Gas sensor chip, sensor and sensor chip production method

A gas sensor and chip technology, applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of low production efficiency and high power consumption, and achieve the effect of improving consistency and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

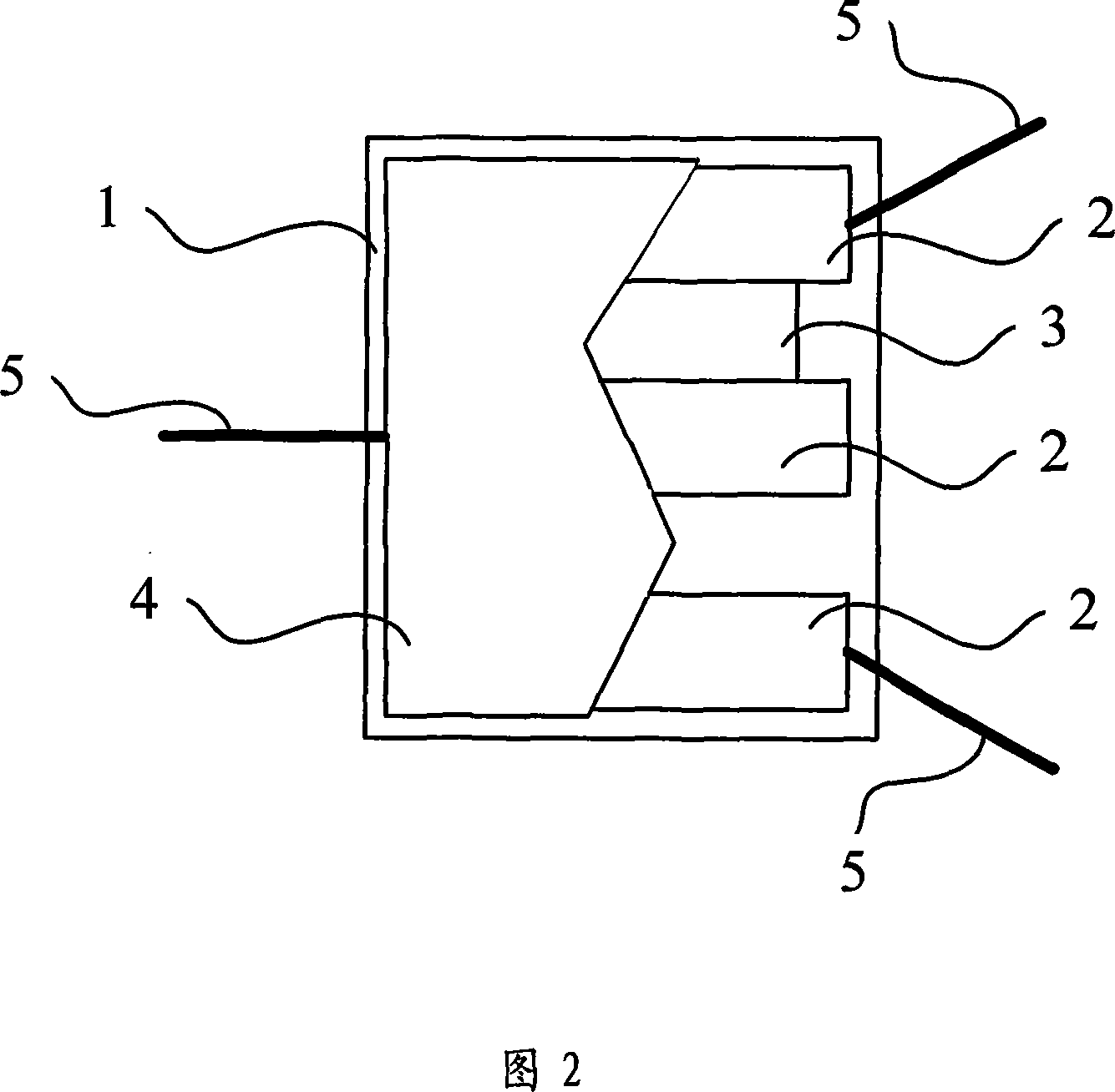

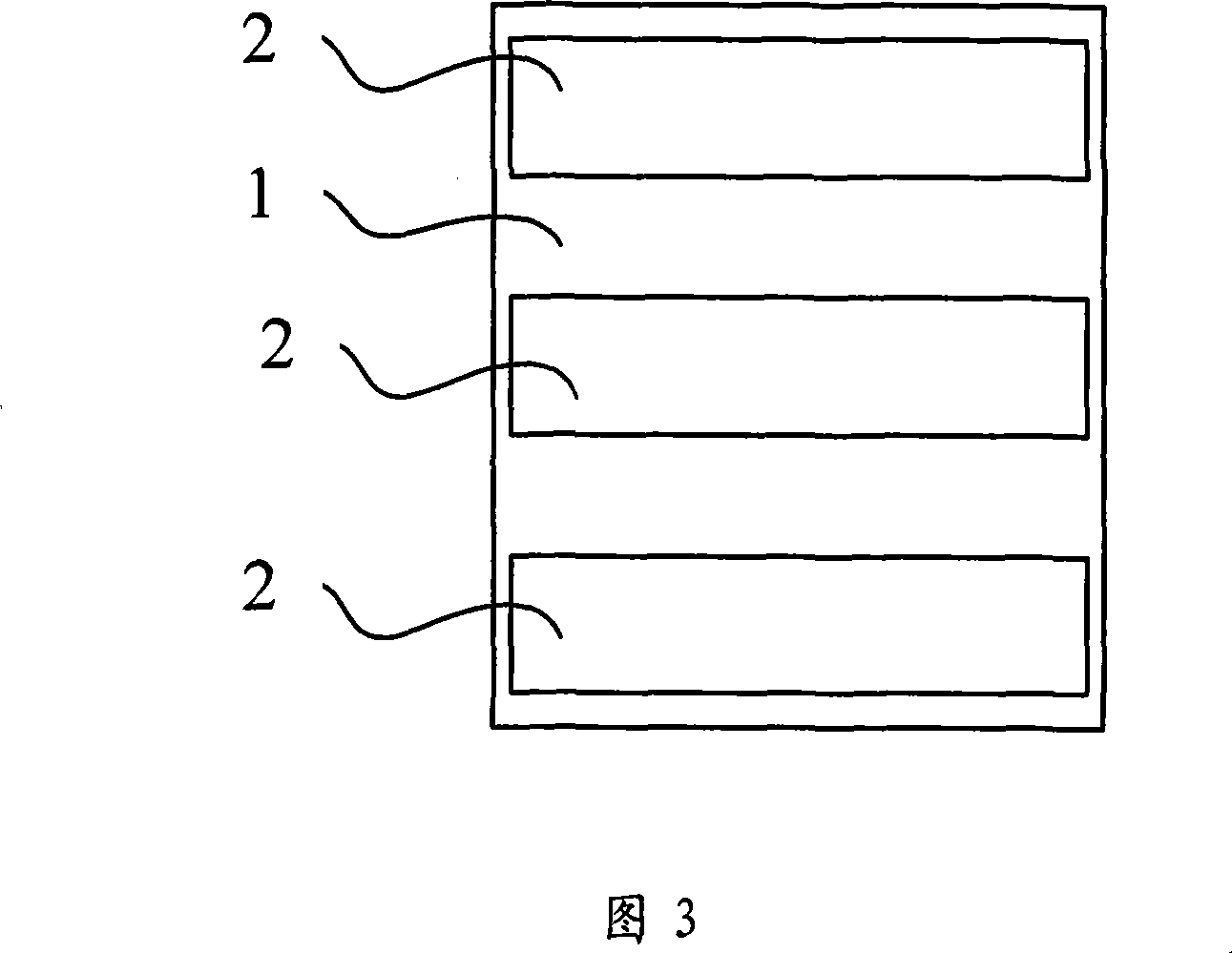

[0026] Fig. 2 is a schematic structural view of a specific embodiment 1 of a gas sensor chip, as shown in Fig. 2 , including a sheet-shaped ceramic substrate 1, an electrode conductive strip 2, a resistance heater 3 and a gas-sensitive coating 4, the electrode conductive strip 2, The resistance heater 3 and the gas-sensitive paint 4 are sequentially printed on the ceramic substrate 1 by screen printing, the electrode conductive strip 2 has two layers, and the resistance heater 3 is located between the two layers of electrode conductive strips 2 Between, the length, width, and thickness of the ceramic substrate 1 are 1 mm, 1 mm, and 0.10 mm, respectively, and the electrode conductive strip 2 and the resistance heater 3 are strip-shaped.

[0027] For the gas sensor chip, its preparation method is as follows:

[0028] Step 1: using ruthenium dioxide or gold doped with other compounds as the electrode paste to print the electrode paste on the ceramic substrate 1 by screen printing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com