Air conditioner automatic liquid recycling control method, air conditioner automatic liquid recycling control system and air conditioner

A control method and control system technology, applied in heating and ventilation control systems, heating and ventilation safety systems, heating methods, etc., can solve damage to internal parts of compressors, inaccurate liquid volume of air-conditioning units, incomplete liquid collection of air-conditioning, etc. problems, achieve the effect of preventing leakage, improving integrity and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

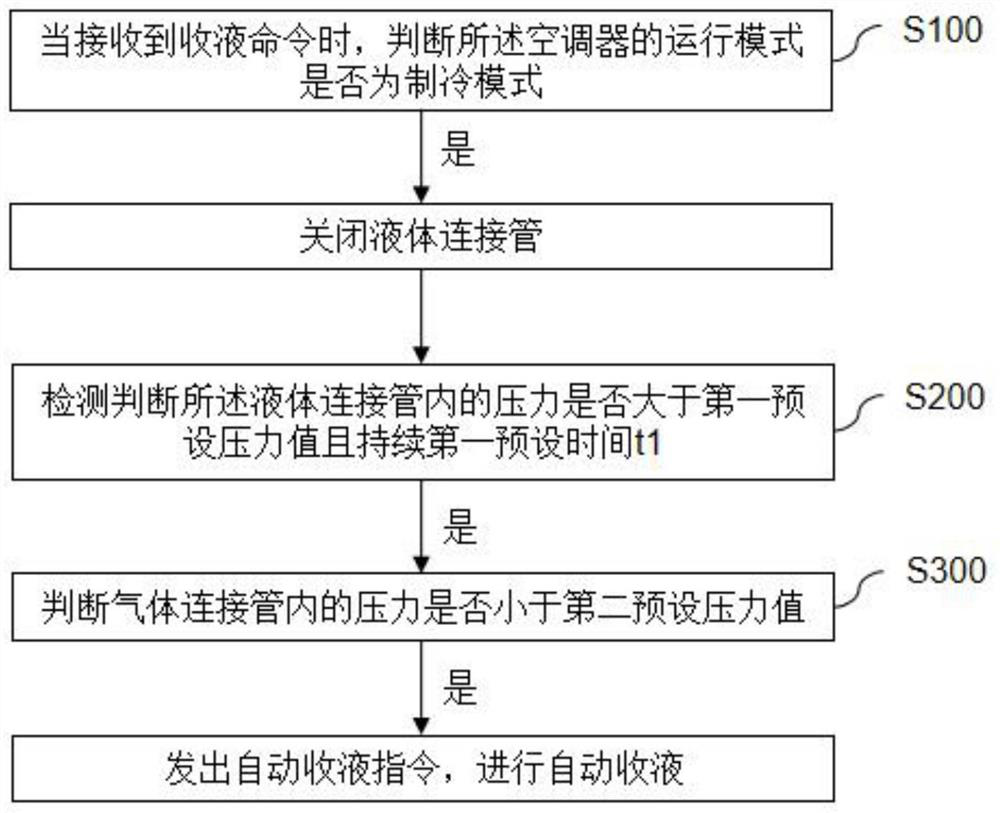

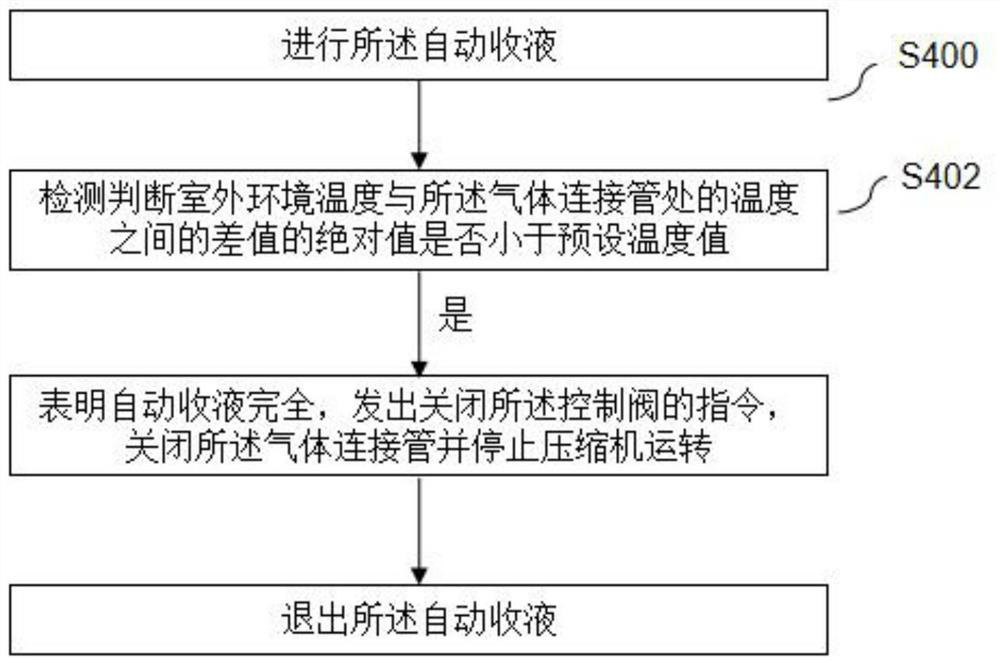

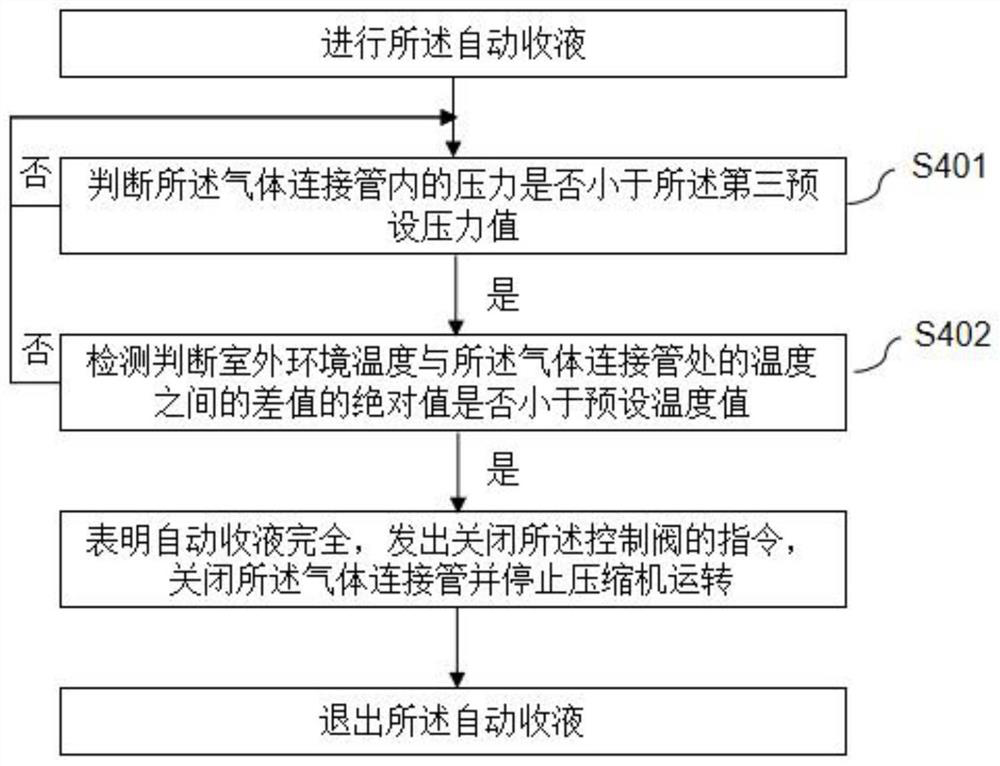

[0051] In order to make the above-mentioned purposes, features and advantages of the present invention more obvious and understandable, the following in conjunction with the attached Figure 1-4 Specific embodiments of the present invention are described in detail.

[0052] See attached figure 1 and 4 , the first aspect of the present invention provides an air conditioner automatic liquid collection control method, the method includes the following steps:

[0053] S100. When receiving the liquid receiving command, judge whether the operation mode of the air conditioner is the cooling mode;

[0054] If yes, then close the liquid connecting pipe 301 and enter step S200.;

[0055] S200. Detect and judge whether the pressure in the liquid connecting pipe 301 is greater than a first preset pressure value and lasts for a first preset time t1;

[0056] If yes, proceed to step S300.;

[0057] S300. Determine whether the pressure in the gas connecting pipe 302 is less than a second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com