Rotary cutting tool with cutter blade regulation mechanism

A cutting tool and rotary technology, which is applied in the field of rotary cutting tools, can solve the problems of tool chatter, rough workpiece surface, burr and shortened tool life, and achieve the effect of easy maintenance and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

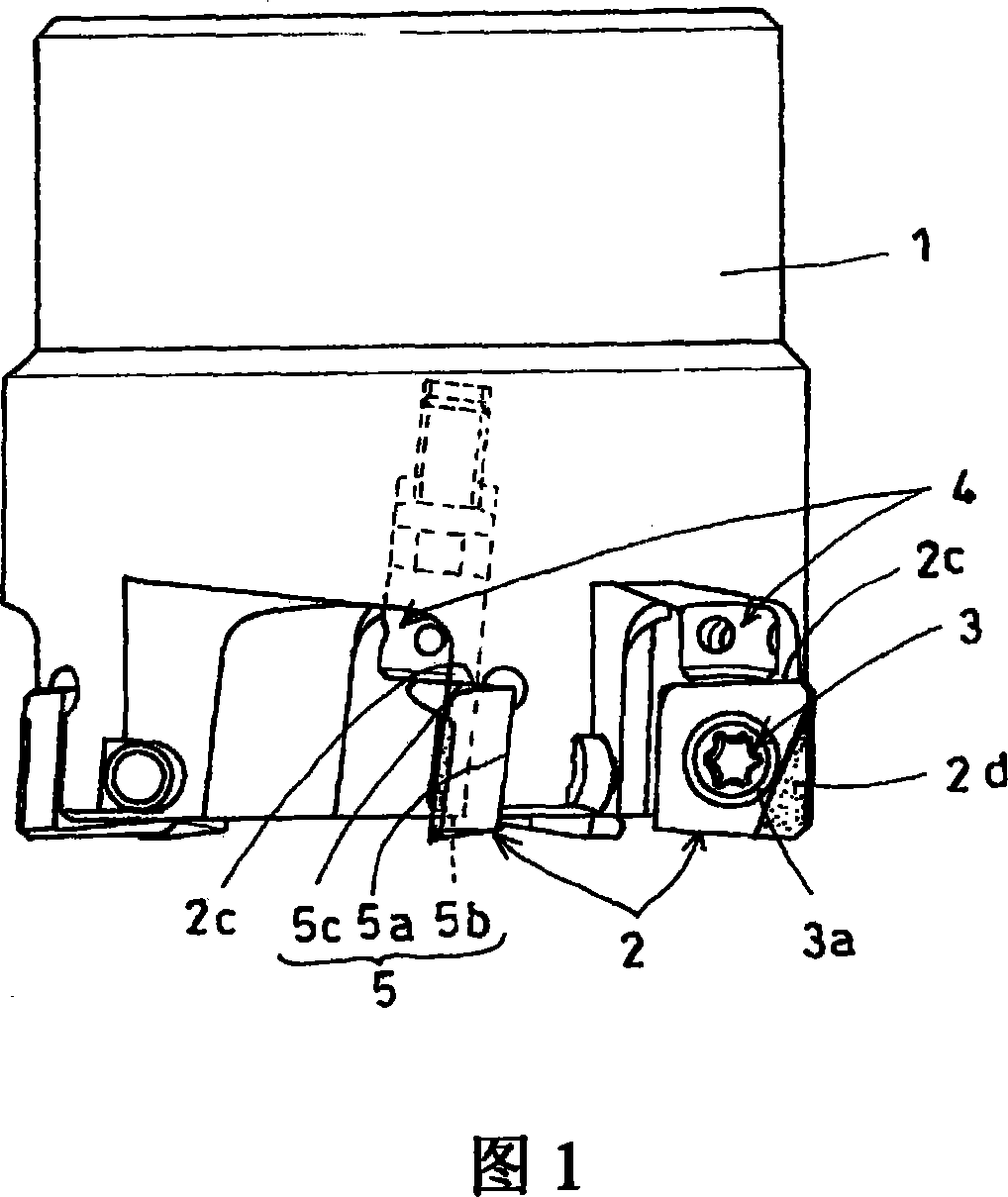

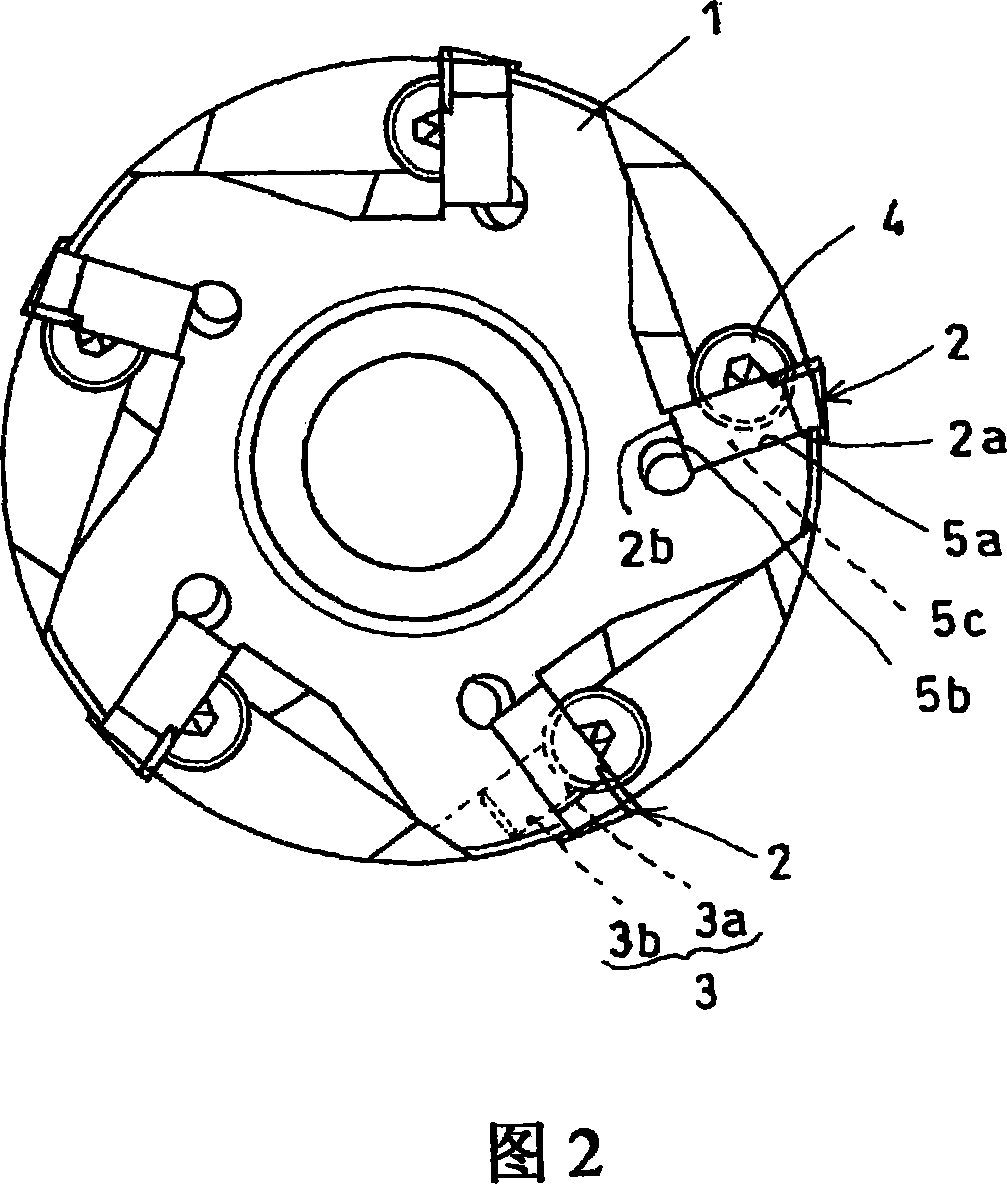

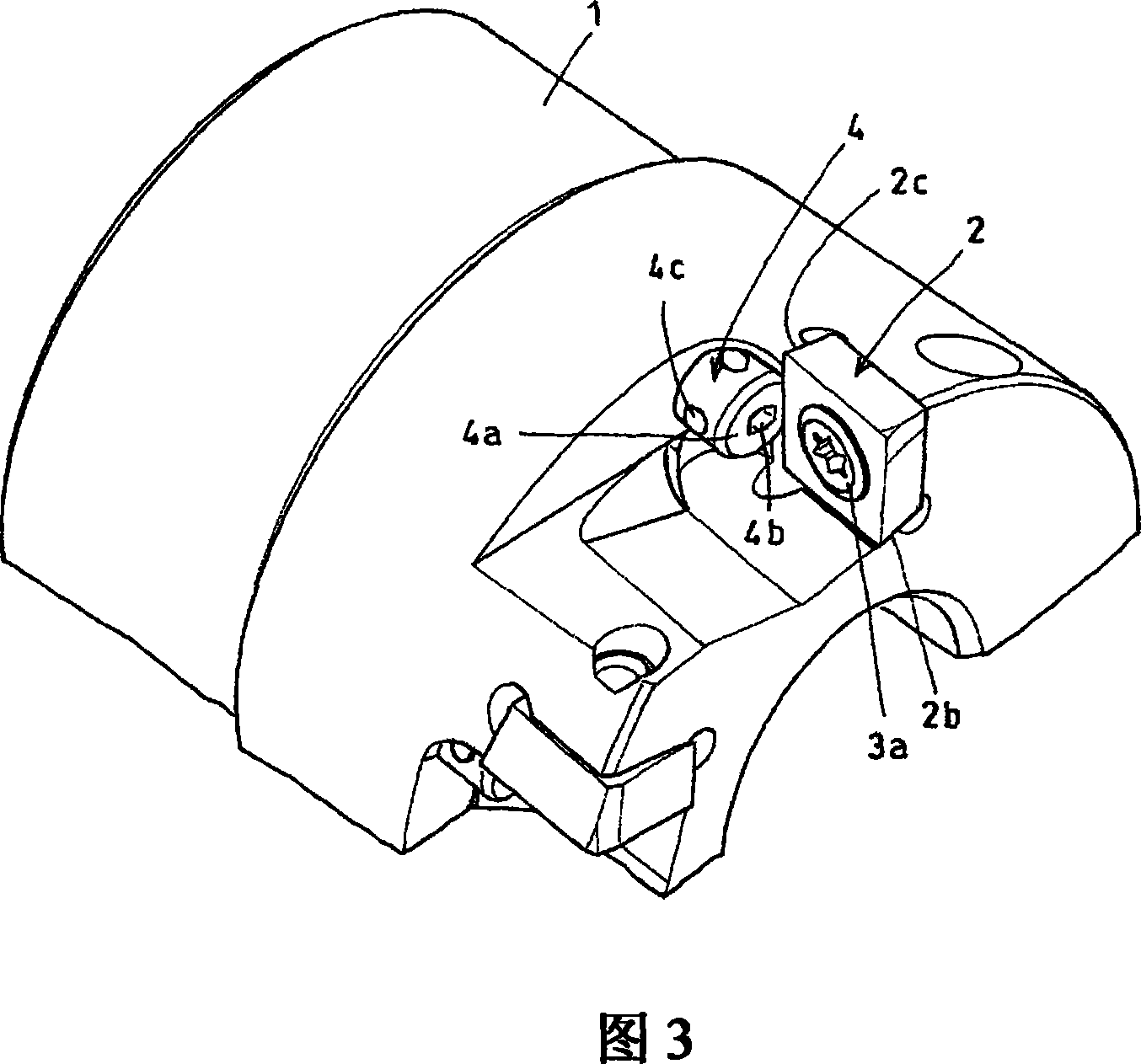

[0043] Next, the rotary cutting tool of the present invention will be described with reference to FIGS. 1 to 6 .

[0044] 1 to 4 show a rotary cutting tool according to a first embodiment of the present invention. The rotary cutting tool shown in the figure is an angle milling cutter, including: a tool body 1; a disposable blade 2; a clamping device 3, which respectively fixes a blade 2 on the tool body 1; and an adjusting screw, which is used to adjust each Position of blade 2.

[0045] A blade mounting groove 5 is formed in the outer periphery at the top end of the tool body 1 . As shown in Figure 4, each blade mounting groove 5 has three seating surfaces, comprising: seating surface 5a, the back 2a of each blade 2 is seated on the seating surface 5a; seating surface 5b, the side 2b of each blade 2 facing the tool axis seated on the seating surface 5b; and a seating surface 5c on which the side 2c of each blade 2 facing the base end of the tool is seated. Thus, the blade ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap