Embedded type connector for printed circuit board

A printed circuit board, embedded technology, applied in the direction of conductive connection, circuit, connection, etc., can solve problems such as complex production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

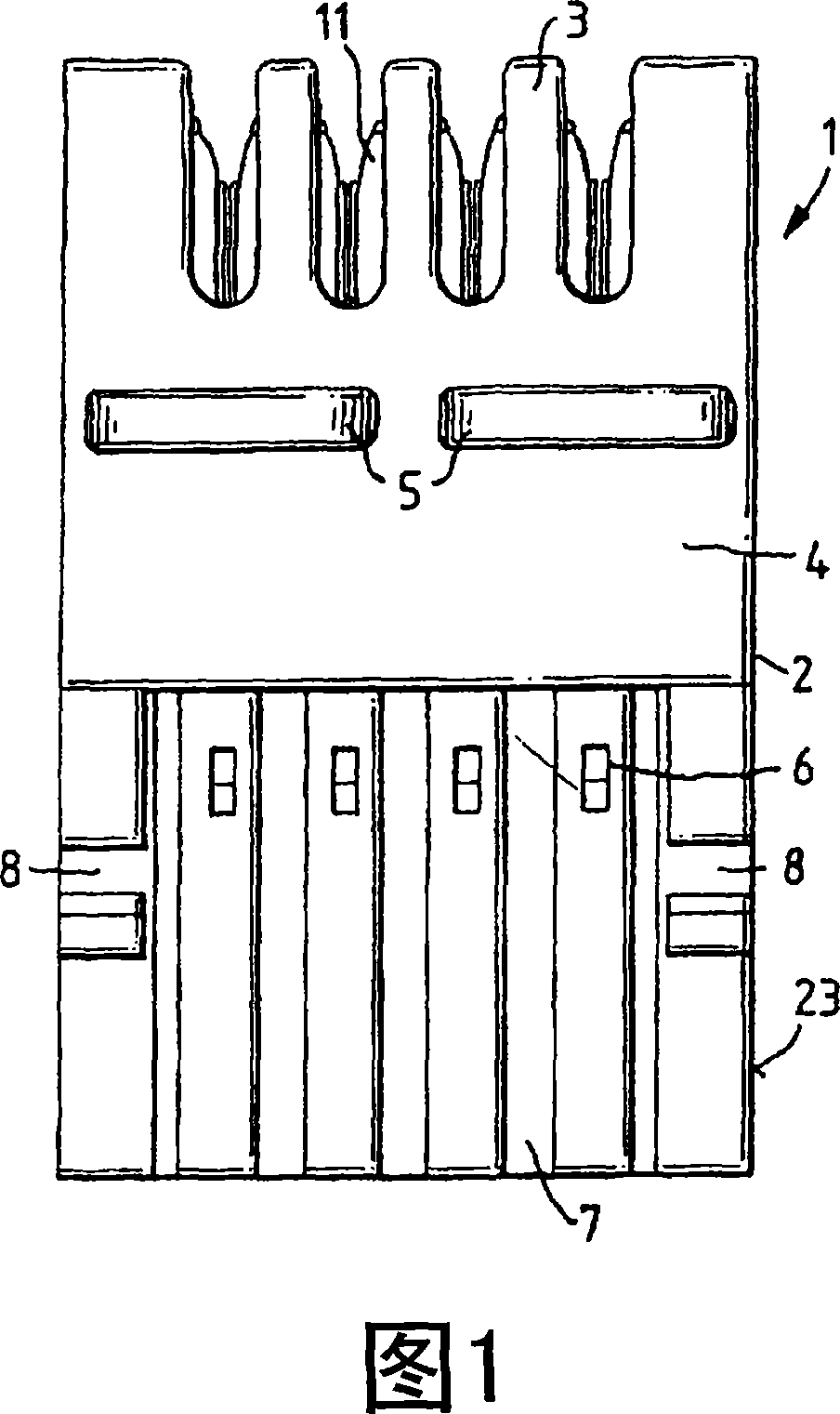

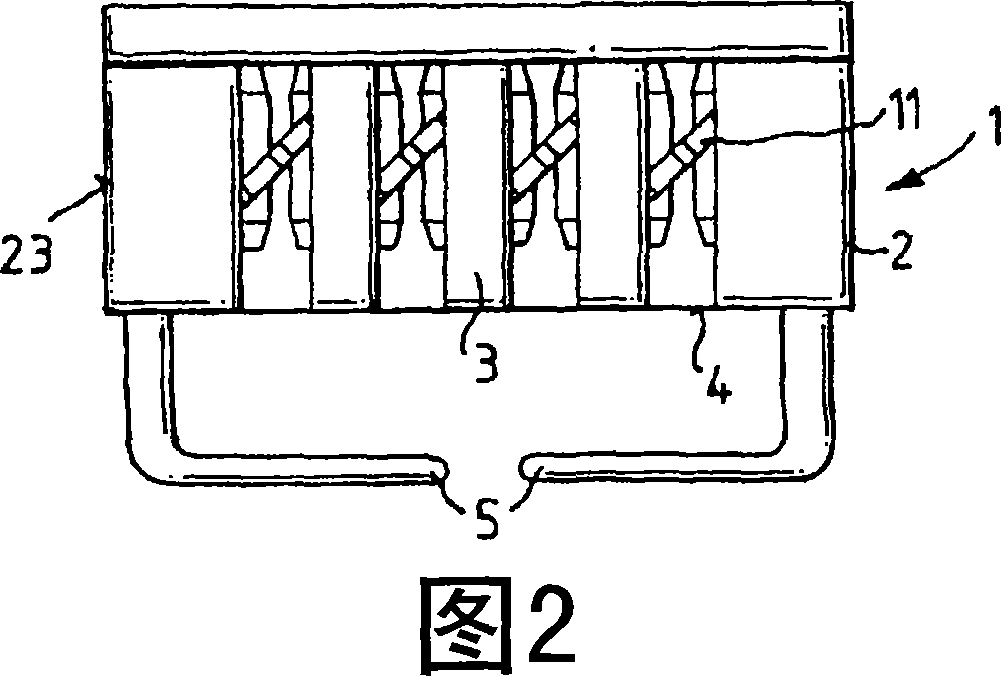

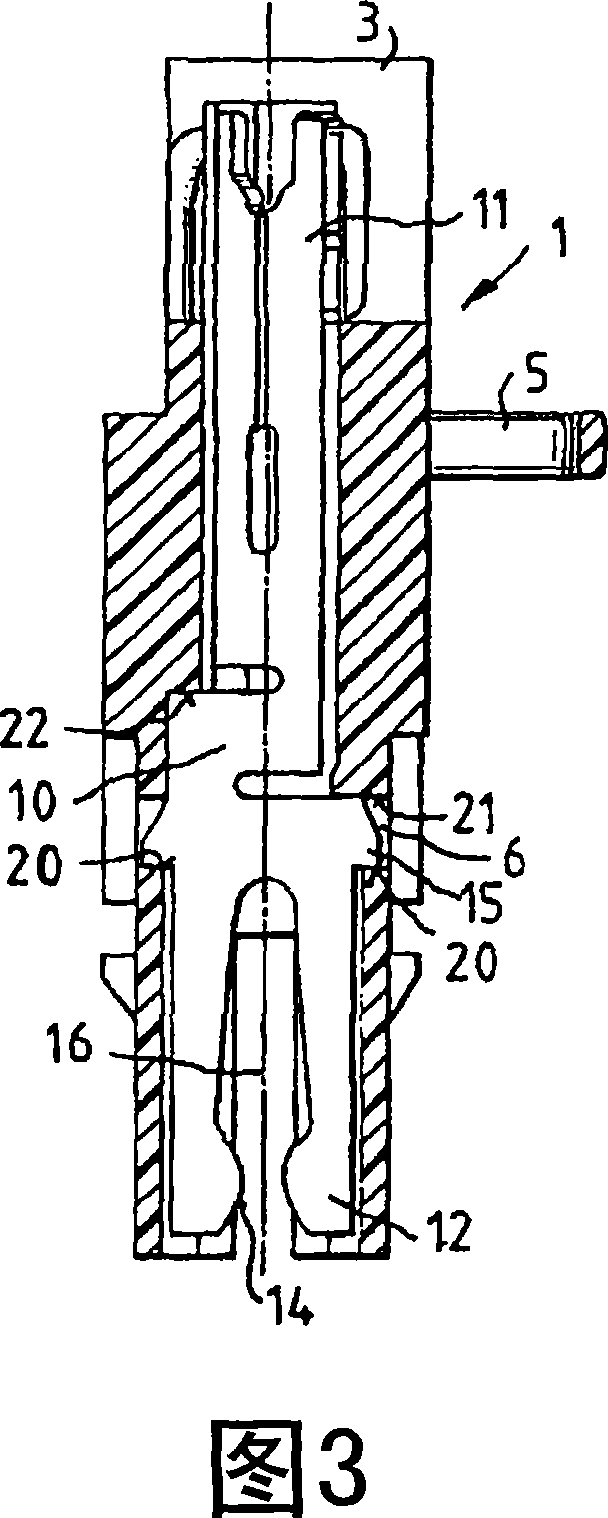

[0017] In FIG. 1, the embedded connector 1 is shown in a side view. The embedded connector 1 includes an integral plastic shell 2 . In the upper region, the plastic housing 2 is formed with clamping ribs 3 between which the insulation piercing contacts 11 of the contact part 10 are arranged (shown in FIG. 4 ). The wire guide 5 is arranged below the clamping rib 3 on the housing wall. The forked contacts 12 of the contact part 10 are arranged in the lower region of the plastic housing 2 , which has a snap-in receptacle 6 formed as a rectangular hole. Between the respective pair of detent sockets 6 , the housing wall 4 has a groove-shaped depression 7 . Furthermore, the housing wall 4 has two sockets 8 on both sides for a locking mechanism (not shown), through which the snap-in connector 1 can be fastened, for example, to a metal front frame. The housing wall 4 is formed on the inside with a slot 9 in which the forked contacts 12 are guided with their side surfaces 13, in whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com