Ink jet printer discharge amount control method, ink droplet spread check method, and orientation film formation method

An inkjet printer, speed control technology, applied in printing, devices for coating liquid on the surface, optics, etc., can solve problems such as difficult orienting film materials, nozzle orientation nozzles being blocked by oriented film materials, nozzle defects, etc., to achieve correction Easy and Precise Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

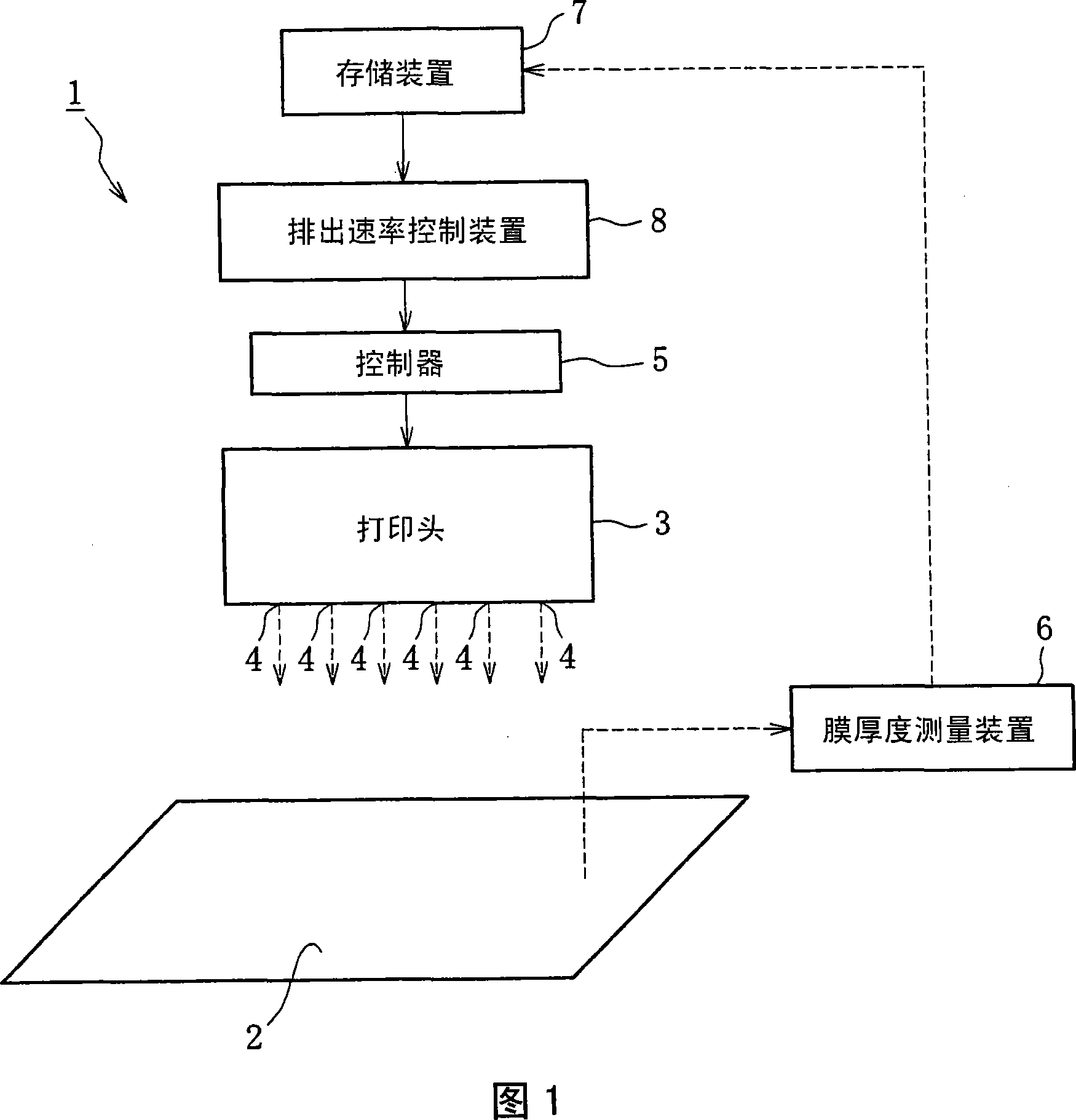

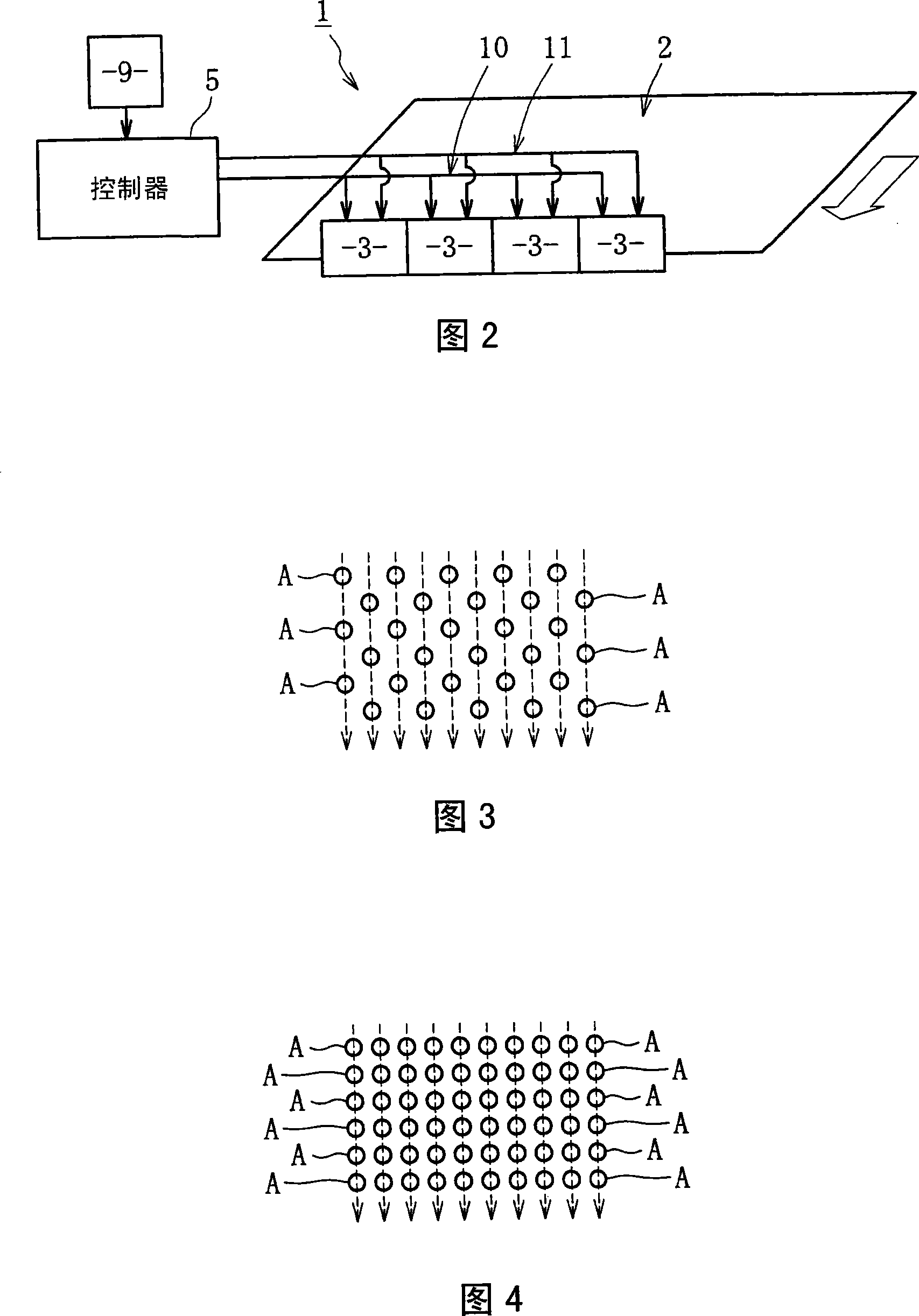

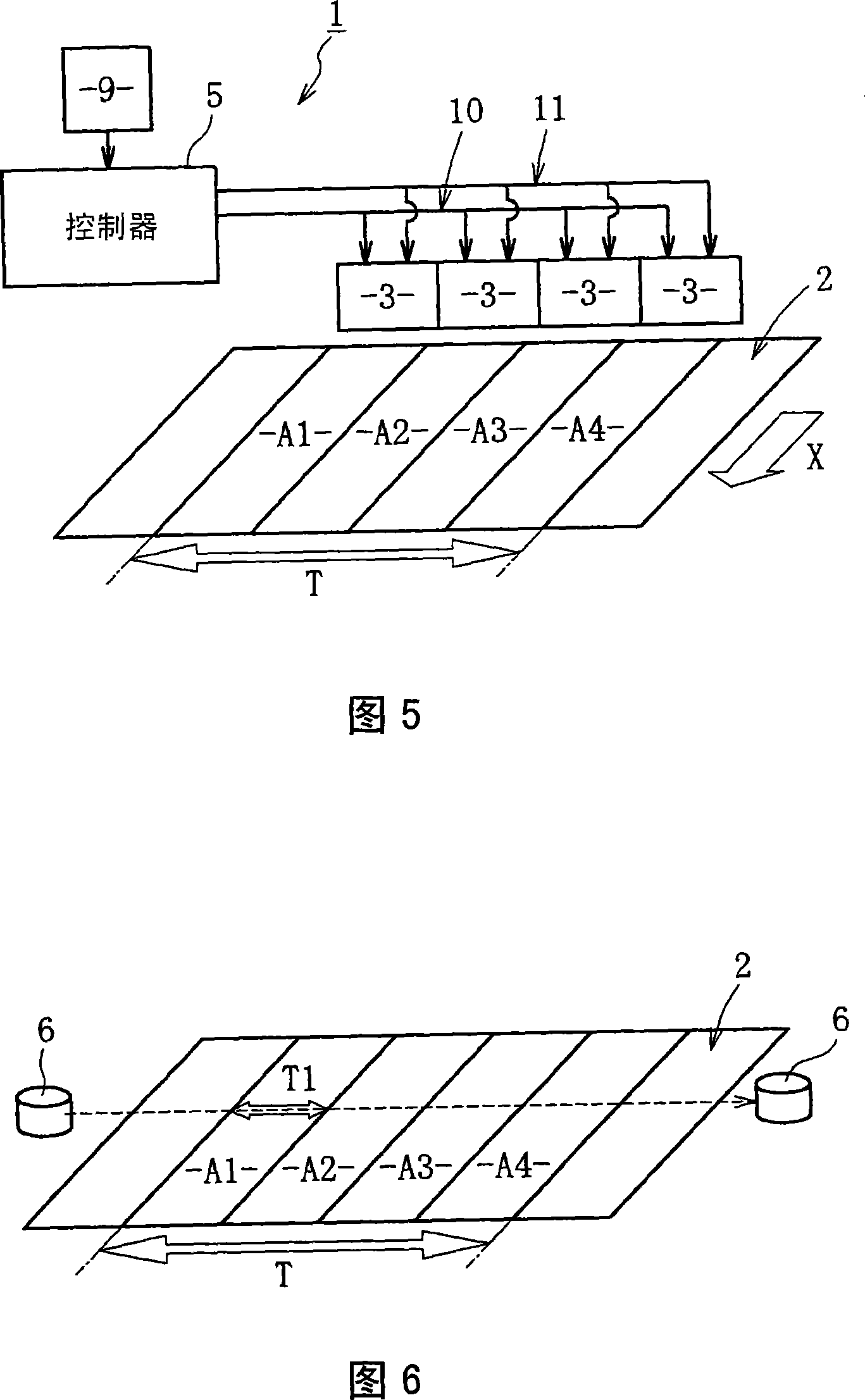

[0099] 1 to 11 are examples showing the first embodiment of the present invention. As shown in Figure 1, the main parts of the discharge rate control device 1 of an inkjet printer include: a transparent glass substrate 2, which is used in a liquid crystal display device, and has the property of not absorbing ink; a controller 5, which is used for Controlling the amount of ink discharged from the plurality of nozzles 4 of the print head 3; a film thickness measuring device 6 for measuring the thickness of the ink on the glass substrate 2 by the ink discharged from the print head 3 with respect to the discharge position of each nozzle 4 The thickness of the formed film. The discharge rate control apparatus 1 additionally includes: storage means 7 for storing correction corresponding to the difference between the target film thickness at the ink discharge position of each nozzle 4 and the film thickness determined by the film thickness measurement means 6 data; discharge rate co...

no. 2 approach

[0109] 12 to 18 are examples showing the second embodiment of the present invention. Fig. 12(a) is a schematic top view showing parts of an ink scatter inspection apparatus including an inkjet print head 1, a transparent type shown in solid lines and used as an inkjet printhead before being coated with a small ink droplet. The glass substrate 2 of the coating and the glass substrate 2 shown in dotted lines and used as the coating after being coated with small ink droplets (a group of small ink droplets 3), FIG. 12 (b) is shown in the same state A schematic side view of each component 1, 2 below. Fig. 13 is a schematic side view showing the arrangement of the inspection camera 4 and a plurality of lighting devices 5, 6 which are components of the ink scatter inspection apparatus.

[0110] According to the second embodiment, as shown in FIG. 12(a), (b), when the glass substrate 2 under the inkjet print head 1 held at a fixed position is moved toward the direction of the arrow, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com