Ion implantation high temperature target

A technology of ion implantation and target disk, which is used in the manufacture of discharge tubes, electrical components, semiconductor/solid state devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

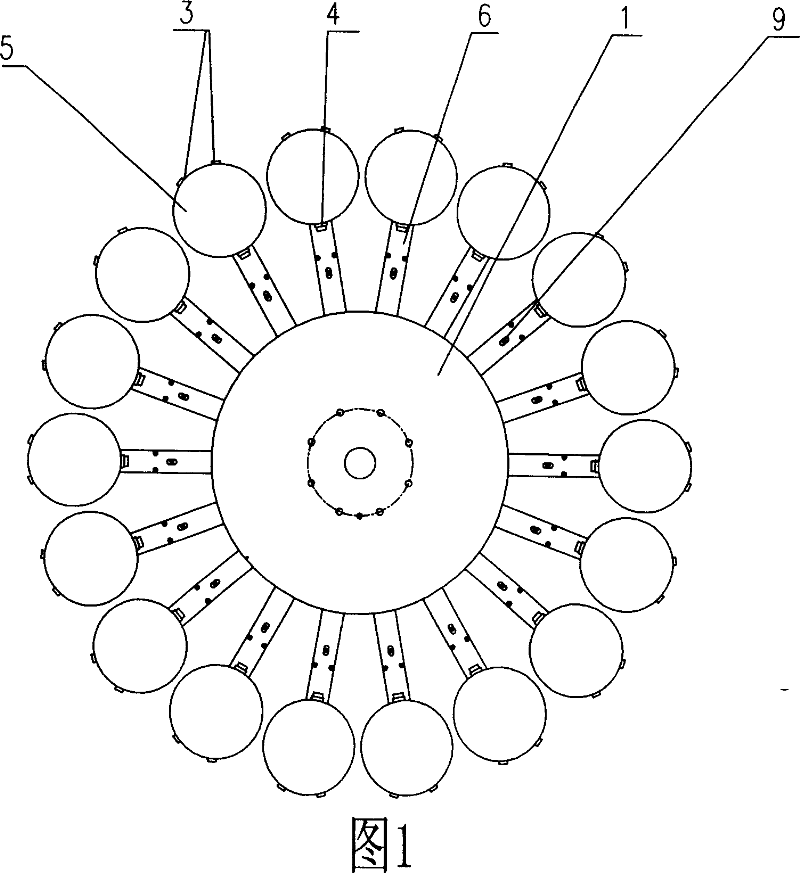

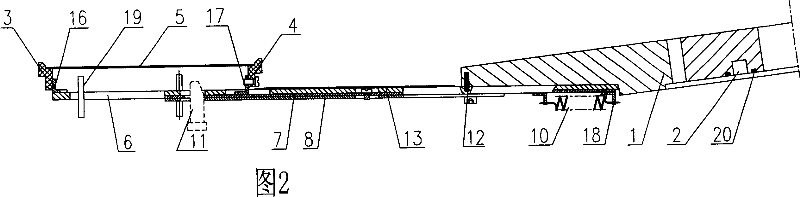

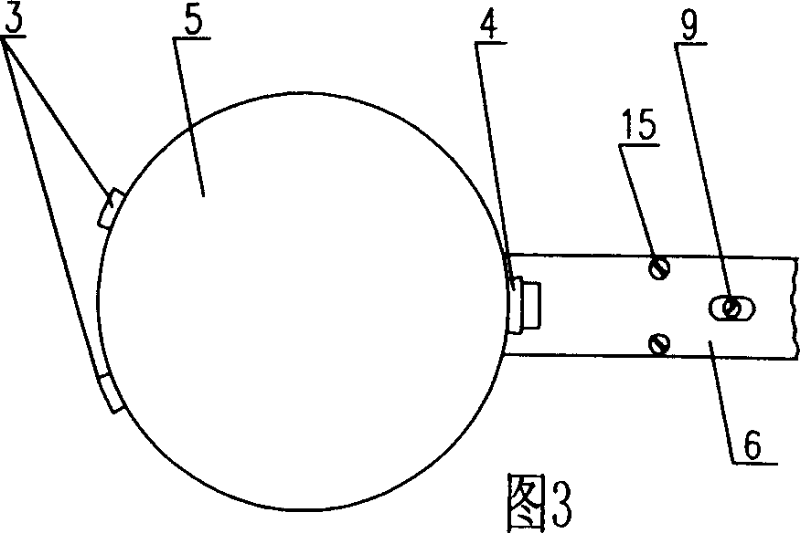

[0031]Refer to the attached drawings. The target base 1 is made of aluminum with good thermal conductivity. Its cooling water path is an annular water tank 2, and it can also be a water jacket composed of two sealing rings 20. The interior is cooled by water and is in a low temperature area. ; The wafer clamping mechanism in the high temperature zone is connected to the target base 1 through the support bar 6 in the temperature transition zone, and the motor drives the target base 1 to rotate. The whole target is designed to hold 18 wafers, and the target claw group clamps the wafer for work Uniform speed rotation (to ensure the high temperature requirements of the wafer during injection, make full use of the heat source and improve thermal efficiency, the structural size of the parts in this area should be as small as possible, designed with the smallest quality and the smallest heat conduction area; to ensure that the wafer is injected at high temperature The surface temperature...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap