasma Displays with Distributed Getter Material and Displays Thus Obtained

InactiveUS20080020668A1Simple manufacturing processOvercomes shortcomingDischarge tube luminescnet screensTube/lamp vessel degassingDisplay deviceGetter

A manufacturing process for the production of plasma display panels is provided which allows obtaining in a simple way displays in which getter materials deposits are present in contact with the atmosphere present in channels or cells of the display. The process includes a step of forming the getter material deposits on a free surface of the magnesium oxide layer at positions essentially corresponding to contact areas between the front glass panel and the barriers on the rear glass panel of the display panel.

Owner:SAES GETTERS SPA

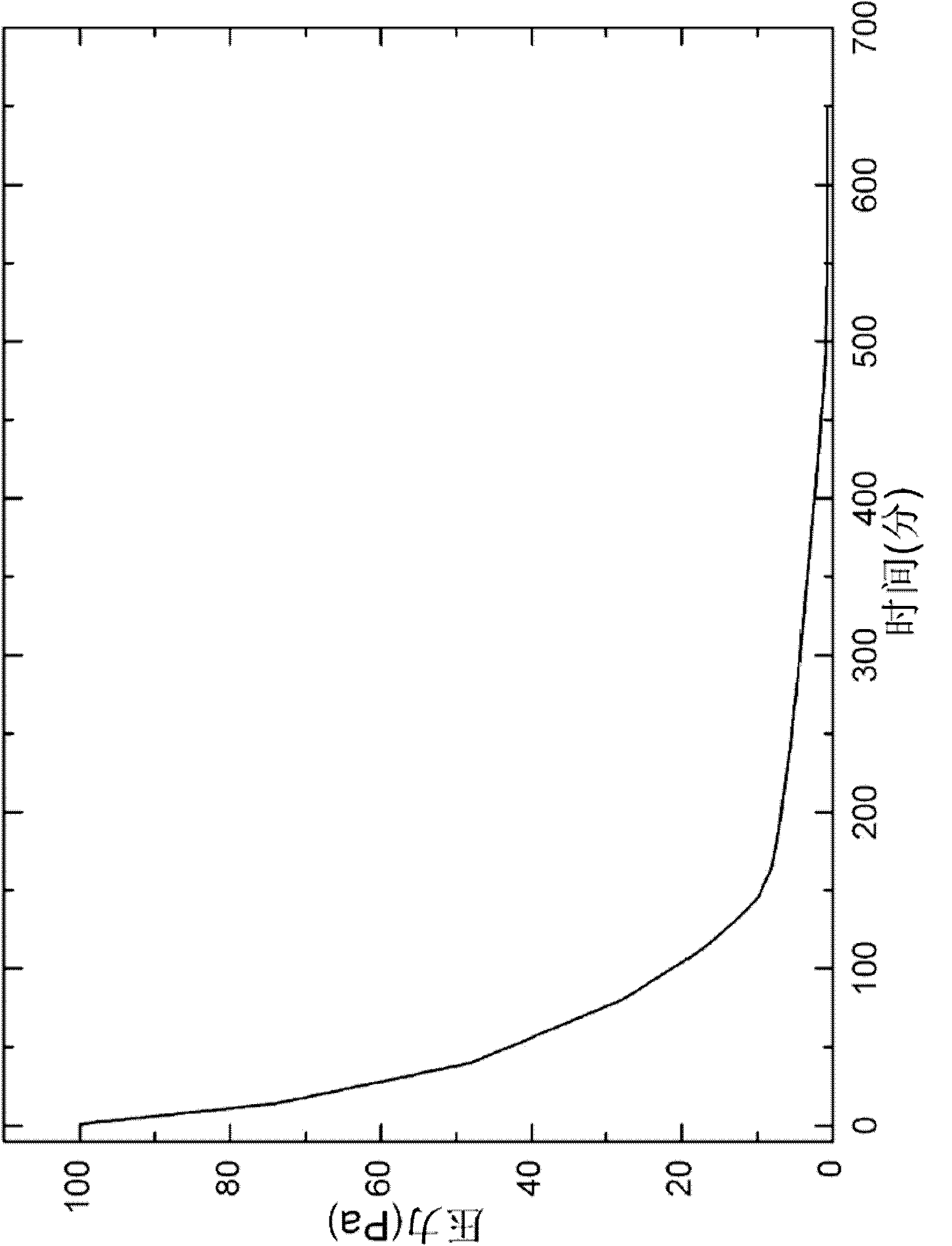

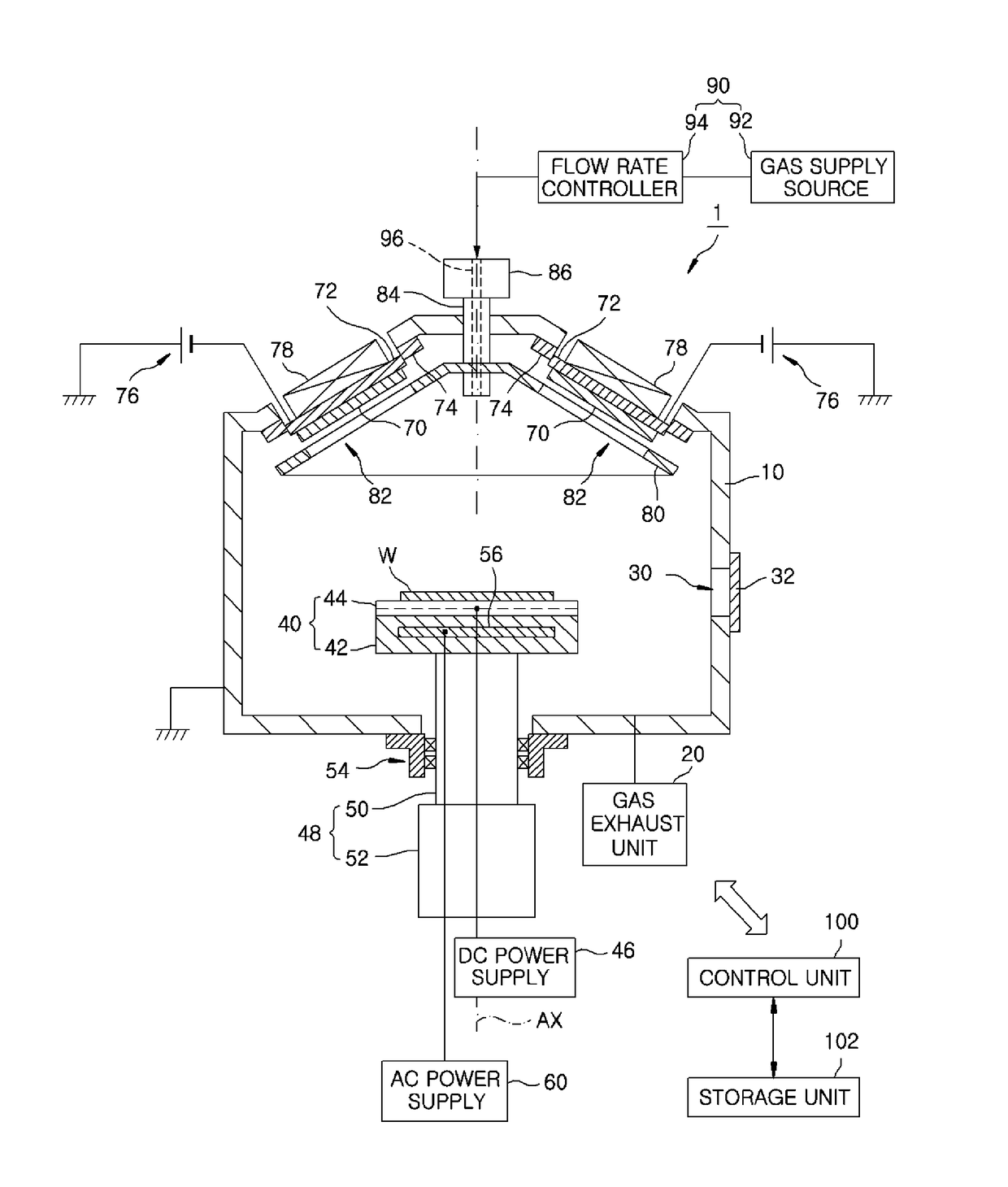

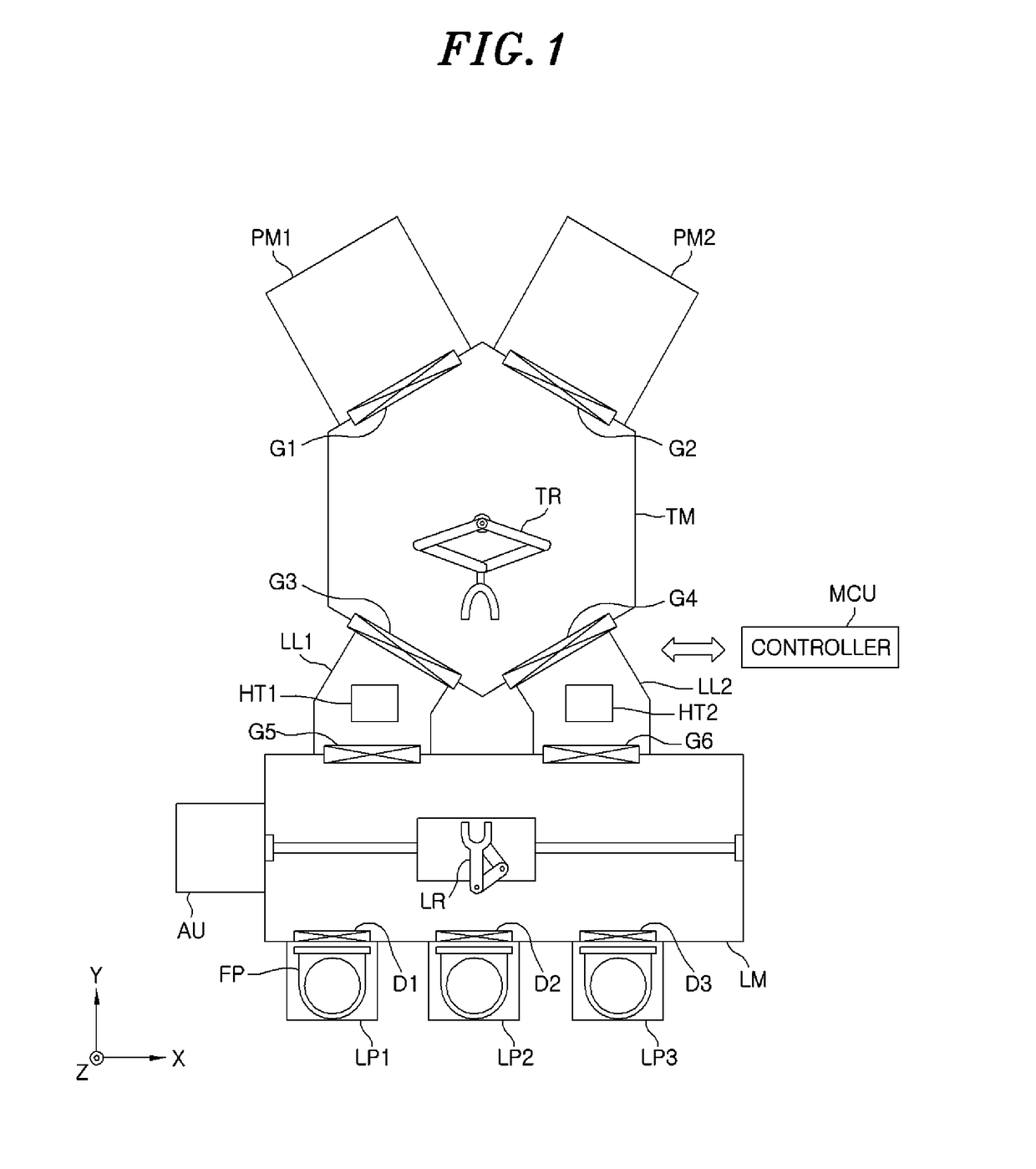

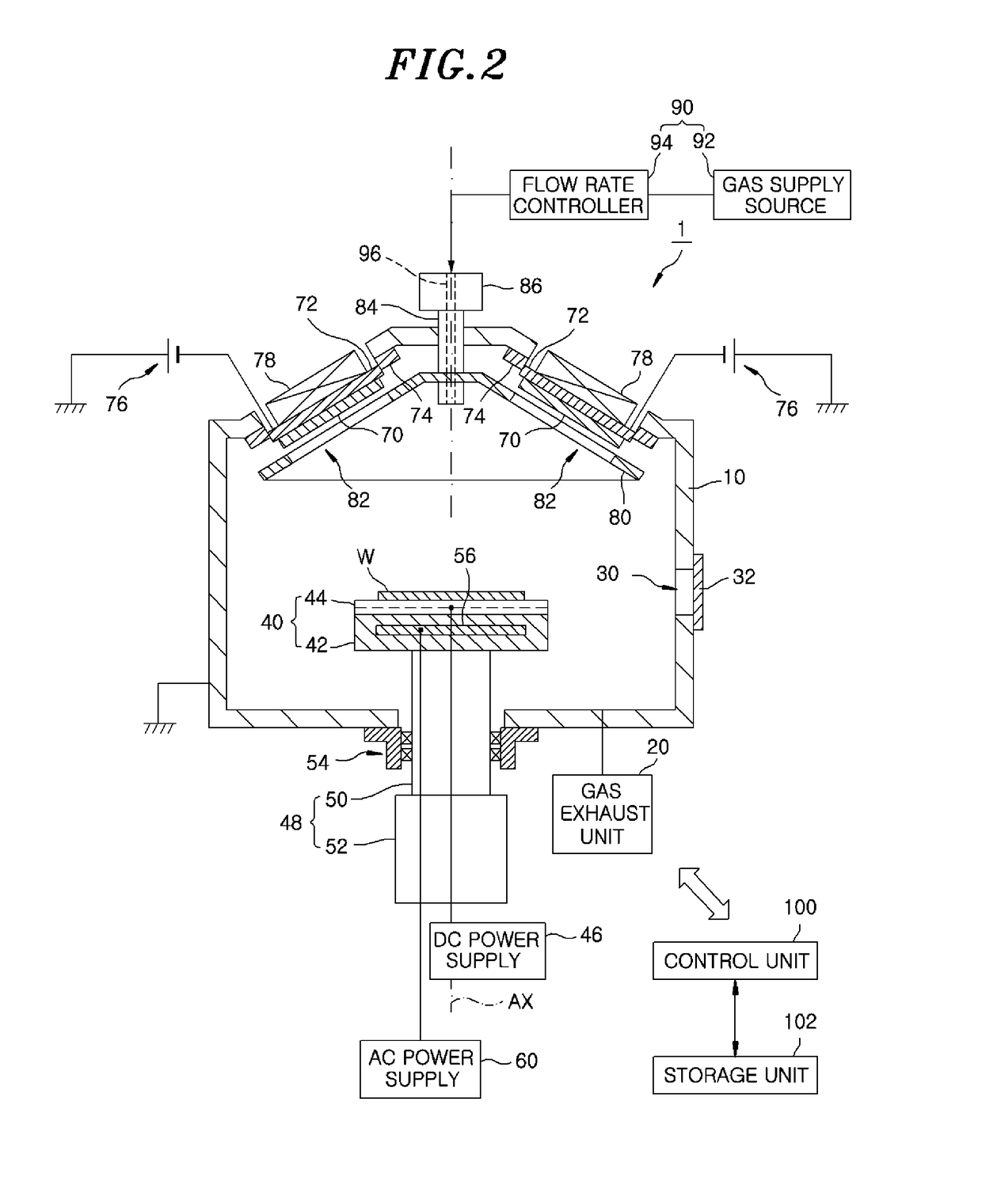

Vacuum exhaust method

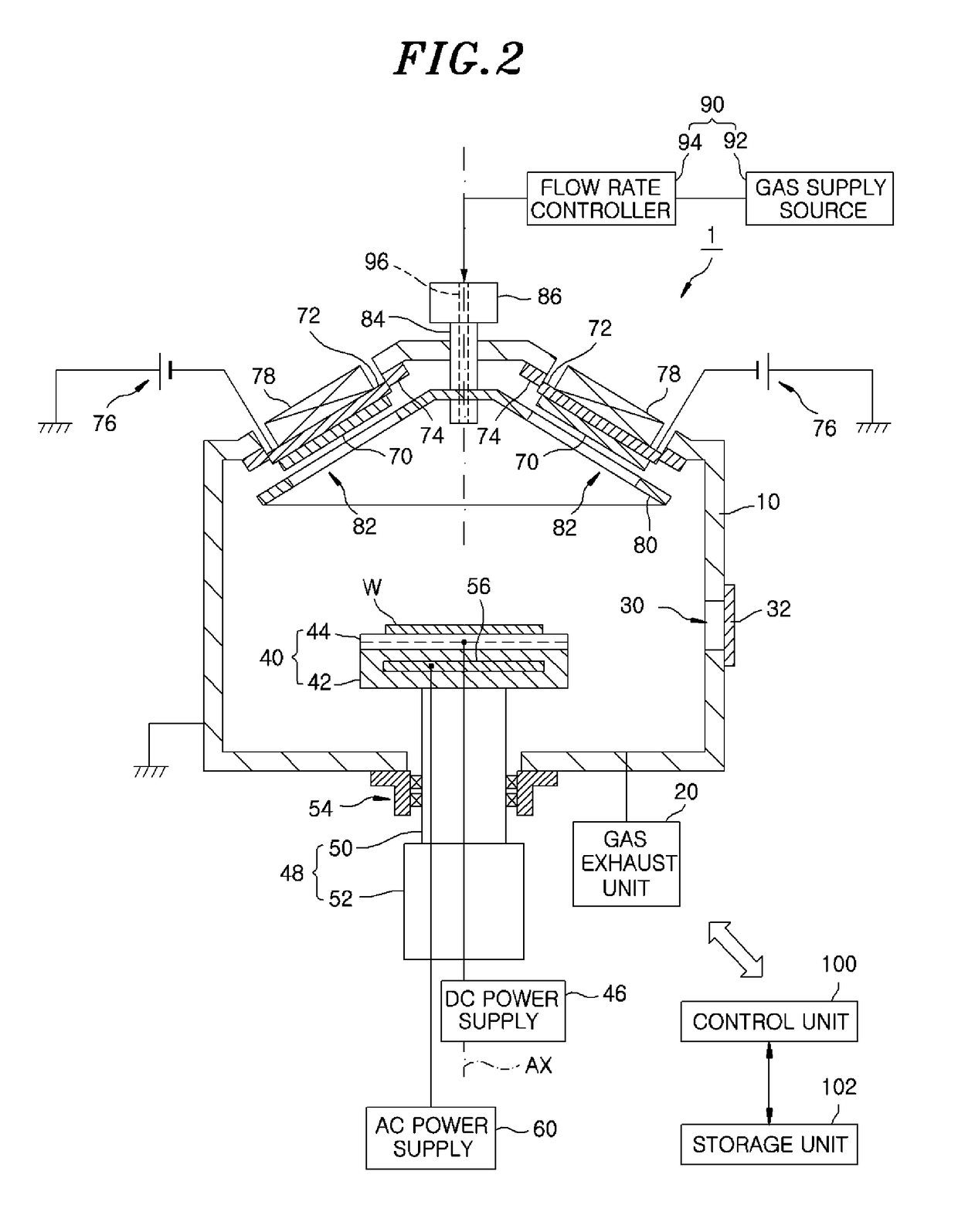

ActiveUS20170345609A1Improving a vacuum level in a processing chamber within a short period of timeTubes with magnetic controlTubes with electrostatic and magnetic controlEngineeringGetter

A vacuum exhaust method is for decreasing a pressure in a processing chamber in which a mounting table configured to mount thereon a substrate is provided by using a gas exhaust unit. The vacuum exhaust method includes mounting a non-evaporated getter (NEG) on the mounting table, and adsorbing an active gas in the processing chamber on the NEG mounted on the mounting table. In the adsorbing the active gas, the NEG is maintained at a predetermined temperature.

Owner:TOKYO ELECTRON LTD

Plasma display panel incorporating a hydrogen-absorbing material

InactiveUS8022628B2Prevent degradationFully removedAddress electrodesSustain/scan electrodesHydrogenPhosphor

A plasma display panel has a front substrate including a plurality of display electrode pairs, a dielectric layer, and a protective layer, and a rear substrate including a plurality of data electrodes, a barrier rib, and a phosphor layer. The front substrate and rear substrate face each other so that the display electrode pairs and the data electrodes intersect, and a hydrogen-absorbing material containing palladium is disposed inside the plasma display panel.

Owner:PANASONIC CORP

Process for the production of plasma displays with distributed getter material and displays thus obtained

InactiveUS7733023B2Simple manufacturing processOvercomes shortcomingDischarge tube luminescnet screensTube/lamp vessel degassingDisplay deviceGetter

A manufacturing process for the production of plasma display panels is provided which allows obtaining in a simple way displays in which getter materials deposits are present in contact with the atmosphere present in channels or cells of the display. The process includes a step of forming the getter material deposits on a free surface of the magnesium oxide layer at positions essentially corresponding to contact areas between the front glass panel and the barriers on the rear glass panel of the display panel.

Owner:SAES GETTERS SPA

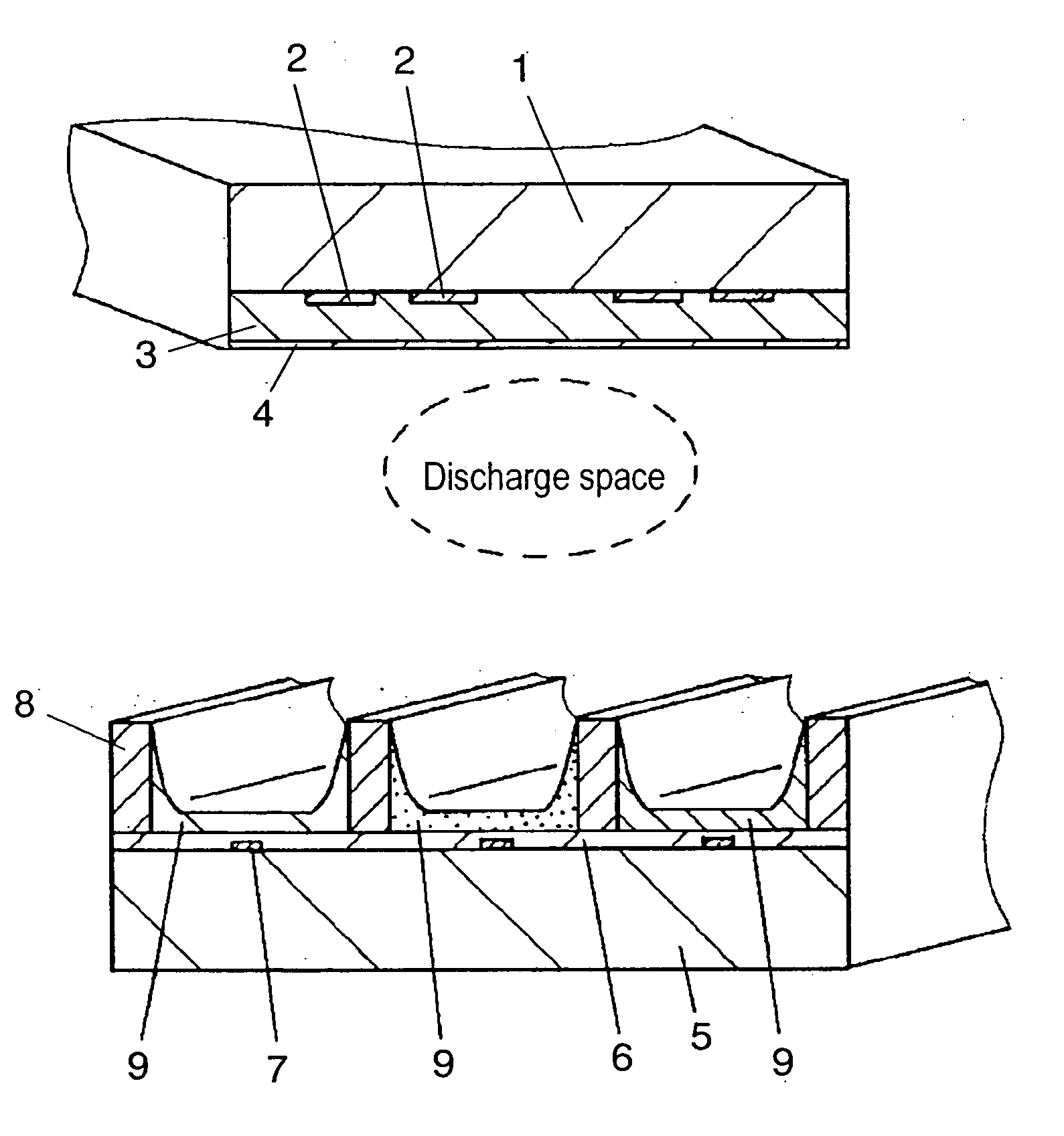

Plasma display panel and manufacturing method thereof

InactiveCN101350282APrevent or improve poor displayImprove qualityAddress electrodesSustain/scan electrodesPhosphorEngineering

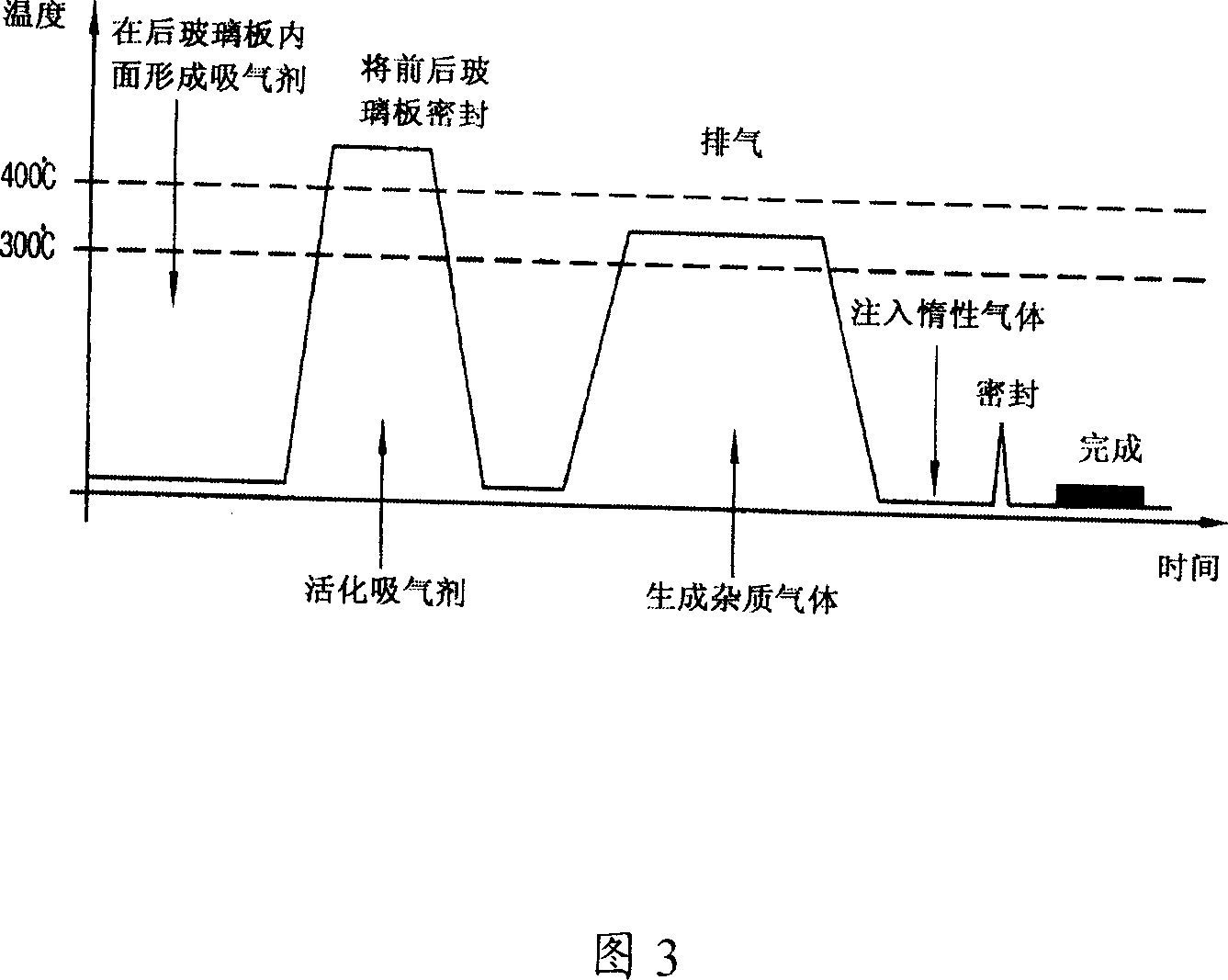

A technology capable of preventing or suppressing a display defect in a PDP (detrimental effect due to local contamination of the display area caused by admixture of impurity gas at the time of introducing discharge gas) is provided. In a PDP, first barrier ribs and first phosphors formed between the first barrier ribs are provided so as to correspond to a display area. In a non-display area outside the display area, an air hole for evacuation from a discharge space and gas filling into the discharge space is provided in a part of an outer perimeter of the panel. Further, an area in which second phosphors having a property of absorbing impurity gas are formed is formed at a position between the display area and the air hole in a part of the non-display area, in particular, in a part of a dummy rib area.

Owner:HITACHI LTD +1

Plasma display panel manufacturing method

InactiveUS7425164B2Static indicating devicesAlternating current plasma display panelsPhosphorInorganic materials

A method of manufacturing a plasma display panel is disclosed. The method includes forming at least one of a dielectric layer on a principal face of a substrate, barrier ribs which partition a discharging space on the dielectric layer, and a phosphor layer disposed between the barrier ribs using an inorganic material into which solution including a degassing material is impregnated.

Owner:PANASONIC CORP

Plasma display panel

InactiveUS20100327742A1Smooth dischargeIncrease brightnessAddress electrodesSustain/scan electrodesX-rayEngineering

A PDP includes a front panel including display electrode (6) formed on glass substrate (3), dielectric layer (8) covering display electrode (6), and protective layer (9) formed on dielectric layer (8); and a rear panel opposing to the front panel to form a discharge space filled with discharge gas, and including an address electrode formed along a direction intersecting with display electrode (6), and a barrier rib partitioning the discharge space, wherein protective layer (9) is formed of a metal oxide made of magnesium oxide and calcium oxide and contains aluminum, and a diffraction angle where a peak of the metal oxide occurs exists between a diffraction angle where a peak of the magnesium oxide occurs and a diffraction angle where a peak of the calcium oxide occurs in an X-ray diffraction analysis on a surface of protective layer (9).

Owner:PANASONIC CORP

Method for producing plasma display panel

InactiveUS20110165818A1Avoid easy removalReduce riskTube/lamp screens manufactureStatic indicating devicesEngineeringHigh definition

Provided is a manufacturing method that allows even a PDP having high-definition cells to exhibit excellent image display performance with reduced power consumption by effectively preventing impurities from adhering to the protective layer. Specifically, in a pre-baking step, a back substrate 9 is baked at a pre-baking temperature. Here, a highest pre-baking temperature is set to be lower than a softening point of a sealing material. The back substrate 9 is superposed on a front substrate 2. Then, a sealing step is performed in a sealing atmosphere prepared by mixing a predetermined amount of a reducing gas with a non-oxidizing gas. The above enables the impurities attributed to organic components due to a sealing material paste to remain as low molecular components, whereby the impurities are evacuated and removed in an evacuating step performed after the sealing step. This prevents adherence of the impurities to the protective layer 8.

Owner:PANASONIC CORP

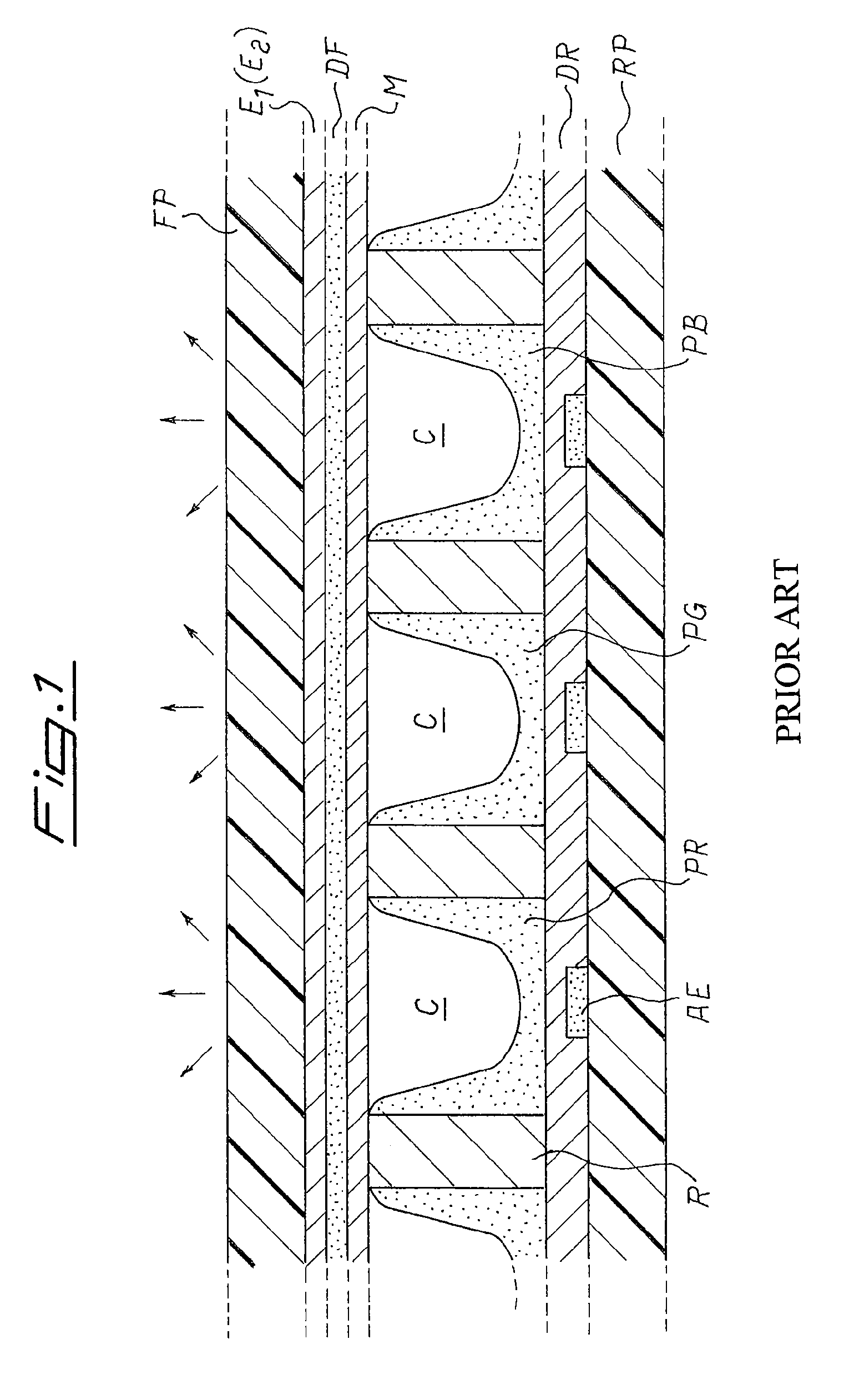

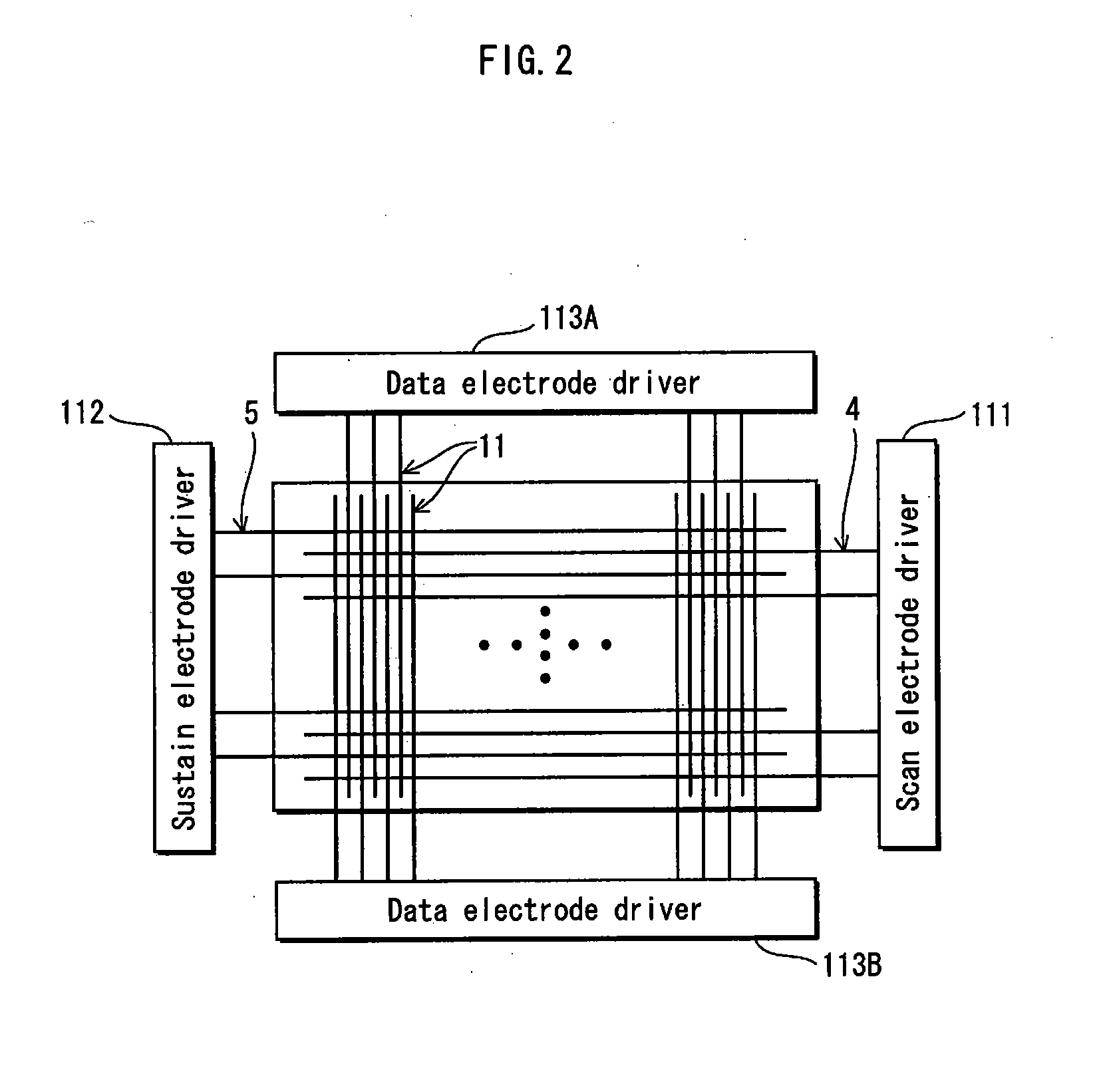

Plasma display panel

InactiveUS7304431B2Suppress luminescenceAlternating current plasma display panelsGas mixture absorptionPhosphorEngineering

A highly reliable plasma display panel which suppresses degradation of phosphor characteristic by removing impurity gases inside the plasma display panel. A front board includes scanning electrodes and maintenance electrodes. A and rear board includes data electrodes; partitions disposed in parallel and an exhaust hole. The scanning electrodes and maintenance electrodes of the front board and the data electrode of rear board cross. A non-evaporating getter such as zeolite is disposed inside plasma display panel near the exhaust hole.

Owner:PANASONIC CORP

AC type plasma display element

InactiveCN102201312AReduce discharge voltageImprove luminous efficiencyAddress electrodesSustain/scan electrodesTectorial membraneDivalent metal

The invention provides an AC type plasma display element (AC PDP), which is characterized by comprising a front substrate formed by a front glass / front dielectric layer / protective film. The protective film is formed by adding the dibastic oxide ((MxMg1-x) O) of a divalent metal oxide (MO) on an MgO substrate. The surface of a rear substrate formed by a rear glass / rear dielectric layer / partition is uniformly coated with a non-volatile oxide adsorption layer. The surface of the non-volatile oxide adsorption layer is formed with a phosphor layer.

Owner:CERAMICS & CHEM TECH

Method for producing plasma display panel

InactiveUS8317563B2Pre-baked substrate is more rapidly loweredDamage to the prebaked substrate caused by rapid cooling is preventedTube/lamp screens manufactureStatic indicating devicesCooking & bakingEngineering

Provided is a manufacturing method that allows even a PDP having high-definition cells to exhibit excellent image display performance with reduced power consumption by effectively preventing impurities from adhering to the protective layer. Specifically, in a pre-baking step, a back substrate 9 is baked at a pre-baking temperature. Here, a highest pre-baking temperature is set to be lower than a softening point of a sealing material. The back substrate 9 is superposed on a front substrate 2. Then, a sealing step is performed in a sealing atmosphere prepared by mixing a predetermined amount of a reducing gas with a non-oxidizing gas. The above enables the impurities attributed to organic components due to a sealing material paste to remain as low molecular components, whereby the impurities are evacuated and removed in an evacuating step performed after the sealing step. This prevents adherence of the impurities to the protective layer 8.

Owner:PANASONIC CORP

Plasma display device

InactiveCN101022071AFully and effectively dischargedFully and effectively excludeGas mixture absorptionSolid cathode detailsDisplay deviceEngineering

This invention relates to a plasma display combined in a certain distance by a front glass plate and a back one, in which, said front plate includes a space formed by the non-discharge region at the side in the front plate and a getter formed in the space characterizing: a, forming a display panel by combining the front glass plate forming more than one spaces in the non-discharge region in the inside surface and a back glass panel forming a getter entrance at the places corresponding to said more than one spaces, b, putting getter from the entrance of getters of the back glass plate and forming said getter in the spaces of the front glass plate, c, sealing the entrance of getters of the back plate, d, discharging impurities from the display panel, e, injecting discharge gas to the display panel.

Owner:LG ELECTRONICS(NANJING) PLASMA CO LTD

A plasma display and its manufacture method

InactiveCN1963980AEfficient removalShorten production timeTube/lamp vessel degassingTube/lamp vessel fillingConductive materialsGlass sheet

The manufacture method for a plasma display comprises: with the plasma display set in a board to remove gas impurity, in the glass plates near the getter, setting inserting hole on the non-discharge area for the getter; near these holes, and arranging non-crystal silicon attached with conductive material and soda-lime glass attached with conductive material for sealing. Besides, the manufacture also includes: using glass plates to bond and seal, discharging impurity in display panel, and injecting the discharging gas.

Owner:LG ELECTRONICS(NANJING) PLASMA CO LTD

Plasma display panel and its manufacturing method

InactiveUS20050168126A1Reduce voltageIncrease brightnessDischarge tube luminescnet screensTube/lamp vessel degassingPhosphorControl manner

A plasma display panel capable of realizing improvement in the characteristics thereof, such as lower discharge voltage, more stable discharge, higher luminance, higher efficiency, and longer life. During a step of sealing the periphery of substrates or before this sealing step, impurity gas other then inert gas is adsorbed by phosphor layers. The impurity gas is released into discharge gas and the impurity is added to the discharge gas in a controlled manner while the panel is lit. This method can realize improvement in characteristics, such as lower discharge voltage, higher luminance, higher efficiency, and longer life.

Owner:PANASONIC CORP

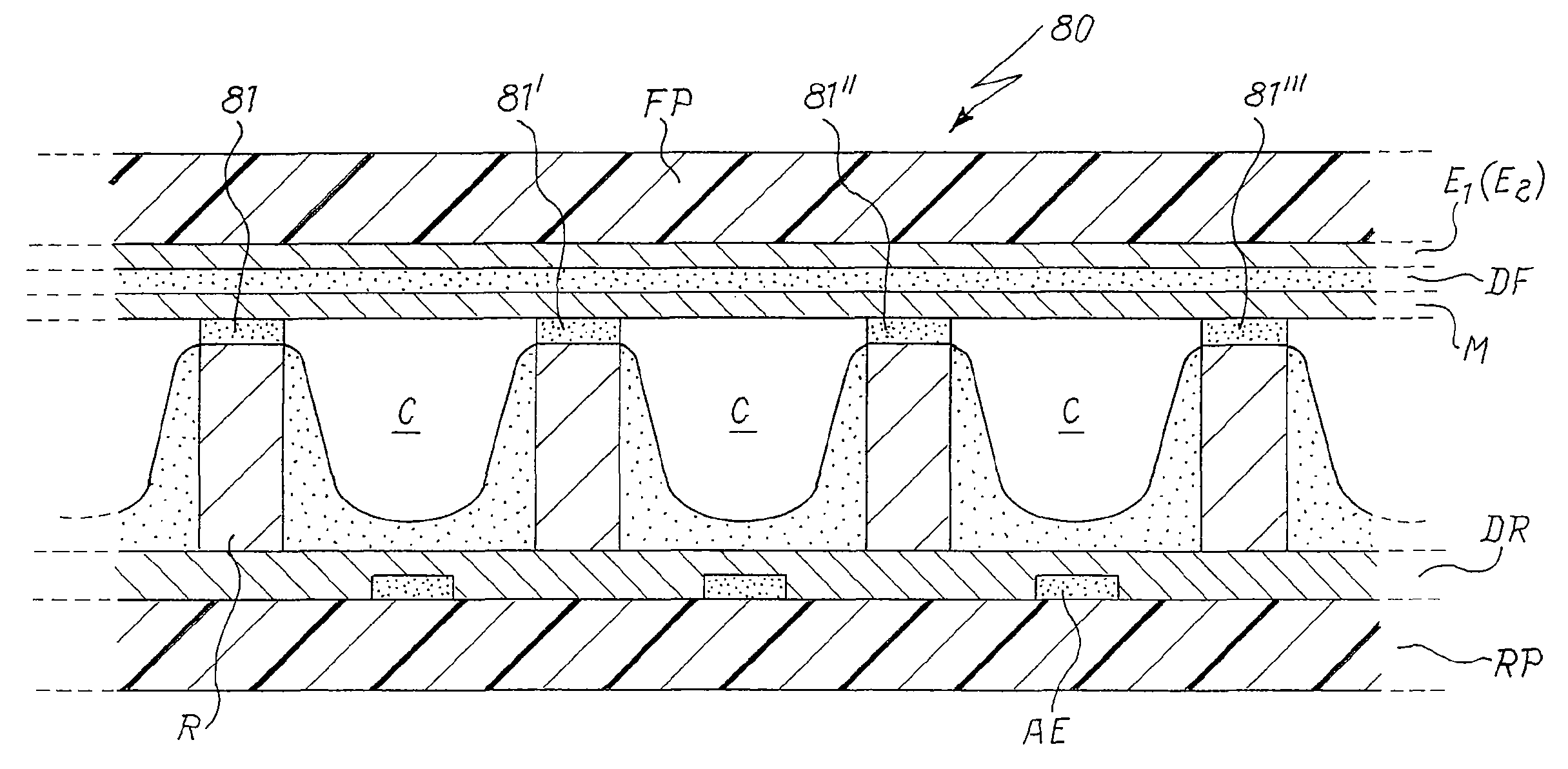

Process for the production of plasma displays with distributed getter material and displays thus obtained

InactiveCN1969359ASimple preparation processTube/lamp vessel degassingGas mixture absorptionMetallurgyDisplay device

A manufacturing process for the production of plasma display panels (80) is described which allows to obtain in a simple way displays wherein, in contact with the atmosphere present in channels (C) or cells of the display, getter materials deposits (81, 81', ...) are present.

Owner:SAES GETTERS SPA

Composite getter for maintaining medium and low vacuum environment and preparation method thereof

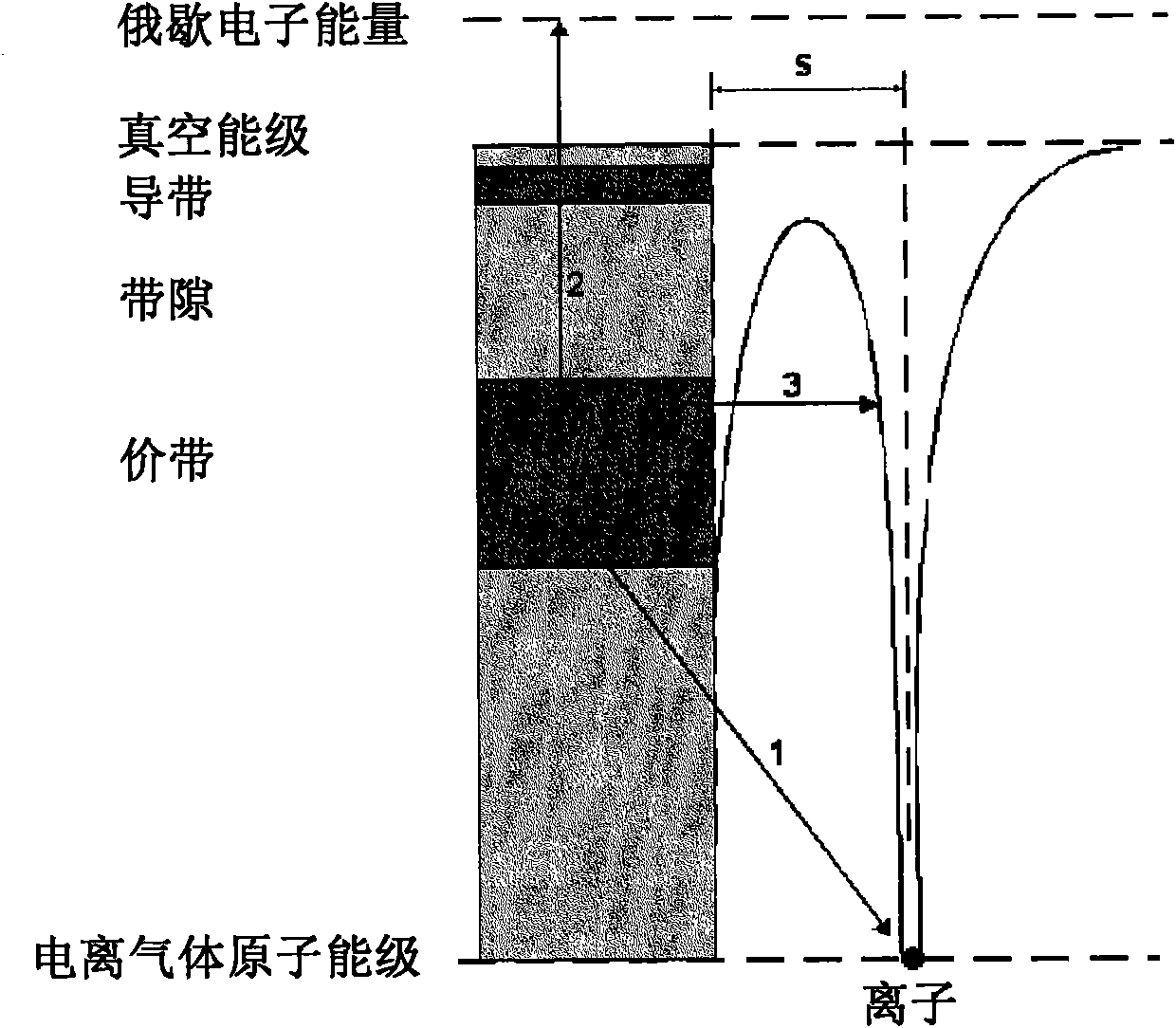

ActiveCN102205228BSimple structureImprovement ingredientsOther chemical processesSemiconductor/solid-state device detailsLithiumIron powder

A composite getter for maintaining medium and low vacuum environment comprises an elemental metal powder getter (3), an alloy powder getter (2), a drying agent powder (1) and a plastic film (4), wherein the elemental metal powder getter (3) and the alloy powder getter (2) are present respectively as one layer and stacked in the center position of the drying agent powder (1) to form a core-clad structure, which is packed in the plastic film (4). The elemental metal powder getter (3) is one or a combination of at least two selected from the group consisting of reduced iron powder, nickel powder and copper powder with a grain size range from 10 to 200 µm. The alloy powder getter (2) is one or a combination of at least two selected from the group consisting of strontium-lithium alloy powder, barium-lithium alloy powder and barium-magnesium alloy powder with a grain size range from 50 to 500 µm. The drying agent powder (1) is one or a combination of at least two selected from the group consisting of calcium oxide powder, strontium oxide powder and barium oxide powder with a grain size range from 20 to 200 µm. The plastic film (4) is breakable automatically under a pressure difference of one atmosphere. The performance properties of this composite getter is not affected when exposed to air for a short period of time. The method for producing the composite getter is also disclosed.

Owner:FUJIAN SUPERTECH ADVANCED MATERIAL

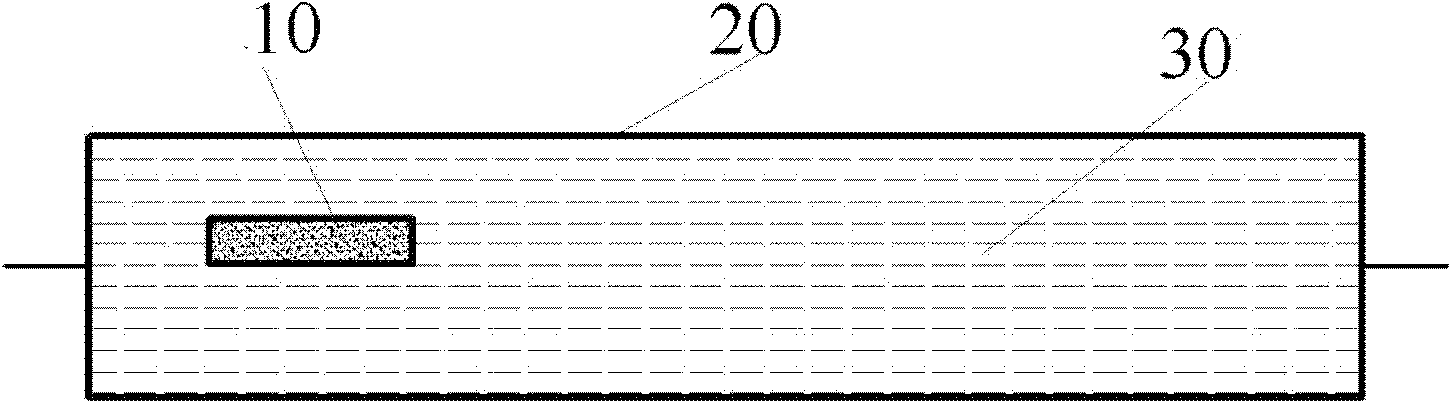

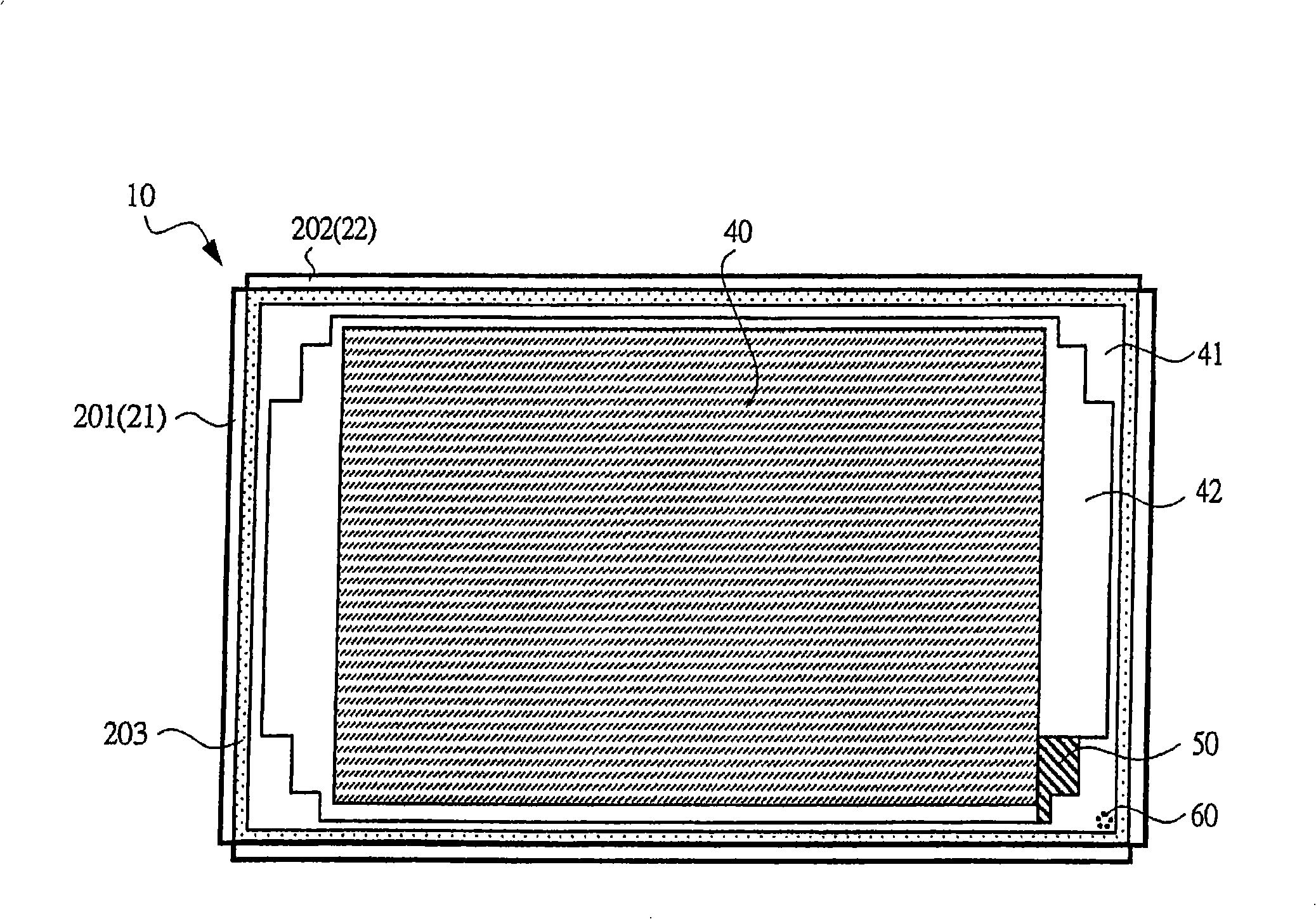

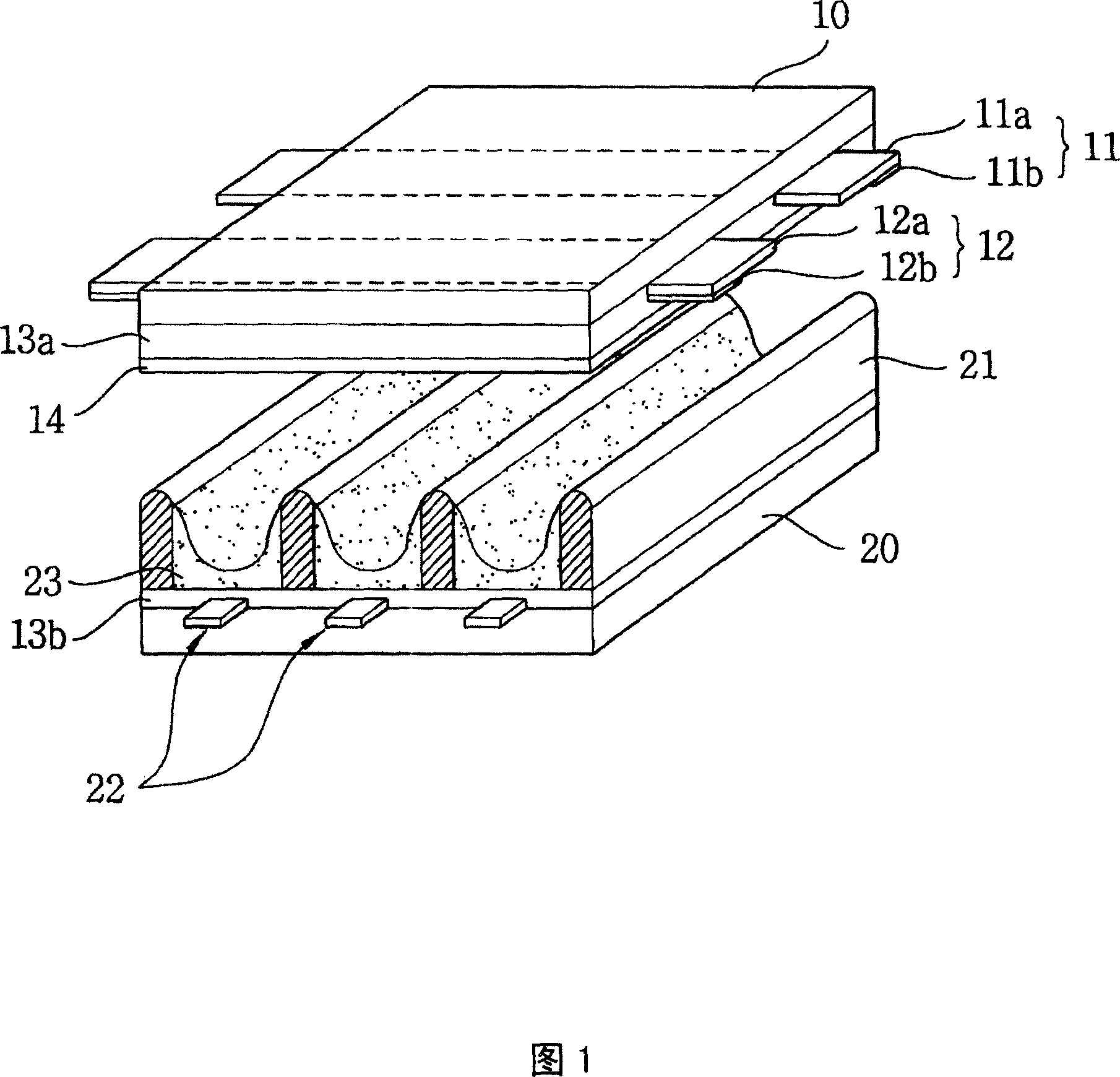

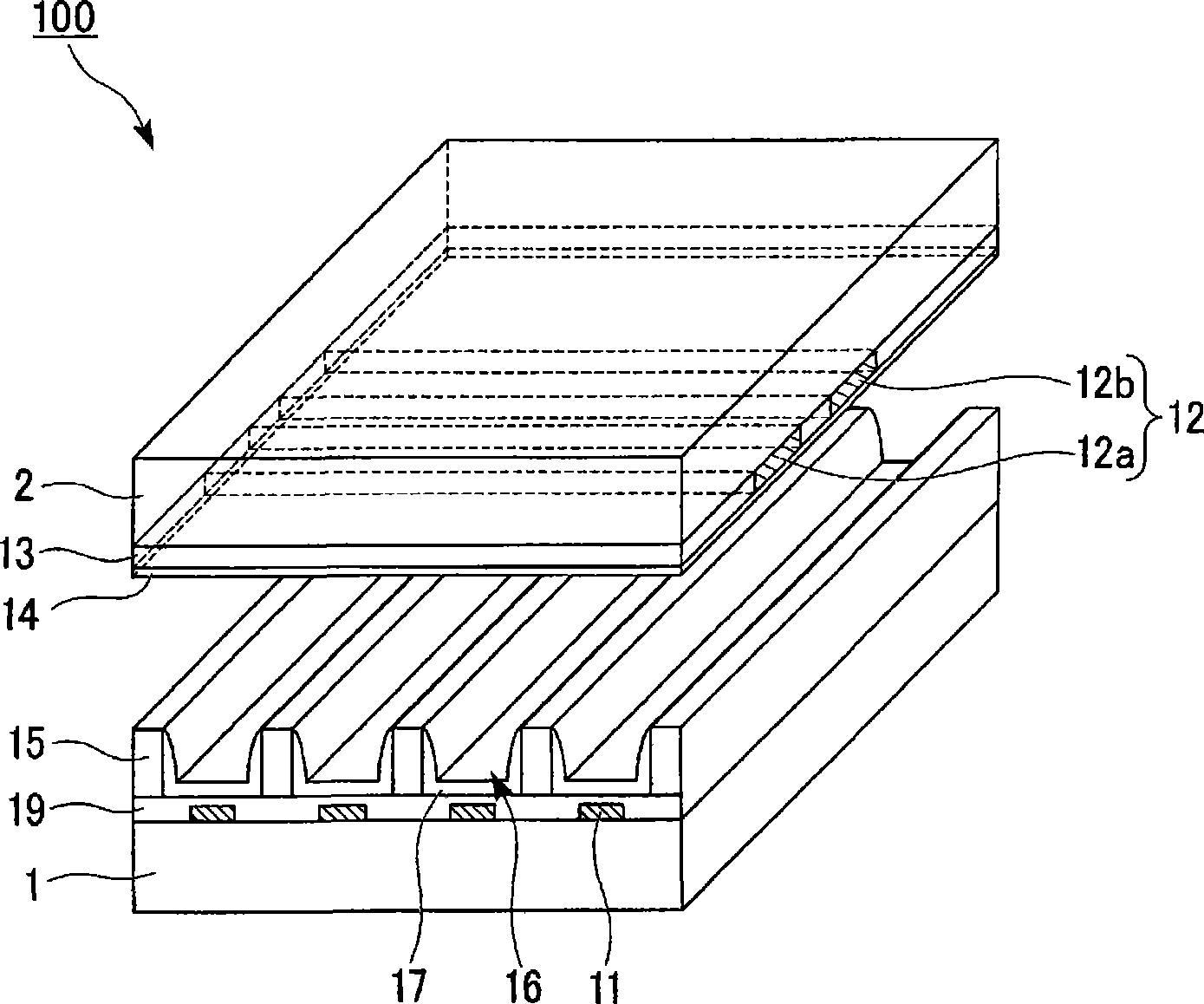

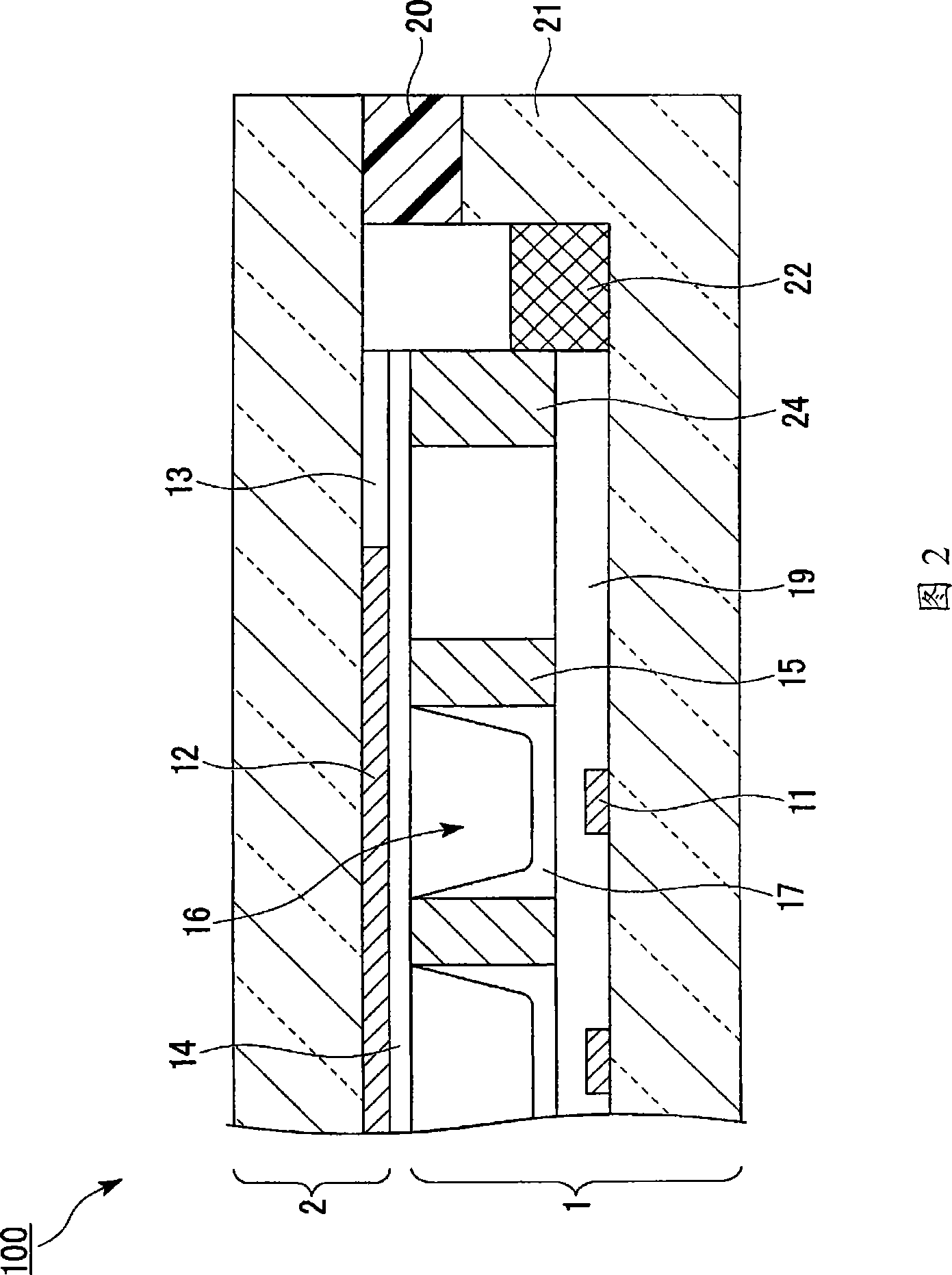

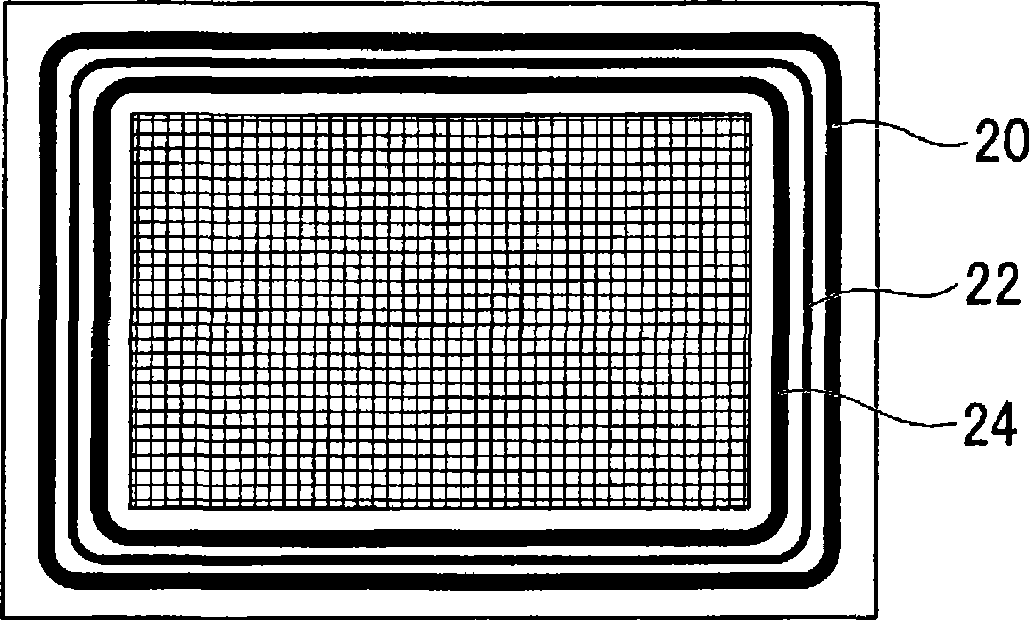

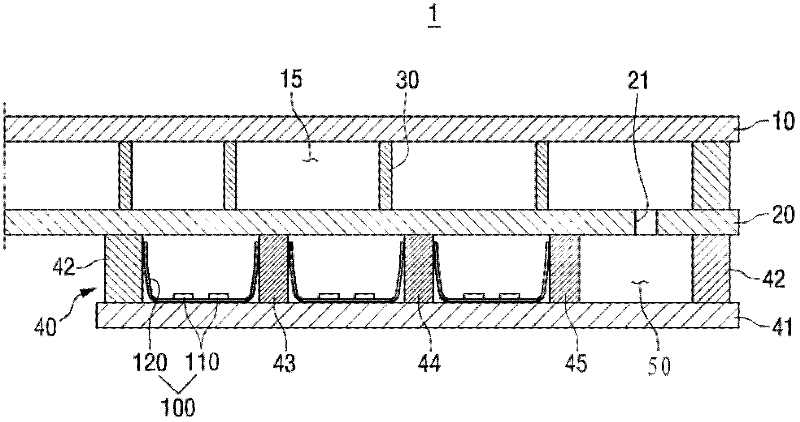

Manufacturing method of sealed panel, and plasma display panel

InactiveCN101421813AReduce initial burn-in processing timeLow puritySustain/scan electrodesTube/lamp vessel degassingUltraviolet lightsEngineering

This invention provides a sealing panel (100) that can suppress a rise in discharge voltage. The sealing panel (100) comprises a resin material-containing sealing material (20) disposed on the whole periphery in a part between a pair of substrates (1,2). A getter (22), which adsorbs an impurity gas released from the sealing material (20) and an impurity gas passed through the sealing material (20), is formed continuously or intermittently along the inner periphery of the sealing material (20). Further, an ultraviolet shielding wall (24) for preventing ultraviolet light generated within the sealing panel (100) from being incident to the sealing material (20) is formed continuously along the inner periphery of the sealing material (20).

Owner:ULVAC INC

Vacuum exhaust method

ActiveUS10014145B2Improving a vacuum level in a processing chamber within a short period of timeTubes with magnetic controlTubes with electrostatic and magnetic controlEngineeringGetter

A vacuum exhaust method is for decreasing a pressure in a processing chamber in which a mounting table configured to mount thereon a substrate is provided by using a gas exhaust unit. The vacuum exhaust method includes mounting a non-evaporated getter (NEG) on the mounting table, and adsorbing an active gas in the processing chamber on the NEG mounted on the mounting table. In the adsorbing the active gas, the NEG is maintained at a predetermined temperature.

Owner:TOKYO ELECTRON LTD

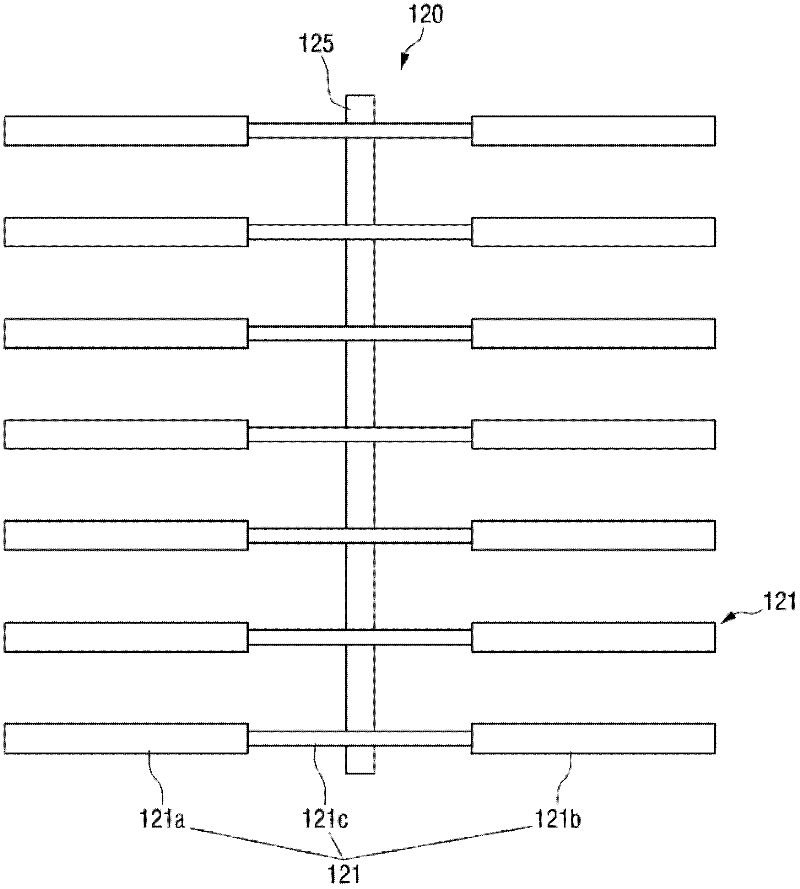

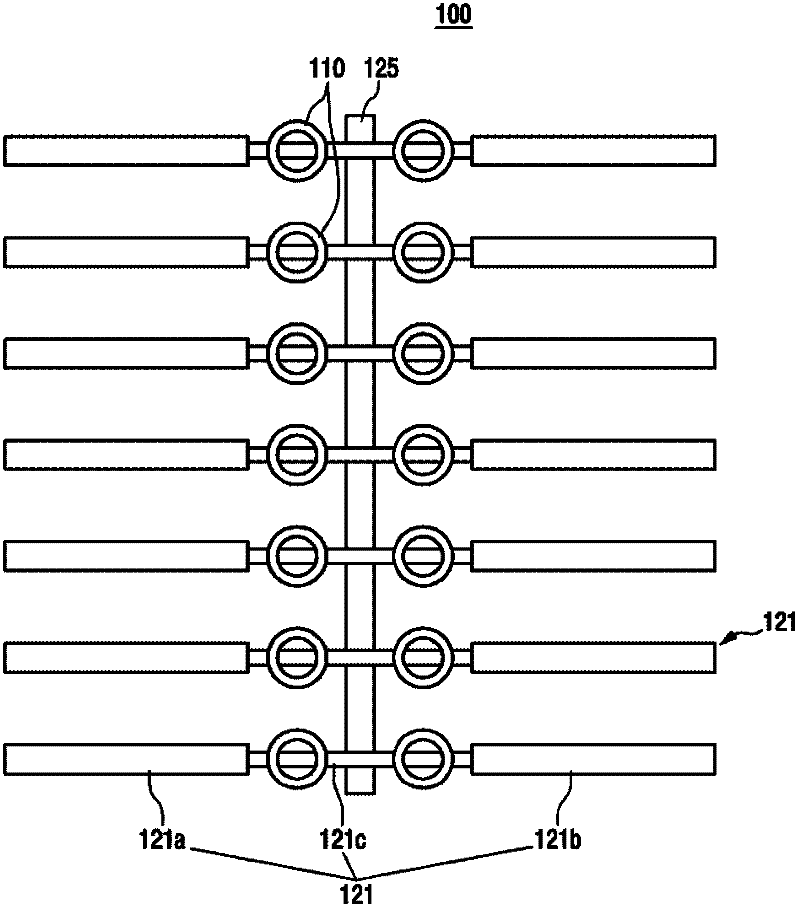

Getter assembly and manufacturing method thereof, and display device including the getter assembly

InactiveCN102386046AGas filling substance selectionTube/lamp vessel degassingDisplay deviceEngineering

The invention provides a getter assembly and a manufacturing method thereof, and a display device including the getter assembly. The getter assembly is mounted in a getter chamber. The getter assembly comprises a plurality of getters, support units to support the plurality of getters. When the getter assembly is mounted the getter chamber, the support unit is elastically deformed to create a pressing force against the plurality of spacer, thereby the getter assembly maintain fixedly in the getter chamber.

Owner:SAMSUNG ELECTRONICS CO LTD

Manufacturing method for plasma display panel

InactiveUS20110042001A1Reduced characteristicsInhibit deteriorationTube/lamp vessel degassingConfectioneryGas compositionIon exchange

The present invention aims to provide a manufacturing method for a PDP which allows even high-definition and ultra-high-definition PDPs to demonstrate an excellent image display capability at improved luminous efficiency, by suppressing variation of a discharge gas composition, and by eliminating an impurity gas in a discharge space effectively.To achieve the aim, deterioration of an absorbent material 39 composed of copper ion-exchanged ZSM-5-type zeolite is prevented, by performing both sealing and evacuation steps for the front substrate 2 and back substrate 9 in a non-oxidizing gas atmosphere. This maintains properties of the absorbent material 39 for absorbing the impurity gas without degradation, even if the absorbent material 39 absorbs a Xe gas in a discharge gas introducing step.

Owner:PANASONIC CORP

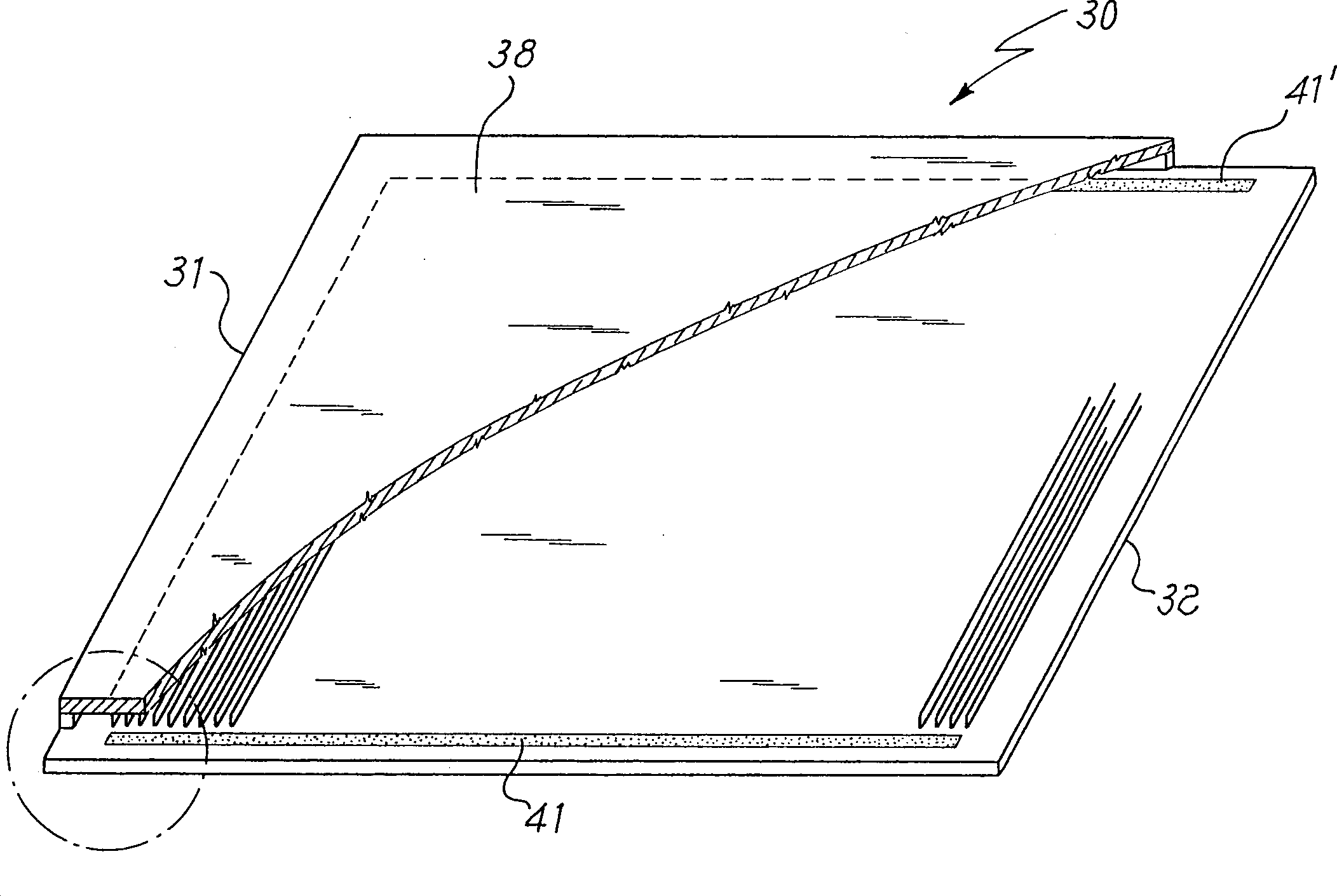

Getter system in plasma plane-plate used as screen

InactiveCN1147907CImprove the extraction processStatic indicating devicesAlternating current plasma display panelsMain channelEngineering

A getter system is disclosed for plasma flat panels used as screens which is composed of one or more nonvaporous-type getter devices arranged in a main channel located on at least one of band areas adjacent to panel side edges intersecting perpendicularly to the direction of secondary channels. By using the getter system of the invention a reduction of the production time is obtained, as well as a better starting quality and the keeping of the starting functional characteristics of these panels.

Owner:SAES GETTERS SPA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com