Process for the production of plasma displays with distributed getter material and displays thus obtained

一种等离子显示板、吸气材料的技术,应用在电气元件、充气放电管、混合气体吸收等方向,能够解决蔓延并且占据等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

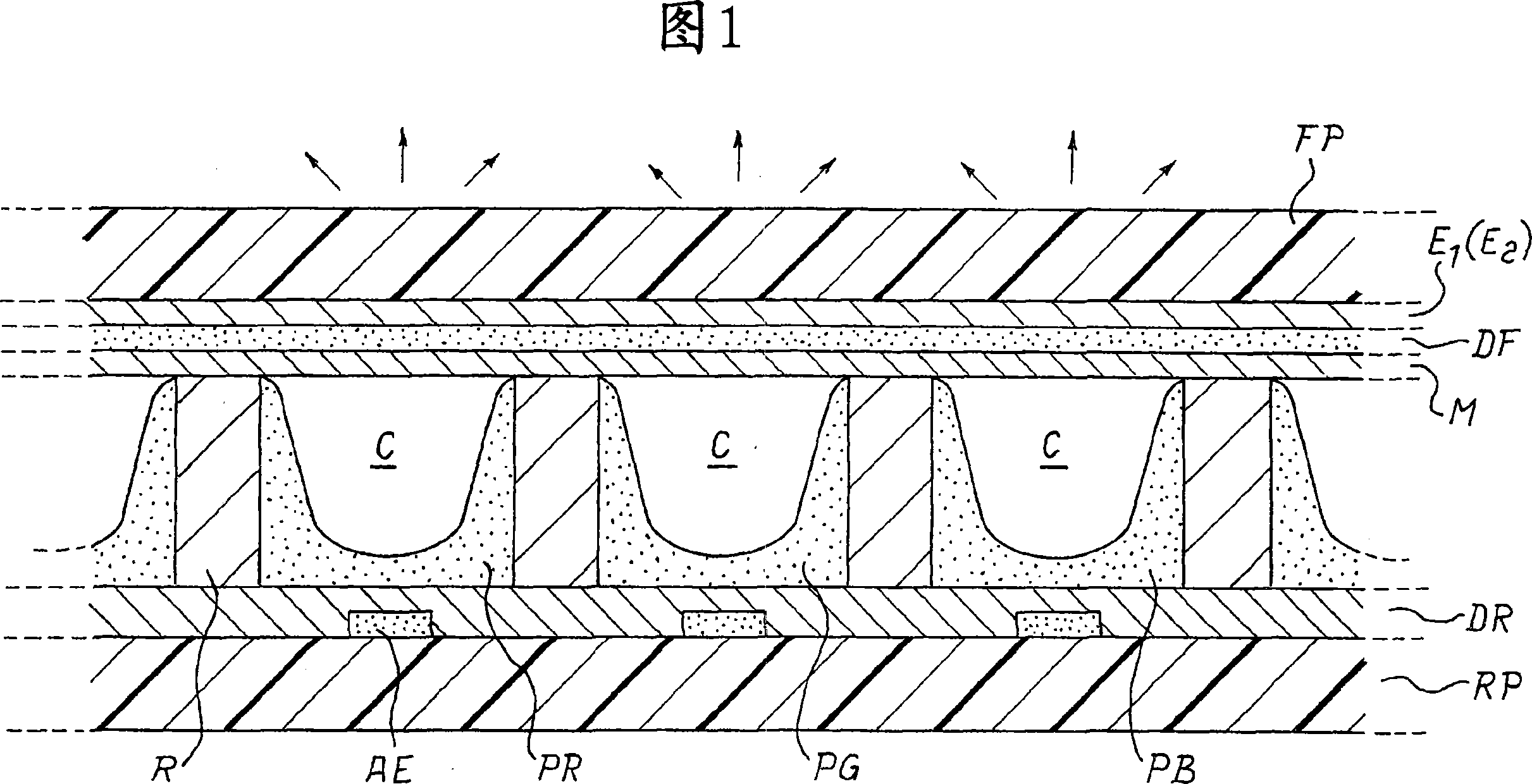

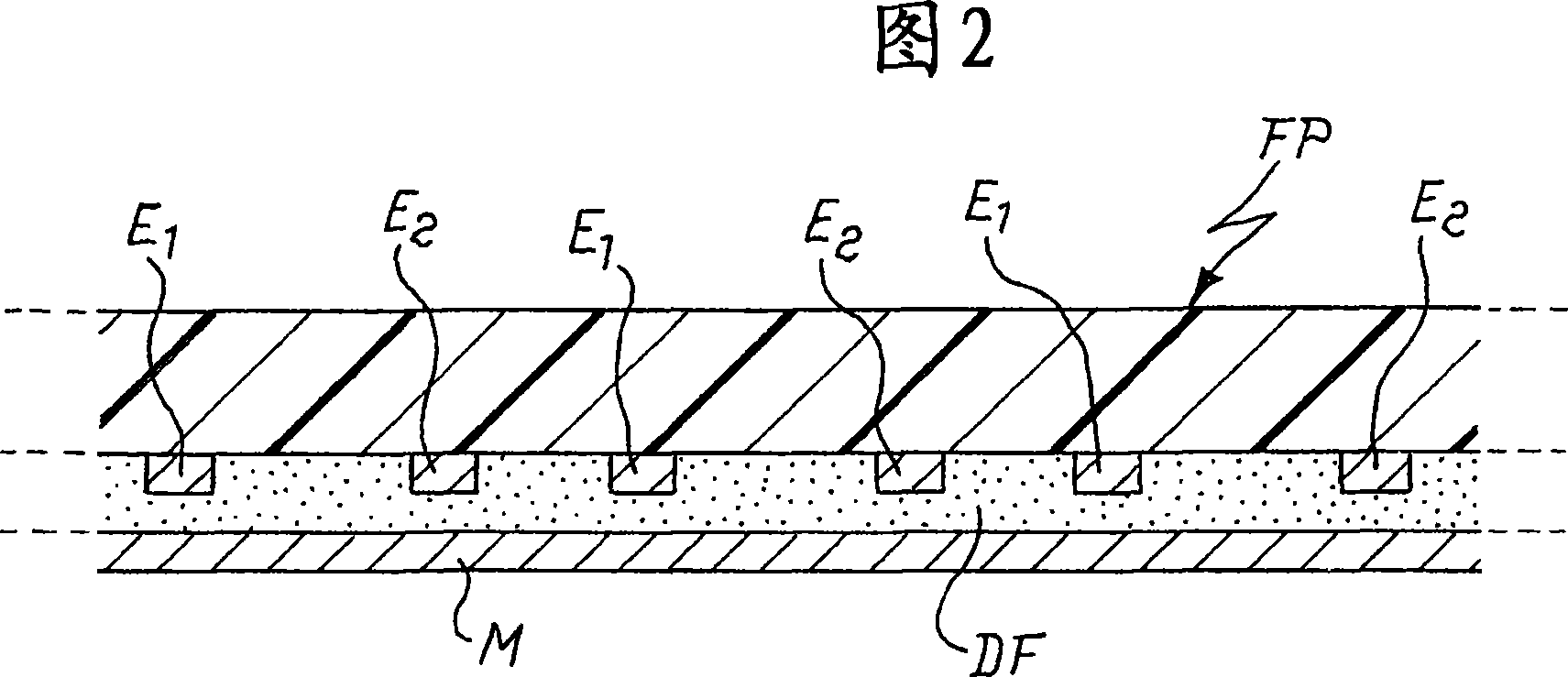

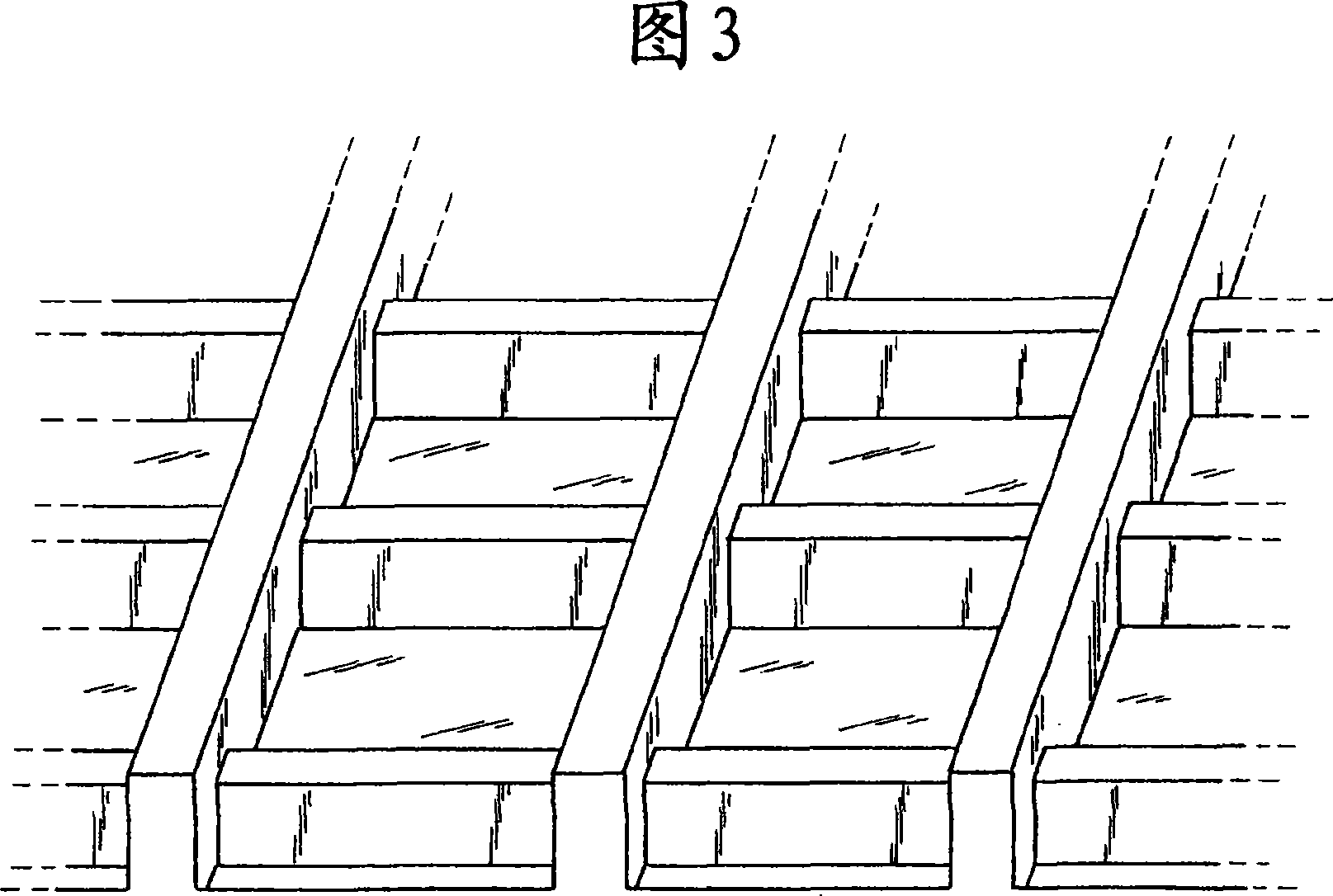

[0030] Figures 1-5 have been described in the Introduction.

[0031] The process of the invention differs from the known processes only in that the manufacture of the front glass plate includes a step of forming a number of getter deposits on the surface, which in the finished display faces the inner space, located in particular corresponding to the contact surface with the upper part of the ribs s position. The getter deposition can be formed on the flat surface of the MgO layer (M in FIG. 1 ) or in grooves formed in this layer. The invention is neutrally applicable in the chamber manufacturing process of suction ducts or PDPs.

[0032] Figure 6 shows various steps characterizing the operation of the invention (in this figure, the front glass plate is shown inverted relative to Figures 1-5). During step a, on the surface of the magnesium oxide layer on which the getter deposition has to be formed, a mask 60 provided with apertures 61, 61', ... is aligned, geometrically corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com