Laminated heat exchanger

A technology of heat exchangers and laminates, which is applied in the direction of heat exchange equipment, indirect heat exchangers, heat exchanger types, etc., can solve problems such as freezing of condensed water, and achieve the effect of avoiding extreme drops and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

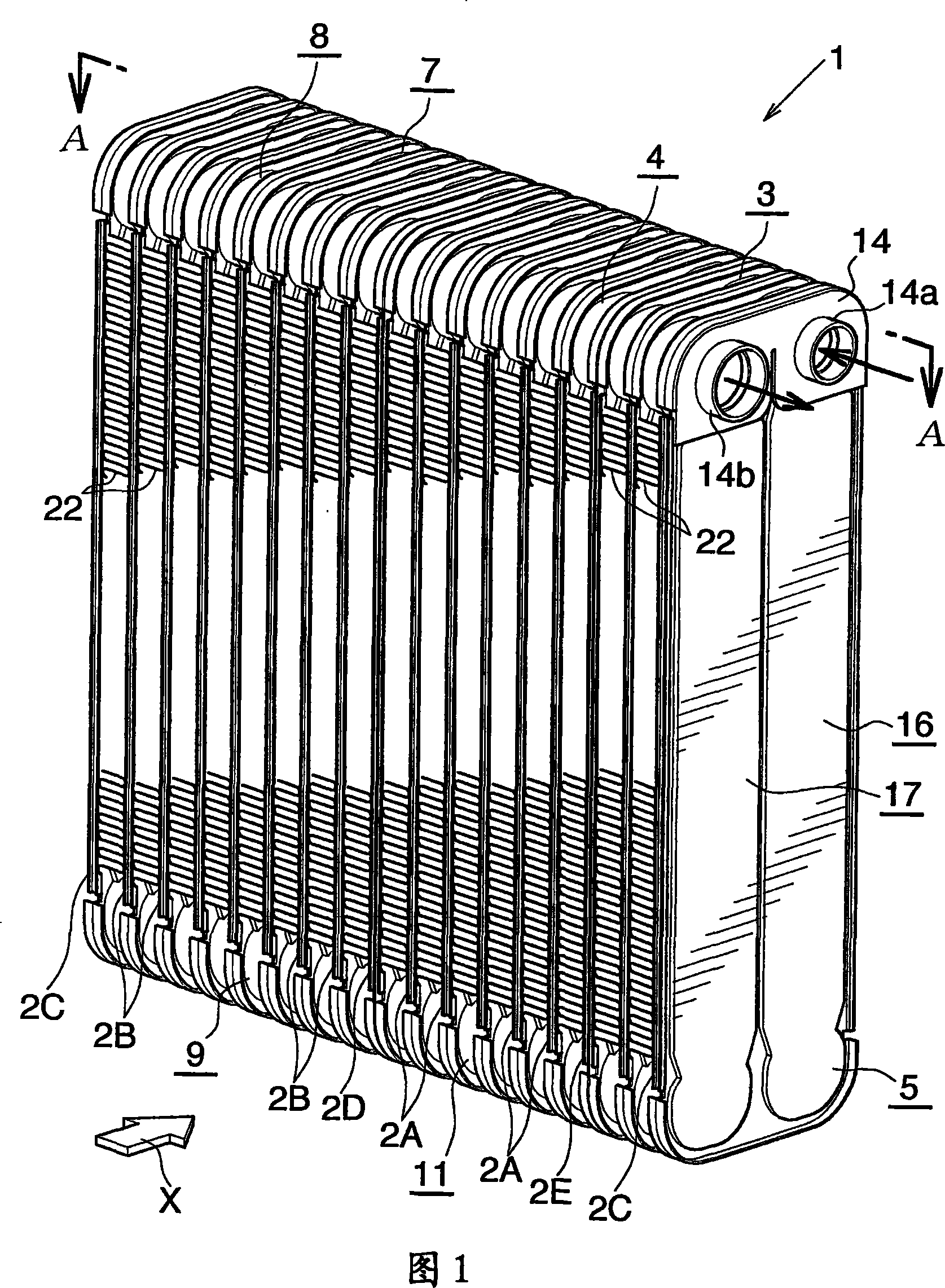

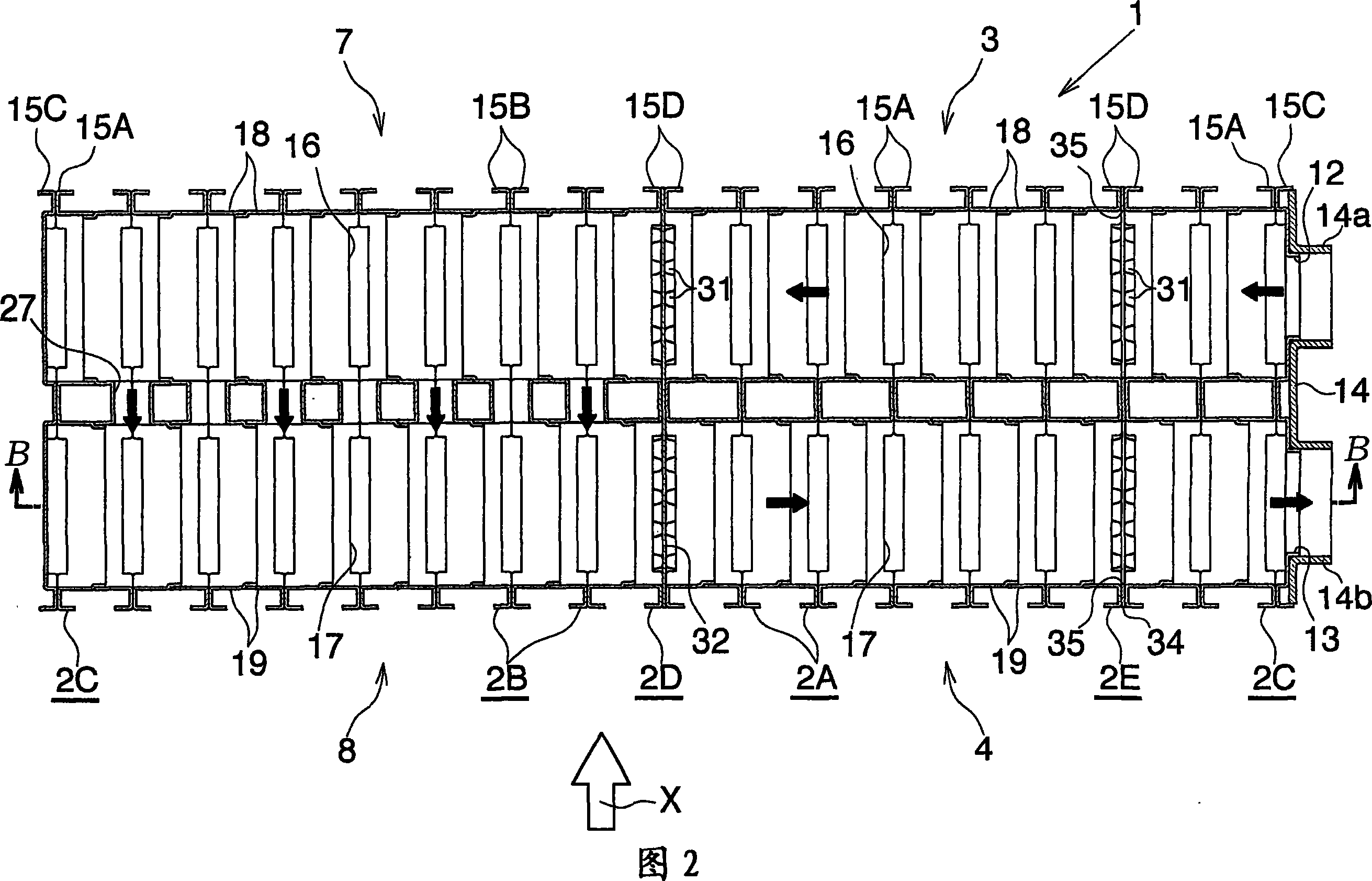

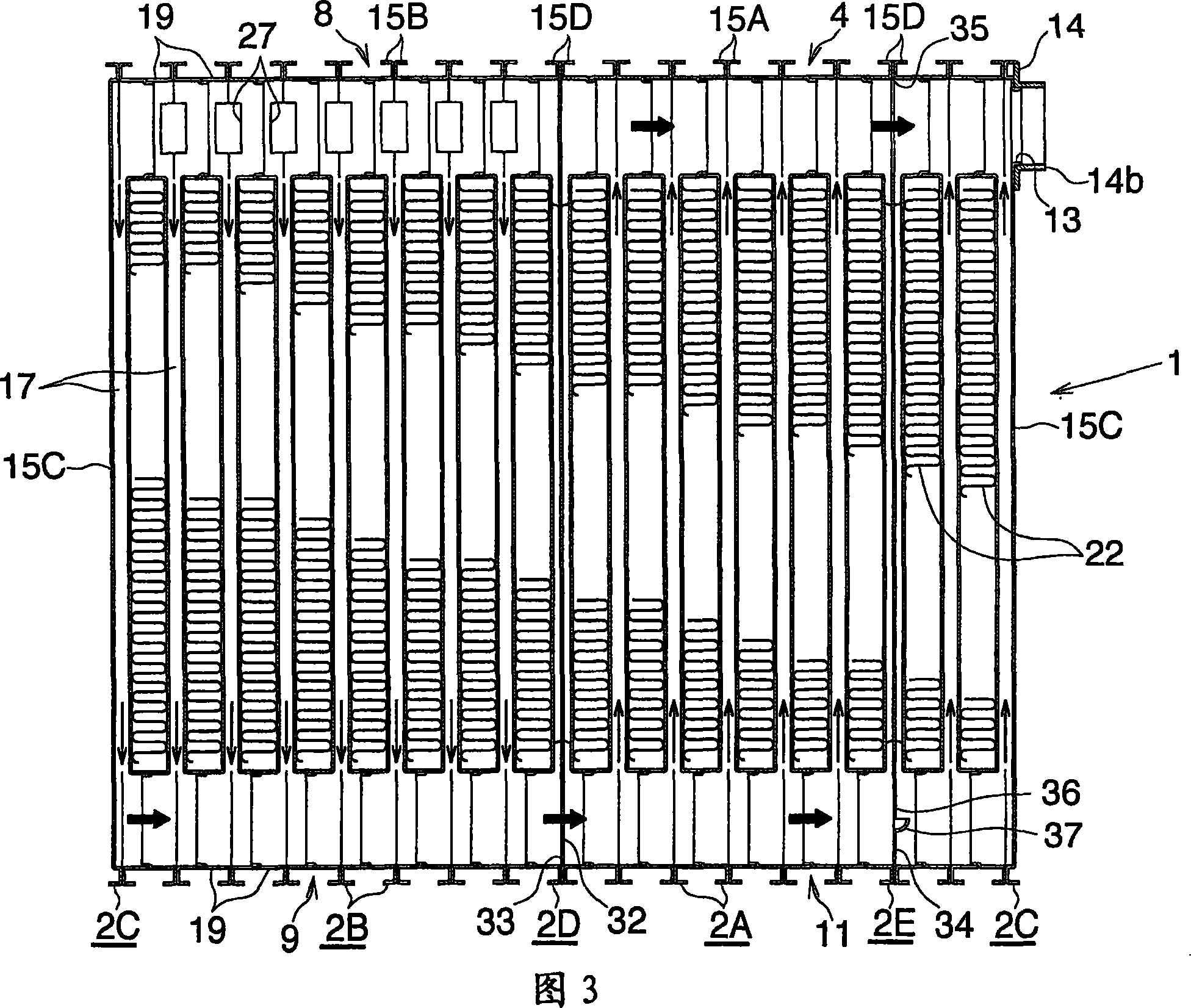

[0052] 1 to 10 show this embodiment.

[0053] 1 to 3 show the overall structure of the evaporator of Embodiment 1; FIGS. 4 to 9 show the structure of the main part of the evaporator; and FIG. 10 shows the flow of refrigerant in the evaporator.

[0054] 1 to 3, the evaporator (1) is designed such that a plurality of flat hollow parts (2A), (2B), (2C), (2D) and (2E) are arranged in a stacked manner in the left and right direction and combined in Together, each flat hollow member has a vertically elongated rectangular shape while their width extends in the front-rear direction (air flow direction). The evaporator (1) includes: a refrigerant inlet header section (3) extending in the left-right direction; a refrigerant outlet arranged behind the refrigerant inlet header section (3) (upstream relative to the air flow direction) and extending in the left-right direction The header section (4); the first intermediate header section (5) arranged under the refrigerant inlet header sect...

Embodiment 2

[0072] 11 to 15 show this embodiment.

[0073] 11 shows the overall structure of the evaporator of Embodiment 2; FIGS. 12 to 14 show the structure of the main part of the evaporator; FIG. 15 shows the flow of refrigerant in the evaporator.

[0074] Referring to Fig. 11, the evaporator (40) is designed in such a way that a plurality of flat hollow parts (41A), (41B), (41C) and (41D) are arranged in a stacked manner in the left and right direction and combined together, the flat hollow Each of the parts has a vertically elongated rectangular shape while their width extends in the front-rear direction (air flow direction). The evaporator (40) includes: a refrigerant inlet header section (42) extending in the left-right direction; a refrigerant outlet header section (43) extending from the refrigerant inlet header section (42) and located on the right side thereof and extending in the left-right direction; a first intermediate header section (44) arranged in front of the refriger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com