Method and device for winding a ribbon comprising a plurality of threads onto a winding body rotating about a rotation axis

A technology of rotating axis and winding body, which is applied to textiles and papermaking, warping machines, manufacturing tools, etc., and can solve problems such as delaying processing operations and not being suitable for production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

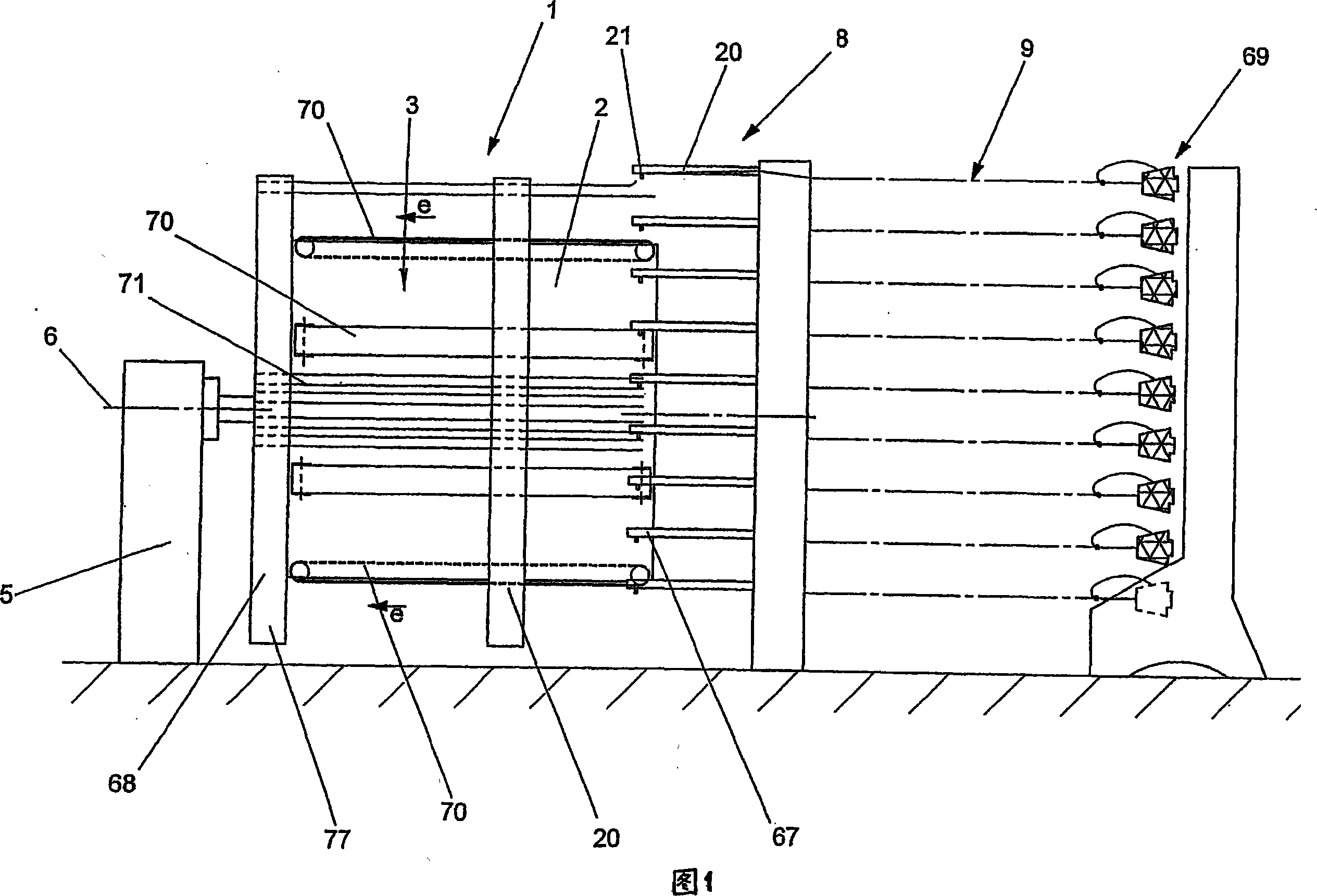

[0053] As shown in FIG. 1 , a warping machine, generally indicated by 1 , basically consists of a warping cylinder 2 as a winding body, which has a substantially cylindrical portion 3 . The warping cylinder 2 is supported in a frame 5 so as to be rotatable about the winding body axis or cylinder axis 6 . In the area of the first end face 67 of the warping cylinder 2, the yarn selection device 8 is arranged in a stationary manner. The yarn selection device comprises a plurality of yarn guides 21 which are successively distributed in the peripheral region of the warping cylinder on the first end face 67 of the warping cylinder. The thread guide axis can be moved parallel, ie parallel to the axis of rotation 6 . The creel 69 is located in the extension of the axis of rotation 6 of the warping cylinder 2 , in line with it. The sheets of yarn 9 are drawn from the creel 69 or other yarn feeding mechanism, where each yarn is fed to one of the yarn guides 21 respectively. As the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com