Steel-wire fastener

A technology of steel wire ropes and fasteners, applied in the direction of transmission elements or pulley ropes or cables, flexible and slender elements, textile cables, etc., can solve the problems of unreliable connection, low bearing capacity, and complicated structure of steel wire ropes, and achieve The effect of simple structure, large bearing capacity and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

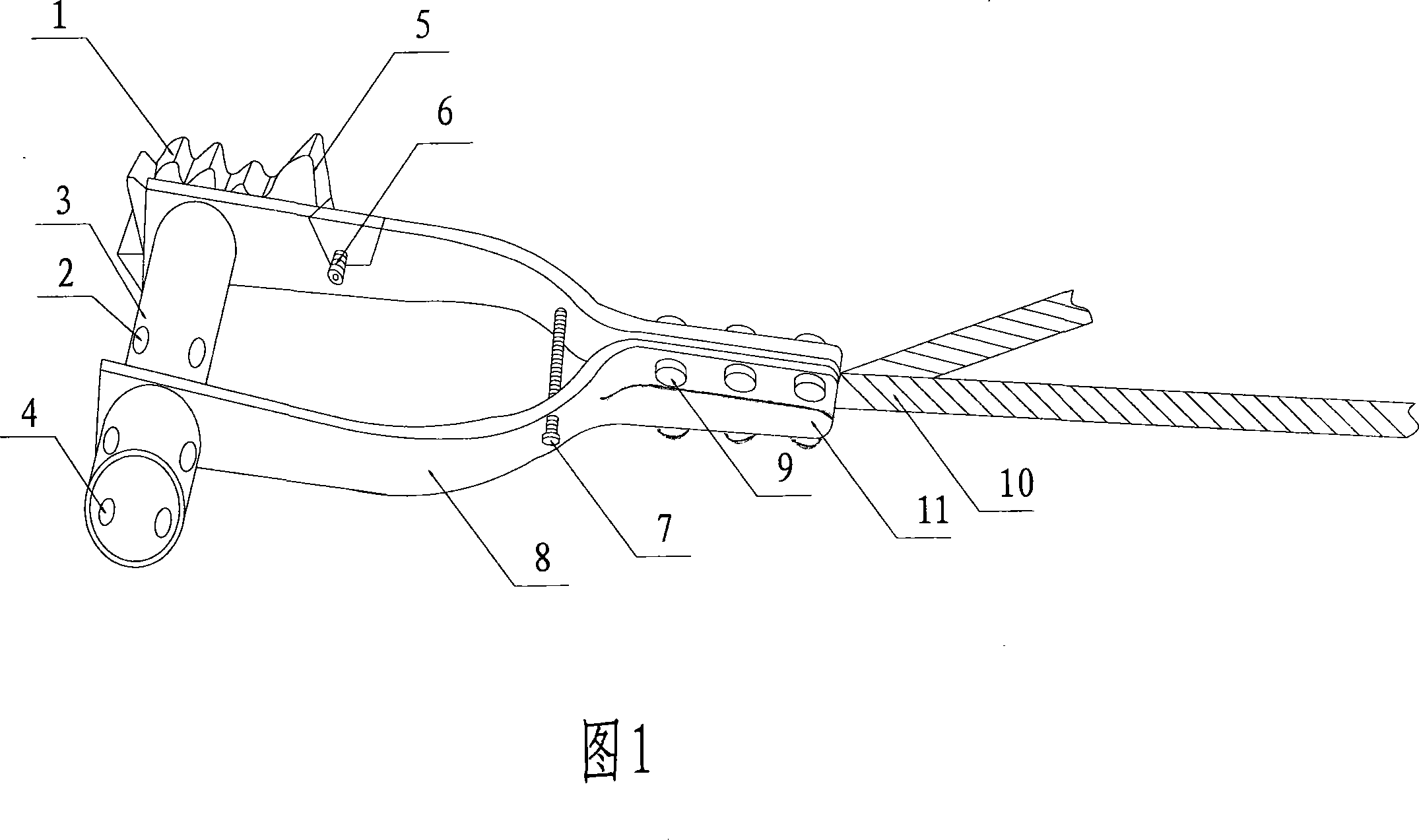

[0012] The Y-shaped base 8 of the present invention is composed of two curved steel sheets or iron sheets that are stamped as a whole, and a rope winding shaft 3 is movably installed in the opening of the fork. The steel wire rope end that is used for wearing fastening is used inside, and the winding shaft 3 is hollow, saves material, reduces cost. One end of the rope reel shaft 3 is provided with a ratchet 1, and the other end is set with a rotating sleeve. The oblique groove matches the oblique teeth on the anti-retraction ratchet 1, the return spring 6 is installed on the tab 5, and the tab 5 is installed on the Y-shaped base 8 on the same side as the anti-retraction ratchet 1, and the tab 5 Under the action of the return spring 6, it is stuck in the wheel groove of the ratchet 1, so that it cannot be reversed. Only after the tab 5 is removed, the ratchet 1 can be reversed. The lower part of the Y-shaped base 8 is riveted as a whole by the rivets 9 on both sides, and a hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com