A plasma display and its manufacture method

A technology of plasma display and manufacturing method, applied in the direction of cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve the problems of production yield decline, damage, unfavorable installation, etc., to reduce manufacturing time and reduce manufacturing cost. cost, productivity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

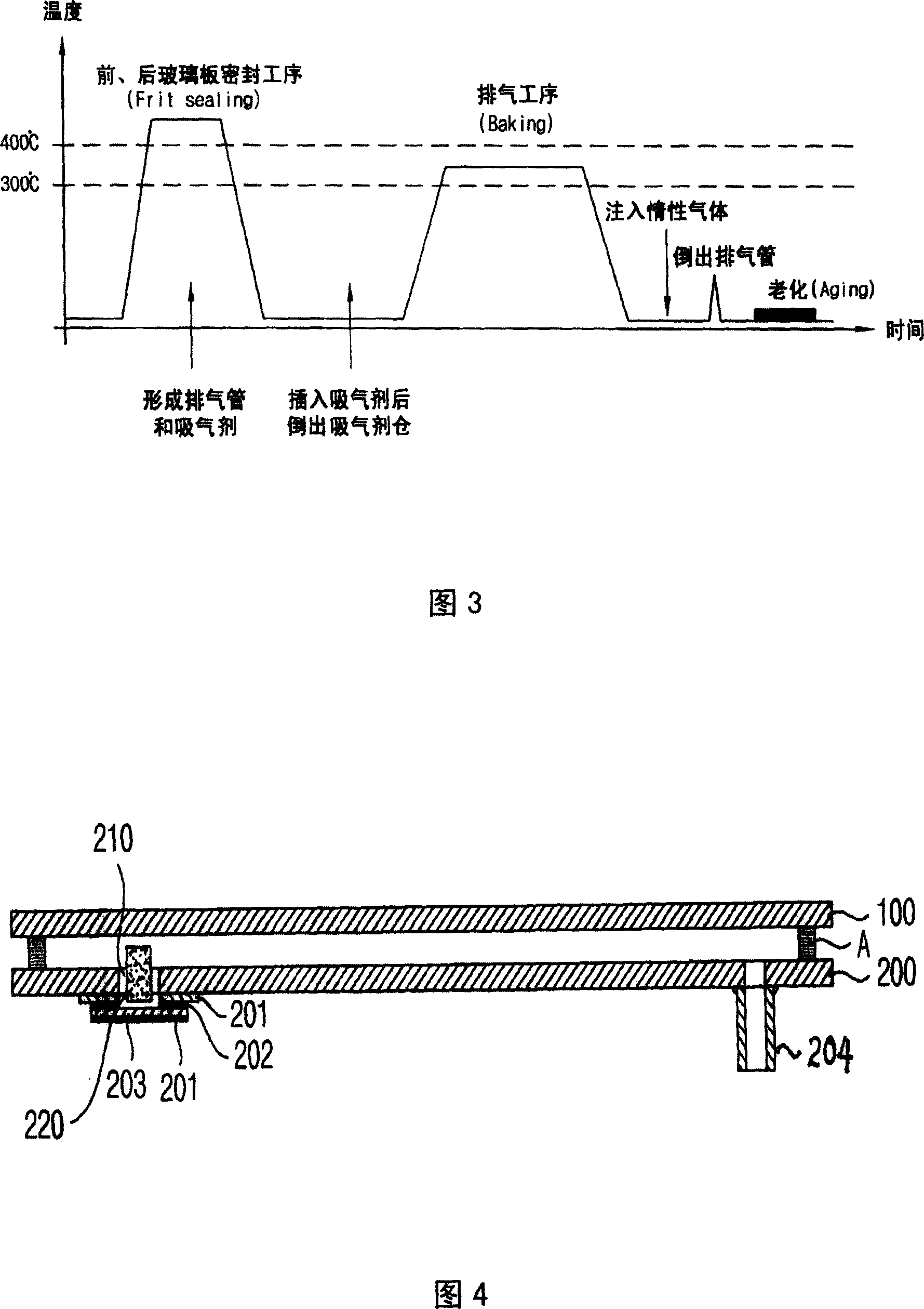

[0032] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

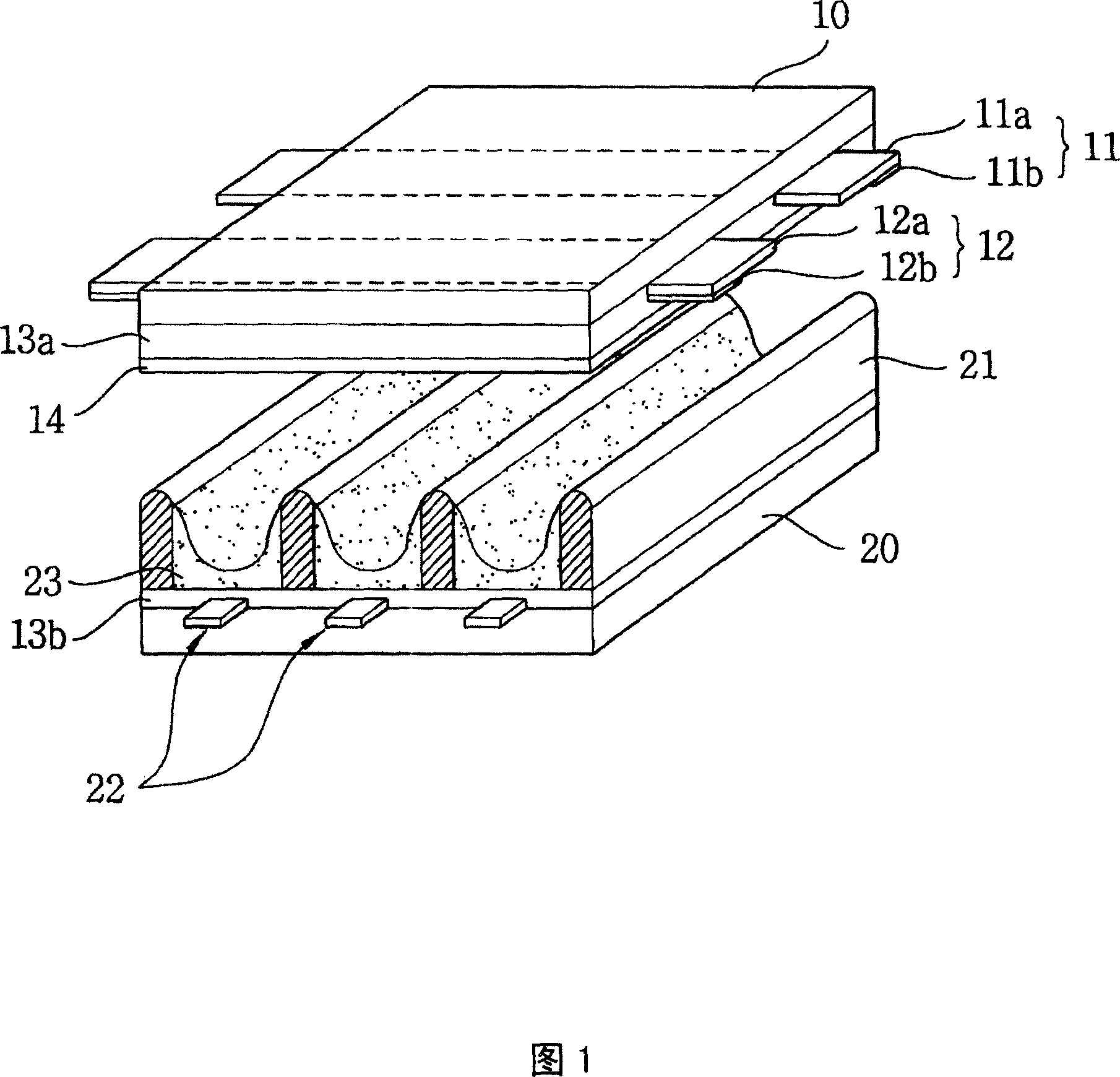

[0033] Fig. 4 is a schematic sectional view of the PDP of the present invention. As shown in FIG. 4 , the PDP of the present invention consists of a front glass plate 100 and a rear glass plate 200 that can display images arranged at a certain distance and are bonded together by a support glass plate A parallel to each other.

[0034] Since the structure of the front glass plate 100 and the rear glass plate 200 of the present invention is the same as the structure of the front glass plate 10 and the rear glass plate 20 of the conventional PDP, it will not be described in detail here.

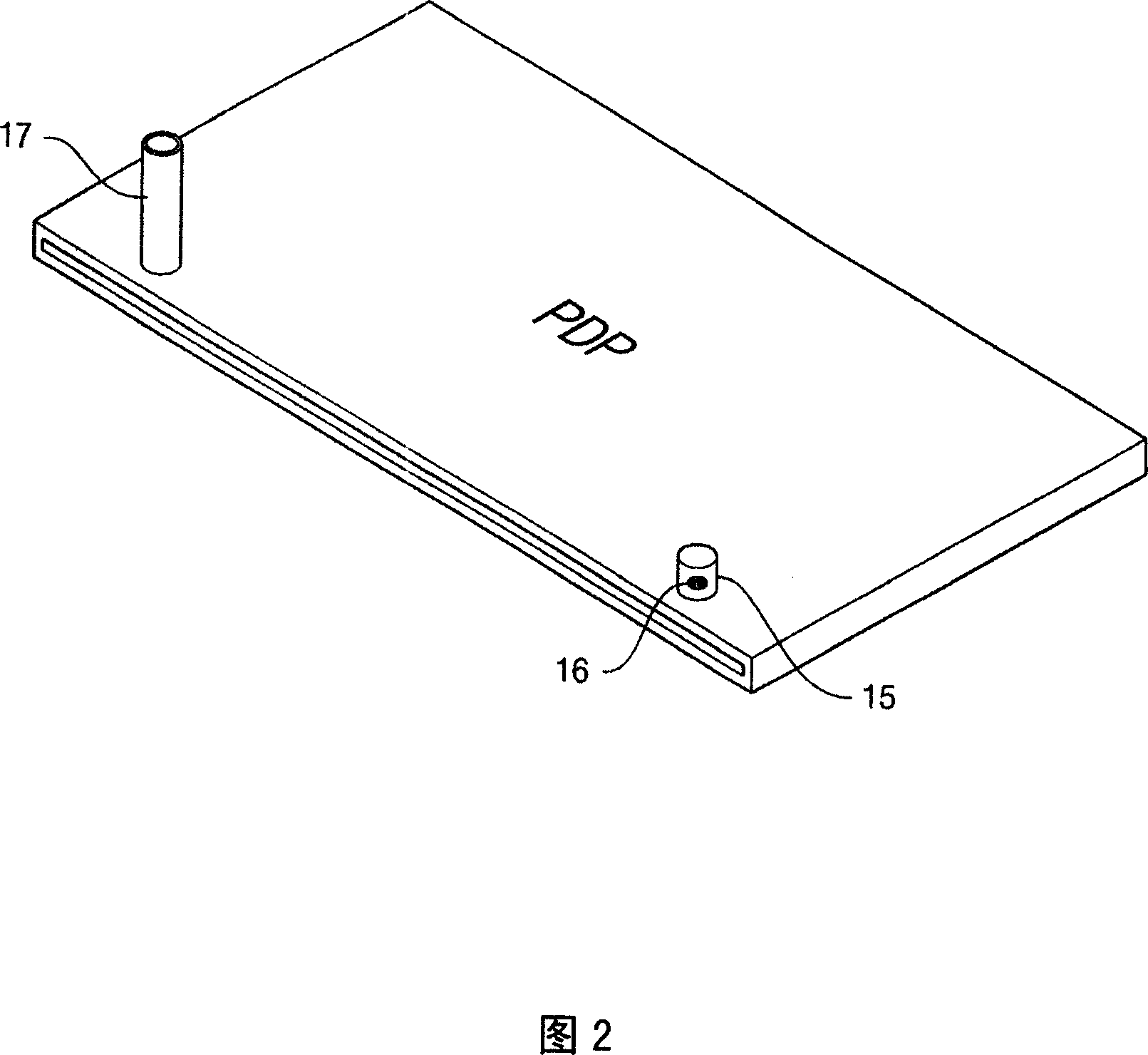

[0035] Only the area where the getter is inserted on the rear glass plate, that is, the getter insertion hole 210 is provided on the outer side of the rear glass plate and the plasma non-discharge area, and the spherical getter is inserted into the getter insertion hole 210 220. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com