Plasma display panel and manufacturing method thereof

A display panel and plasma technology, applied in the direction of AC plasma display panels, cold cathode manufacturing, electrode system manufacturing, etc., can solve the problems of insufficient activation of getters, etc., and achieve the effect of improving poor display and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, embodiments of the present invention will be described in detail based on the drawings. In addition, in all the drawings for describing the embodiments, in principle, the same reference numerals are assigned to the same parts, and repeated description thereof will be omitted.

[0036]

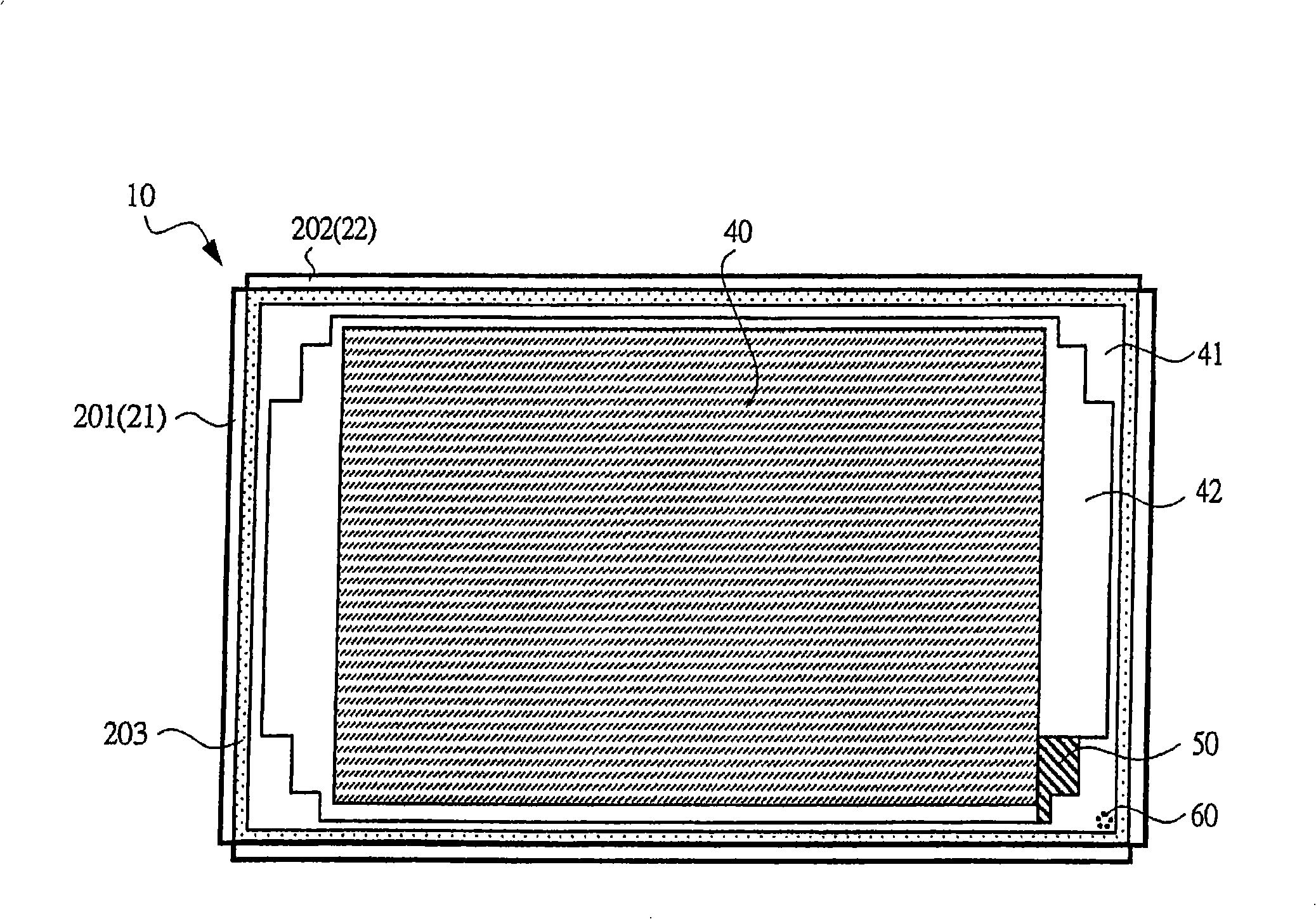

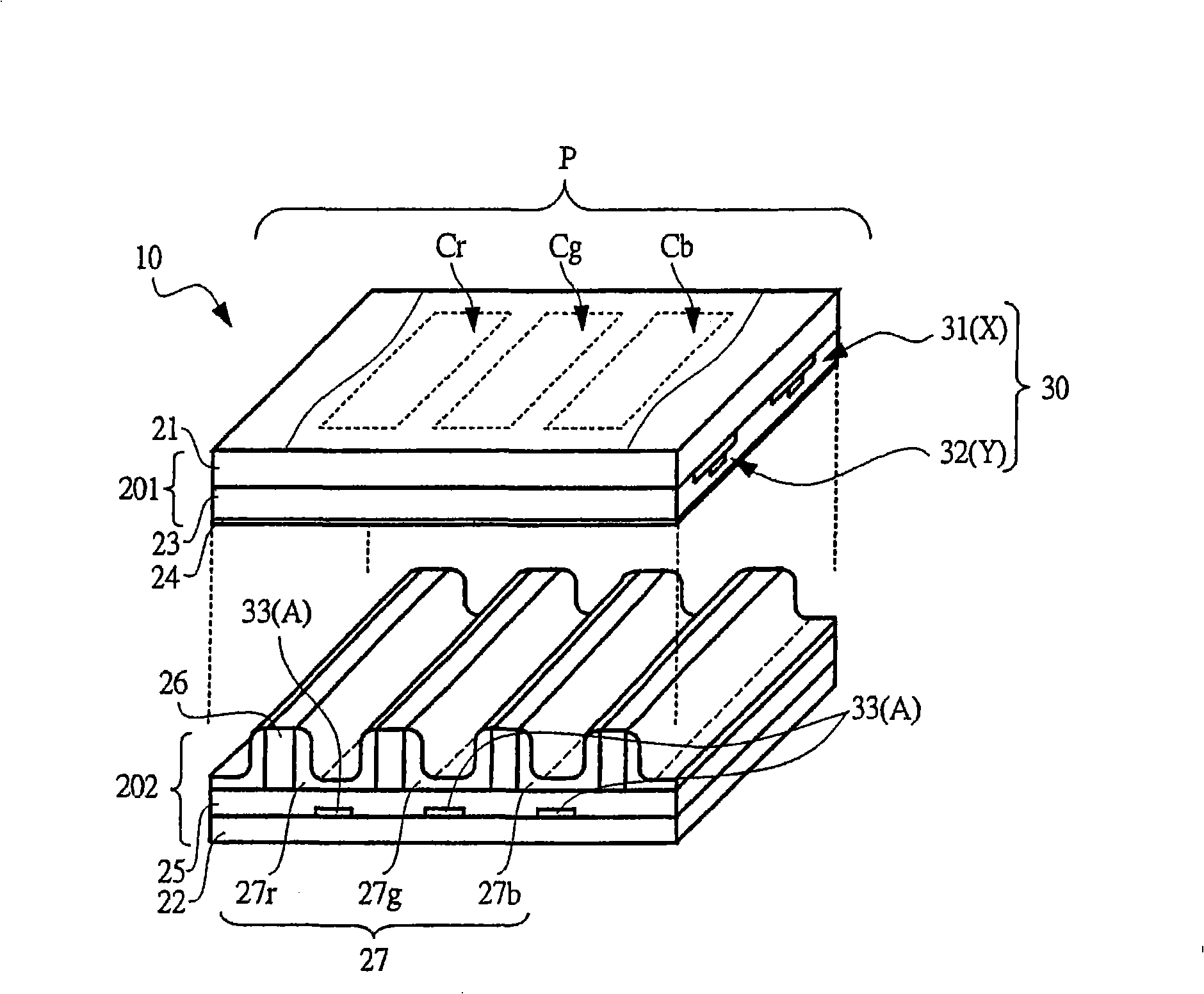

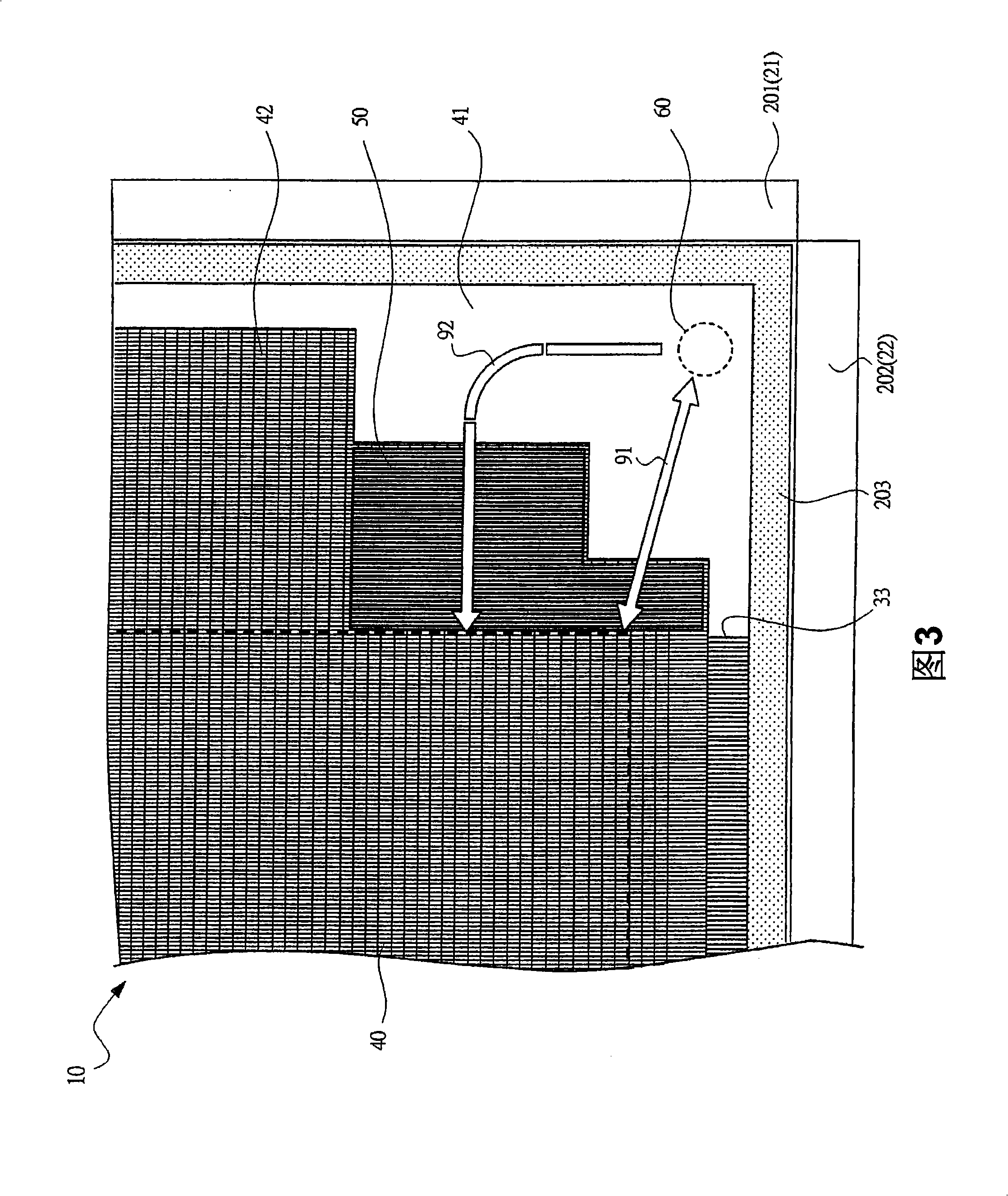

[0037] exist figure 1 In , the appearance of the PDP (first structural example) according to one embodiment of the present invention, that is, the planar structure viewed from the front side is shown. In this PDP (panel) 10, the first substrate (front glass substrate) 21 and the structure of the second substrate (rear glass substrate) 22 (the first substrate structure 201, the second substrate structure 202) are relatively combined. After the sealing region 203 is sealed with frit (sealing material), the interior of the panel (the region to be the discharge space) is evacuated through the vent hole 60, and the discharge gas is introduced to complete the sealing.

[0038]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com