Surface modifying method for promoting water separating selective of osmotic vaporization membrane

A technology of pervaporation membrane and surface modification, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problem of easy grafting reaction, and achieve the effect of low price, wide source and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

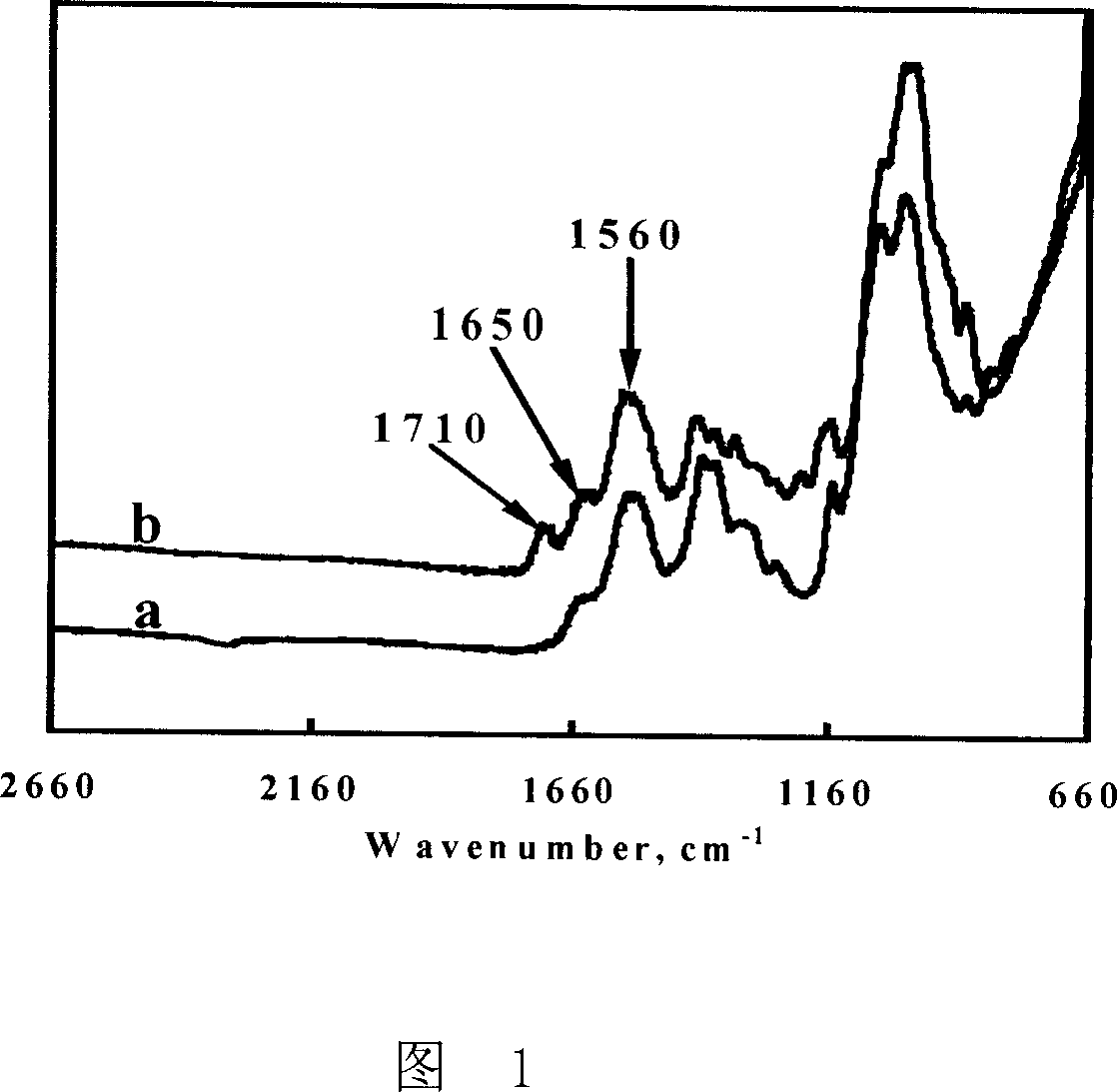

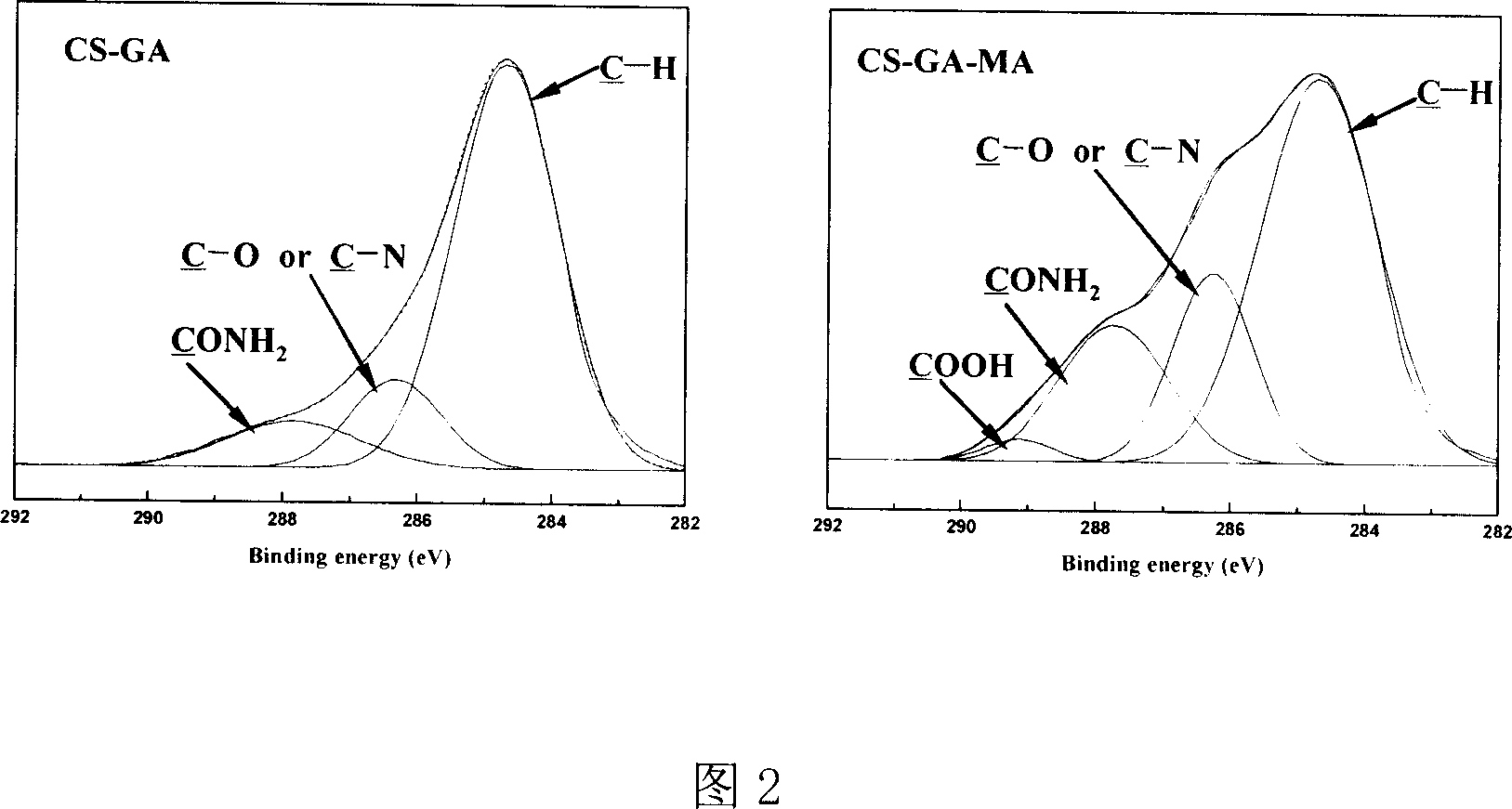

Embodiment 1

[0026] Example 1. Preparation of glutaraldehyde-crosslinked chitosan film: Chitosan was purchased from Xianju Chemical Products Co., Ltd. (China, Zhejiang), with a deacetylation degree of 88% and a viscosity-average molecular weight of 550,000. The cross-linking agent glutaraldehyde (25% aqueous solution) was purchased from China Wulian Chemical Factory, and maleic anhydride, glacial acetic acid, absolute ethanol, isopropanol, etc. were purchased from Hangzhou Huipu and Wuxi Zhanwang Chemical Products Company. A certain quality of chitosan was dissolved in 2% glacial acetic acid aqueous solution to obtain a solution with a concentration of 2%. Add 1% GA (relative to the mass of chitosan) into the filtered chitosan solution and stir evenly. The chitosan solution containing 1% glutaraldehyde was cast on a level-adjusted glass plate, and dried at 40°C for two days to obtain a chitosan film with a dense structure and 1% glutaraldehyde cross-linked. The membrane was heat-treated a...

Embodiment 2

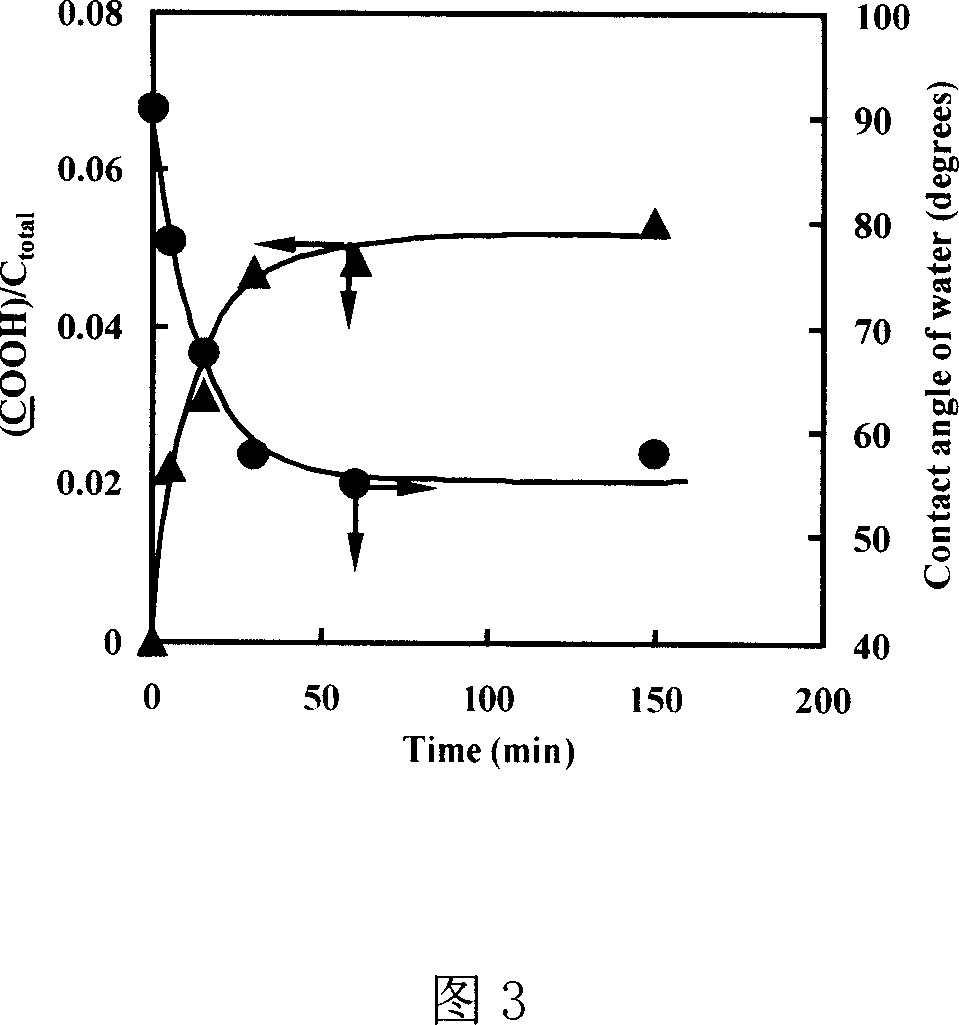

[0029] Embodiment 2: According to the modification treatment steps in Embodiment 1, changing the conditions of the modification treatment can obtain different modification results, and the corresponding results are shown in the chart in the following beneficial effects.

Embodiment 3

[0030] Example 3. According to the experimental procedure in Example 1, the content of glutaraldehyde was changed when preparing the glutaraldehyde cross-linked chitosan film, and a series of cross-linked chitosan films with different cross-linking degrees were prepared. Then, according to the modification treatment steps in Example 1, and the surface modification time was determined as 60 minutes, the surface carboxylation modification was carried out on these crosslinked chitosan films.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap