Manufacturing method of sealed panel, and plasma display panel

A plasma and display panel technology, which is applied in the direction of AC plasma display panels, discharge tube/lamp manufacturing, exhaust sealing, etc., can solve the problems such as the reduction of impurity gas detachment speed, and achieve the purpose of suppressing the reduction of purity, shortening the aging treatment time, The effect of shortening the initial aging treatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Embodiments of the present invention will be described below with reference to the drawings. In addition, in each drawing used in the following description, the scale of each member is appropriately changed in order to make each member recognizable.

[0053] In addition, in this specification, the "inner surface" of a board|substrate refers to the board|substrate side surface which opposes this board|substrate among both surfaces of this board|substrate.

[0054] (plasma display panel)

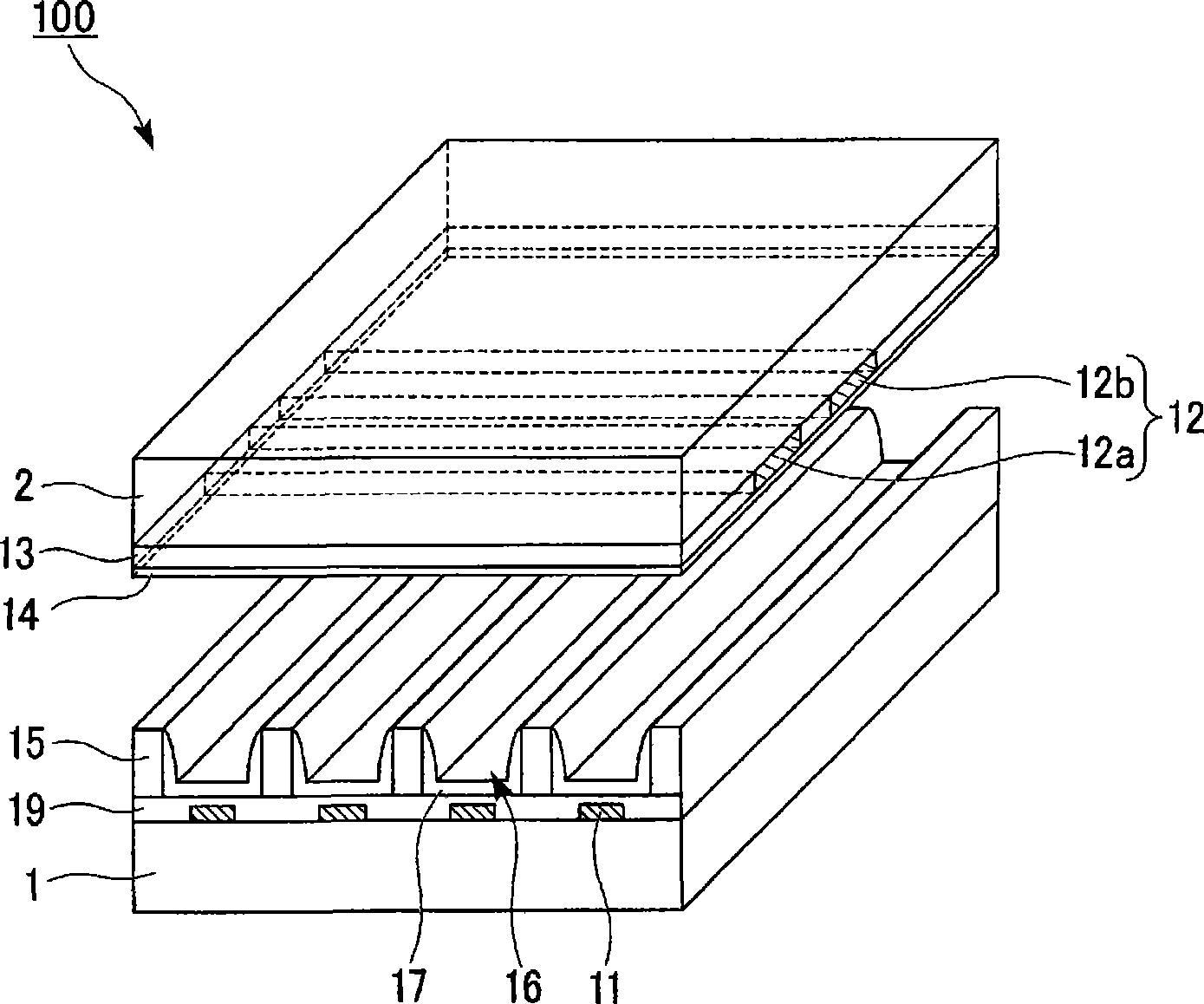

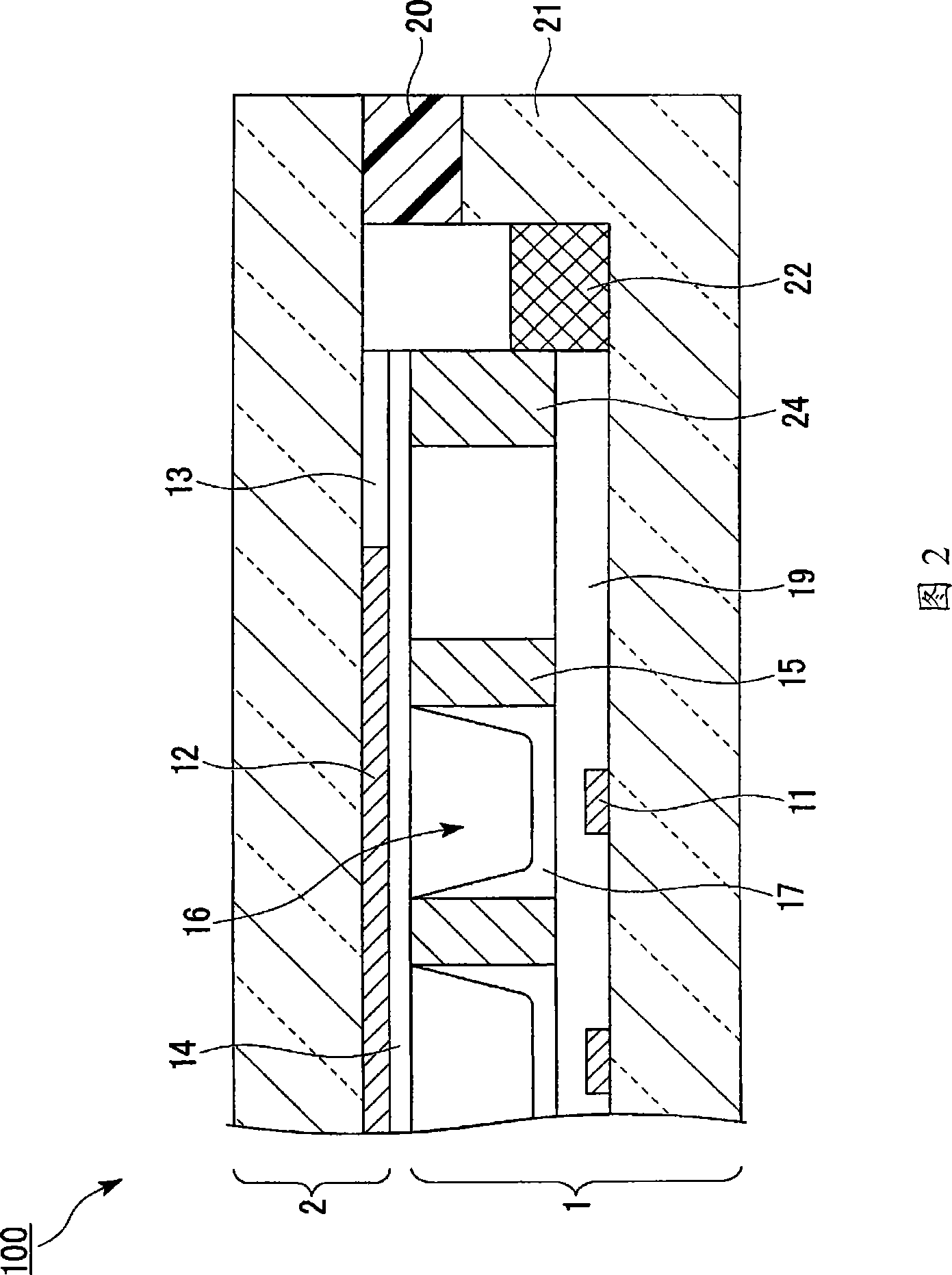

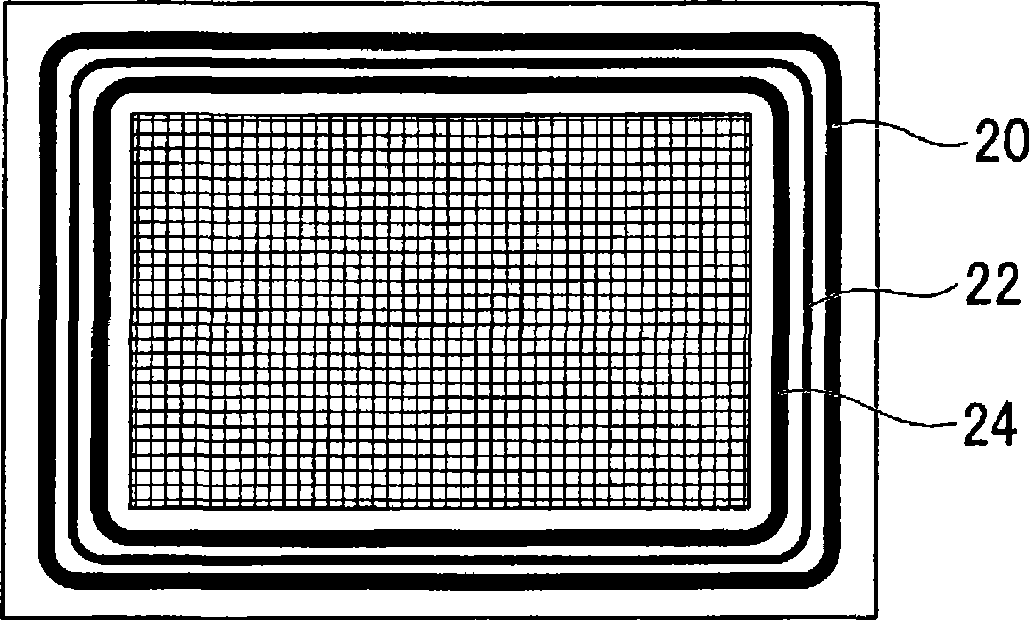

[0055] figure 1 It is an exploded perspective view of a three-electrode AC type plasma display panel. This plasma display panel (hereinafter referred to as "PDP") 100 includes a rear substrate 1 and a front substrate 2 arranged to face each other, and a plurality of discharge cells 16 formed between the substrates 1 and 2 .

[0056]Stripe address electrodes 11 are formed at predetermined intervals on the inner surface of rear substrate 1 . To cover the address electrodes 11, a diele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com