Light-emitting element, manufacturing method thereof, light-emitting device, and electronic device

A technology of light-emitting components and manufacturing methods, which is applied in the direction of electroluminescent light sources, electrical components, luminescent materials, etc., and can solve problems such as difficulty in obtaining light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

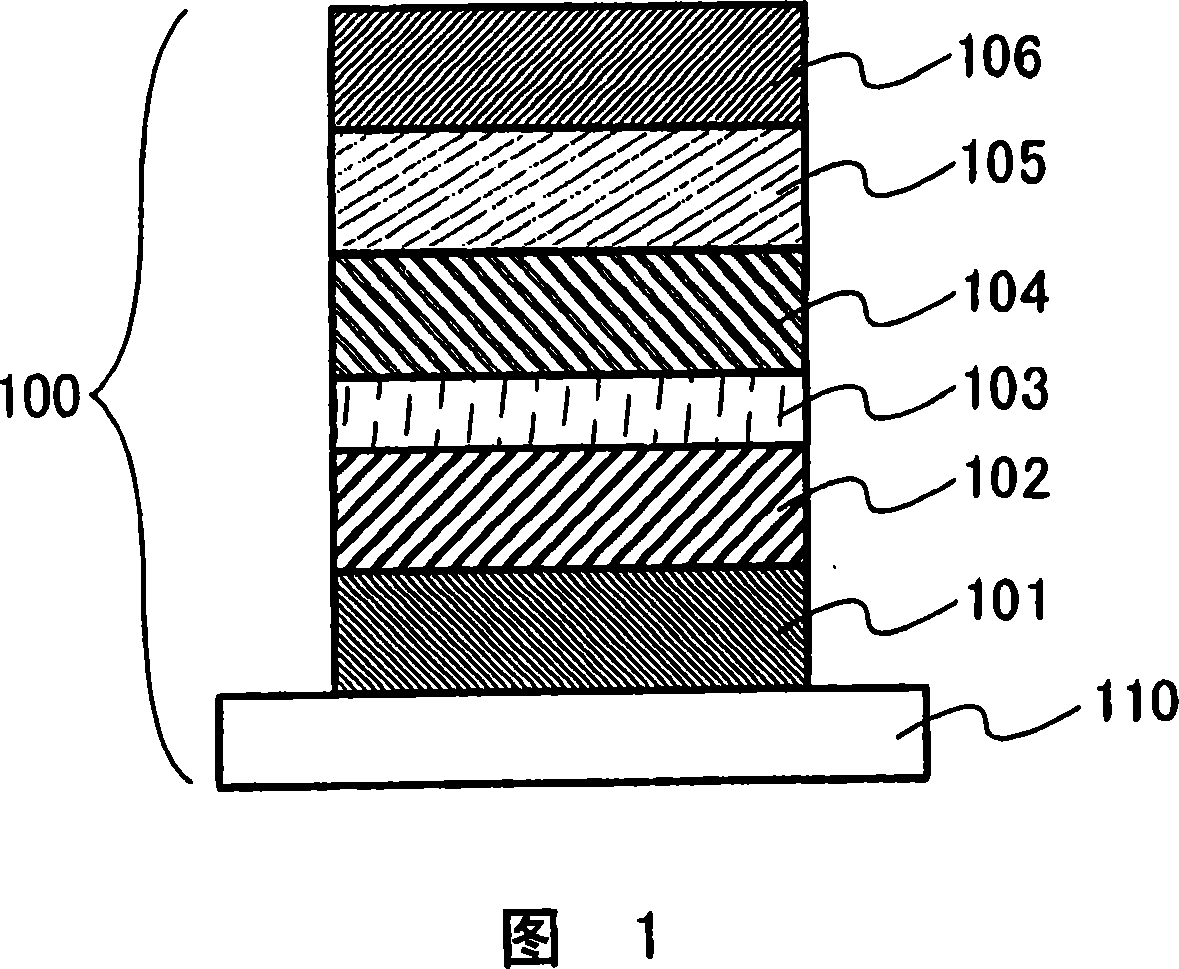

[0145] In this embodiment mode, a method for manufacturing a thin-film light-emitting element of the present invention will be described with reference to FIG. 1 .

[0146] 1 is a thin film element 100, which has on a substrate 110: a first electrode 101 and a second electrode 106; a first insulating layer 102 and a second insulating layer 105 adjacent to each electrode; The light-emitting layer formed by the first layer 103 and the second layer 104 is between the two insulating layers 105 . This embodiment mode is a method of manufacturing a light-emitting element capable of obtaining light emission from a light-emitting layer by performing heat treatment after forming a thin film, and will be described below.

[0147] The substrate 110 serves as a support for the light emitting element. As the substrate, for example, glass, quartz, or plastic can be used. In addition, as long as it can function as a support body in the process of manufacturing a light-emitting element, the...

Embodiment approach 2

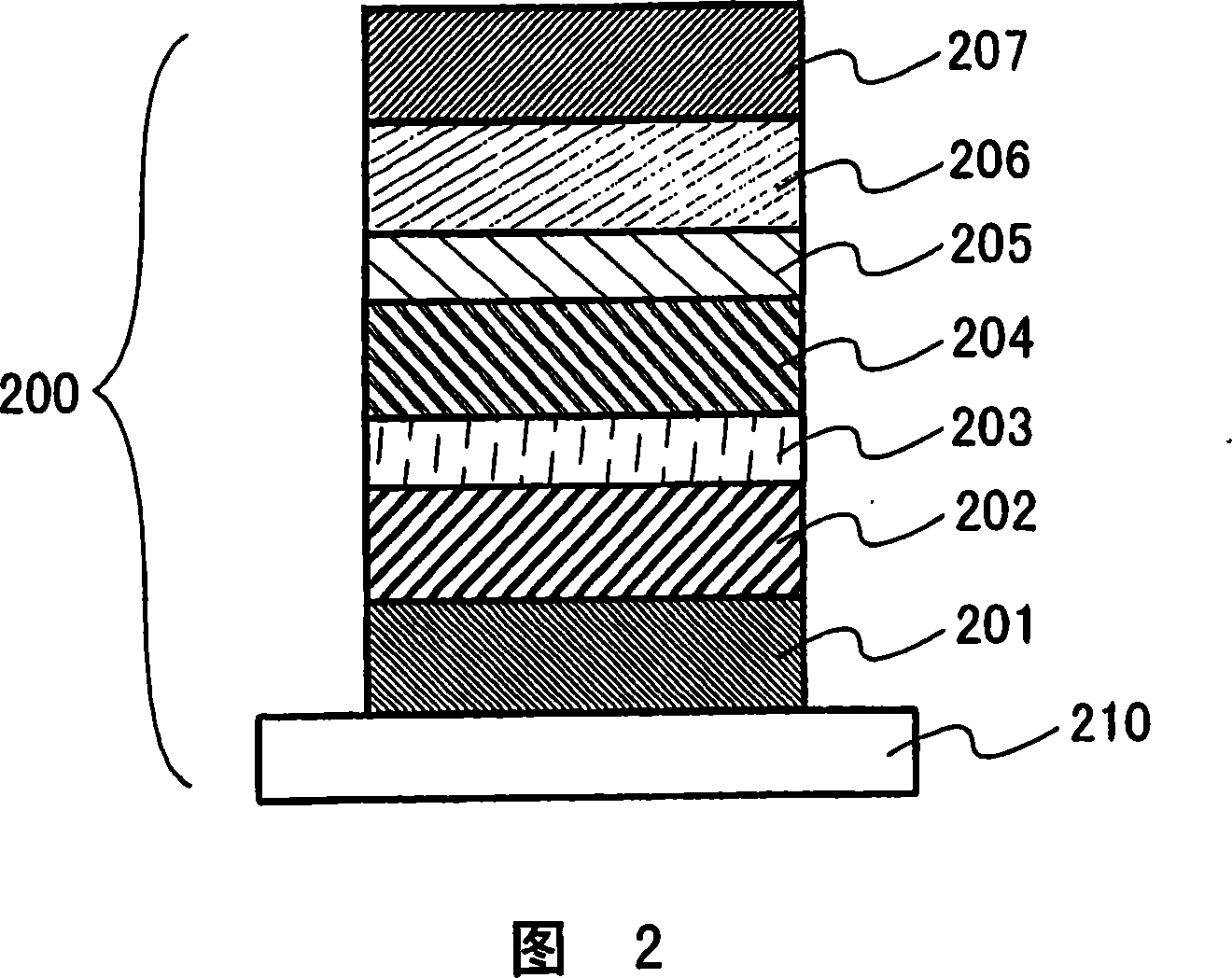

[0157] In this embodiment mode, a thin film light emitting element of the present invention will be described with reference to FIG. 2 .

[0158] 2 is a thin film element 200, which has on a substrate 210: a first electrode 201 and a second electrode 207; a first insulating layer 202 and a second insulating layer 206 adjacent to each electrode; The light-emitting layer composed of the first layer 203 , the second layer 204 and the third layer 205 is between the two insulating layers 206 . As in Embodiment 1, a light-emitting element capable of emitting light from a light-emitting layer obtained by performing a heat treatment after forming a thin film will be described below.

[0159] The materials described in Embodiment 1 can be used for the substrate 210 , the first electrode 201 and the second electrode 207 , and the first insulating layer 202 and the second insulating layer 206 .

[0160] The first layer 203 and the third layer 205 are layers containing a luminescent cent...

Embodiment approach 3

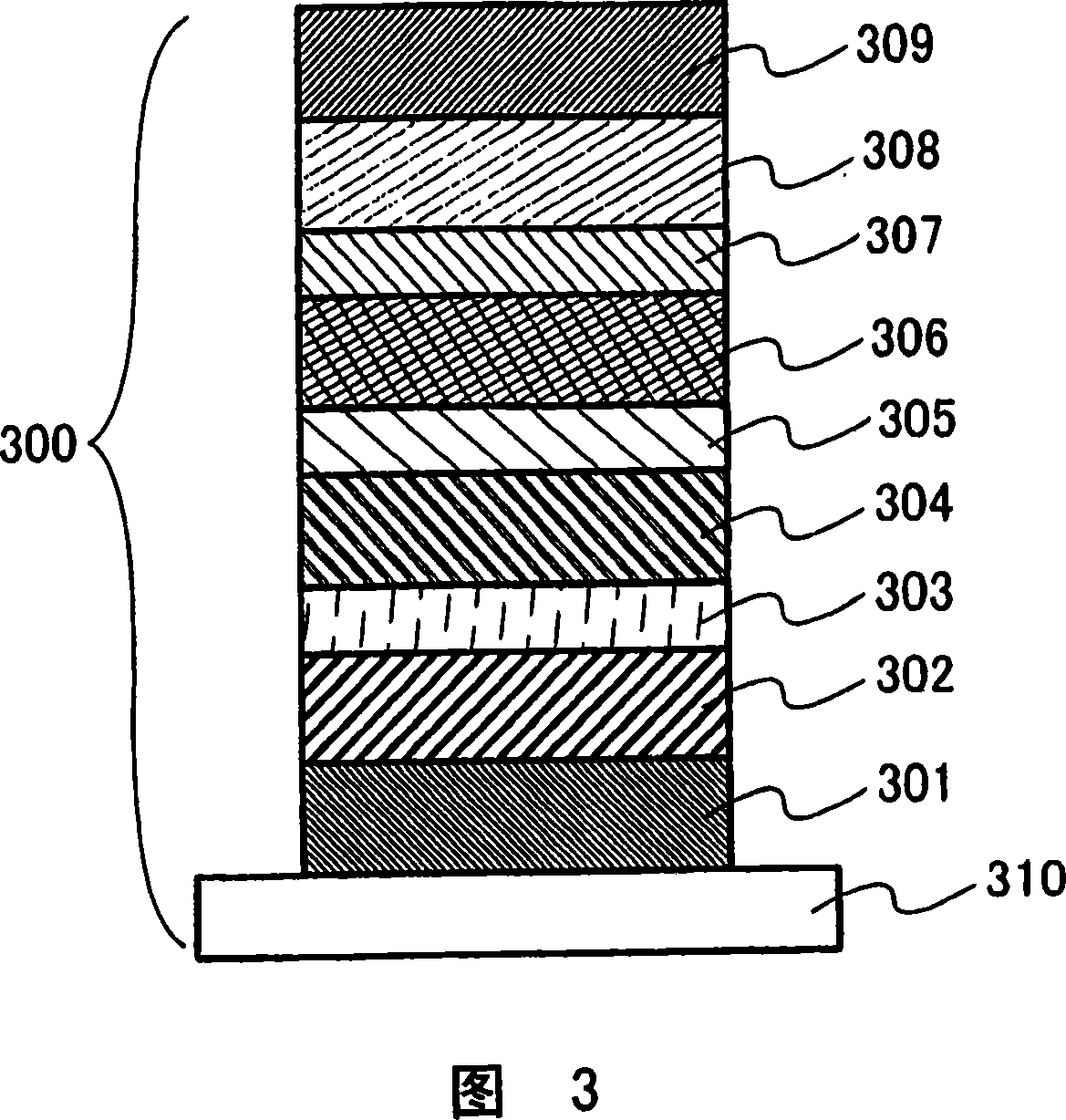

[0166] In this embodiment mode, a thin film light emitting element of the present invention will be described with reference to FIG. 3 .

[0167] 3 is a thin film element 300, which has on a substrate 310: a first electrode 301 and a second electrode 309; a first insulating layer 302 and a second insulating layer 308 adjacent to each electrode; The first layer 303 , the second layer 304 , the third layer 305 , the fourth layer 306 and the fifth layer 307 between the two insulating layers 308 . As in Embodiment 1, by performing heat treatment after forming a thin film, light emission can be obtained from a plurality of layers containing a matrix material constituting a light emitting layer, as will be described below.

[0168] The materials described in Embodiment 1 can be used for the substrate 310 , the first electrode 301 and the second electrode 309 , and the first insulating layer 302 and the second insulating layer 308 .

[0169] The first layer 303, the third layer 305,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com