Projector

A projection device and adjustment device technology, applied in projection devices, installations, televisions, etc., can solve problems such as the inability to implement the optical-mechanical focal length design value, incorrect focal length, and unclear images, so as to improve the quality of projection imaging and improve assembly efficiency , Improving the effect of image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

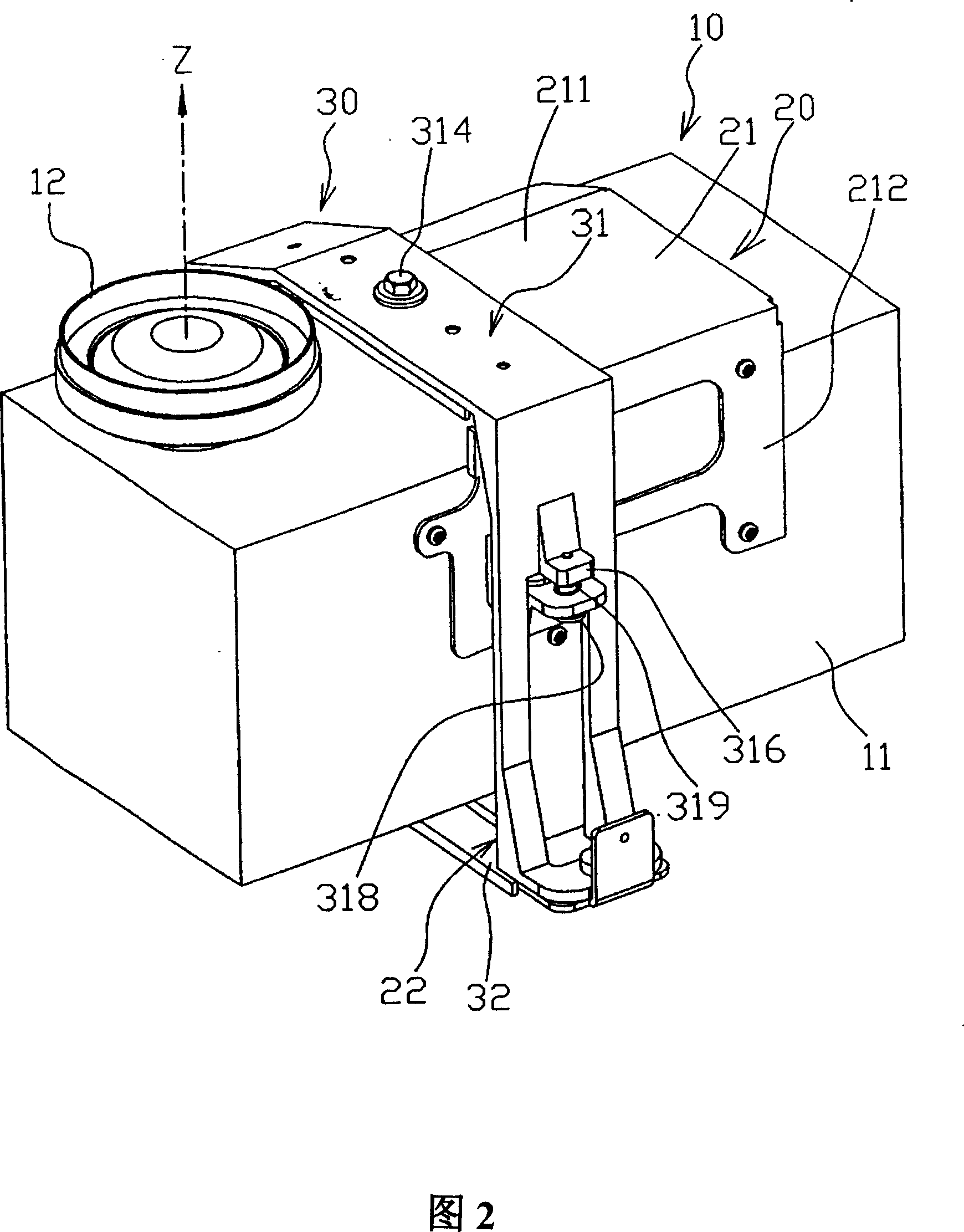

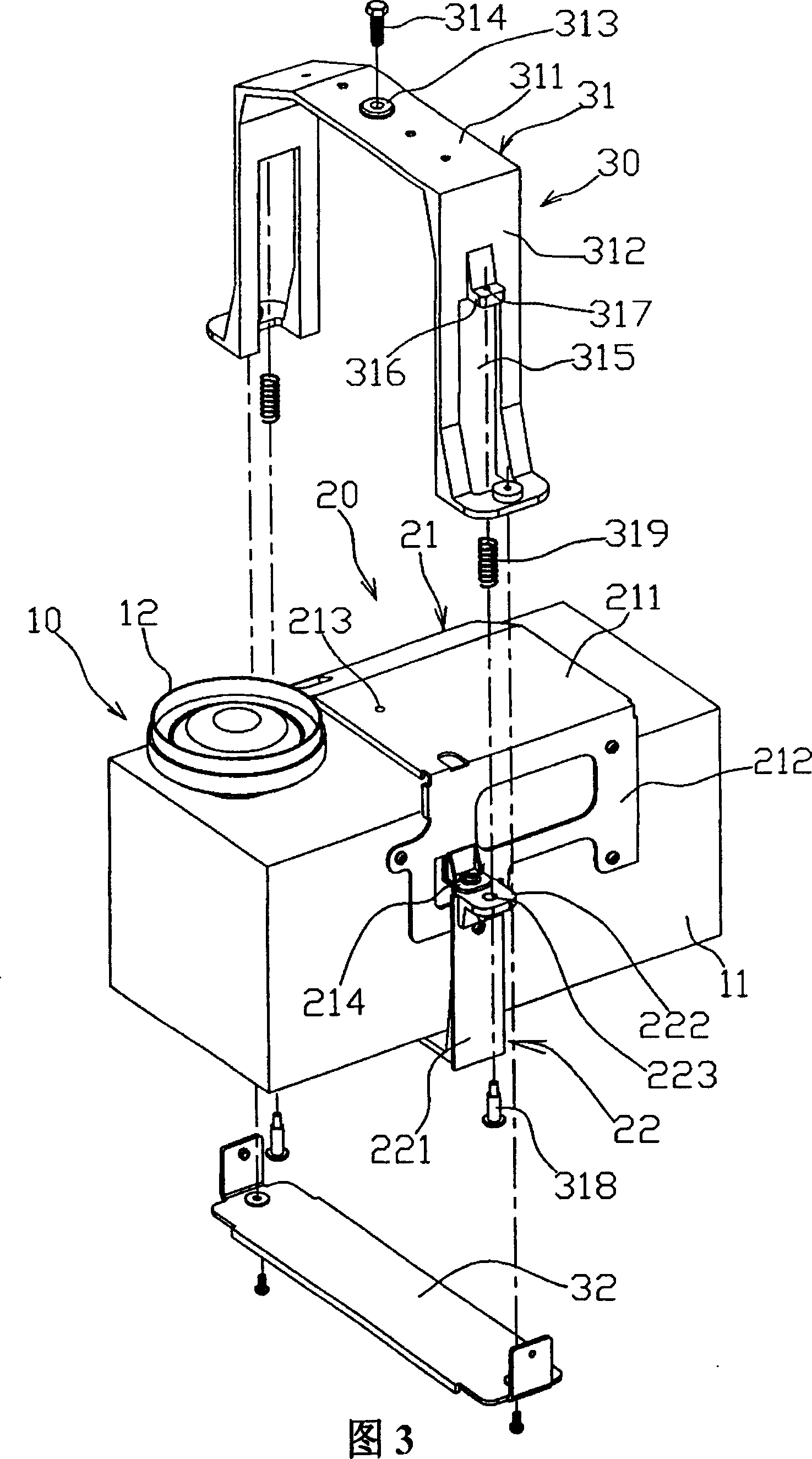

[0016] Please refer to Figures 2, 3, and 4, the projection device of the present invention includes an optical machine device 10 and an adjustment device 30; the optical machine device 10 includes an optical machine 11 and an optical machine fixing assembly 20, the optical machine 11 is provided in front of There is a projection lens 12, the projection direction of the projection lens 12 is defined as the Z-axis direction, the reference direction for focus adjustment, the optical-mechanical fixing assembly 20 includes an optical-mechanical fixing frame 21 and an optical-mechanical fixing base 22, the The optical engine fixing frame 21 is fixed or screwed on the optical engine 11, and includes a first fixing surface 211 perpendicular to the Z-axis direction and two second fixing surfaces 212 located on both sides of the first fixing surface 211. The first fixing surface 211 is provided with an inner adjusting screw hole 213. In a preferred implementation, the first fixing surface 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com