Inflating overpressure spill valve for vacuum

A relief valve and overpressure technology, applied in safety valves, balance valves, valve devices, etc., can solve the problems of unsuitable high vacuum environment, system component damage, system pressure explosion, etc., and achieve low cost, simple installation and debugging, good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

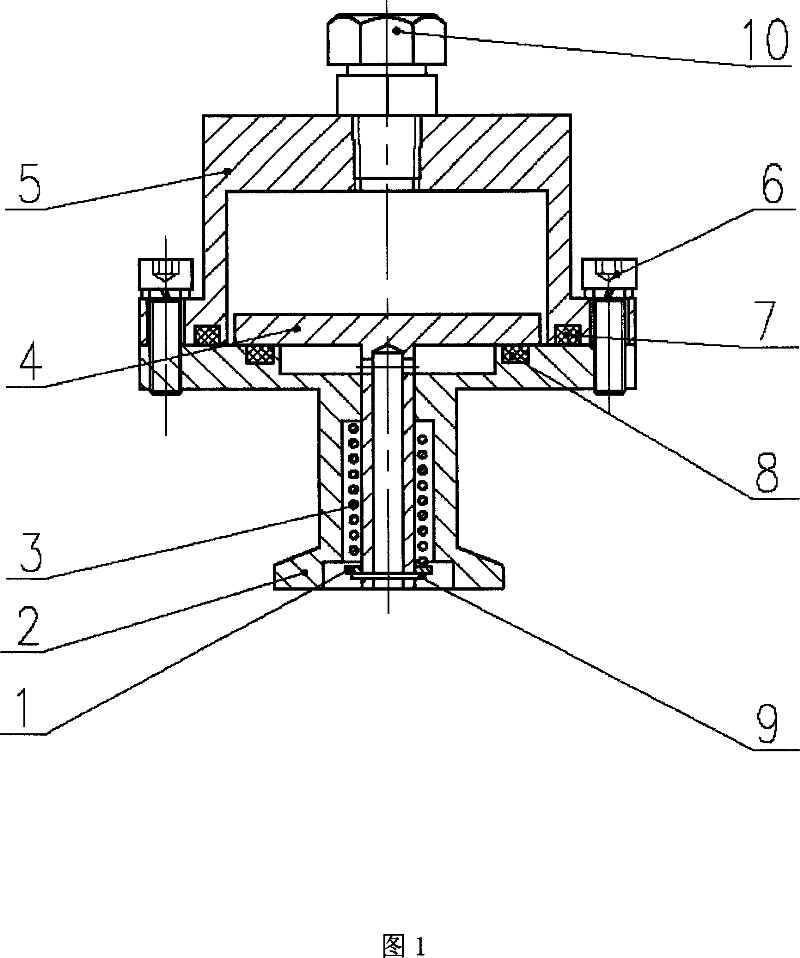

[0021] Referring to Figure 1, the main components of the vacuum relief valve device are: gasket 1, KF interface 2, spring 3, overflow sealing cover 4, outer cover 5, hexagon socket head screw 6, O-ring 7 and O-ring 8, circlip 9, ferrule joint 10.

[0022] The KF interface 2 is connected to the vacuum system, and the gas inflated enters from the through hole at the lower end of the overflow sealing cover plate 4, and the gas pressure acts on the overflow sealing cover plate 4. When the pressure is greater than the pre-pressure of the spring 3, the overflow sealing Cover plate 4 is jacked up, spring 3 is compressed, and overflows. When the air pressure at both ends of the overflow sealing cover 4 is balanced, under the elastic force of the spring 3, the overflow sealing cover 4 moves down to aut...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap