Multistage compression type rotary compressor

A rotary compressor and rotary compression technology, which is applied to rotary piston machines, rotary piston pumps, mechanical equipment, etc., and can solve problems such as unstable operation, noise, and flap beating of the second rotary compression unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

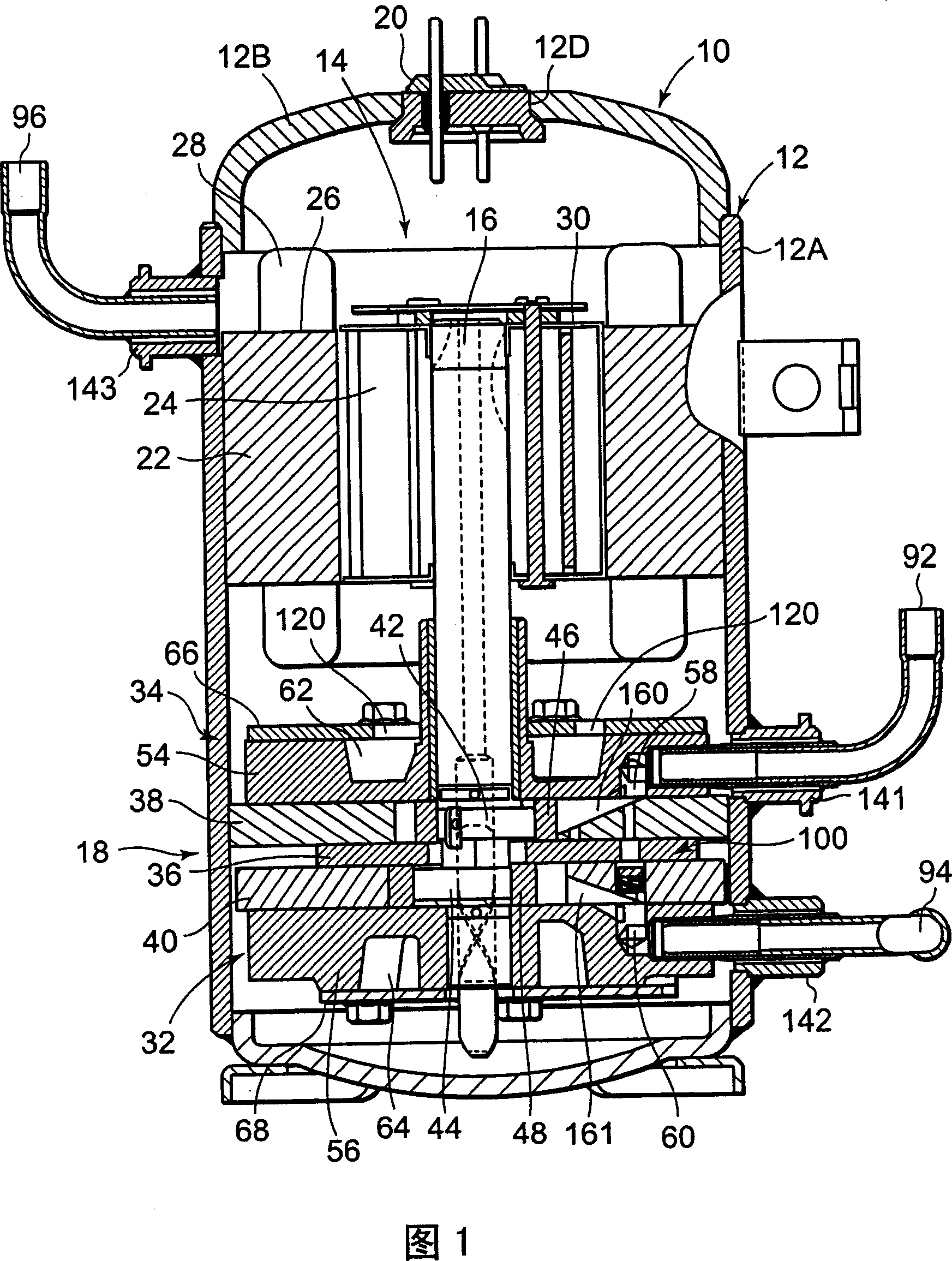

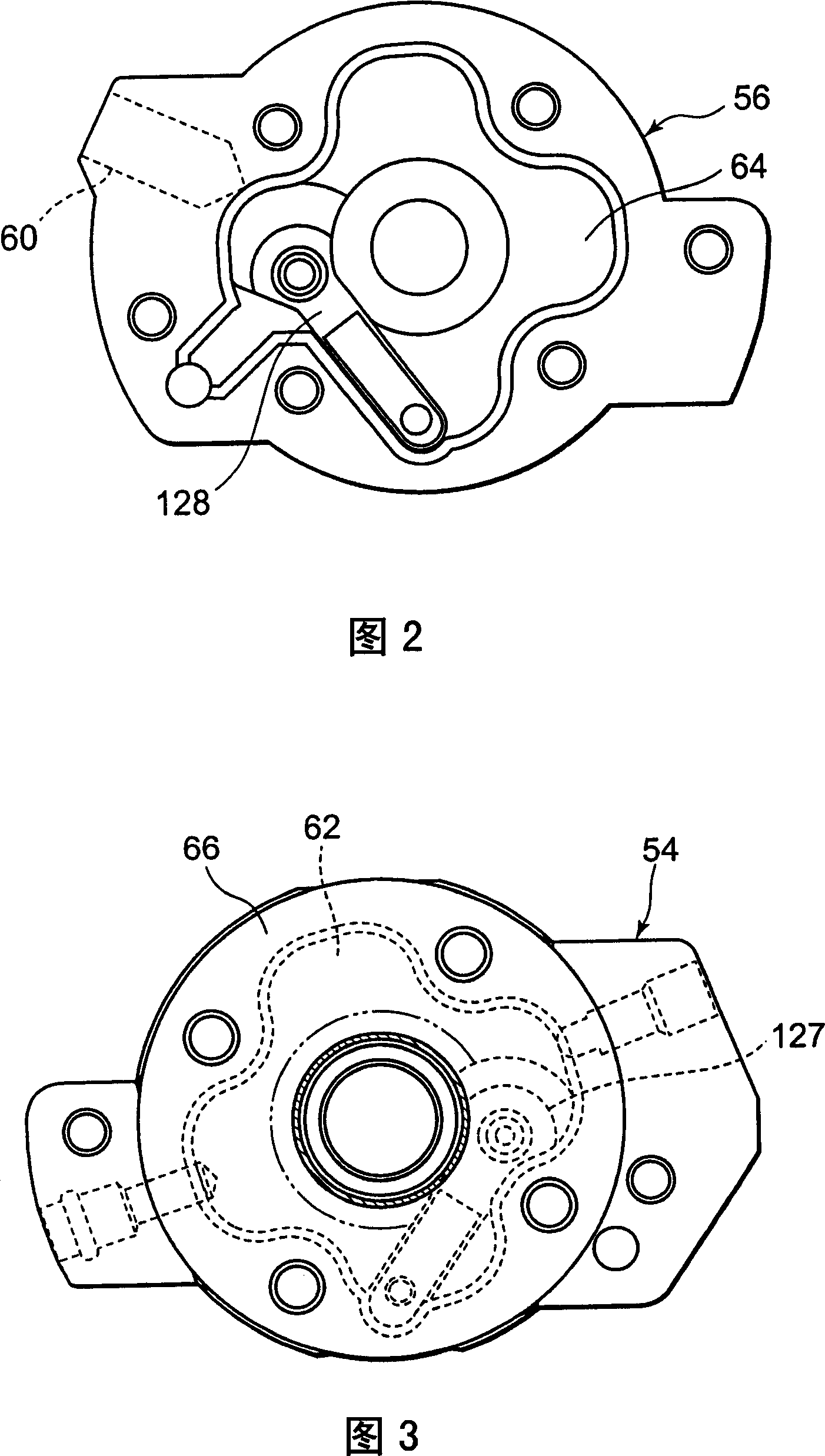

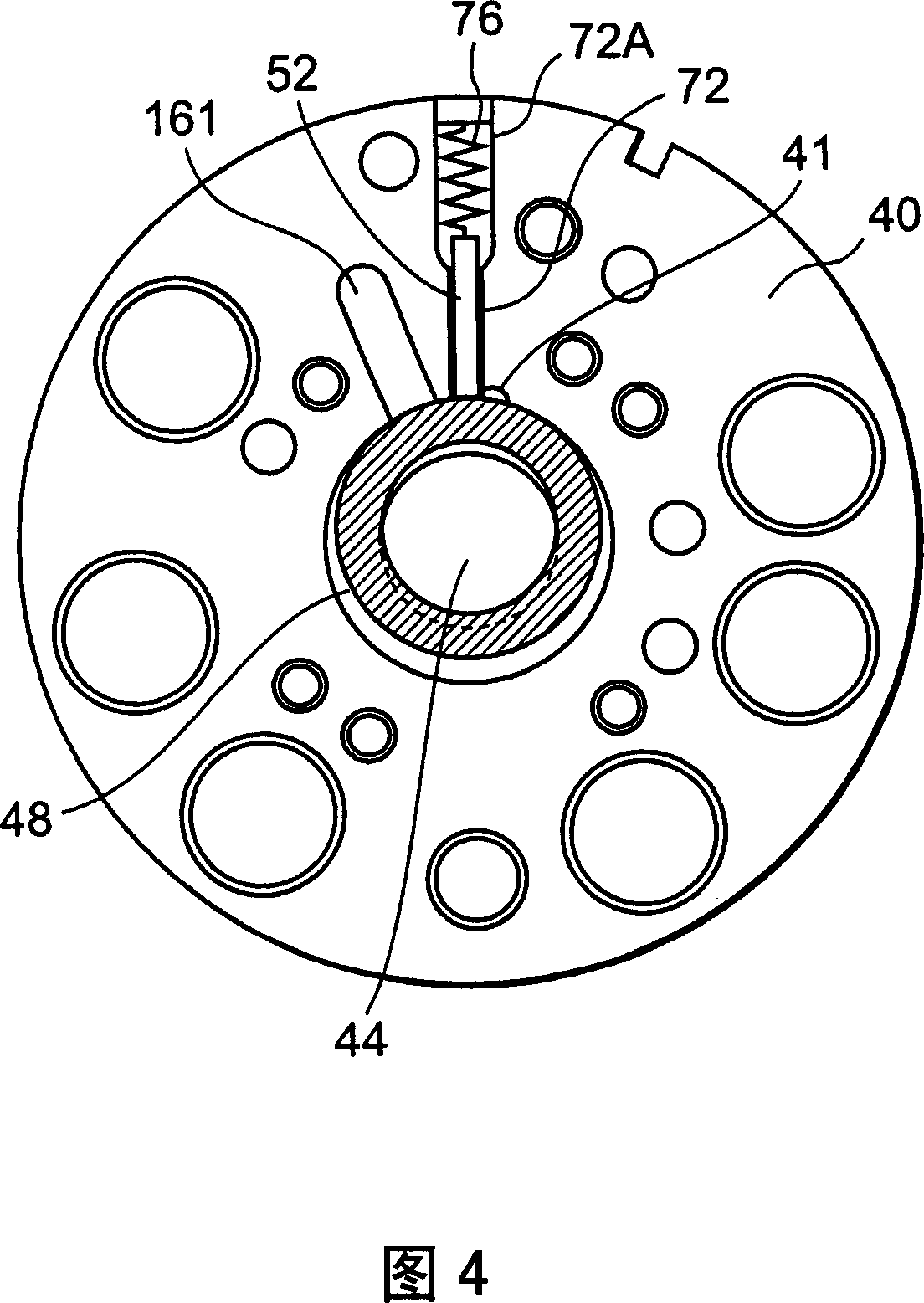

[0069] FIG. 1 is a longitudinal section side of an internal high-pressure multi-stage (two-stage) compression rotary compressor 10 provided with a first rotary compression unit 32 and a second rotary compression unit 34 as an embodiment of the multistage compression rotary compressor of the present invention. Figure 2 is a bottom view of the lower support member 56 of the first rotary compression unit 32, Figure 3 is a top view of the upper support member 54 of the second rotary compression unit 34 (the state of installing the upper cover), and Figure 4 is the first FIG. 5 is a bottom view of the lower cylinder 40 of the rotary compression unit 32 , and FIG. 5 is a plan view of the upper cylinder 38 as a cylinder constituting the second rotary compression unit 34 . In FIG. 1 , the rotary compressor 10 of the embodiment sucks and compresses the intermediate-pressure refrigerant gas compressed and discharged by the first rotary compression unit 32 into the second rotary compressi...

Embodiment 2

[0114] In addition, in the above-mentioned embodiment (Embodiment 1), the communication path 100 is formed in the sealed container 12 of the rotary compressor 10, and the suction port 161 and the suction port 160 are connected, but the communication path 100 of the present invention is not limited to this position. , as long as the intermediate-pressure area and the low-pressure area are connected, for example, it may also be formed outside the sealed container 12 . 9 and 10 show an example at this time. In addition, in FIG. 9 and FIG. 10 , the parts assigned the same symbols as in FIG. 1 to FIG. 8 have the same or similar effects, and description thereof will be omitted.

[0115] In this case, the communication path 200 is configured to communicate the refrigerant introduction pipe 92 and the refrigerant introduction pipe 94 through the valve device 117 so as to be openable and closable. The communication passage 200 is a passage for communicating the region of the intermedi...

Embodiment 3

[0125]11 is a third embodiment of the multi-stage compression rotary compressor of the present invention, showing an internal intermediate pressure multi-stage (two-stage) compression rotary compressor 10 including a first rotary compression unit 32 and a second rotary compression unit 34. sectional side view of . In addition, the bottom view of the lower support member 56 of the first rotary compression unit 32 is the same as that of FIG. The bottom view of the lower cylinder 40 of the compression unit 32 is the same as in FIG. 4 , and the top view of the upper cylinder 38 serving as a cylinder constituting the second rotary compression unit 34 is the same as in FIG. 5 .

[0126] In FIG. 11 , the rotary compressor 10 of the embodiment sucks and compresses the refrigerant gas at an intermediate pressure compressed by the first rotary compression unit 32 into the second rotary compression unit and discharges it into the hermetic container 12, and then discharges it. The intern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com