Apparatus for measuring thickness of glass substrate

A glass substrate and equipment technology, applied in the field of thickness measurement equipment, can solve problems such as the inability to provide measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

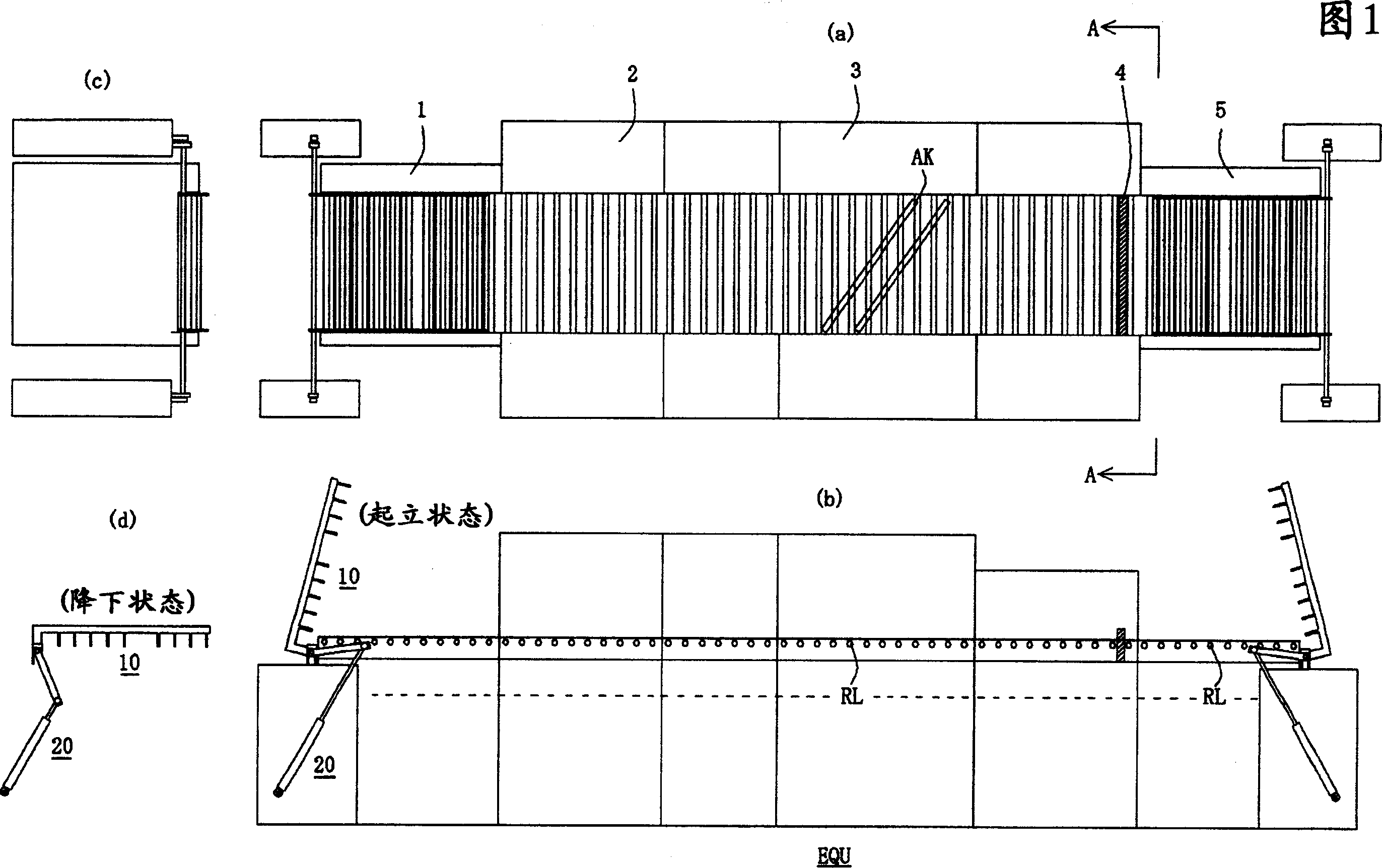

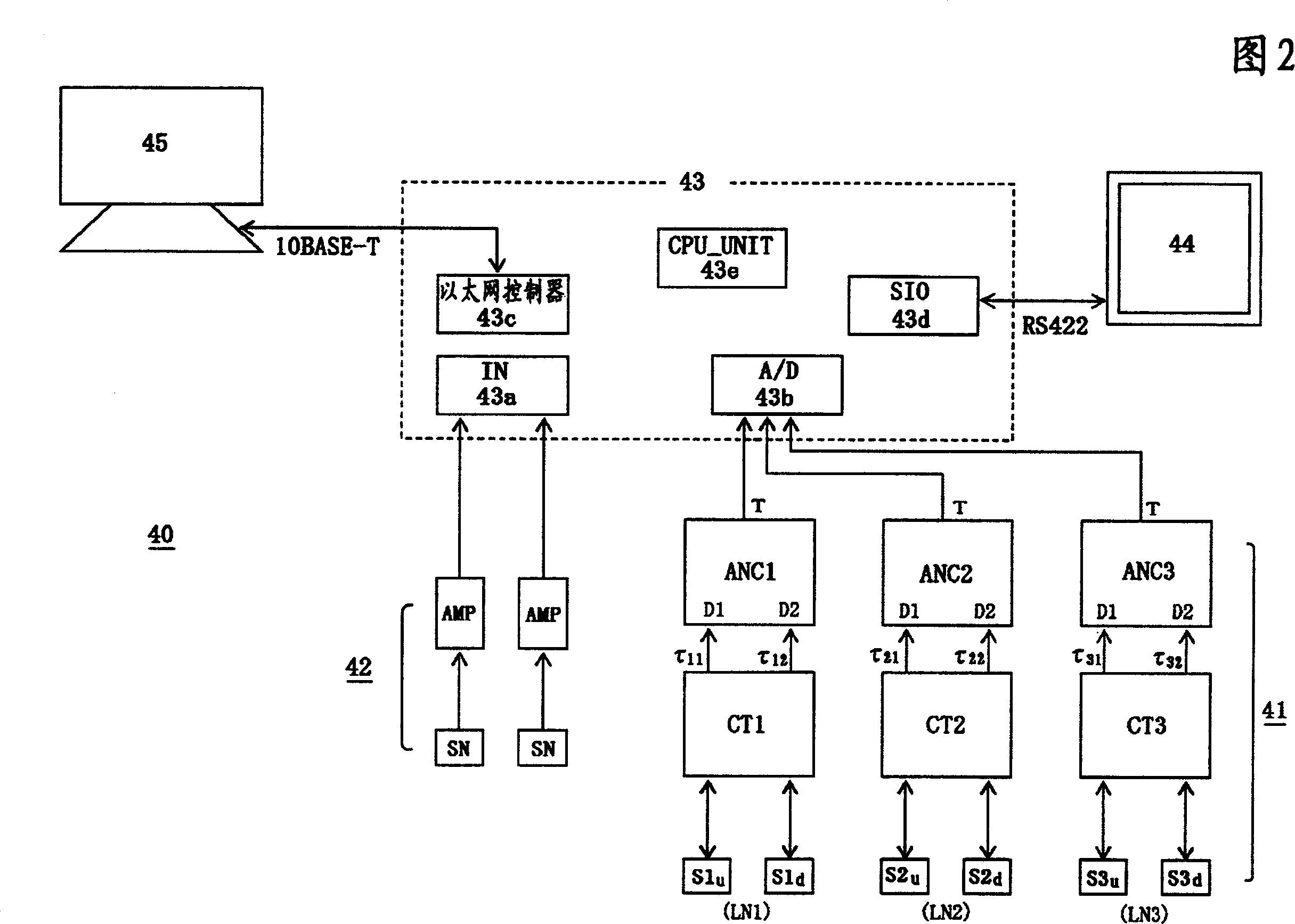

[0022] The present invention will now be described in detail with reference to preferred embodiments. FIG. 1 is a block diagram showing a post-processing apparatus EQU equipped with a thickness measuring apparatus 40 embodying the invention. In FIG. 1 , a plan view (a), a front view (b), and a left elevation view (c) are illustrated. In this post-processing equipment EQU, the glass substrate thinned by the chemical polishing process is sequentially subjected to washing treatment, drying treatment, and thickness measurement treatment.

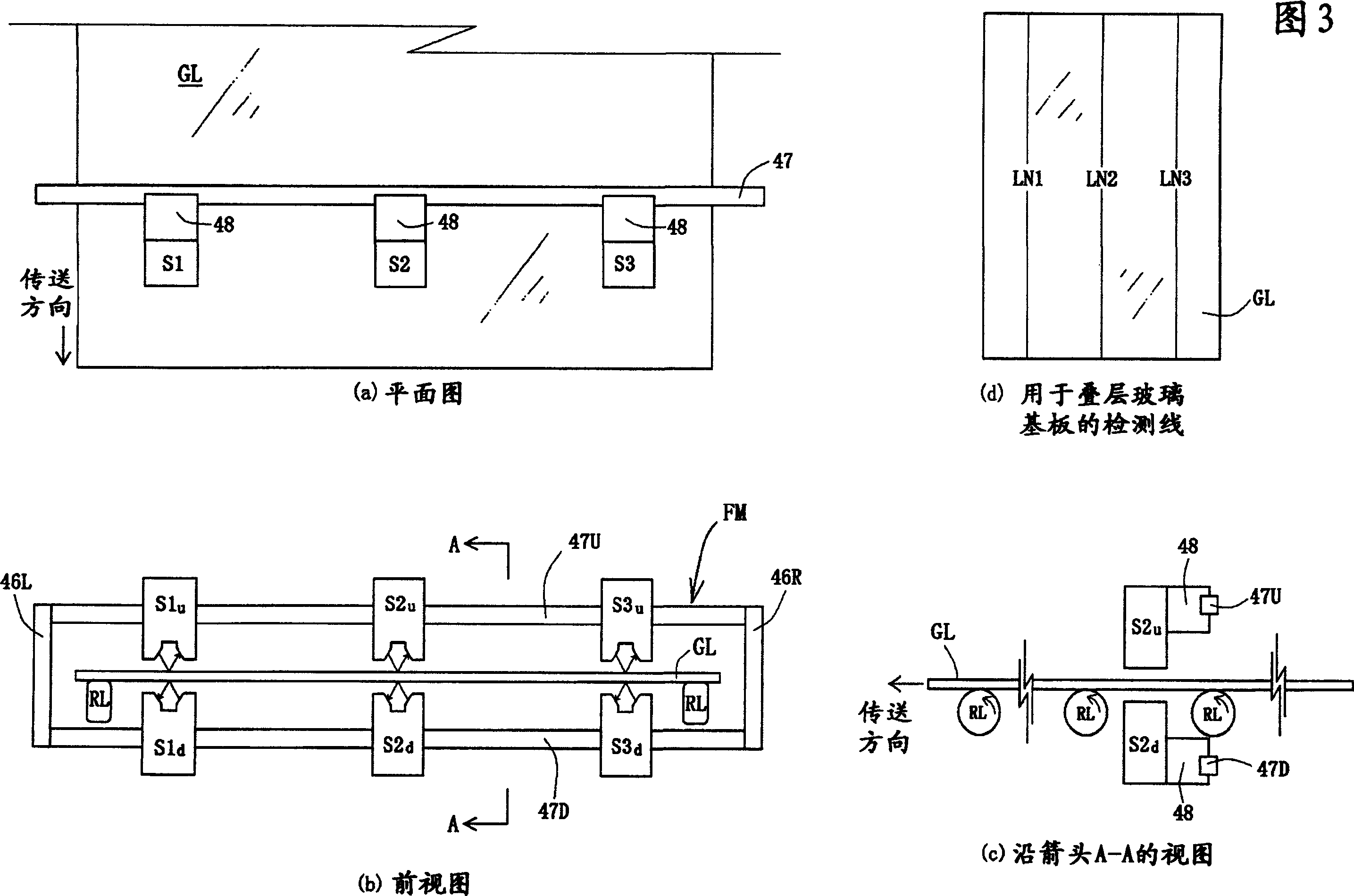

[0023] In this embodiment, the laminated glass substrate GL for a liquid crystal display is assumed without limitation as a glass substrate GL (see FIG. 9 ), in which a liquid crystal confinement region 61 is provided between two glass substrates 60 , 60 in the display. A chemical polishing process, such as but not limited to, is performed by immersing the laminated glass substrate GL in a fluorinated acid-based polishing solution with its peri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com