Vehicle crane

A technology of truck cranes and truck cranes, applied in the field of truck cranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

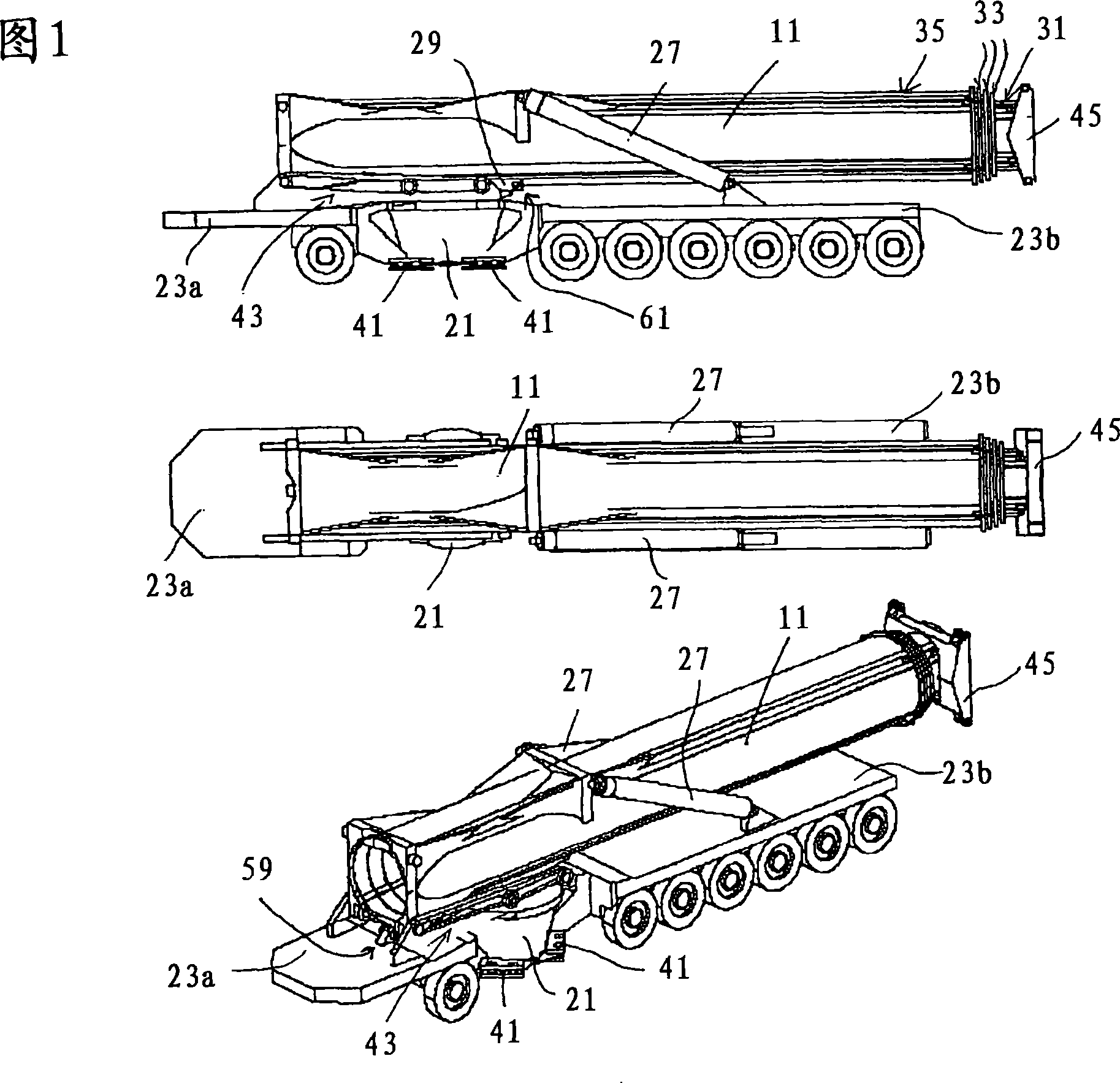

[0059] Figure 1 shows a part of the truck crane according to the invention in three different views. The part shown in Fig. 1 is a component part of the first transport unit that allows road transport, and it comprises a saddle tractor not shown and a front sub-chassis 23a and a front sub-chassis 23a that can be connected on the saddle tractor with a belt. The chassis of the rear sub-chassis 23b. A pot-shaped tower support 21 , which connects the two sub-chassis 23 a , 23 b to one another, is fixedly incorporated in the chassis.

[0060] The tower support 21, which is equipped with a plurality of connecting points 41 for mounting the tower support which will be explained in more detail below, is used to support the lower end of a tower 11 which is shown in FIG. 1 in its lying down transport position. In this transport position, the tower 11 extends laterally beyond the tower support 21 and rests on the chassis 23a, 23b.

[0061] The tower 11 is telescopic and comprises five ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com