Printer and printing method

A technology of a printing device and a printing head, applied in directions such as printing, can solve the problems of lack of convenience for users, increased waiting time, frequent and other problems, and achieve the effects of reducing printing density unevenness and streaks, reducing time, and preventing overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

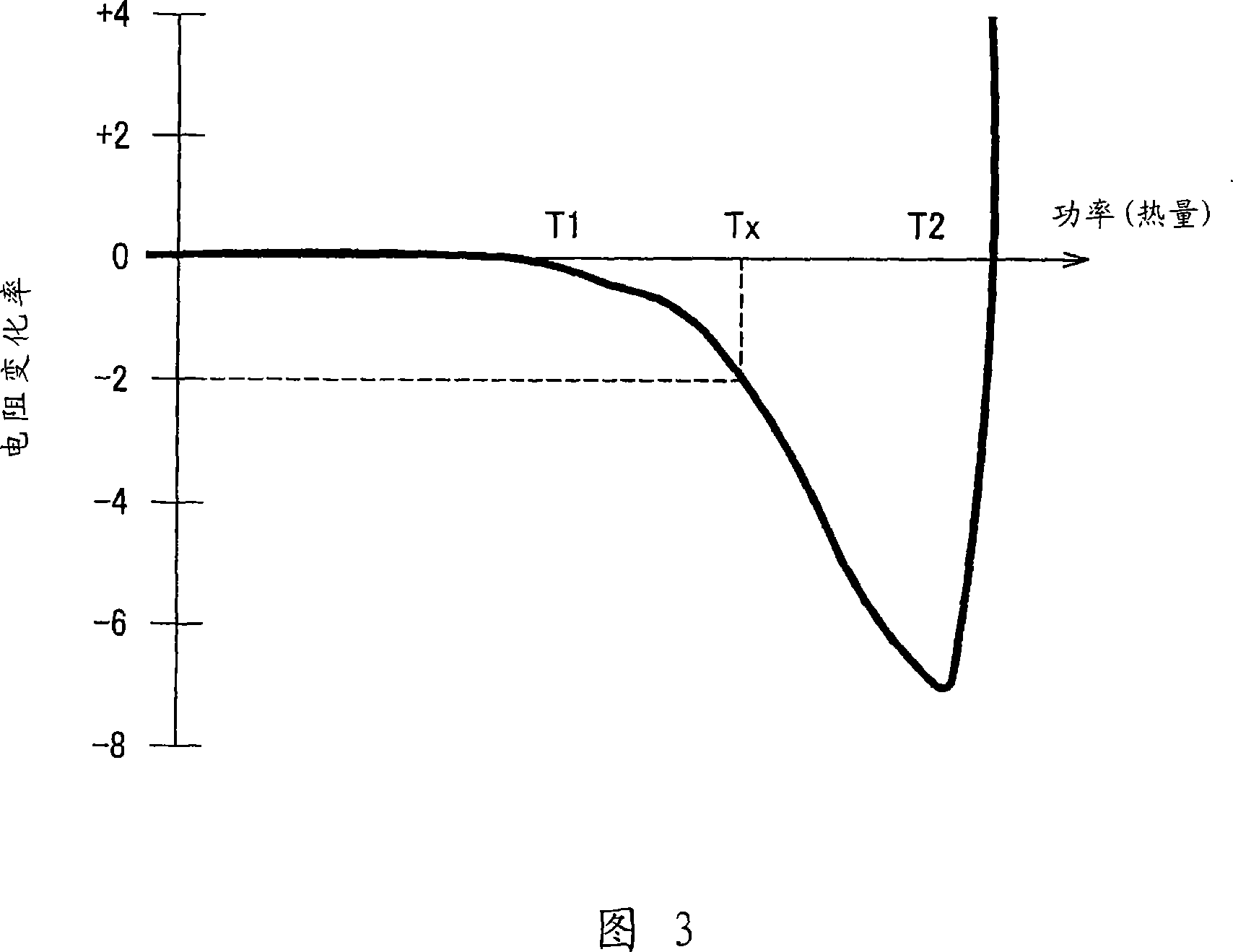

AI Technical Summary

Problems solved by technology

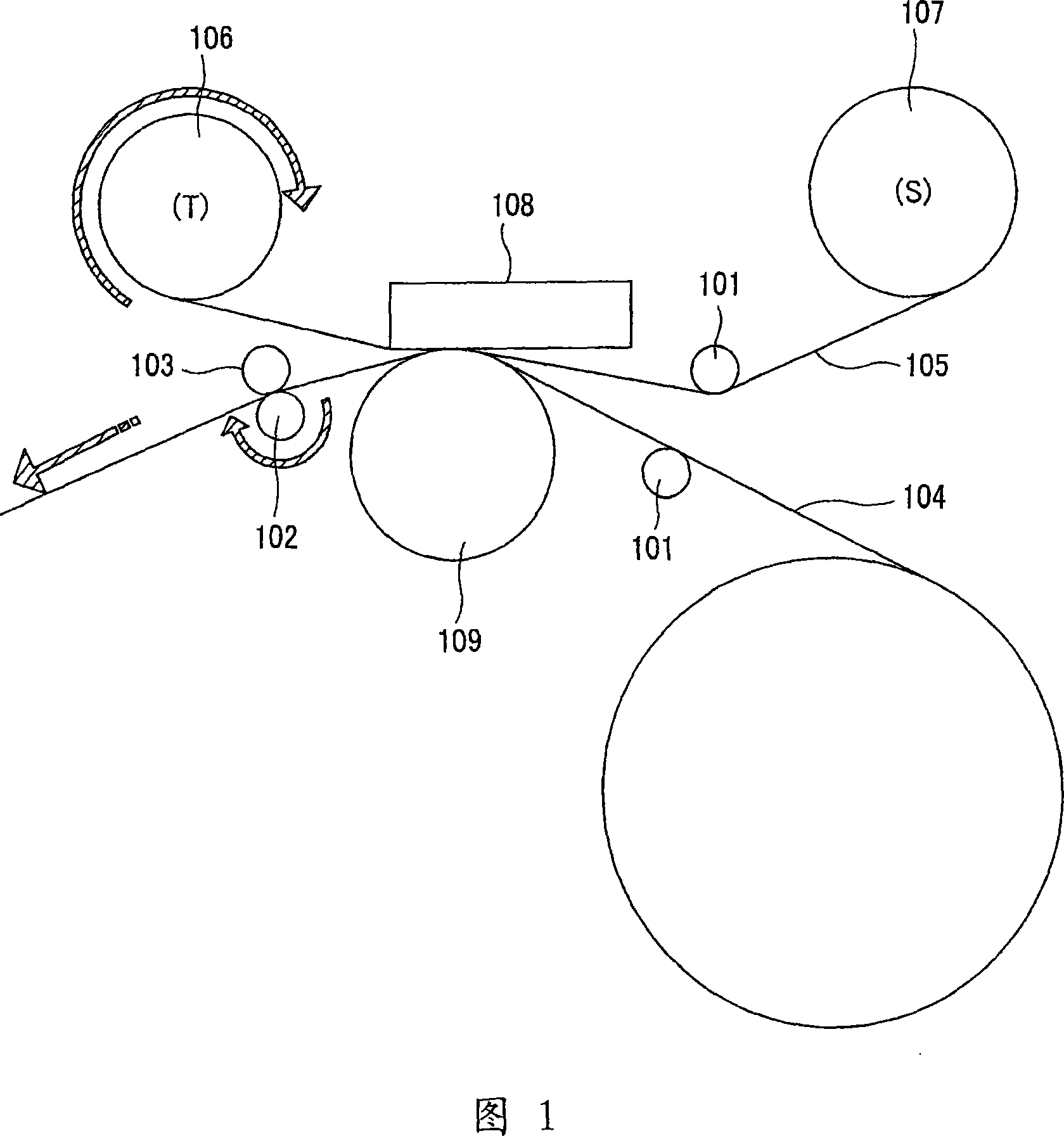

Method used

Image

Examples

no. 1 example

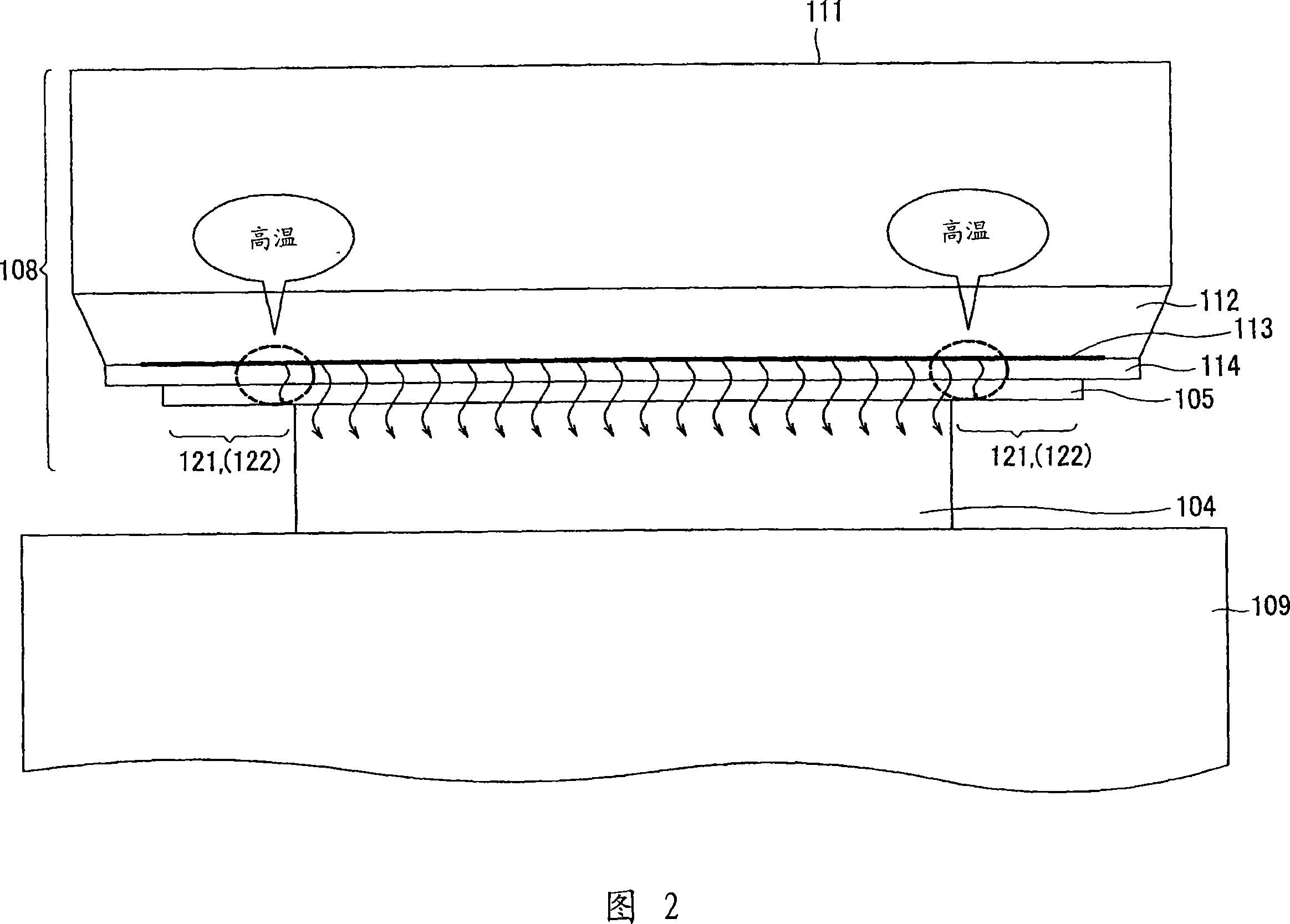

[0106] Similar to the first embodiment, the above-described printer 1 can be a standard-speed printing mode for ordinary printing, and a low-speed printing mode specially set when the temperature of the thermal head 108 becomes higher due to stored heat.

[0107] Standard speed printing mode enables printing at high speed as with a conventional printer. The instantaneous heat value per unit area of the heating element 113 is higher than that of a conventional printer, and the conveying speed of the printing medium 104 is also set higher than that of a conventional printer. On the other hand, the low-speed printing mode makes the instantaneous calorific value per unit area of the heating element 113 less than the standard speed printing mode, and the conveying speed of the printing medium 104 is lower than the standard speed printing mode, so as to put more pressure on the thermal head. The heat stored in 108 is dissipated to the printing medium 104 and the transfer wheel 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com