Getter system in plasma plane-plate used as screen

A technology of plasma and flat plate, applied in the field of degassing system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

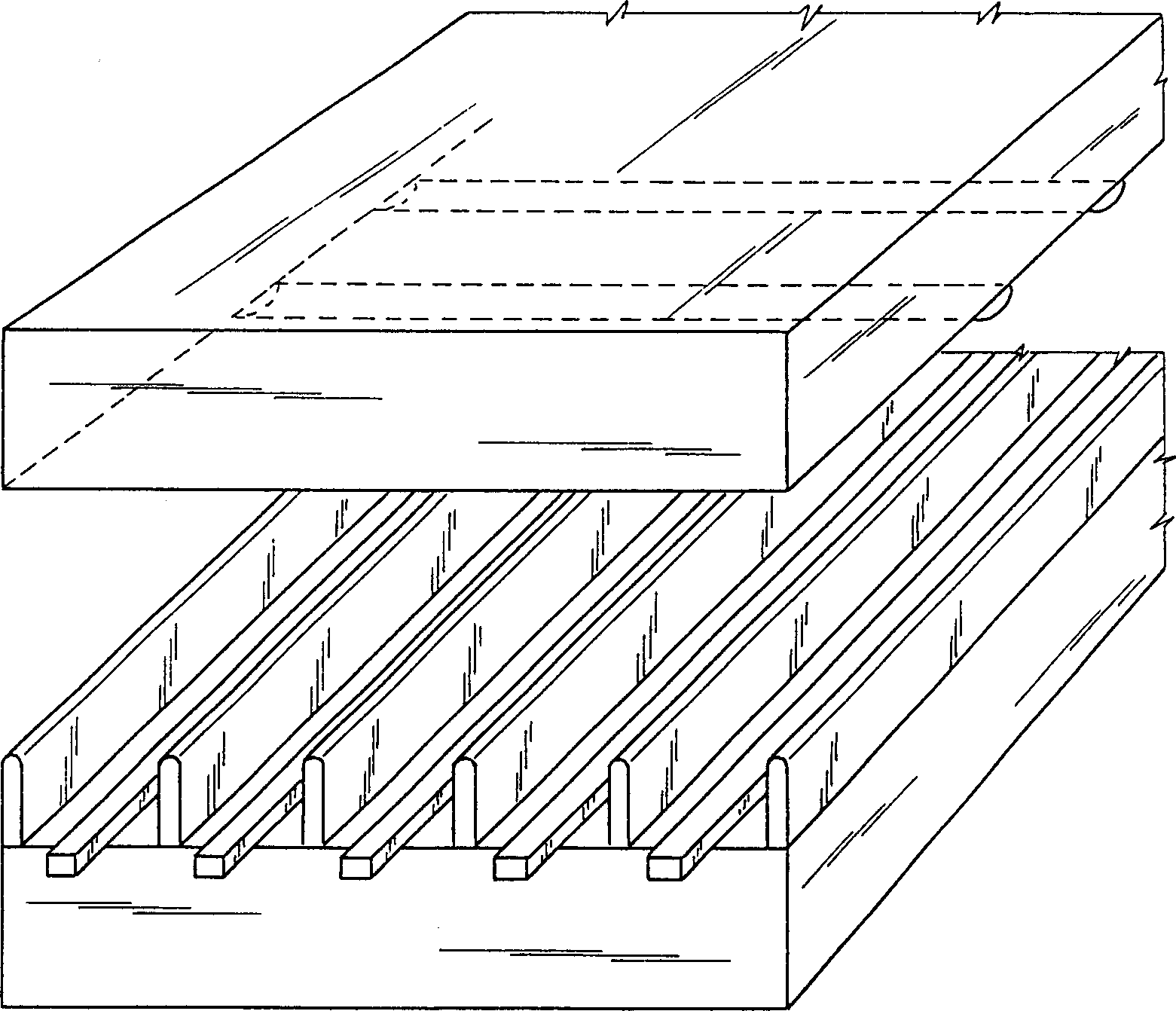

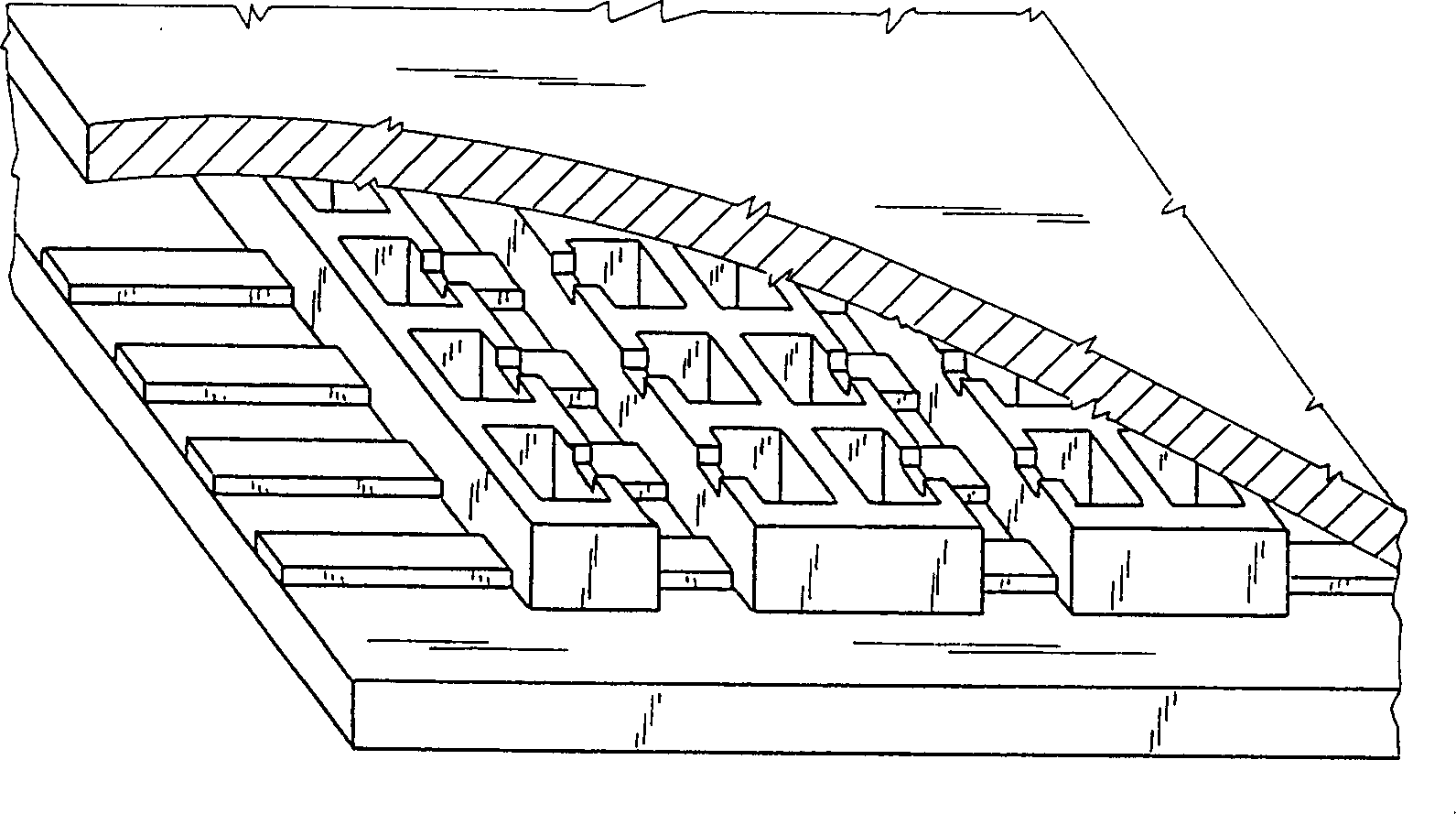

[0016] The following description will address the figure 1 A plasma display panel with a simple channel structure of the type shown is performed because figure 2 The structure shown with a chamber connected to a channel is substantially equivalent for the problem to be solved by the present invention.

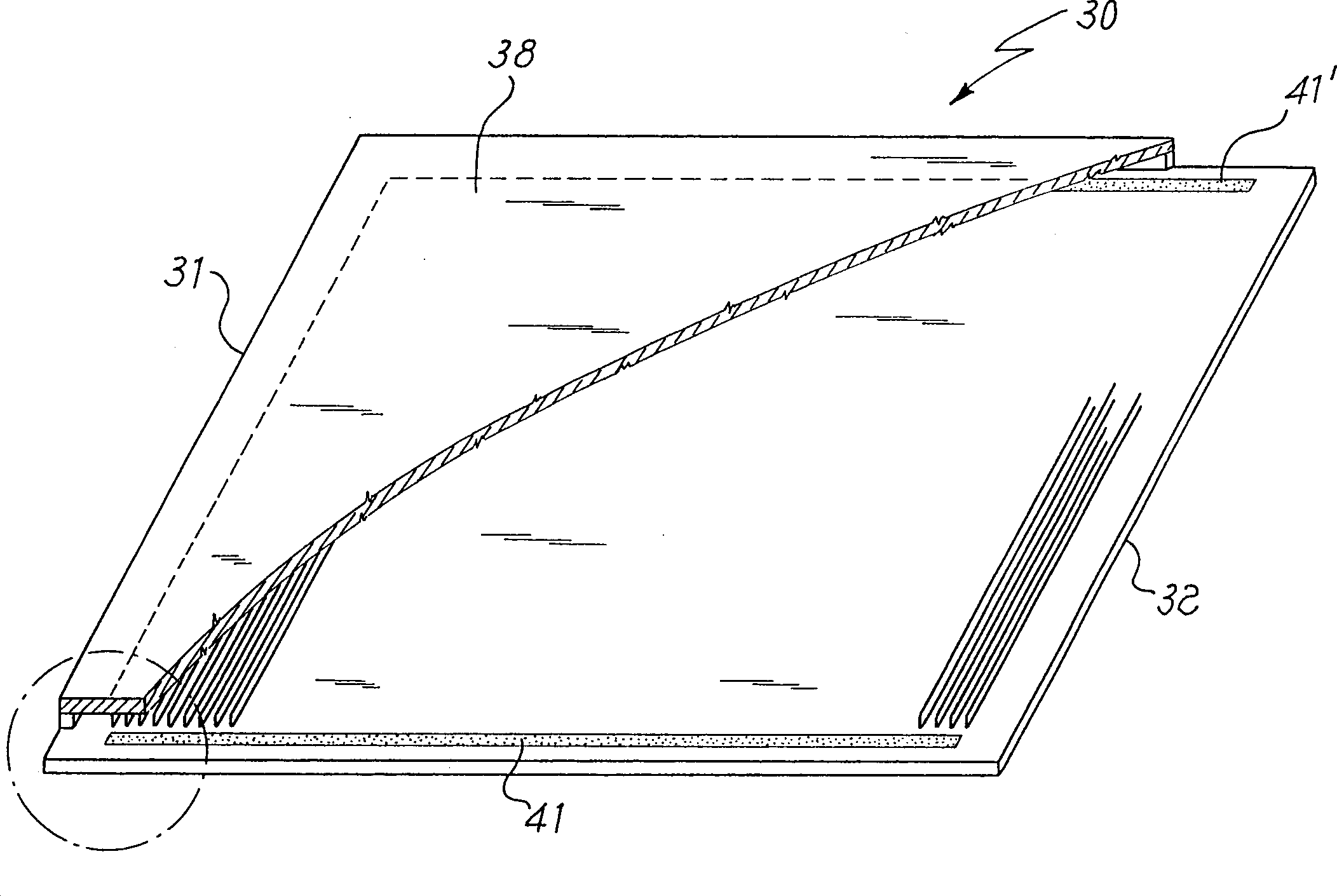

[0017] For clarity, image 3 and image 3 a only shows the main structure of the plasma display panel, and thus does not show some functional parts, such as the conductive material plating layer constituting the electrode or the fluorescent substance deposited in the channel. see image 3 and image 3 a, the plasma plate 30 is composed of a front glass part 31 and a rear glass part 32, which are sealed to each other by melting a low-melting glass paste 33 in the peripheral area 34. Contained in the interior space is a structure having channels 35, 35', ... defined by side walls 36, 36', .... The channel structure shown extends over most of the surface of the display pane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com