Versatile exhausting box for blood transfusion

A universal and liquid-dispensing box technology, which is applied in the direction of subcutaneous injection equipment and equipment introduced into the body, etc., can solve the problems of infusion pipeline danger, reverse back pumping gas entry, exhaust dead angle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

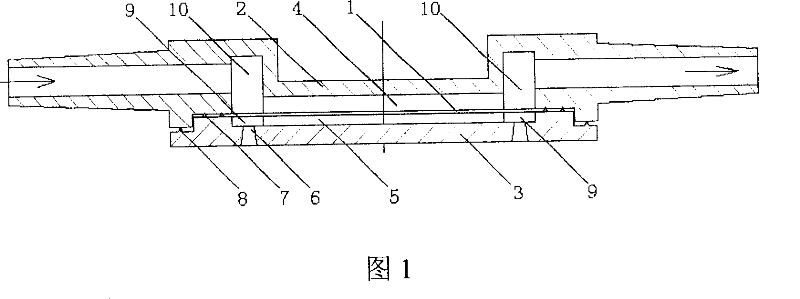

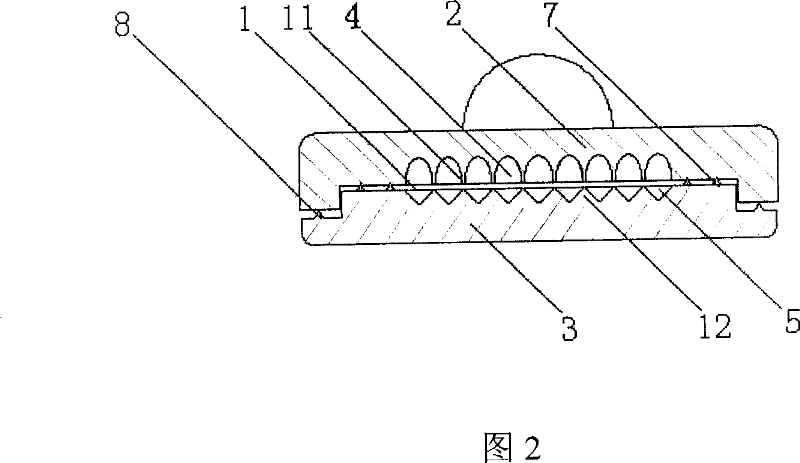

[0015] Referring to Fig. 1, the basic structure of the embodiment of this technical solution comprises exhaust film (1), liquid distribution box (2) and exhaust cover (3), and the concave liquid separation box (2) that arranges side by side on the liquid separation box (2) Groove (4), the end face of the liquid separation tank (4) of the liquid separation box (2) and the end face of the exhaust cover (3) are clamped to separate the exhaust film (1), and the two ends of the liquid separation tank (4) are respectively connected to the liquid collection chamber (10), and then communicate with the infusion pipeline, the liquid separation tanks (4) are arranged side by side with each other, the end face of the liquid separation box (2) and the end face of the exhaust cover (3) are buckled face to face, during which A whole piece of exhaust membrane (1) is sandwiched and placed, the overall structure is 2-dimensional symmetry, and there is no direction restriction for assembly.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com